whitmore wire rope lubricant free sample

Wire Rope Lubricant quickly penetrates to the core. This ensures that the rope is lubricated throughout while providing a nondrying, nontacky film on the outside of the rope which protects outer strands from corrosion as well as lubricating the wire rope drums and sheaves.

Crosby’s Vitalife®products are the preferred wire rope lubricants in the industry because of their ability to penetrate into wire rope and displace water and contaminants, thus reducing wear and corrosion throughout the rope.Available in a variety of container sizes.

Whitmore’s Wire Rope Lubricant products also coat these strands to prevent friction and wear. This results in longer wire rope life, less downtime for rope changes and more production.

Whitmore’s Wire Rope Lubricant is easily pumpable at temperatures down to -25°F (-35°C). Its nondrying film remains flexible in the most extreme weather conditions, which eliminates flaking and peeling.Whitmore’s Wire Rope Lubricant can be used to lubricate all sizes of wire rope, as well as chains, leaf springs and other applications where penetrating oil is needed. It may be applied by hand or automatic lube system.

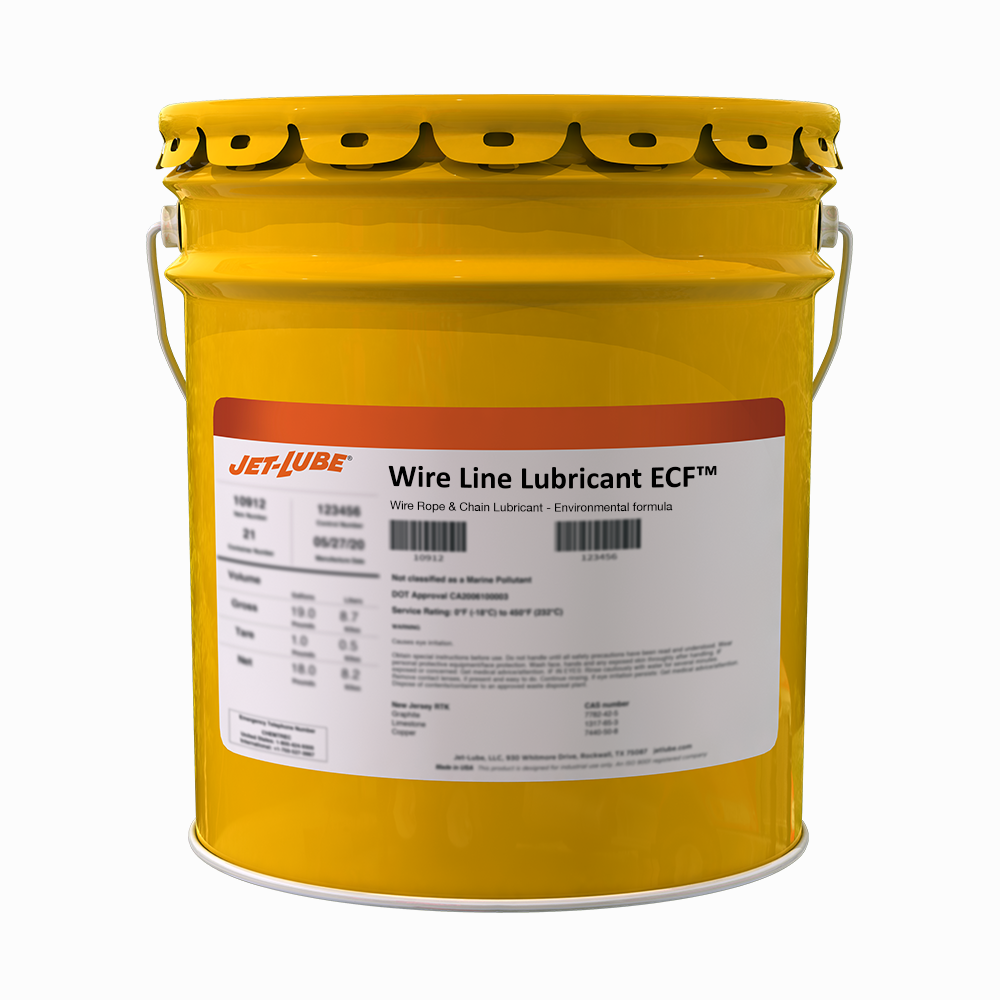

Bret Jenkins (Whitmore®/Jet-Lube®, USA) and Michael D. Holloway (5th Order Industry LLC, USA), explain how to determine which grease is best for your heavy equipment.

