wire rope 7 x 19 free sample

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for 316 Stainless Steel Bar Stock , Stainless Steel Cable Wire Rope , Stainless Steel Cutter , We are sincerely looking forward to establishing good cooperative relationships with customers from at home and abroad for creating a bright future together.

Control cables,Guardrail,Standing rigging,Running rigging, excavation, logging of any type of terrain, tramway, elevator, oil and gas, drilling, marine and electrical constructions.

Includes standard products such as wire ropes composed of strand (s) of 0.03mm wires as well as special wire ropes composed of strand (s) of 0.013mm ultra-fine wires.

Saky Steel Co.,Ltd is located in Jiangsu Province. The company was founded in 1995. Now the company covers totally 220,000 square meters . The company has a total employee of 150 out of whom 120 are professionals .The company has been continually expanding itself ever since it‘s founded .Now the company is a ISO9001:2000 certified company and has been continually awarded by the local government .

Sakysteel is specicalizing in manufacturing of Stainless steel Wire,Wire Rope, Welding,Flat Wire,Profile Wire.It is capable of supplying various types of stainless steel products in different grades,hardness and surface.our factory supply raw material from TISCO,LISCO,BAOSTEEL,JISCO,ZPSS,SAKYSTEEL,etc.

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Factory Free sample Shower Support Bar - 304 316 316L stainless steel wire rope 6×19 7×19 1×19 – Saky Steel, The product will supply to all over the world, such as: Canada, Albania, Armenia, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it"s a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

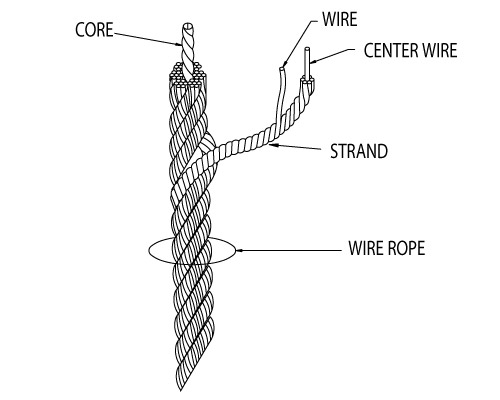

Wire rope is several strands of metal wire twisted into a helix forming a composite "rope", in a pattern known as "laid rope". Larger diameter wire rope consists of multiple strands of such laid rope in a pattern known as "cable laid".

In stricter senses, the term "wire rope" refers to a diameter larger than 3/8 inch (9.52 mm), with smaller gauges designated cable or cords.[1] Initially wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 3/64 in. diameter while most wire ropes begin at a 1/4 in. diameter.[2] Static wire ropes are used to support structures such as suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Our company has been concentrating on brand strategy. Customers" pleasure is our greatest advertising. We also source OEM service for 7*19 Steel Wire Rope, Aisi316 1x19 Pvc Wire Rope, Hot Dip Galvanized Wire Rope, We have extensive goods supply and the price is our advantage. Welcome to inquire about our products.

Stainless steel wire rope use high-quality AISI304, AISI316 as stainless steel raw materials. It has excellent corrosion resistance, high temperature resistance and low temperature resistance. It is widely used in petrochemical industry, aviation, automobile, fishing, building decoration and other industries. After electrolytic polishing, the stainless steel wire rope becomes bright and the corrosion resistance feature is greatly enhanced.

Stainless steel wire rope adopt fully automated production lines . The production process consists of wire drawing, stranding and closing. Wire drawing is to draw a thick steel wire rod into thin wire. Stranding is to synthesize wire into strands, and closing is to reshape strands into rope. After these three processes are completed, they undergo quality inspection, packaging, and finally become a finished product .

