wire rope bracing made in china

They are heavy duty, precision machined gripping devices which are designed to grip wire rope from light loads to ultimate breaking loads. They are designed for use when light, compact grip is desired and where conductor damage is not a factor. They work on any lay wire rope. These grips will hold regardless if the wire is greased, dirty, wet, tarred, plated, etc. Each grip comes with a wide range of adapters and liners to grip different size wire rope.

Pull wire and cable while maintaining tension until the line can be permanently anchored. Use with stranded bare steel wire and cable in applications where marring can be tolerated. Clamps with spring-loaded jaws grip the cable before tensioning to aid proper positioning. The clamp with latch provides a more secure grip that prevents wire and cable from slipping out of the jaws. Warning: Do not use as an anchor.

Pull the trigger by one hand and the wire rope grip will be opened easily and release instantly to quickly insert or remove wire. Specially designed for gripping a wide range of cables.

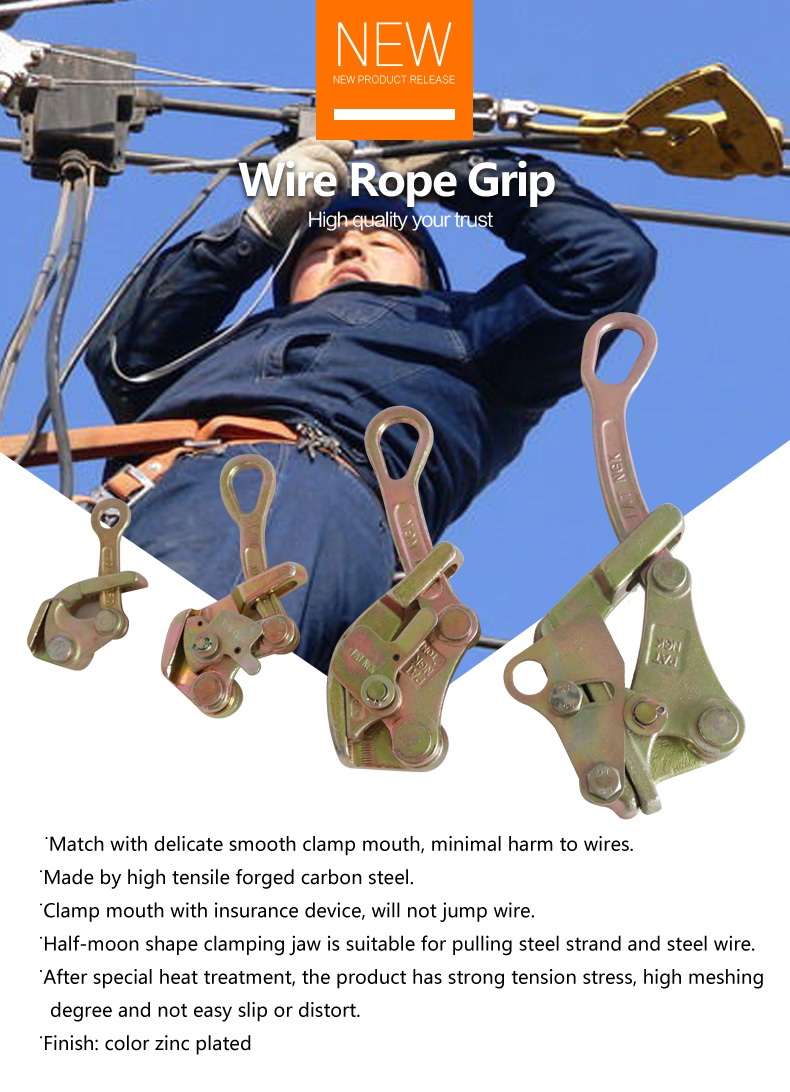

Wire Rope Grips are manufactured from drop-forged, heat-treated steel for excellent durability, They are forged of alloy steel with heat treatment, Forged alloy steel construction is durable yet lightweight. The rack has strong anti-tension with high occlusion strength. They are not easy to slide and deformation, yellow chromate finish protects grips from rust and corrosion.

