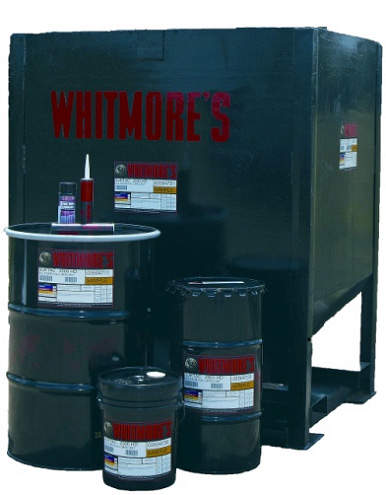

whitmore wire rope lubricant in stock

Wire Rope Lubricant quickly penetrates to the core. This ensures that the rope is lubricated throughout while providing a nondrying, nontacky film on the outside of the rope which protects outer strands from corrosion as well as lubricating the wire rope drums and sheaves.

Wire ropes contain numerous moving parts which require lubrication. Each time the rope bends or flexes, the internal strands rub together. Whitmore"s Wire Rope Lubricant coats these strands to prevent friction and wear. This results in longer wire rope life, less downtime for rope changes and more production.

Whitmore"s Wire Rope Lubricant quickly penetrates to the core. This ensures that the rope is lubricated throughout while providing a nondrying, nontacky film on the outside of the rope which protects outer strands from corrosion as well as lubricating the wire rope drums and sheaves.

Whitmore"s Wire Rope Lubricant is easily pumpable at temperatures down to -25°F (-35°C). Its nondrying film remains flexible in the most extreme weather conditions which eliminates flaking and peeling.

Whitmore"s Wire Rope Lubricant can be used to lubricate all sizes of wire rope as well as chains, leaf springs and other applications where a penetrating oil is needed. It may also be applied by hand or automatic lubrication system.

We only replace items if they are defective or damaged. If you need to exchange it for the same item, send us an email at ecorders@indlube.com and send your item to: Industrial Lubricant Company PO Box 70 Grand Rapids Minnesota US 55744.

Wire Rope Lubricant quickly penetrates to the core. This ensures that the rope is lubricated throughout while providing a nondrying, nontacky film on the outside of the rope which protects outer strands from corrosion as well as lubricating the wire rope drums and sheaves.

Whitmore"s Wire Rope Lubricant quickly penetrates to the core. This ensures that the rope is lubricated throughout while providing a nondrying, nontacky film on the outside of the rope which protects outer strands from corrosion as well as lubricating the wire rope drums and sheaves. Whitmore"s Wire Rope Lubricant is easily pumpable at temperatures down to -25 DegreeF (-35 DegreeC). Its nondrying film remains flexible in the most extreme weather conditions which eliminates flaking and peeling.

ApplicationsWhitmore"s Wire Rope Lubricant can be used to lubricate all sizes of wire rope as well as chains, leaf springs and other applications where a penetrating oil is needed. It may also be applied by hand or automatic lubrication system.

The most robust, lithium-based, bearing grease in the Whitmore lubricant line. This extreme pressure grease is designed for heavy duty applications. Whitmore recommends this product where the most severe, high and shock loads are encountered. Ideal for warm climates.

Enclosed gear oils have been formulated to meet the unique demands of heavily loaded, industrial gearing systems. These oils contain molybdenum disulfide, a colloidal lubricant which provides extreme pressure protection under severe load and shock load.

Whitmore"s toughest lubricant recommended for use on draglines and shovels. This lubricant contains a high molecular weight polymer that resists drying, oxidation, and thermal decomposition. It does not emulsify in water, making it ideal for components exposed to rain, ice and snow, and in many areas, a single grade can be used year-round.

BioRail® EP and LF biodegradable rail curve lubricants, prove that you don"t have to compromise performance in order to be environmentally responsible. BioRail has proven itself, not only in the laboratory, but where it counts - on the rail. Its stable chemistry ensures that it pumps in the coldest climates and stands up at the wiping bar in all weather conditions. This lubricant provides outstanding gauge-face lubrication on rail curves.