Stainless steel wire rope use high-quality AISI304, AISI316 stainless steel as raw materials. with many or many strands of fine wire twisted into a flexible rope. Stainless steel wire rope adopt fully automated production lines . The production process consists of wire drawing, stranding and closing. Wire drawing is to draw a thick steel wire rod into thin wire. Stranding is to synthesize wire into strands, and closing is to reshape strands into rope. After these three processes are completed, they undergo quality inspection, packaging, and finally become a finished product. Main specifications: 1X7, 7X7, 6X7+FC, 6X7+IWRC, 1X19, 7X19, 6X19+FC, 6X19+IWRC. (Fiber Core (FC):This core is made of either natural fibres or polyroplylene and provides excellent elasticity.In addtion,the fibre core is impregnated with lubricant during manufacture.It is thereby lubricated internally thus reducing internal corrosion and wear between wires.) , (Independent Wire Rope Core (IWRC): This core is usually composed of a sepate7*7 wire rope around which wire strands are laid.The steel core increases the strength by7%and the weight by10%.These steel cores provide more substantial support than fibre cores to the outer strands during the rope’s operating life thus ensuring even stress distribution and retention of the rope shape.Steel centres resist crushing,distortion and are more resistant to heat and increase the strength of the rope.), The lay direction can be right (symbol Z) or left (symbol S), Stainless steel wire Rope can be produced in accordance with GB/T 9944-2015, ISO, BS, DIN, JIS, ABS, LR and other international and foreign advanced standards. Min tensile strength 1770mpa, 1570mpa, 1670mpa, 1860mpa, 1960mpa.

Stainless Steel Wire Rope has excellent corrosion resistance able to work normally in the harsh environment of various harmful media, high temperature resistance and low temperature resistance,Able to withstand various loads and variable loads.

Good softness, suitable for traction, pulling, strapping and other purposes. It is widely used in wire drawing, weaving ,hose,wire ropes, filtration equipment, steel strand, spring, electronic instruments, medical treatment, Anti-theft devices, Labor protection, Grain nail,etc

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for Factory Free sample 7*19 Stainless Steel Cable - Stainless Steel Wire Rope2 – Bangyi , The product will supply to all over the world, such as: Barcelona, Poland, Netherlands, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need a trusted supplier and value information.

7x19 Type 316 stainless steel wire rope has excellent flexibility and is commonly used in winch lines. It can also be used for garage door cable, exercise equipment and sailboat rigging. The 7x19 construction is comprised of seven strands of 19 individual wires in each strand.

7x19 Type 316 stainless steel wire rope has excellent flexibility and is commonly used in winch lines. It can also be used for garage door cable, exercise equipment and sailboat rigging. The 7x19 construction is comprised of seven strands of 19 individual wires in each strand.

Steel wire ropes are widely used in many applications such as crane, tower crane, surface and underground mining, excavation,logging of any type of terrain, tramway, elevator, oil and gas, drilling, marine and electrical constructions.. The selection of a rope must consider the strength, fatigue and abrasion resistance, crushing resistance, resistance to metal loss and deformation

Wire rope is technically defined as multi-wire strands laid geometrically around a core while also used more generally as a term to classify multiple product families including aircraft cable, coated aircraft cable, general purpose wire rope, strand, rotation resistant wire rope, compacted/swaged wire rope, and cable laid wire rope.

Aircraft cable does not fit the definition of wire rope in the strictest sense as it does not have an independent core, but rather a strand core, in which the center is one of the strands that is laid with the outside strand layers. Aircraft cable is available in diameters 3/8" or less with breaking strengths similar to that of equal diameter independent wire rope core (IWRC) and is available in stainless steel and galvanized steel.

Wire rope can be galvanized via three processes. Listed from least corrosion-resistant to the most corrosion-resistant, they are electro-galvanizing, hot-dip galvanizing, and drawn-galvanizing. In addition to being the most corrosion-resistant types of galvanized wire rope, drawn-galvanized has another added benefit which is a breaking strength that is the same as bright wire rope does. Electro-galvanized and hot-dip galvanized wire rope have breaking strengths that are approximately 10% lower.

