wire rope 7 x 19 factory

This cable features a 7 x 19 construction and is available in diameters ranging from 3/32″ to 3/8″. Custom spools are offered, as well as, bulk spools of 5,000 feet. The wire rope is made from grade 304 stainless steel for optimal corrosion resistance and durability.

SwageRight™ creates quality galvanized stainless steel wire rope in a 7x19 diameter that is best suited for rigging, lifting, towing, and heavy construction applications. Galvanization is ideal for heavy-duty applications and offers greater protection against deformation and wear.

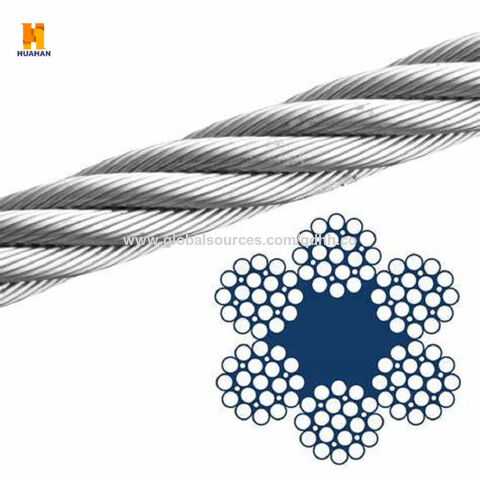

6x19 construction wire rope is available with either FC (fibre core) or WSC (wire strand core). When supplied with a wsc the rope is more commonly referred to as 7x19. The rope is very popular in diameters from 3mm to 16mm and is used on a variety of applications. 6x19 FC and 6x19 WSC (7x19) is very flexible in diameters 3mm to 6mm and is used for many requirements where wire ropes are running over pulleys. 7x19 construction is readily available in both galvanised and marine grade stainless steel.

7x19 AISI316 stainless steel wire rope is used for a wide range of applications. Extremely flexible when compared to both 1x19 and 7x7, the 7x19 construction is often used where a flexible stainless steel wire rope is particularly required. 7x19 performs well for running applications. Used extensively throughout the marine industry as well as for general engineering applications, 7x19’s excellent flexibility make it a favourite for control cable and a variety of marine rigging applications, examples of which are shown below:

This cable features a 7x19 construction and is available in diameters ranging from 3/32" to 1/2". Custom spools are offered, as well as, bulk spools of 5,000 feet. The wire rope is made from grade 316 stainless steel for maximum corrosion resistance and durability.

This cable features a 7x19 construction and is available in diameters ranging from 3/32" to 1/2". Custom spools are offered, as well as, bulk spools of 5,000 feet. The wire rope is made from grade 316 stainless steel for maximum corrosion resistance and durability.

These ropes are standard for Tuf-Grip assemblies for smaller sizes such as control cable applications. Choose from two materials: stainless steel or galvanized carbon steel wire rope. Standard utility cable and fittings are suitable for most applications. We offer standard end fittings to let you use aircraft cable as small as 1/16 inch in diameter. If you need one even smaller than that, please call us.

See charts for minimum breaking force and weight per foot. Notice all ropes have a steel core – the only one recommended for Tuf-Grip assemblies. All Tuf-Grip assemblies use a pre-formed rope construction because of its ability to maintain its integrity when inserted into the fittings before swaging occurs.

BrandsMcKissickUnionConductix WampflerBlock DivisionESCODetroit HoistNew England RopesHudsonPower TeamInsulatusFelcoThernOrion RopeworksCommonwealth CanvasSchmalzGunnebo JohnsonChicagoGorbelRopeblockBahcoIndustrial MagneticsLacledePeerlessSpancoSamsonAervoeMAG-MATECMEsmetKlein ToolsSkookumMutual IndustriesWalker MagneticsCasarNewcoecoZohmTractelLiberty Glove ProductsTecnomagneteElvexLittle MuleHänel RotomatHarringtonPro-LineTeufelbergerPhillystranLUG-ALLLiftGuardWireCraftersMetreelSlingmax® Rigging SolutionsKulkoniCoffingduraklearStraightpointMillerElebiaSuncor StainlessChester HoistCooper ToolsMalta DynamicsRUDTerrierADBBudgit HoistsEagle Manufacturing CompanyTuff BuiltElk RiverSuperClampActekAccoTrue TemperCortlandBridon-BekaertRigid LifelinesCampbellJergensJD NeuhausANVERCrosbyNicopress3M / DBI SalaUltra SafeDurabiltShaw-BoxJeamarWirerope WorksEnerpacJ.C. Renfroe & SonsPattersonYaleMazzellaMorse StarrettSimplexCambridge InternationalANCRA InternationalR&M Materials Handling

Wire Rope 7x19 Stainless Steel AISI 316Very flexible Stainless Steel Wire Rope. Is used for halyards but can also be used for many other applications.