Whitmore’s Earthkeeper WRL is an excellent wire rope oil that is specially formulated to protect industrial wire ropes. This Whitmore wire rope lubricant is specially formulated to penetrate to the core of a rope and is an ideal choice for marine environments. This Whitmore oil contains anti-wear additives that help to prevent wear and maximize the service life of a rope. In addition, this biodegradable Whitmore grease enhances the capability of a wire rope to withstand extreme pressure. This rope lubricant from Whitmore Manufacturing Company is suitable for a wide range of industrial applications and can be used near waterways and in ecologically sensitive areas.

Crosby’s Vitalife®products are the preferred wire rope lubricants in the industry because of their ability to penetrate into wire rope and displace water and contaminants, thus reducing wear and corrosion throughout the rope.Available in a variety of container sizes.

Whitmore’s Wire Rope Lubricant products also coat these strands to prevent friction and wear. This results in longer wire rope life, less downtime for rope changes and more production.

Whitmore’s Wire Rope Lubricant is easily pumpable at temperatures down to -25°F (-35°C). Its nondrying film remains flexible in the most extreme weather conditions, which eliminates flaking and peeling.Whitmore’s Wire Rope Lubricant can be used to lubricate all sizes of wire rope, as well as chains, leaf springs and other applications where penetrating oil is needed. It may be applied by hand or automatic lube system.

To become a leading market player in the Wire Rope Lubricants industry, variousare currently executing new technologies,, product innovations, expansions, and long-term contracts. The report includes company profiles of all the leading players as well as small-scale players operating in the Wire Rope Lubricants market. The Company Profiles segment contains key market players’ SWOT analysis, organization advancements, recent developments, company acquirement, growth strategies, global market share, and product portfolios. Ouranalysis also includes insightful information to help new players identify market risks and challenges to measure the level of competitiveness in the said market.

Prolongs the life of wire rope, sheaves, pulleys, drums, guides, pins and rollers in a variety of applications, including cranes, hoists, marine tow and mooring lines, dockside cables, aerial tramways, dredges, draglines, mining, elevators and many other applications in construction, mining, transportation and manufacturing.

Whitmore"s specialty lubricants have kept the wheels of industry turning since 1893. Over 75 of these years have been spent as a leader in manufacturing innovative, extreme-pressure lubricants specifically for the mining industry.

For over 116 years, our expertise has made us the preferred manufacturer of lubricants for gears, bearings, chains, cams, and wire ropes used in the mining industry. You will find Whitmore products in use throughout Europe, Asia, Australia, South America, Russia, the US and Canada.

All lubricants developed and manufactured at our Rockwall, TX facility undergo extensive testing and are 100% quality-checked before they are shipped.

Whitmore"s SurStik 800 coating on an open gear; the dense, protective coating contains oil-soluble extreme-pressure additives, in combination with solid lubricants.

Whitmore"s open-gear lubricants are designed to perform in the harshest environments and in the most demanding applications, reducing wear, minimizing equipment downtime, prolonging equipment life and lowering your operating costs. They are used worldwide on kilns, ball mills, shovels and draglines.

Whitmore"s extreme-pressure greases are designed for use in severe applications across a variety of conditions, including high load, heat, moisture and a wide range of operating speeds. Protection from wear and high load is accomplished through the use of innovative additives that enhance film strength and adhesive properties. Our product line includes Matrix®, Caliber™ Blue, Caliber 3M and 5M, and Caliber XR.

Our product line includes Paragon™, Paragon Gold, Decathlon™ HD (synthetic) and GF 365 (semi-synthetic). A hallmark of Whitmore"s enclosed-gear oils is long lubricant life. Our no-cost oil analysis program ensures that the product performs consistently year after year, protecting your equipment.

Whether the goal is to protect the rope itself, the drum lagging or the sheaves, Whitmore has the products to meet the need. Products include Whitmore"s drag-rope lubricant, wire-rope lubricant and WR-5.

You don"t have to compromise performance in order to be environmentally responsible. Whitmore"s complete line of high-performance biodegradable lubricants meets or exceeds industry standards and protects your valuable equipment, while protecting the earth.

Whitmore"s family of quality products and services are sold throughout the world through a service-intensive global distribution network, consisting of over 130 authorized distributors who are committed to technical support and total customer satisfaction.