Wire rope is specified by the number of strands in the rope, the number of wires in each strand, and a description of the core’s material of construction. For example, the notation “6x7 FC” means that the rope has six strands with seven wires in each strand and a fiber core. Commonly used core designations include FC (fiber core), independent wire rope core (IWRC), wire strand core (WSC), and poly core (PC).

There are two elements to wire rope lubrication, the core, and outer strands. IWRC wire rope always has a lubricated core (unless specially ordered as otherwise). Bright wire rope always has lubricated outer strands. Galvanized wire rope can be manufactured in either dry finish or lubricated with respect to the outer strands. Typically stainless steel wire rope is manufactured with a lubricated IWRC and dry finish outer strands.

There is no exact answer as to what the difference is. Cable is generally reserved for smaller diameter ropes, and often in constructions 1 x 7, 7 x 7, 1 x 19, 3 x 3, and 3 x 7. Wire rope is a term generally used for products over 3/8” in diameter, and in constructions such as 6 x 25, 6 x 36, 6 x 37, 6 x 42, and more.

Construction refers to the arrangement of the wires used during stranding. There are numerous ways to strand any individual cable, and this gives us many constructions. Often you will hear “7 x 7” or “7 x 19,” and these numbers represent constructions. Each different construction, although often close in break strength, will carry very different properties. As a general rule of thumb, the more wires in a construction, the more flexible a cable will become. This means that at the same diameter, a 1 x 19 cable (which is 19 wires) will be less flexible than a 7 x 19 cable (133 wires). What happens when you have two constructions that comprise of the same amount of wires, do they have different properties? Yes. A good example here is a 7 x 19 cable and a 19 x 7 cable. Each is made of 133 wires, but laid differently. Both of these cables are very flexible, however due to the construction, a 19 x 7 cable has rotation resistant properties. Seeing as it is less prone to spinning, a 19 x 7 is often used on hoists, where a 7 x 19 is often used in fitness equipment, aircraft controls, and running rigging. The best takeaway from this - different constructions serve different purposes. The more wires, the more flexible your cable will be. If you have any additional questions, please contact a product manager and they will be able to help you.

These numbers are specifically referring to grades of stainless steel. The commercial standard stainless steel is 302 or 304. These have corrosion resistance, and are good for creating a product with longevity. There is an overlap in stainless steel grades, our product is made using material from this overlap, and is considered to be 302 and 304. 305 Stainless is considered to be “non-magnetic” however it is not. 305 stainless will always inherently have some magnetism; however this is lower than the standard amount in 302/304 stainless. 316 stainless is used in two major places – highly corrosive marine environments, as well as food/medical grade products. What 316 gives up in overall break strength, it makes up in very high corrosion resistance. For mor information on wire stainless grades, view our austenic types chart.

This is a standard from the US Government for setting specifications for cable and wire rope. Unless built specifically to another specification, we manufacture all of our products to conformity with the current RR-W-410 standard. To view the current standard listed on our website, please click here.

Mil-Spec cable is cable that is manufactured to specifications set by the US Military. MIL-DTL-83420 is the name of one of these specifications – one regarding 7 x 19 and 7 x 7 aircraft cable. To manufacture cable to this specification, a company must be on the Qualified Producers List. Loos & Company is one of the select few who can manufacture cable to this specification. For more information on how to understand Military Callouts, view our QPL-83420 Quick Reference Guide.

No. Galvanized cable is made of wire that has been coated in a layer of zinc. This zinc will slow the corrosion process slightly; however, if the cable is nicked or placed in a high corrosion environment, it will generally lose its zinc coating and become susceptible to corrosion. A good place to see this is on automotive components. Many auto parts are galvanized, but still rust – anyone who services their car regularly can attest to this.