Attach these clamps by running a wire rope through the jaws to create an attachment point anywhere along the wire rope. The eye is often used with a ratchet puller.

It is also called cable grip, wire rope pulling grip, also known as "pork chops" due to their shape which are used for getting a "bite" on wire rope in the middle of the line. They work great for tensioning projects like zip lines, bracing cables and utility lines, just to name a few. They are typically connected to some kind of mechanical pulling unit, whether it"s a cable comealong or a lever chain hoist. These types of pullers help you to achieve serious leverage and tension cable to your desired specification

This cable grip tool grip is used in various applications including general use in wire rope distributor warehouses, in the field with construction crews, in the field with construction crews, in mines-coal-silver-copper (used in conjunction with mining conveyors), and anywhere wire rope is used. Widely to be used in the power, communications, and general construction fields to pull wire and cable.

Aluminum Alloy Wire Grip For Conductor Automatic Come Along Clamp is suitable to tighten the Insulated conductors or adjust of sag. With high stength aluminum titanium alloy forging, the weight is light. The jaw part adopts a special texture processing so that It can firmly clamp the cable and does not hurt the inner core whether winter or summer. Aluminum Alloy Wire Grip For Conductor Automatic Come Along Clamp is used to adjust sag in the operation of erecting wire and sagging.

Unlike traditional cable grips, these grips were designed to work easily with just one hand. The "trigger" design of these grips allows for total dexterity and easy manipulation so the wire rope pulling grip can be opened and installed on the line in just a matter of seconds, using only one hand. Heavy-duty design ensures these grips will hold up out in the field.

One-handed operation thanks to "trigger" design--simply pull on trigger with one hand and the wire rope pulling grip will open easily and release instantly

There are a number of tools and methods for tensioning high tensile wire. One method uses a cable puller (come-along) in combination with a tool such as this high-quality china made wire puller. The high tensile wire is placed in the jaw of the Grip. When used properly, the grip"s smooth, V-groove jaw will not damage galvanized coating on wire.

Lightweight, especially economical grip Designed for working with solid and stranded bare wire from .08" (2 mm) to .20" (5.1 mm) Single "V" groove jaw Made in china, All models are fitted with swing down safety latch as standard.

WARNING: Before each use, clean jaw area and inspect grip for proper operation to avoid slippage. When used on/near energized lines, ground, insulate, or isolate grip before pulling. Do not exceed rated capacity. Always match proper size and type of grip to application. Wire Rope Grips are to be used for temporary installation, not for permanent anchorage.

Wire ropes can be seen everywhere around us, they are made of strands or bundles of individual wires constructed around an independent core, suitable for construction, industrial, fitness, commercial, architectural, agricultural, and marine rigging applications.

Wire rod is made from high carbon steel wires(0.35 to 0.85 percent carbon) in a hot rolling process of a required diameter, usually from 5.5mm to 8 mm.

Wire rod is drawn to the required diameter by the 1st drawing machine after descaling dust and rust, adding mechanical properties suitable for application.

Positioning the wires different or the same size lay in multiple layers and same direction, or cross lay and diameter is maintained by one-third of the rope size.

So in theory, it is very simple to manufacture wire ropes. However there are many more details that must be closely monitored and controlled, and this requires time and experienced personnel since it is a super complicated project you cannot imagine.

Purpose of the present invention is exactly will propose a kind of simple in structure, materials and production process is few, cost is low and the steel rope pulled tension brace type large plastic greenhouse of economy and durability, to overcome the deficiencies in the prior art.

This steel rope pulled tension brace type large plastic greenhouse proposed by the invention, it has strut, plastic film, it is characterized in that having between strut the steel cable of tension to connect, above the steel cable or below have plastic film fixing with it, the side is plastic film to be opened/closed or wall.

The wire rope handling of reinforcing and frame rope reinforcement by connection are arranged between the strut group, and steel cable is by rope cramp and the tension of stringing button.