Attempting to understand which grease is best for a given application can be a difficult task. Various controlled test methods have been established to make the selection process less painful. Many facilities use several different greases, often leading to costly misapplication mistakes. There has been a concerted effort to minimize the number of greases used in a facility; this technique is known as lubricant consolidation. Maintenance teams are in search of a few greases to take the place of several that are being used. After a grease is in service, it undergoes changes due to contamination and extreme conditions. There are several tests that have been developed that can determine the health of grease, and provide warning signs of impending bearing failure. These in-service tests can help identify misapplications, wear conditions, contamination and potential grease failure.

This test calculates the measurements of greases" extreme pressure and wear protection ability in a dynamic environment (Figure 1). Three steel balls are placed at the bottom of the vessel. A test vessel is filled with the grease of interest. A fourth ball is held in with a chuck and forced onto the three balls. Load is applied to the fourth ball and turned. The load at which the balls begin to gall or seize is considered the weld point. The wear dynamic is the size of the scar that develops prior to seizing. The greater the weld numbers, the more stress the grease can withstand before the test specimens cold weld. The lower the wear scar value, the better protection the grease will provide while under dynamic stress. This is perhaps the best test method available for determining a lubricants ability to withstand load and protect from wear. Superior grease will have weld numbers above 600 kg and scar values below 0.50 mm.

Table 1 compares various greases and their physical properties. The physical properties relate to various environments in the mine environment: water washout, extreme pressure, extreme scuffing and oil separation from the grease.

If most bearings fail due to wear and load, the four-ball test values will provide guidance in your grease selection. If the bearings fail due to lack of grease, yet proper grease frequency is being carried out, then water washout or melting could be occuring. The water washout data, as well as the dropping point, are important considerations. If the grease appears to have lost consistency, then the mechanical stability of the grease is in question and the worked penetration value must be considered.

Wire ropes contain numerous moving parts which require lubrication. Each time the rope bends or flexes, the internal strands rub together. Whitmore’s Wire Rope Lubricant coats these strands to prevent friction and wear. This results in longer wire rope life, less downtime for rope changes and more production.

Whitmore’s Wire Rope Lubricant quickly penetrates to the core. This ensures that the rope is lubricated throughout while providing a nondrying, nontacky film on the outside of the rope which protects outer strands from corrosion as well as lubricating the wire rope drums and sheaves.

Whitmore’s Wire Rope Lubricant is easily pumpable at temperatures down to -25°F (-35°C). Its nondrying film remains flexible in the most extreme weather conditions which eliminates flaking and peeling.

Whitmore’s Wire Rope Lubricant can be used to lubricate all sizes of wire rope as well as chains, leaf springs and other applications where a penetrating oil is needed. It may also be applied by hand or automatic lubrication system.

Wire ropes can be utilized in a number of applications. The intended application generally will dictate the initial lubrication of the wire rope by manufacturers. For example, some wire ropes are employed for the support of structures such as buildings and bridges. These ropes remain nearly static, so there is little need to relubricate them. They will not have the same internal friction and wear (although still subjected to surface corrosion) as a dynamic rope utilized in heavy equipment applications for lifting or hauling purposes.

Wire ropes used in crane services often employ a fiber core which is saturated in oil with strands of wire wrapped around it. This fiber core acts as a sponge to actively drain or release lubricant when the rope is subjected to bending or loading. Most wire ropes fail from the inside, so this fiber core can be beneficial if binding conditions occur.

Wire ropes without a fiber core are typically coated with a lubricant during the manufacturing process to lessen internal friction and to coat the surface in order to minimize corrosion due to water or the environment.

While there are standards in place for lubricants used during the manufacturing process, most are generic and only help put you on the right track in your lubricant selection. Of course, all wire rope lubricants should have corrosion control properties as well as penetrating capabilities to get as far into the core of the wire rope as possible.