For cable to be useful, it needs to be attached to mechanical components. For instance, on a weight cable machine at a gym, the handle bar that you pull down needs to be attached to the cable, and the other end needs to be attached to the weight. A cable assembly is made by taking a length of cable, and mechanically attaching fittings on the end so that you may connect it to the proper components. The process of mechanically attaching these fittings is often “swaging” (pronounced: sway-jing, or s-wedge-ing). This is putting mechanical force on the outside of the fitting until it is tightly fitted onto the cable.

For additional information about Wire, Cable, Wire Rope and more, visit www.loosco.com and look through our Glossary of Terms as well as our Technical Information section. As always, should you have any additional questions, feel free to ask them by commenting below, or email marketing@loosco.com and we can help shed some light on the subject.

We don"t collect information from our users. Only emails and answers are saved in our archive. Cookies are only used in the browser to improve user experience.

Common Uses: winch lines, slings, sailboat rigging, wire and cable railing, garage doors, marine industry, irrigation, exercise equipment, agriculture industry, pulleys and sheaves uses, fencing and railings.

Construction The size and number of wires in each strand, as well as the size and number of strands in the rope greatly affect the characteristics of the rope. In general, a large number of small-size wires and strands produce a flexible rope with good resistance to bending fatigue. The rope construction is also important for tensile load (static, live or shock) abrasive wear, crushing, corrosion and rotation. The number of strands and wires will influence the flexibility, fatigue and wear resistance of any given wire rope. Rope selection is often a compromise. Generally the more load bearing wires in the rope the greater the flexibility, however the smaller the wires the less abrasion resistance. For example, the same nominal diameter 7 x 7 wire would be less flexible than a 7 x 19 wire, hence a large number of small size wire and strands produce a flexible rope with good resistance to bending fatigue wear. The construction of wire rope is defined by the number of outer strands (first number), and the number of wires within that strand (second number) and then by the arrangement of the wires in each strand (shown in brackets). The wires in each strand can be arranged in several ways, for example a 6 x 19 construction the 19 wires in each strand are laid 9 around 9 around 1 centre wire.

Endurance Dyform 6 20-22// Usha Martin Crane Wire Rope 23-25// Wire Rope Slings Overview 26 // Tri-flex Wire Rope Slings 27 // Wire Rope Terminations 27 //

Core The core of a steel wire rope serves as a foundation for the strands, providing stability by keeping them in place throughout the life of the rope. Wire ropes can be supplied with either a fibre or wire core. Grade Wire rope can be manufactured in different steel grades, which directly affects the Minimum Breaking Force, (MBF). The higher the grade the higher the MBF. Common wire grades include: 1570, 1770, 1960 and 2070 Finish Wire Ropes can be supplied as Black (self-colour), Galvanised or Stainless Steel. Wire rope is lubricated at the time of manufacture, to help reduce friction between wires and strands, and the friction between the rope and drum or sheave. In addition, the lubrication retards corrosion and inhibits possible rotting of the fibre core.

RHOL Right Hand Ordinary Lay LHOL Left Hand Ordinary Lay RHLL Right Hand Lang’s Lay LHLL Left Hand Lang’s Lay Pref Preformed Post Postformed WRC Wire Rope Core WSC Wire Strand Core FC Fibre Core FW Filler Wire Strand Construction D or d Diameter (in millimetres)

Rotating or Non-Rotating Rotation resistant wire ropes are manufactured to resist rotation under load and are suitable for crane use and where long lengths are required.

Clamping Wire Rope To ensure complete safety, it is imperative that wire ropes are clamped correctly. The diagrams below are a guide only. Please refer to the relevant Australian Standards AS 2076 for further information.

Correct Spooling of Steel Wire Rope on Drum It is imperative to correctly spool wire rope onto a drum. Improper spooling induces torque within the rope, which in turn reduces the life of the rope.

tension to avoid any slack on inner layers that can be crushed or nicked against the groove walls by outer layers. In general, the tighter the line, the better the spooling, but the rope should be tensioned with at least 2% of the breaking load or 10% of the working load.

