wire rope bracing free sample

Early tower installations for radio broadcasting offered problems similar to those met in guying stacks, poles, derricks and similar structures. Guys for these moderate-height structures were commonly made of regular wire rope.

Structural strand is now used for guy systems. Where larger diameter wire rope was once used, structural strand, with its higher modulus of elasticity and lower diameter-to-strength ratio, allows for smaller diameter guys. This reduction in diameter reduces ice and wind loads, which may be important in the overall design of the tower. Structural strand’s higher modulus of elasticity (less stretch) also allows for less take-up of the bolts during tensioning.

Structural strand and wire rope is used for the main cables, suspenders and wind cables of highway, pedestrian and pipeline suspension bridges. Structural strand is manufactured through 5 1/2” diameter and wire rope up to 7” diameter.

Pre-stretching greatly reduces the constructional stretch ofthe structural strand or wire rope and improves the overall elastic stability. While in the pre-stretcher, overall lengths and intermediate tower and suspender points can be measured to close tolerances under prescribed tensions.

In a tied arch bridge, the bridge deck is suspended by structural strand or wire rope hangers hung from a steel or concrete arch. Tied arch bridges normally cross short to medium spans. Structural strand has been used in tied arch bridges having span lengths of more than 1,000 feet.

Each corner of the span is connected to the counterweights by sets of large wire ropes which operate over parallel-grooved sheaves at the top of the towers. Using powered winch drums, smaller wire ropes raise and lower the movable span.

The lengths of the counterweight ropes in each of the four corners must be matched closely to ensure equalization of tension. Uniform stretch also is an important factor. In vertical lift bridges where counterweight clearances are limited, ropes should have minimal constructional stretch. Counterweight ropes can be pre-stretched to reduce constructional stretch, and measured under tension to ensure closer control of rope lengths. Normally, operating ropes do not require pre-stretching since minor length adjustments can be made at the drums.

A properly damped, suspension system, consisting of cables designed to resist all superimposed static loads, may be covered with a light roofing material.

This invention relates generally to building construction methods and apparatus, and more specifically to an improved cable hold down and bracing system that ties building components together or to the ground, providing stabilization and resistance to uplift or overturning caused by wind, ground movement, earthquakes, or similar forces.

The cable hold down and bracing system of this invention provides a method and apparatus for tying building components together or to the ground, providing stabilization and resistance to uplift or overturning caused by wind, ground movement, earthquakes, or similar forces. The inventive system uses a system of cables or rods strung between the foundation or other base and the top corners of any shear diaphragm. The invention"s cables are kept under tension regardless of the shrinkage of wooden components, providing evenly-distributed compression on the structure"s framing members. As a result, any relative movement caused by vertically applied ("uplift") forces or horizontally applied forces is prevented from the first moment of application, greatly reducing the damage typically attributed to impact loading. This differs from the destructive effect of vertical and horizontal movement on traditional "hold-down" techniques, which cannot adjust to the slack caused by the shrinkage of wood framing, making them highly vulnerable to impact loading stresses. The inventive system may also be used with metal framing instead of wood.

This creates a highly unified, rigid structure capable of resisting uplift and overturning forces. By incorporating specially-designed stranded wire rope or cables, springs, and brackets, the inventive system maintains an evenly-distributed compression amongst structural framing members over the life span of a structure, regardless of dimensional changes caused by wood and/or increased loads that may be imposed due to earthquakes, soil movement, settling, hurricane, typhoons, or similar forces.

FIG. 1 is a cutaway side elevation view of a cable hold down and bracing system of this invention, illustrating the components and assembly of the inventive system.

FIG. 1 is a cutaway side elevation view of a cable hold down and bracing system of this invention, illustrating the components and assembly of the inventive system. The inventive system may be installed in the following manner:

1. An anchor bolt 36 is embedded in the foundation 16 of the structure, extending through a drilled hole 20 in the mud sill 24. This will serve as the lower securement point for the stranded wire rope 46, which ties the foundation to the top of the shear diaphragm(s).

2. An anchor bolt strap component 40, which is a rectangular steel box that has a hole through the single thickness short side 40a and a hole through both thicknesses of the double thickness short side 40b, is secured to the mud sill 24 by a nut 32 threaded on the anchor bolt 36 and tightened against a square flat washer with a round hole 28a (washer 28a prevents distortion of the long legs of the anchor bolt strap 40 and provides a seat against which the nut 32 is tightened). The double thickness short side 40b of the anchor bolt strap component 40 faces the mud sill 24. The anchor bolt strap 40 transmits forces from the anchor bolt 36 to the "dead-end" cinching device 44a and in turn to the stranded wire rope 46.

3. A "dead-end" device or other cable gripping device 44a, comparable in design, function, and strength to that offered by Fargo Manufacturing Company, P.O. Box 2900, Poughkeepsie, N.Y. 12063 is inserted through the hole of a square flat washer 28b (washer 28b prevents distortion of the long legs of the anchor bolt strap 40 and provides a seat for the shoulder of "dead-end" cinching device 44a which grips the stranded wire rope 46). This assembly passes up through the hole of the single thickness short end 40a of the anchor bolt strap 40.