WIRE ROPE LUBRICANTWire ropes contain numerous moving parts which require BENEFITS:lubrication. Each time the rope bends or flexes, the internalstrands rub together. Whitmore"s Wire Rope Lubricant coats these • PROLONGS WIRE ROPE LIFE - readily penetrates to thestrands to prevent friction and wear. This results in longer wire core and lubricates internal strands.rope life, less downtime for rope changes and more production. • NONTACKY - eliminates dirt pick-up and lubricant sling-off.Whitmore"s Wire Rope Lubricant quickly penetrates to the core. • EXTREME LOAD-CARRYING ABILITY - extends wire ropeThis ensures that the rope is lubricated throughout while providing life and minimizes downtime.a nondrying, nontacky film on the outside of the rope which • AVAILABLE IN AN AEROSOL SPRAY - lubricates hard-to-protects outer strands from corrosion as well as lubricating the wire reach areas.rope drums and sheaves. APPLICATIONS:Whitmore"s Wire Rope Lubricant is easily pumpable attemperatures down to -25°F (-35°C). Its nondrying film remains Whitmore"s Wire Rope Lubricant can be used to lubricate all sizesflexible in the most extreme weather conditions which eliminates of wire rope as well as chains, leaf springs and other applicationsflaking and peeling. where a penetrating oil is needed. It may also be applied by hand or automatic lubrication system. RECOMMENDED APPLICATION RATES: Drip System: First Week - 3 drops per minute per inch diameter rope. Second Week and Thereafter - 1 drop per minute per inch diameter rope. Spray System: Every 15 minutes for 30 seconds (on payout only).

PACKAGING Nonreturnable Aerosol Cans Shuttle Tanks Drums Kegs Pails Totes 12 per case For warranty information, scan the QR code. You can also email us at sales@whitmores.com Or write to the Sales Department at the address below.

930 Whitmore Drive • Rockwall, Texas 75087 • USA • (972) 771-1000 • 800-699-6318 An ISO 9001 and ISO 14001 registered company • www.whitmores.com

The Global Wire Rope Lubricants Market Report provides Insightful information to the clients enhancing their basic leadership capacity identified with the global Wire Rope Lubricants Market business, including market dynamics, segmentation, competition, and regional growth. The strategy of expansion has been adopted by key players who are increasing their production capacities to cater to the increasing demand for various application.

New traders at intervals the Wire Rope Lubricants Market face strong competition from ancient world traders as they try with technological revolutions, dependableness and commonplace of Wire Rope Lubricants Market product affairs. The report is at risk of project regarding this Wire Rope Lubricants Market evolutions and additionally the magnitude of competition, value and extra.

Others players have been profiled into detail so as to offer a glimpse of the market leaders. Moreover, parameters such as Wire Rope Lubricants related investment & spending and developments by major players of the market are tracked in this Global report.

The Wire Rope Lubricants Market is widely partitioned reliant on the predictable updates in the enhancement of parameters for example, quality, trustworthiness, end customer solicitations, applications, and others. The Wire Rope Lubricants Market report contains general successful parameters, confinements, and besides has in detail illumination of the noteworthy data close by the present and future examples that may concern the advancement. The comprehensive Wire Rope Lubricants Market report elucidates within and outside representation of current advancements, parameters, and establishments.

The key regions analyzed in this study include North America, Europe, Japan, China, India, Korea, South East Asia, South America, Middle East and African countries. The leading players of Wire Rope Lubricants Market and their geographical presence across the globe are estimated based on production capacity, utilization ratio, consumer base, demand and supply scenario, profit margin and Wire Rope Lubricants marketers.

Data Lab Forecast calculated the market size for the Wire Rope Lubricants market using a bottom-up approach, wherein manufacturers value data for different type (Biodegradable Wire Rope Lubricant, Non-Biodegradable Wire Rope Lubricant), of Wire Rope Lubricants market was recorded as well as forecast for the future years was made. Data Lab Forecast sourced these values from industry experts and company representatives, and externally validated through analyzing historical sales data of respective manufacturers to arrive at the overall market size. Various secondary sources such as company annual reports, white papers, investor presentations and financial reports were also studied by Data Lab Forecast.

In this report, Wire Rope Lubricants market has been segmented into following categories, in addition to the industry trends which have also been detailed below:

Global Wire Rope Lubricants market also specifically underpins end-use application scope and their improvements based on technological developments and consumer preferences.

Market dynamics, Wire Rope Lubricants economy manufacturing, opportunities on the total pricing of this top manufacturer and improvement trend analysis;

The Global Wire Rope Lubricants Market Report provides Insightful information to the clients enhancing their basic leadership capacity identified with the global Wire Rope Lubricants Market business, including market dynamics, segmentation, competition, and regional growth. The strategy of expansion has been adopted by key players who are increasing their production capacities to cater to the increasing demand for various application.