The present invention adopts the strut of one group of group to be arranged in battle array, tighten with the steel cable stay bolt, between each group strut, wear tow and frame rope again, form frame, the generally auxilliary from the outside lid of plastic film, with the steel cable contact position be the semi-surrounding structure, clamp fixingly again with the film of plastic production, the wall of canopy is with also hanging envelope with film, sometimes be the insect protected meter of booth, wall is hung earlier one deck fly net, and the film volume is set in the outside again, so as booth every worm, ventilative and insulation.For smaller booth, the film of cover cap ceiling can also outwards be assisted in canopy simply, and the film folder is folder from inside to outside, but this mode is not suitable for using in the snowy area of meeting.

It is the goal of LKS Wire Rope to provide manufactured rigging products and hardware which are competitively priced and delivered on time with zero defects at quality and service levels that are consistent with the expectations of our customers. We fully understand that to do so is good business. The success of LKS Wire Rope depends on our commitment to associate involvement, continual improvement, and improved business performance goals.

nVent CADDY cable bracing is a simple seismic bracing method for mechanical, electrical, plumbing (MEP) and fire sprinkler systems, including CPVC pipe systems. Cable bracing is the only option when brace lengths exceed the brace length limitation of 9"-7" (3 m) for strut or when confined/crowded spaces make rigid systems difficult to install. The system includes steel cables complying with the ASCE® 19 pre-streching requirements, attachment fittings, swaged oval sleeves & related tools, as well as pre-assembled kits.

All over the world, professional companies generally use guy wires as a supporting element to stabilize structures in the antenna, communications, and utility projects.

Why is the guy wire so important? And how is it used? If you do not have a clear understanding, do not worry, In this complete guide, We’re going to dig deep into ‘guy wire‘, you can jump to any section that interests you:

Aguy wireis a tensioned cable, wire, or rope that is used to brace, guide or secure all sorts of structures like ship masts, electric poles, radio towers, or wind turbines, which are of considerable heights and not self-supporting in place.

The cables bear a high tension, so for industrial purposes, the cable consists of wires of galvanized steel, which makes the guy wires extremely strong.

The guy derives from a Dutch word, gei, which was a rope used to fix a furled sail to a mast. When it came to any line used to keep something stable, it was also named strand wire, stay wire, guy strand, guy cable, guy anchors, sometimes mistakenly called ”guide wire” (The word guide is of French origin which has nothing to do with guy wire).

A guy wire is designed to transfer some of the weight of the structures to the ground. It is used to support kinds of electric poles and towers in the power system, or hold up aerial masts for broadcasting and communications.

One side of a guy wire is connected to a point high up on the structure, and the other hand is anchored to a safe point on the solid ground, creating a diagonal line. An anchor concreted into the solid ground can is used to hold one or more guy wires steady.

Utility Lines run for longer distances with many utility poles or towers, and they need to cross many places. Because of the enormous tension stress of utility lines between the poles or towers, on the opposite side, guy wires are connected from the pole to the ground to support the unbalanced lateral loads, make sure the structures be straight and prevent the ground from moving.

Guy wire is designed to use with several fittings and components for different applications, and they are used together to provide stability to towers, antennas, and other utility structures.

According to the program, the dead end grip comprises guy wire dead end grips, preformed dead end grip used on the conductor, and preformed grip. Guy wire preforms are used on end poles. The guy wire preforms join the anchor rod or insulator to achieve the use of setting the pole.

After the stay wire goes around the anchor rod, the 3 bolt clamp bites the close of the stay wire to protect against the stay wire from slipping down. The grooves of this guy clamp the stay wire, and the bolt will secure two pieces of guy clamp clamping the stay wire.

The Pole band is also a fitting utilized together with the guy wire. According to the arrangement, the pole band incorporates a single offset pole band and a double offset pole band. According to the program, you will find utility pole bands, telephone pole brackets, and cable pole bands.

An insulatorat a stay wire or guy wire is under pressure if it’s connected at both ends. Substances have higher compressive strength than strength because the pressure is acting to pull on the substance while forces are tending to push it.

Insulatorsfor use in stay wire are made so that strain on the cord is converted into a force, as shown in the picture of a stay insulator made from porcelain, glass, or ceramic.

The taller the structures are, the more substantial and more Transverse distance due to the wind force. Almost all the towers and masts more than 20 feet have guy wires supporting them. The height may be decreased to 10 feet when the tower or mast is set in areas of steep terrain or with frequent severe weather.