There are numerous methods of applying lubricant to wire ropes. For machinery in which the rope can move, you may choose to use a drip, spray or trough method. These methods apply lubricant at a single point and utilize the movement of the rope to spread the lubricant over the entire length of the system. Some trough systems are pressurized, which can be advantageous, as they push the lubricant into the rope.

If the wire ropes are static, manual brushing or sprays usually are the easiest way to apply lubricant. In most cases, it is best to remove excess lubricant from the surface to help minimize dirt and water from sticking to the lubricant, especially in dirty environments.

Wire rope forms an important part of many machines and structures. It is comprised of continuous wire strands wound around a central core. There are many kinds of wire rope designed for different applications. Most of them are steel wires made into strands wound with each other. The core can be made of steel, rope or even plastics.

Wire ropes (cables) are identified by several parameters including size, grade of steel used, whether or not it is preformed, by its lay, the number of strands and the number of wires in each strand.

A typical strand and wire designation is 6x19. This denotes a rope made up of six strands with 19 wires in each strand. Different strand sizes and arrangements allow for varying degrees of rope flexibility and resistance to crushing and abrasion. Small wires are better suited to being bent sharply over small sheaves (pulleys). Large outer wires are preferred when the cable will be rubbed or dragged through abrasives.

There are three types of cores. An independent wire rope core (IWRC) is normally a 6x7 wire rope with a 1x7 wire strand core resulting in a 7x7 wire rope. IWRCs have a higher tensile and bending breaking strength than a fiber core rope and a high resistance to crushing and deformation.

A wire strand core (WSC) rope has a single wire strand as its core instead of a multistrand wire rope core. WSC ropes are high strength and are mostly used as static or standing ropes.

Wire ropes also have fiber cores. Fiber core ropes were traditionally made with sisal rope, but may also use plastic materials. The fiber core ropes have less strength than steel core ropes. Fiber core ropes are quite flexible and are used in many overhead crane applications.

The lay of a wire rope is the direction that the wire strands and the strands in the cable twist. There are four common lays: right lay, left lay, regular lay and lang lay. In a right lay rope the strands twist to the right as it winds away from the observer. A left lay twists to the left. A regular lay rope has the wires in the strands twisted in the opposite direction from the strands of the cable. In a lang lay rope, the twist of the strands and the wires in the strands are both twisted the same way. Lang lay ropes are said to have better fatigue resistance due to the flatter exposure of the wires.

Wire ropes are made mostly from high carbon steel for strength, versatility, resilience and availability and for cost consideration. Wire ropes can be uncoated or galvanized. Several grades of steel are used and are described in Table 1.

Steel cable wire is stiff and springy. In nonpreformed rope construction, broken or cut wires will straighten and stick out of the rope as a burr, posing a safety hazard. A preformed cable is made of wires that are shaped so that they lie naturally in their position in the strand, preventing the wires from protruding and potentially causing injury. Preformed wire ropes also have better fatigue resistance than nonpreformed ropes and are ideal for working over small sheaves and around sharp angles.

Lubricating wire ropes is a difficult proposition, regardless of the construction and composition. Ropes with fiber cores are somewhat easier to lubricate than those made exclusively from steel materials. For this reason, it is important to carefully consider the issue of field relubrication when selecting rope for an application.

There are two types of wire rope lubricants, penetrating and coating. Penetrating lubricants contain a petroleum solvent that carries the lubricant into the core of the wire rope then evaporates, leaving behind a heavy lubricating film to protect and lubricate each strand (Figure 2). Coating lubricants penetrate slightly, sealing the outside of the cable from moisture and reducing wear and fretting corrosion from contact with external bodies.

Both types of wire rope lubricants are used. But because most wire ropes fail from the inside, it is important to make sure that the center core receives sufficient lubricant. A combination approach in which a penetrating lubricant is used to saturate the core, followed with a coating to seal and protect the outer surface, is recommended. Wire rope lubricants can be petrolatum, asphaltic, grease, petroleum oils or vegetable oil-based (Figure 3).