New traders at intervals the Wire Rope Lubricants Market face strong competition from ancient world traders as they try with technological revolutions, dependableness and commonplace of Wire Rope Lubricants Market product affairs. The report is at risk of project regarding this Wire Rope Lubricants Market evolutions and additionally the magnitude of competition, value and extra.

Others players have been profiled into detail so as to offer a glimpse of the market leaders. Moreover, parameters such as Wire Rope Lubricants related investment & spending and developments by major players of the market are tracked in this Global report.

The Wire Rope Lubricants Market is widely partitioned reliant on the predictable updates in the enhancement of parameters for example, quality, trustworthiness, end customer solicitations, applications, and others. The Wire Rope Lubricants Market report contains general successful parameters, confinements, and besides has in detail illumination of the noteworthy data close by the present and future examples that may concern the advancement. The comprehensive Wire Rope Lubricants Market report elucidates within and outside representation of current advancements, parameters, and establishments.

The key regions analyzed in this study include North America, Europe, Japan, China, India, Korea, South East Asia, South America, Middle East and African countries. The leading players of Wire Rope Lubricants Market and their geographical presence across the globe are estimated based on production capacity, utilization ratio, consumer base, demand and supply scenario, profit margin and Wire Rope Lubricants marketers.

Data Lab Forecast calculated the market size for the Wire Rope Lubricants market using a bottom-up approach, wherein manufacturers value data for different type (Biodegradable Wire Rope Lubricant, Non-Biodegradable Wire Rope Lubricant), of Wire Rope Lubricants market was recorded as well as forecast for the future years was made. Data Lab Forecast sourced these values from industry experts and company representatives, and externally validated through analyzing historical sales data of respective manufacturers to arrive at the overall market size. Various secondary sources such as company annual reports, white papers, investor presentations and financial reports were also studied by Data Lab Forecast.

In this report, Wire Rope Lubricants market has been segmented into following categories, in addition to the industry trends which have also been detailed below:

Global Wire Rope Lubricants market also specifically underpins end-use application scope and their improvements based on technological developments and consumer preferences.

Market dynamics, Wire Rope Lubricants economy manufacturing, opportunities on the total pricing of this top manufacturer and improvement trend analysis;

In case you dont find what you are looking for, please get in touch with our custom research team at TableofContents GlobalWireRopeLubricantsMarketInsights,Forecastto2027 1StudyCoverage

The purpose of the Global Wire Rope Lubricants Market 2021-2028 report is to provide strategic information, analysis, and investment evaluation to help decision-makers make informed investment decisions. A summary of all the major and minor projects undertaken by the companies involved in Wire Rope Lubricants is also included in the report.

The Wire Rope Lubricants Market Research report 2021 provides insight into the Wire Rope Lubricants industry in the future by providing facts and figures, meanings, definitions, SWOT analysis, expert opinions, and forecasts for the coming years. Additionally, the report provides a detailed analysis of the major key players, segmentation and applications, geographical analysis and contains information about the industry overview, definition, specifications, raw materials and suppliers, cost structure analysis, and research and development status. This report presents a comprehensive and detailed analysis of the current state of the industry.

There are several aspects covered in the report, including technological advancements made in the Wire Rope Lubricants market, sales made in the global market, production annually, profits made by the industry, and government initiatives taken to increase market growth.

This report analyzes and forecasts the global Wire Rope Lubricants market size (value and volume) by company, major regions/countries, products, and application, historical data from 2014 to 2018, and forecasts to 2028.

This study focuses on the most important global Wire Rope Lubricants manufacturers in order to define, describe, and analyze sales volume, value, market share, market competition landscape, SWOT analysis, and development plans over the next few years.

The objective is to analyze the Wire Rope Lubricants in terms of individual growth trends, future prospects, and the contribution they make to the total market.

Mining operations occur under some of the world’s most demanding conditions. For large excavation equipment, maintaining peak productivity and limited unscheduled downtime requires effective lubrication management. CSWI offers a line of industry-leading lubricants for open gears, bearing, gearboxes, wire ropes, and other extreme applications supported by an extensive distribution network to ensure availability.

8613371530291

8613371530291