Even though the installation is easy, the guy wire should not be installed do-it-yourself, experienced professionals should only do it. You should prepare the guy wire and fittings, such as guy grip, guy clamp, or guy thimble before the installation.

Then: Attach the other side of the guy wires to points on the ground, and tight the cables so that all of them can’t move. Ideally, the three wires should be mounted 120 degrees(If four wires then 90 degrees) and as far as possible apart from each other.

Tension inspection before delivery:In the factory, The expert should handle proper equipment to do the workload capability test. The current condition and strength of the cable should be considered.

Tension breaking strength examination before installation:The engineershould examine strands regularly to ensure that the wires comply with the tension breaking strength limits.

The base metal is steel produced by the open-heart, basic oxygen, or electric furnace procedure. It is of quality and purity that if attracted to the dimensions and coated with zinc, the strand and also wires will probably be of uniform quality and possess the properties and attributes as prescribed in ASTM A475.

The zinc-coated wire is free of imperfections not consistent with good commercial practice. The zinc coating is constant and of reasonably uniform thickness.

As a reliable guy wire manufacturer and supplier in China, RAX Industry can supply you with a series of guy wires. Custom sizing and pricing are also available. If you have any questions, contact us now.

A guy wire is a tensioned cable, wire, or rope that is used to brace, guide or secure all sorts of structures like ship masts, electric poles, radio towers, or wind turbines, which are of tremendous heights and not self-supporting in place.

The cables bear a high tension, so for industrial purposes, the cable consists of wires of galvanized steel, which makes the guy wires extremely strong.

The guy apparently derives from a Dutch word, gei, which was a rope used to fix a furled sail to a mast. When it came to be used of any rope used to keep something Stable, It was also named strand wire, stay wire, guy strand, guy cable, guy anchors, sometimes mistakenly called ”guide wire” (The word guide is of French origin which has nothing to do with guy wire).

A guy wire is designed to transfer some of the weight of the structures to the ground. It is used to support kinds of electric poles and towers in the power system, or hold up aerial masts for broadcasting and communications.

One side of a guy wire is connected to a point high up on the structure, and the other hand is anchored to a safe point on the solid ground, creating a diagonal line.

The taller the structures are, the more substantial and transverse distance due to the wind force. Almost all the towers and masts more than 20 feet have guy wires supporting them. The height may be decreased to 10 feet when the tower or mast is set in areas of steep terrain or with frequent severe weather.

A supported scaffold consisting of a platform supported by brackets which are secured in place around the circumference or perimeter of a chimney, stack, tank, or other supporting structure by one or more wire ropes placed around the supporting structure.

A suspension scaffold consisting of a platform suspended by one rope from an overhead support and equipped with means to permit the movement of the platform to desired work levels.

Separate ropes secured at their top and bottom ends closer to the plane of the building face than the outermost edge of the platform. By drawing the static line taut, the platform is drawn against the face of the building.

A suspension scaffold consisting of a platform supported by hangers (stirrups) suspended by two ropes from overhead supports and equipped with means to permit the raising and lowering of the platform to desired work levels.

Items whose strength, configuration, or lack of stability may allow them to become dislocated and shift and therefore may not properly support the loads imposed on them. Unstable objects do not constitute a safe base support for scaffolds, platforms, or employees. Examples include, but are not limited to, barrels, boxes, loose brick, and concrete blocks.

nVent CADDY Seismic Solutions protect people, property and equipment during and after a seismic event by ensuring business continuity and continued operation of critical infrastructure and services. nVent CADDY"s innovative seismic bracing solutions reduce the total installed cost, and the provided installation technique training and guidance ensures seismic code and standards compliance.

From design to construction to inspection, we keep our process transparent to ensure a full understanding of the final bracing installation, whether it requires cable or rigid bracing solutions.

Can"t find the fastener or product you are looking for or need more information about our "Wire/Forged Hardware Turnbuckles, HooksMending Plates,Corner Braces & More"? Call us today or click the quote button.

8613371530291

8613371530291