Petrolatum compounds, with the proper additives, provide excellent corrosion and water resistance. In addition, petrolatum compounds are translucent, allowing the technician to perform visible inspection. Petrolatum lubricants can drip off at higher temperatures but maintain their consistency well under cold temperature conditions.

Various types of greases are used for wire rope lubrication. These are the coating types that penetrate partially but usually do not saturate the rope core. Common grease thickeners include sodium, lithium, lithium complex and aluminum complex soaps. Greases used for this application generally have a soft semifluid consistency. They coat and achieve partial penetration if applied with pressure lubricators.

Petroleum and vegetable oils penetrate best and are the easiest to apply because proper additive design of these penetrating types gives them excellent wear and corrosion resistance. The fluid property of oil type lubricants helps to wash the rope to remove abrasive external contaminants.

Wire ropes are lubricated during the manufacturing process. If the rope has a fiber core center, the fiber will be lubricated with a mineral oil or petrolatum type lubricant. The core will absorb the lubricant and function as a reservoir for prolonged lubrication while in service.

If the rope has a steel core, the lubricant (both oil and grease type) is pumped in a stream just ahead of the die that twists the wires into a strand. This allows complete coverage of all wires.

After the cable is put into service, relubrication is required due to loss of the original lubricant from loading, bending and stretching of the cable. The fiber core cables dry out over time due to heat from evaporation, and often absorb moisture. Field relubrication is necessary to minimize corrosion, protect and preserve the rope core and wires, and thus extend the service life of the wire rope.

If a cable is dirty or has accumulated layers of hardened lubricant or other contaminants, it must be cleaned with a wire brush and petroleum solvent, compressed air or steam cleaner before relubrication. The wire rope must then be dried and lubricated immediately to prevent rusting. Field lubricants can be applied by spray, brush, dip, drip or pressure boot. Lubricants are best applied at a drum or sheave where the rope strands have a tendency to separate slightly due to bending to facilitate maximum penetration to the core. If a pressure boot application is used, the lubricant is applied to the rope under slight tension in a straight condition. Excessive lubricant application should be avoided to prevent safety hazards.

Some key performance attributes to look for in a wire rope lubricant are wear resistance and corrosion prevention. Some useful performance benchmarks include high four-ball EP test values, such as a weld point (ASTM D2783) of above 350 kg and a load wear index of above 50. For corrosion protection, look for wire rope lubricants with salt spray (ASTM B117) resistance values above 60 hours and humidity cabinet (ASTM D1748) values of more than 60 days. Most manufacturers provide this type of data on product data sheets.

Cable life cycle and performance are influenced by several factors, including type of operation, care and environment. Cables can be damaged by worn sheaves, improper winding and splicing practices, and improper storage. High stress loading, shock loading, jerking heavy loads or rapid acceleration or deceleration (speed of the cable stopping and starting) will accelerate the wear rate.

Corrosion can cause shortened rope life due to metal loss, pitting and stress risers from pitting. If a machine is to be shut down for an extended period, the cables should be removed, cleaned, lubricated and properly stored. In service, corrosion and oxidation are caused by fumes, acids, salt brines, sulfur, gases, salt air, humidity and are accelerated by elevated temperatures. Proper and adequate lubricant application in the field can reduce corrosive attack of the cable.

Abrasive wear occurs on the inside and outside of wire ropes. Individual strands inside the rope move and rub against one another during normal operation, creating internal two-body abrasive wear. The outside of the cable accumulates dirt and contaminants from sheaves and drums. This causes three-body abrasive wear, which erodes the outer wires and strands. Abrasive wear usually reduces rope diameter and can result in core failure and internal wire breakage. Penetrating wire rope lubricants reduce abrasive wear inside the rope and also wash off the external surfaces to remove contaminants and dirt.

Many types of machines and structures use wire ropes, including draglines, cranes, elevators, shovels, drilling rigs, suspension bridges and cable-stayed towers. Each application has specific needs for the type and size of wire rope required. All wire ropes, regardless of the application, will perform at a higher level, last longer and provide greater user benefits when properly maintained.