Lubricating Steel Wire Ropes All steel wire ropes supplied by Robertsons are lubricated at the time of manufacture, however, periodic lubrication with good quality acid free and moisture free lubricant during use is required to ensure best performance. The following are accepted ways to lubricate wire ropes during use.

Steel Wire Rope Cutting Procedure Hand cutters for cutting ropes up to 8mm in diameter are sufficient. Mechanical or hydraulic cutters will be required for wire ropes with larger diameters.

Careless cutting can result in the balance of tension in the rope being destroyed. In every case, each side of the cut must be correctly seized to prevent strand

C: Both ends of the seizing wire are then pulled tight and twisted together for a length of one rope diameter. The twisted connection is then hammered into a strand valley.

Typical Steel Wire Rope Failures Steel wire rope is tough and durable, however eventually it will reach the end of its safe service life. Below are some examples of typical damage and deterioration. Steel wire ropes should be inspected every 12 months.

Storing Steel Wire Ropes Ensure steel wire rope is stored in a weather-proof storage space. If wire rope is to be kept unused for a considerable amount of time, it must be protected from the elements. The ideal storage area is a dry, well-ventilated building or shed. Avoid closed, unheated, tightly sealed buildings or enclosures because condensation will form when warm, moist outside (ambient) air envelopes the colder rope. Although wire rope is protected by a lubricant, this is not totally effective since condensation can still occur within the small sections between strands and wires, thereby causing corrosion problems. Ensure the reels are kept up off the ground, or are placed on a concrete floor. • Reels should be mounted on jacks or placed on a swift (with a brake arrangement) and care taken to see that the reel rotates as the rope unwinds • Ensure clearance for free rotation of the reel when the rope end is pulled and maintain continuous tension during haul off Correct Handling of Steel Wire Ropes Incorrect handling of steel wire ropes can cause kinking or loops Ropes should be stored in a clean dry place under cover. Reels or coils should be kept off the ground and supported by timber. They should also be examined periodically and rope dressing renewed as required. 1) Unreeling and Uncoiling Reels should be mounted on jacks and care taken to see that the reel rotates as the rope unwinds. Timber should be applied as a lever to one of the flanges to act as a brake, keeping the rope tight and preventing the reel from over- running. When the ropes are supplied in coils a turntalbe or swift should be employed and the free end pulled out with event tension as the swift, or turnatable revolve. Over-winding should be avoided at all times to obviate kinking. Coils may also be unwound by securing the free outside end of the rope and then rolling the coil along the ground; care being taken at all times to ensure that the coil is held firmly together, avoiding tight coils or kinks. Ropes should be stored in a clean dry place under cover. Reels or coils should be kept off the ground and supported by timber. They should also be examined periodically and rope dressing r newed as required. 1) Unreeling and Uncoiling Reels should be mounted on jacks and care taken to see that th reel ro ates as the rope unwinds. Timber should be applied as a lever t one of the flanges to act as a brake, keeping the rope tight and pr ve ting the reel from over- run ing. When the ropes are supplied in coils a turntalbe or swift should b employed and the fre end pulled out with vent tension as the swift, or turnatable revolve. Over-winding should be avoided t all times to obviate kinking. Coils may also be unwound by securing the free outside end of the rope and then rolling the coi along the ground; care being taken t all times to ensure that the coil is held firmly together, avoiding tight coils or kinks. Ropes should be stored in a clean ry lace under cove . R ls or coils shoul be k pt off the ground and supported by timber. They should also be examined periodically and rope dressing renewed as required. 1) Unreeling and Unc iling Re s should be mounted on jacks and c re taken to se that the reel r tates as the rope u winds. Timbe should be appl ed as a lever to one of the flanges to act as a brake, keeping the rope tight and preventing the reel from over- running. When the rope are supplied in coils a turntalbe or swift employed and the free end pulled out w th event tension as the swift, or tur atabl rev lve. Ov r-winding shoul be av ided at all t mes to obviate kinking. Coils may also be unwound by sec ing the fr e out id end of th rope and the rolling the c il along the ground; care being taken at all times to ensure that the coil is held firmly together, avoiding tight coils or kinks. Ropes should be stored in a clean dry place under cover. Reels or coils should be kept off the ground and supported by timber. They should also be examined periodically and rope dressing renewed a required. 1) Unreeling and Uncoiling Reels should be mounted on jacks and care taken to see that the reel rotates as the rope unwinds. Timber should be applied as a lever to one of the flanges to act as a brake, keeping the rope tight and preventing the reel from over- running. When the ropes are supplied in coils a turntalbe or swift should be employed and the free end pulled out with event tension as the swift, or turnatable revolve. Over-winding should be avoided at all times to obviate kinking. Coils may also be unwound by securing the free outside end of the rope and then rolling the coil along the ground; care being taken at all times to ensure that the coil is held firmly together, avoiding tight coils or kinks. Ropes should be stored in a clean dry place under cove . R els or coils should be k pt off the ground and supported by timber. They should also be xamined p riodically and rope dressing renewed as required. 1) Unreeling and U c iling Reels should be mounted on jacks and care taken to see that the reel tates as the rope u winds. Timb r should be appl ed as a lev r to ne of the flanges to act as a brake, keeping the rope tight and prev nti g the reel from over- running. When the rope are supplied in coils a turntalbe or swift empl y d and the free end pull d out with event tensi n as the swift, or t r at ble rev lve. Ov r-winding sh uld be avoided at all times to bviate kinki g. Coils may also be unwound by securing the free out id nd of the rop and then rollin the coil a ong the ground; care being taken at ll times to ensure that the coil is held firmly together, avoiding tight coils or kinks. forming in the steel wire rope, causing permanent damage. Below is a summary of the correct way to handle steel wire rope:

Although the steel wire rope is lubricated at the time of manufacture, a suitable lubricant should be applied every three months. The reels containing the steel wire ropes should also be rotated 90 degrees every three months.

11. Handling and Care of Wire Ropes 1. Handling and Care of Wire Ropes 11. Handling and Care of Wire Ropes 11. Handling and Care of Wire Ropes 1 . Handling and Care of Wire Rop s

2) Seizings It is important that before cutting ropes are properly seized with annealed mild steel wire or strand to avoid slack wires and possible rope distortion. 2) Se zings It s important that before cutting ropes are properly s ized with annealed mild steel wire or strand to avoid slack wires and possible rope distortion. 2) Seizings It is important that bef re cutting ropes are properly seized with annealed mild steel wire or strand to avoid slack wires and possible rope distortion. 2) Seizings It is important that before cutting ropes are properly seized with annealed mild steel wire or strand to avoid slack wires and possible rope distortion. 2) Seiz ngs It is important that before cutting ropes are properly seized with annealed mild steel wire or strand to avoid slack wires and possible rope distortion.

Wire Rope Terminations Hand spliced or machine swaged slings, with your choice of terminations, can be manufactured and tested (if required) on our premises at short notice. All slings and assemblies are permanently marked with safe working loads, based on a 5:1 factor of safety. Machine Swaging Aluminium Ferrules Sizes 2mm – 52mm. Copper Ferrules Sizes 2mm – 10mm Steel Ferrules Sizes 9mm – 75mm Swage Sockets Sizes 3mm – 52mm Hand Splicing from 2mm – 75mm dia

Galvanised Fibre RHOL 28 20.4 Galvanised Fibre RHOL 35.6 25.8 Galvanised Fibre RHOL 44 31.8 Galvanised Fibre RHOL 53 38.5 Galvanised Fibre RHOL 63 45.8 Galvanised Fibre RHOL 74 53.8 Galvanised Fibre RHOL 86 62.4 Galvanised Fibre RHOL 113 81.5 Galvanised Fibre RHOL 143 103 Galvanised Fibre RHOL 176 127 Galvanised Fibre RHOL 213 154 Galvanised Fibre RHOL 253 183 Galvanised Fibre RHOL 450 326