Note: The components described in items #1-3 above simply provide a means of securely affixing the stranded wire rope 46 to the foundation 16. This arrangement is not vital nor important to the function of the invention. For example, the anchor bolt strap 40 can extend into the foundation 16, eliminating the need for the anchor bolt 36, nut 32, and square flat washer 28a. With reduced loads, washer 28b can be eliminated.

4. The stranded wire rope or cable 46 extends through hole 21 in the structure"s subfloor 56 and sole plate 60 (which are separated from mud sill 24 by floor joist 48), and hole 23 in top plates 68 (which are separated from sole plate 60 by vertical framing members 64). The stranded wire rope 46 is passed up through any other intervening horizontal (or perpendicular) framing members to the last in-line horizontal (or perpendicular) framing member 68 of the shear diaphragm.

6. A "dead-end" cinching device 44b is inserted over the stranded wire rope 46 and through the hole in the flat metal plate 72. The "dead-end" device transfers the load from the stranded wire rope 46 to the top plate 68, evenly distributing the forces generated by earthquake, wind, or other external forces and restricting any movement of the top of the shear diaphragm relative to the ground or other attachment points.

7. A further "dead-end" device 44c is inserted in one end of a compression spring 80. This assembly is then placed over the stranded wire rope 46 and on the top of the flat metal plate 72.

8. The stranded wire rope 46 is then pulled taut, and force is applied to the top of the "dead-end" device 44c, causing the "dead-end" device 44c to slide down the stranded wire rope 46 to compress the spring 80 against "dead-end" cinching device 44b, keeping "dead-end" cinching device 44b and the metal load spreading plate 72 in direct contact with the structure"s top plate 68.

The stranded wire rope may be tensioned by pulling the stranded wire rope away from "dead-end" cinching device 44c while simultaneously exerting force against the top of "dead-end" cinching device 44b until the metal spring 80 is properly compressed. This tensioning may be accomplished by any number of existing or specialized tools.

As the wooden framing of a structure shrinks or settles over time, slack in the stranded wire rope 46 is continually eliminated. The metal spring 80, under constant compression, forces the "dead-end" cinching device 44b down on the cable to the point at which metal load spreading plate 72 remains in contact with the structure"s top plate (horizontal framing member) 68. The "dead-end" cinching device 44b has an internal spring that forces the wedges to be repositioned on the stranded wire rope 46.

In the event of an earthquake, sudden earth movement, high winds, hurricane, or similar force that causes uplift, the structure" top plate 68 typically moves away from the foundation. When this occurs, the metal load spreading plate 72 causes the "dead-end" cinching device 44b to grip the stranded wire rope 46, maintaining tension on the stranded wire rope 46 and preventing further movement. This dynamic adaptation resists separation, uplift, and overturning forces.

When properly installed, the inventive system provides continuous connection (rigidity) between the top of a structure"s shear diaphragms and the structure"s foundation. This rigidity prevents damage from uplift, downward forces, or overturning forces typically caused by settling of soil, sudden or gradual earth movements, earthquakes, high winds, and hurricanes.

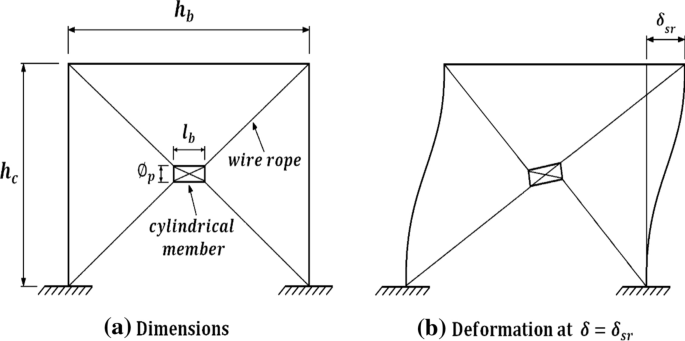

You may want to give a little more thought to using wire rope (cable) as x-bracing in a building, because what you think you might gain in strength per unit area, becomes fairly destructive in terms of the stretch and elongation of the wire rope under lateral loading. Stretch and prestretching relate to the wire rope system itself and really seating the individual wires within the lay-up of each cable. Remember that elongation relates to A (area) and E (modulus of elasticity) and the stress in the element. Thus, the building will move much more (rack) with the cable x-bracing.

As Cvg mentioned wire rope used for structures should be prestretched, and most guyed structures or tension cable structures are designed to, or can, tolerate the elongation and stretch in the cables. That is, the building or roof system or bridge deck deflection and movement are designed for and can be tolerated. Take a look at round bars with turnbuckles, and end fittings which pin or bolt to connection plates on the columns. These can be galvanized for exposed applications. When x-bracing is not protected or hidden in a solid wall, it becomes something of a safety hazard at lower elevations where it can be run into.

nVent products shall be installed and used only as indicated in nVent"s product instruction sheets and training materials. Instruction sheets are available at www.nvent.com and from your nVent customer service representative. Improper installation, misuse, misapplication or other failure to completely follow nVent"s instructions and warnings may cause product malfunction, property damage, serious bodily injury and death and/or void your warranty.

nVent products shall be installed and used only as indicated in nVent"s product instruction sheets and training materials. Instruction sheets are available at www.nvent.com and from your nVent customer service representative. Improper installation, misuse, misapplication or other failure to completely follow nVent"s instructions and warnings may cause product malfunction, property damage, serious bodily injury and death and/or void your warranty.