Lubrication Engineers, Inc. has found through years of field experience, that longer wire rope life can be obtained through the use of penetrating lubricants, either alone or when used in conjunction with a coating lubricant. Practical experience at a South African mine suggests that life cycles may be doubled with this approach. At one mine site, the replacement rate for four 44-mm ropes was extended from an average 18.5 months to 43 months. At another mine, life cycles of four 43-mm x 2073 meter ropes were extended from an average 8 months to 12 months.

In another study involving 5-ton and 10-ton overhead cranes in the United States that used 3/8-inch and 5/8-inch diameter ropes, the average life of the ropes was doubled. The authors attribute this increased performance to the ability of the penetrating lubricant to displace water and contaminants while replacing them with oil, which reduces the wear and corrosion occurring throughout the rope. A good spray with penetrating wire rope lubricant effectively acts as an oil change for wire ropes.

In these examples, the savings in wire rope replacement costs (downtime, labor and capital costs) were substantial and dwarfed the cost of the lubricants. Companies who have realized the importance of proper wire rope lubrication have gained a huge advantage over those who purchase the lowest priced lubricant, or no lubricant at all, while replacing ropes on a much more frequent basis.

Wire rope lubricants are designed for coating and protection of a wire rope from corrosion and they minimize the internal and external wear. The lifespan of a wire rope can be dramatically amplified when it is coated with a lubricant, i.e., lack of lubrication would result in reduction of longevity for wire ropes.

Wire rope lubricants find a wide range of applications in industrial fields, including mining, forestry, shipping, construction cranes, building elevators (lifts) and suspension bridges. These applications can be also be categorized based on consumption of lubricants. The lubricants used during the manufacturing of ropes come under category 1, whereas the lubricants used during the working conditions of wire ropes come under category 2.

Additionally, fatigue life of ropes can also be greatly extended by proper lubrication, when the wires can move freely to balance the stress distribution caused by drums or sheaves. The lubricant must reach the fiber cores or they will absorb moisture and encourage corrosion. Today, new legislative environmental guidelines are driving the users to give deliberation not only to the typical wire rope lubricants that lubricate and protect the wire ropes, but that are also considered as environment friendly.

The Kirkpatrick Group, Inc. has been the Original Equipment Manufacturer of Dynagard™ Environmental Lubricants and Wire Rope Lubrication equipment for over 30 years. We developed the first successful Wire Rope Lubrication System

Full Sail Marine maintains offices around the world to offer quick response services to our clients in the Commercial, Government, Cruise and Offshore industries. With locations throughout North America and Europe, we stand ready

Manufacturer of wire rope & cable lubricants including grease. Specifications of wire rope & cable grease include pour point of minus 25 degrees F, flash point of 120 degrees F, viscosity of 3.28 at 100 degrees F & 12.8 at 40 degrees F, & specific gravity of 0.89. Wire rope & cable grease capacities include ability to penetrate wire rope, evaporate & leave a film of molybdenum disulphide in the core to lubricate each wire strand. Wire rope & cable grease can be applied by spraying, brushing or dipping in a in-line tank with no heating requirements. Grease is available in 25 lb. pail or 55 gal. drums. Compliant with ASTM standards.

This product is a semi-fluid wire rope lubricant designed to meet the lubrication and corrosion prevention requirements of wire ropes working under all conditions. Typical application areas are dockside and ship crane ropes, drag lines, hoists and mobile cranes.

Wire Rope Lube will penetrate between the rope strands to provide integral lubrication and to provide both internal and external protection against corrosion caused by wet, adverse weather conditions and sea water.

Crosby’s Vitalife®products are the preferred wire rope lubricants in the industry because of their ability to penetrate into wire rope and displace water and contaminants, thus reducing wear and corrosion throughout the rope.Available in a variety of container sizes.

Whitmore’s Wire Rope Lubricant products also coat these strands to prevent friction and wear. This results in longer wire rope life, less downtime for rope changes and more production.