Other sizes and information about 7x19 wire rope on request.Custom madeWant to make a quotation for your total rigging yourself? This is possible within the wire rope 7x19 section by following these 6 easy steps:

Eyes are mainly used as an attachment to rigging screws or forks. Eye terminals are engraved with the wire size and swage depth, making them easier to work with and to press or swage onto the wire.

Forged from low carbon stainless steel AISI 316L every Petersen Forged Swage Eye is increadibly strong and light. Petersen swage eyes can be used with many different wire-rope constructions.

Fork terminals are amongst the most commonly used wire end fittings, they are normally attached to pre drilled anchor plates or steel constructions. Also used in combination with toggles, eyes or U-bolts.

Fork terminals are amongst the most commonly used wire end fittings, they are normally attached to pre drilled anchor plates or steel constructions. Also used in combination with toggles, eyes or U-bolts.

The "T" Terminals all features, engraved wire size, Blue Wave logo, and swage depth marking for faster and easier swaging. Be aware t-terminal fitting is mast brand related, exact dimensions are critical for proper function.

Hi-MOD - Petersen Shroud Terminals (also known as Spoon terminals) are exclusively manufactured at the Petersen factory in England. Forged from low carbon stainless steel AISI 316L (1.4404) every Petersen Swage Shroud Terminal is incredibly strong and light.

Be aware Stemball terminals are mast brand related, exact dimensions are critical for proper function. Stemball terminals can be used in combination with Blue Wave Cups.

Swage Stemballs from Petersen are forged from low carbon stainless steel AISI 316L and is incredibly strong. Petersen swage stemballs can be used with many different wire-rope constructions.

Thread Terminals UNF all feature engraved wire size, Blue Wave logo, and swage depth marking for faster and easier swaging. The UNF thread is more refined compared to metric and has a longer life span.

Metric thread is less refined compared to UNF thread and more subjected to wear. In general the thread terminal on the wire side is right-handed, thereby left-handed thread is the exception.

The Blue Wave Chromed Bronze Body features a number of details that makes it the best choice for exclusive and durable rigging. The sleek, open Bronze body prevents the threads from sizing up.

Nicopress Copper and Zinc-Plated Copper Oval/Duplex Compression sleeves (sometimes called ferrules), are used for making eye and lap splices on wire rope. They are economical and can hold approximately 100% of the cable"s rated breaking strength, depending on the cable size and type used and conform to MS51844. We have determined through pull-testing that Nicopress Oval Sleeves will hold military specification grade aircraft cable in tension until it breaks, when the cable is made to military specifications for 3x7. 7x7, 7x19 and 6x19 IWRC and correctly applied with Nicopress Tools. Here used in combination with a thimble.

Perfection Chain’s high strength steel wire rope is sourced from Korea and China and available in a variety of strand and wire configurations and coating options to protect against corrosion, including electroplated, hot-dip galvanized, and vinyl. We also carry uncoated and stainless steel wire rope. Our 3/8″ or smaller diameter wire rope, generally referred to as “Aircraft Cable,” is available in constructions of 7×7 and 7×19, with 7×19 being more flexible. Our larger diameter wire rope is available in 6×19 construction.

Wire rope is several strands of metal wire twisted into a helix forming a composite "rope", in a pattern known as "laid rope". Larger diameter wire rope consists of multiple strands of such laid rope in a pattern known as "cable laid".

In stricter senses, the term "wire rope" refers to a diameter larger than 3/8 inch (9.52 mm), with smaller gauges designated cable or cords.[1] Initially wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 3/64 in. diameter while most wire ropes begin at a 1/4 in. diameter.[2] Static wire ropes are used to support structures such as suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

The 1/4″ Swaged Stainless Steel Wire Rope Cable is a 7 x 19 strand aircraft cable. Factory cut & swaged. Moderate corrosion resistance & remains ductile over long periods running over sheaves. Best used for saltwater applications. The most commonly used cable for boat lifts.

Oasis Dock Supply recommends 7 x 19 aircraft cables for boat lift applications. 7 x 19 means the rope has seven strands and there are nineteen wires in each strand. Always consider at least a 5:1 safety factor when figuring working loads. A test certificate for all cables is available upon request.

The main items including AISI 304 and AISI 316 stainless steel wire rope 1x19,7x7 and 7x19. Our products have a good reputation due to strict quality control, mature production technology and stable quality.

8613371530291

8613371530291