Galvanised Fibre RHOL 4.3 3.2 Galvanised Fibre RHOL 5.8 4.3 Galvanised Fibre RHOL 7.7 5.8 Galvanised Fibre RHOL 17.6 12.4 Galvanised Fibre RHOL 30.8 22.5 Galvanised Fibre RHOL 39 28.4 Galvanised Fibre RHOL 48.2 35.1 Galvanised Fibre RHOL 69.4 50.5 Galvansed Fibre RHOL 12 8.8

Galvanised Wire RHOL 63 41.8 Galvanised Wire RHOL 90 60.2 Galvanised Wire RHOL 107 70.7 Galvanised Wire RHOL 124 82 Galvanised Wire RHOL 161 107 Galvanised Wire RHOL 204 135 Galvanised Wire RHOL 252 167 Galvanised Wire RHOL 304 202 Galvanised Wire RHOL 363 241 Galvanised Wire RHOL 426 283 Galvanised Wire RHOL 493 328 Galvanised Wire RHOL 644 428 Galvanised Wire RHOL 816 542 Galvanised Wire RHOL 911 604 Galvanised Wire RHOL 1009 669 Galvanised Wire RHOL 1220 810 Galvanised Wire RHOL 1700 1110

Galvanised Wire RHOL 18.9 10.4 Galvanised Wire RHOL 27.2 14.3 Galvanised Wire RHOL 37.2 20.2 Galvanised Wire RHOL 47.5 25.66 Galvanised Wire RHOL 59.3 32 Galvanised Wire RHOL 73 39.4

Blue Fibre RHOL 4.3 3.16 Blue Fibre RHOL 5.8 4.2 Blue Fibre RHOL 7.7 5.5 Blue Fibre RHOL 12 8.6 Blue Fibre RHOL 17.6 12.4 Blue Fibre RHOL 30.8 22.1 Blue Fibre RHOL 48.2 34.6

POWERFORM® 8/8P • A high strength eight strand rope with plastic impregnated core ideal for situations where longer service life is required • High fatigue life resulting from the unique compaction process • Maximum resistance to crushing. Recommended for multi-layer spooling operations

• A sample of rope from each production batch is tested to destruction • Greater surface contact area resulting from the eight strand construction and compacted finish give longer rope life and reduced sheave wear • Optional plastic impregnation of the steel core. (P) signifies full plastic impregnation of the steel core.

POWERFORM® 35/35P • Superior strength and resistance to rotation • Suitable for use on single part and multi-part hoist reeving systems • High fatigue life due to unique compaction process • A sample of rope from each production batch is tested to destruction

1013.0 103.0 1138.0 116.0 1268.0 129.0 1405.0 143.0 1535.0 156.0 1700.0 173.0 1735.0 177.0 1858.0 189.0 2023.0 206.0 2200.0 224.0 2266.0 231.0 2374.0 242.0

1083.0 110.0 1218.0 124.0 1357.0 138.0 1503.0 153.0 1651.0 168.0 1819.0 185.0 1856.0 189.0 1985.0 202.0 2162.0 220.0 2349.0 239.0 2425.0 247.0 2541.0 259.0

52 2256.0 230.0 *Mass per unit length of POWERFORM 35P increases by approx. 3%. Note: • POWERFORM 35P is available on special request and prior confirmation. • Rope sizes and Breaking Force not shown in the standard table, may be available on request and prior confirmation.

Note: • POWERFORM 8P is available for rope diameter 16mm and above on special request and prior confirmation. • Rope sizes and Breaking Force not shown in the standard table, may be available on request and prior confirmation.

POWERFORM® 6/6P • A high strength rugged six strand rope ideal for situations where longer service life is required • Can be substituted for any six strand construction to improve service life • High fatigue life due to unique compaction process • A sample of rope from each production batch is tested to destruction

Typical Steel Wire Rope Sling Description Hand spliced or machine swaged slings, with your choice of terminations, can be manufactured and tested (if required) on our premises at short notice. All slings and assemblies are permanently marked with safe working loads, based on a 5:1 factor of safety.