Whitmore’s Wire Rope Lubricant is easily pumpable at temperatures down to -25°F (-35°C). Its nondrying film remains flexible in the most extreme weather conditions, which eliminates flaking and peeling.Whitmore’s Wire Rope Lubricant can be used to lubricate all sizes of wire rope, as well as chains, leaf springs and other applications where penetrating oil is needed. It may be applied by hand or automatic lube system.

LUBEGARD Wire Rope Lubricant is patented, aquatically non-toxic & biodegradable. It contains a unique blend of corrosion inhibitors, thickeners and wear reducers. Ideal for all types of wire ropes and chains in a variety of services and environments. Wire Rope Lubricant is biodegradable, non-toxic, and leave no oil slick! Biodegradable (EPA Shake Flask Test, EPA 560/6-82-003 with unacclimated inoculum) / Aquatically non-toxic (EPA 600/4-90-027, Rainbow trout test). Forms liquid protective layer, does not foul automatic applicators, Excellent for manual application, Water and salt water resistant. Can be applied in many ways; spray, wipe, dip or brush it on. It can also be applied with various low viscosity core lubricators. Apply as necessary for lubrication and corrosion protection.

VGP Compliant - Shell Naturelle S2 Wire Rope Lubricant A is an Environmentally Acceptable Lubricant under the definitions of the USA EPA 2013 Vessel General Permit.

Low toxicity towards the environment - Made from >60% renewable raw materials. Shell Naturelle S2 Wire Rope Lubricant A is also classed as minimally toxic and non-bioaccumulative.

Proper lubrication of your wire rope, chain and cable can safely extend its operational life regardless of application. Cranes, elevators, shovels, drilling rigs, suspension bridges and draglines are some of the many applications that use wire rope, chain or cable to perform work such as pulling, dragging or hoisting. These applications often are exposed to harsh environmental conditions, including extreme weather. Lubrication Engineers can help your wire rope, chain and cable last longer and operate safely by implementing a lubricant reliability program and recommending the right lubricants for the job.

Most wire ropes are lubricated during the manufacturing process, but this lubricant will not last the entire life of the rope. When looking for a lubricant to relubricate your wire rope, choose one that contains no acids or alkalis, possesses the adhesive strength to stay on the rope, can penetrate between wires and strands, has high fluid film strength, resists oxidation and remains pliable. It is important to remember that most wire ropes fail from the inside out. Corroded rope can be a safety hazard, as there is no way to determine its remaining strength and life. Proper lubrication will help prevent deterioration of wire rope due to rust and corrosion.

Because most wire ropes fail from the inside, it is critical to ensure the center core receives sufficient lubricant. LE recommends a combined regimen in which a penetrating lubricant is used to saturate the core, followed by a coating lubricant to seal and protect the outer surface. LE offers several penetrating and coating type wire rope lubricants to suit your specific needs.

Penetrating lubricants contain an evaporative solvent that facilitates migration of the lubricant into the core of the wire rope, then evaporates, leaving behind a heavy lubricating film that protects and lubricates each strand.

Wirelife Almasol Coating Grease (451-453) is a soft, semifluid calcium-based grease designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its tacky, water-resistant characteristics enable it to adhere strongly to rapidly moving parts, seal out damaging moisture, protect against premature wear and shield metal against corrosive attack.

Typical Applications: Wire rope, chain links, pins, bushings, cable sheave bushings, cables, open and closed silent and roller chains, and small, slow-turning gearboxes that require a semifluid lubricant

Wirelife Almasol Coating Lubricant (2002) is a fluid wire rope lubricant that provides a tough outer coating to seal and protect against fretting corrosion, wear and rust – even under extreme load and moisture. It seals and protects better than any product available. When used in conjunction with Wirelife Monolec Penetrating Lubricant, maximum protection and wear reduction is achieved.

Wirelife Almasol Syn Coating Lubricant (2022) is an extremely tacky, nonasphaltic synthetic lubricant with exceptionally high film strength. Perfect for extreme environments and conditions, it is the ultimate outer surface protector for wire rope and cable and comes from the same advanced technology that LE developed to protect large open gears in the mining and quarry industries. It derives its high load-carrying capacity from its synergistic blend of an extreme pressure additive and Almasol, LE’s exclusive wear-reducing additive.