(3) Diagonal bracing in both directions shall be installed across the entire inside face of double-pole scaffolds used to support loads equivalent to a uniformly distributed load of 50 pounds (22.7 kg) or more per square foot (929 square cm).

(2) Transverse bracing forming an “X” across the width of the scaffold shall be installed at the scaffold ends and at least at every third set of posts horizontally (measured from only one end) and every fourth runner vertically. Bracing shall extend diagonally from the inner or outer posts or runners upward to the next outer or inner posts or runners. Building ties shall be installed at the bearer levels between the transverse bracing and shall conform to the requirements of § 1926.451(c)(1).

(3) On straight run scaffolds, longitudinal bracing across the inner and outer rows of posts shall be installed diagonally in both directions, and shall extend from the base of the end posts upward to the top of the scaffold at approximately a 45 degree angle. On scaffolds whose length is greater than their height, such bracing shall be repeated beginning at least at every fifth post. On scaffolds whose length is less than their height, such bracing shall be installed from the base of the end posts upward to the opposite end posts, and then in alternating directions until reaching the top of the scaffold. Bracing shall be installed as close as possible to the intersection of the bearer and post or runner and post.

(2) Brackets (including those provided with pointed metal projections) shall be anchored in place by nails unless it is impractical to use nails. When nails are not used, brackets shall be secured in place with first-grade manila rope of at least three-fourth inch (1.9 cm) diameter, or equivalent.

(2) Poles shall be secured to the structure by rigid triangular bracing or equivalent at the bottom, top, and other points as necessary. When the pump jack has to pass bracing already installed, an additional brace shall be installed approximately 4 feet (1.2 m) above the brace to be passed, and shall be left in place until the pump jack has been moved and the original brace reinstalled.

(3) Boatswains" chair tackle shall consist of correct size ball bearings or bushed blocks containing safety hooks and properly “eye-spliced” minimum five-eighth (

5/8) inch (1.6 cm) diameter fiber, synthetic, or other rope which will satisfy the criteria (e.g., strength, slip resistance, durability, etc.) of first grade manila rope.

(3) The blocks for fiber or synthetic ropes shall consist of at least one double and one single block. The sheaves of all blocks shall fit the size of the rope used.

(5) Two-point scaffolds shall not be bridged or otherwise connected one to another during raising and lowering operations unless the bridge connections are articulated (attached), and the hoists properly sized.

(1) When two or more scaffolds are used they shall not be bridged one to another unless they are designed to be bridged, the bridge connections are articulated, and the hoists are properly sized.

(3) Scaffolds shall be suspended from metal outriggers, brackets, wire rope slings, hooks, or means that meet equivalent criteria (e.g., strength, durability).

(2) Platforms supported by wire ropes shall have hook-shaped stops on each end of the platforms to prevent them from slipping off the wire ropes. These hooks shall be so placed that they will prevent the platform from falling if one of the horizontal wire ropes breaks.

(ii) Each supporting rope shall be hitched around one end of the bearer and pass under the platform to the other end of the bearer where it is hitched again, leaving sufficient rope at each end for the supporting ties.

(3) Suspension ropes and cables shall be connected to the overhead supporting members by shackles, clips, thimbles, or other means that meet equivalent criteria (e.g., strength, durability).

(1) Scaffolds shall be equipped with additional independent support lines, equal in number to the number of points supported, and of equivalent strength to the suspension ropes, and rigged to support the scaffold in the event the suspension rope(s) fail.

(4) Power systems used to propel mobile scaffolds shall be designed for such use. Forklifts, trucks, similar motor vehicles or add-on motors shall not be used to propel scaffolds unless the scaffold is designed for such propulsion systems.

(iv) When power systems are used, the propelling force is applied directly to the wheels, and does not produce a speed in excess of 1 foot per second (.3 mps); and

(2) Each bracket shall be attached to the securing wire rope (or ropes) by a positive locking device capable of preventing the unintentional detachment of the bracket from the rope, or by equivalent means.

(5) When a wire rope is placed around the structure in order to provide a safe anchorage for personal fall arrest systems used by employees erecting or dismantling scaffolds, the wire rope shall meet the requirements of subpart M of this part, but shall be at least

(6) Each wire rope used for securing brackets in place or as an anchorage for personal fall arrest systems shall be protected from damage due to contact with edges, corners, protrusions, or other discontinuities of the supporting structure or scaffold components.

(7) Tensioning of each wire rope used for securing brackets in place or as an anchorage for personal fall arrest systems shall be by means of a turnbuckle at least 1 inch (2.54 cm) in diameter, or by equivalent means.

(8) Each turnbuckle shall be connected to the other end of its rope by use of an eyesplice thimble of a size appropriate to the turnbuckle to which it is attached.

8613371530291

8613371530291