1065.0 109.0 1165.0 119.0 1295.0 132.0 1425.0 145.0 1505.0 153.0 1665.0 170.0 1885.0 192.0 1975.0 201.0 2135.0 218.0 2325.0 237.0 2475.0 252.0 2650.0 270.0 2810.0 286.0

Machine Swaging Aluminium Ferrules Sizes 2mm – 52mm Copper Ferrules Sizes 2mm – 10mm Steel Ferrules Sizes 9mm – 75mm Swage Sockets Sizes 3mm – 52mm Hand Splicing from 2mm – 75mm dia

1004.0 102.0 1112.0 113.0 1226.0 125.0 1246.0 127.0 1362.0 139.0 1483.0 151.0 1609.0 164.0 1741.0 177.0 1877.0 191.0 2019.0 206.0 2166.0 221.0 2317.0 236.0

*Mass per unit length of POWERFORM 6P increases by approx. 3%. Note: • POWERFORM 6P is available only for 16mm and above on special request and prior confirmation. • Rope sizes and Breaking Force not shown in the standard table, may be available on request and prior confirmation.

0.78 120° 0.87 0.99 1.09 1.22 1.35 1.48 1.63 1.76 1.94 2.10 2.20 2.40 2.60 3.10 3.40 4.00 4.30 4.90 5.40 5.90 6.50 7.00 7.70 8.30 9.10 9.60 10.50 12.50 13.80

0.78 120° 0.87 0.99 1.09 1.22 1.35 1.48 1.63 1.76 1.94 2.10 2.20 2.40 2.60 3.10 3.40 4.00 4.30 4.90 5.40 5.90 6.50 7.00 7.70 8.30 9.10 9.60 10.50 12.50 13.80

0.96 0.78 0.55 0.72 1.21 0.99 0.70 0.91 1.50 1.22 0.86 1.13 1.81 1.48 1.05 1.36 2.14 1.74 1.23 1.61 2.54 2.07 1.47 1.91 2.94 2.40 1.70 2.21 3.85 3.14 2.22 2.89 4.85 3.95 2.80 3.65 5.63 4.91 3.48 4.53 7.27 5.92 4.20 5.46 8.67 6.9 5.01 6.52 10.18 8.30 5.88 7.65 11.79 9.61 6.81 8.86 15.41 12.56 8.9 11.58

1.11 0.96 0.78 0.55 0.55 0.48 0.39 0.27 1.40 1.21 0.99 0.70 0.70 0.61 0.50 0.35 1.73 1.50 1.22 0.86 0.86 0.75 0.61 0.43 2.10 1.81 1.48 1.05 1.05 0.91 0.74 0.52 2.47 2.14 1.74 1.23 1.23 1.07 0.88 0.61 2.94 2.54 2.04 1.47 1.47 1.27 1.04 0.73 3.40 2.94 2.40 1.70 1.70 1.48 1.21 0.85 4.45 3.85 3.14 2.22 2.22 1.93 1.58 1.11 5.61 4.85 3.95 2.80 2.80 2.44 1.99 1.40 6.97 6.0 4.91 3.48 3.48 3.03 2.47 1.74 8.40 7.27 5.92 4.20 4.20 3.65 2.98 2.10 10.03 8.67 7.07 5.01 5.01 4.36 3.56 2.50 11.77 10.18 8.30 5.88 5.88 5.12 4.18 2.94 13.63 11.79 9.61 6.81 6.81 5.93 4.84 3.40 17.81 15.11 12.56 8.90 8.90 7.75 6.32 4.45

Tri-Flex slings provide strength and flexibility. Because of the patented TRI-FLEX SLING construction, there are substantial savings in material and machine costs in the larger sizes.

8613371530291

8613371530291