Wirelife Monolec Penetrating Lubricant (2001) has excellent corrosion resistance and high load-carrying (EP) properties. It penetrates to the core of wire ropes, whether they are running or stationary. It is also excellent as a penetrating lubricant for chains of all sizes and works well in a variety of other industrial applications. When used in conjunction with Wirelife Almasol Coating Lubricant, maximum protection and wear reduction is achieved.

It contains a petroleum solvent to enhance its ability to penetrate. The solvent evaporates, leaving behind a film of heavy-bodied lubricant that protects and lubricates each strand and resists leakage from the wire rope core. Available in bulk sizes or in an aerosol version.

Typical Applications: All stationary or moving wire ropes or cables under heavy loads; chains of all sizes; mining and construction applications such as standing and running lines, draglines, cranes and derricks; marine applications such as cranes, hoists and drilling rigs; any other application that requires excellent rust protection for steel parts.

Designed for marine environments and other applications where environmental concerns require the use of a very low toxicity wire rope and chain lubricant, LE’s Wirelife Low Tox Penetrating Lubricant (2011) has excellent load-carrying capability and provides outstanding protection against rust, while having the lowest possible toxic effect on the environment.

Earthwise EAL Wire Rope Grease (3353) is recommended for use in applications on or near the waterways. It is an EAL and meets the specifications required by the EPA’s Vessel General Permit (VGP). It is readily biodegradable, exhibits minimal aquatic toxicity and will not accumulate in the cells of fish and other aquatic life forms. It is a soft, semifluid formulation designed to coat wire rope as well as moving chain and cable parts to ensure long life and smooth, quiet operation. Its semi-tacky, water-resistant characteristics enable it to adhere to the application and seal out damaging moisture and protect against rust formation.

Typical Applications: Applications near or around waterways including: Wire rope; chain links, pins and bushings; cable sheave bushings, bearings and strands; open and closed silent and roller chains. Ideal for use in automatic lubrication systems.

LE is happy to offer industrial lubricant and reliability recommendations for a variety of applications, and to provide product-specific data on all of our items to help you make the right decision. To learn more about our wire rope lubricants, wire rope lubricators as well as our other enhanced lubricants and lubricant reliability products, please

Whether you are working with manufacturing equipment, automotive equipment, or any other industrial equipment, you need products you can count on to reduce friction and wear. Kimball Midwest carries the right chain and rope lubricants for your operation. Our

Pune, Maharashtra, India, December 15 2021 (Wiredrelease) MarketResearch.Biz –:The report discusses everything marketers are asking before investing in the global Wire Rope Lubricants market during the forecast period 2021-2027. It provides detailed insights into current trends, market share, market size, sales value, and volume. The data used in this report has been drawn from trusted industry sources, paid resources, and verified sources. This research serves as a systematic guide for marketers to make informed decisions. Key Players of the Global Wire Rope Lubricants market provide detailed insights into their company profiles, product portfolio, geographic presence, statistical analysis, and key developments and growth strategies. Additionally, the Global Wire Rope Lubricants Market report offers a comprehensive analysis and discussion of the COVID-19 pandemic as to how it has impacted the market. This study explains how the epidemic will affect the market dynamics and what the future opportunities are for market players.

Then the report focuses on global major leading industry players providing information such as company profiles, product picture, and specification, capacity, production, Wire Rope Lubricants, cost, revenue, and contact information. Upstream raw materials, equipment, and downstream consumer analyzes are also performed. Additionally, the Wire Rope Lubricants industry development trends and marketing channels are analyzed.

Updated reports (free extracts available) include the option to access premium features covering a wide range of historical, current, and future data. Other important updates to the Global Wire Rope Lubricants Market report include reviews of manufacturing and launch prices as well as refined pricing models. This report incorporates new content to help provide key market knowledge to decision-makers and provides up-to-date forecasts that outline the economic situation and impact of COVID-19.

The report outlines the products, applications, and specifications for the reader. The study lists the leading companies operating in the global Thermal Wire Rope Lubricantsmarket and highlights the key changing trends adopted by companies to maintain dominance. Using SWOT analysis and Porter’s five forces analysis tool, the strengths, weaknesses, opportunities, and threats of the leading companies are all mentioned in the report. All major players in this global market are profiled with details such as product type, business overview, sales, manufacturing base, competitors, applications, and specifications.

The latest Survey on Global Wire Rope Lubricants Market has been conducted with various industry organizations from different geographies to create a 100+ page report. This study is a perfect combination of qualitative and quantitative information highlighting key market developments, challenges facing the industry and competition, gap analysis, and available new opportunities and trends in the market.

The report provides a basic overview of the industry including definitions, classifications, applications, and industry chain structure. The Wire Rope Lubricants Market analysis is provided for the international markets including development history, competitive landscape analysis, and development status of key regions.

Chapter 4: Presenting the Wire Rope Lubricants Market Factor Analysis Porters Five Forces, Supply/Value Chain, PESTEL assessment, Market Entropy, Patent/Trademark Analysis.

Chapter 6: Evaluating the main manufacturers of the Wire Rope Lubricants market which incorporates its Competitive Landscape, Peer Group Analysis, & Company Profiles.

This content has been published by MarketResearch.Biz company. The WiredRelease News Department was not involved in the creation of this content. For press release service enquiry, please reach us at [email protected].

Wire Rope Lubricants market report determines the market share, size, current and future trends, challenges, and forecast for the year 2029. It also assesses the market drivers, restraints, growth indicators, market dynamics, and risk. The business strategies and potential growth opportunities are mentioned in this report. It also gives a lot of information on gross margin, SWOT analysis, CAGR, and future prospects of major key players. This research segmented the market by types, applications, and by geographical regions along with the new techniques and manufacturing cost structures of the Wire Rope Lubricants market. The Report highlights the data on global market developments and the competitive landscape.

Our research analysts have thoroughly studied and carried out the research through primary and secondary research methods, which will highlight the critical information. The global Wire Rope Lubricants Market study digs into the major drivers of market demand as well as supplier strategies and other key aspects. It emphasizes market features such as main drivers, growth opportunities, risk factors, and challenges in the global market. This research will help businesses make profitable strategies and capital investments as it will allow them to develop their marketplace successfully in both global and regional markets.

The Wire Rope Lubricants market is segmented by types, applications, key players, and region to get a closer look at the market threats and opportunities which will enable the buyers to make strategic improvements in their businesses.

Exxon Mobil Corporation, Total S.A., Shell Global, Kluber Lubrication, Lubrication Engineers, Castrol, ROCOL, Bel-Ray Company, Whitmore, The Crosby Group, Fuchs, The Kirkpatrick Group, Royal Manufacturing Company, Wirerope Works Inc., Schaeffer Manufacturing Co., HVL Group, Magna Group, Bans Group of Companies, HP Lubricants

In conclusion, the report is the compilation of the accurate information gathered from industry experts. The Wire Rope Lubricants Market report is the credible source for achieving the market research that will aid to accelerate your business. It also explains different business models, key business strategies, the current level of market development, market share and size, and the current level of competition in the market.

Whitmore’s Earthkeeper WRL is an excellent wire rope oil that is specially formulated to protect industrial wire ropes. This Whitmore wire rope lubricant is specially formulated to penetrate to the core of a rope and is an ideal choice for marine environments. This Whitmore oil contains anti-wear additives that help to prevent wear and maximize the service life of a rope. In addition, this biodegradable Whitmore grease enhances the capability of a wire rope to withstand extreme pressure. This rope lubricant from Whitmore Manufacturing Company is suitable for a wide range of industrial applications and can be used near waterways and in ecologically sensitive areas.

The global Wire Rope Lubricants market was valued at million in 2021 and is projected to reach US$ million by 2028, at a CAGR of % during the forecast period.

The global key manufacturers of Wire Rope Lubricants include Exxon Mobil Corporation, Total S.A., Shell Global, Kluber Lubrication, Lubrication Engineers, Castrol, ROCOL, Bel-Ray Company and Whitmore, etc. In 2021, the global top five players have a share approximately % in terms of revenue.

We surveyed the Wire Rope Lubricants manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

8613371530291

8613371530291