wire rope cable clamp installation supplier

Wire rope clips, also called wire rope clamps, consist of a U-shaped bolt, a metal saddle piece, and two nuts. They are used in wire rope loop assemblies and are ideal for field installations. We offer several models to meet your specific needs.

Wire rope clip is otherwise known as a wire rope clamp, wire cable clamp, wire clamp, wire clip, U-bolt, etc. It is widely used for making eye-loop connections or join two wire rope cable ends together. The traditional styles of wire rope clips usually have three components: a U-shaped bolt, a forged or cast iron saddle, and two nuts.

The wire rope clips are available in a range of sizes and finishes, while you can easily find the difference from the appearance, traditional wire clips with u bolt, saddle and nuts, fist grip, stamped cable clamp.

Cast and malleable wire rope clips can only be used under light duty loads applications with relatively light loads, such as handrails, fencing, guard rails, etc.

While the drop forged wire rope clip variety is recommended for important, critical or sustaining overhead loads, such as guy lines, support lines, scaffolding, etc. The drop forged wire rope clips can be used in critical suspending, guying, and tie-down applications for the die forging process make them strong and more durable and the heating and hammering steps make their structure to be consistent and conform to the shape of the forged item.

Simplex and duplex cable clamps are also known as single stamped wire clip and double stamped cable clip are composed of stamping plate, saddle, and bolts, feature an aesthetic design, used for outdoor light duty applications.

Wire rope clips are available in a variety of materials and finishes but basically three types of materials, carbon steel, cast, malleable iron, and stainless steel.

Carbon steel wire rope cable clamps are galvanized, or hot dipped galvanized, the galvanised metal wire clamp has an added zinc layer to prevent rusting and protect against scratching and the addition of carbon corresponds with an increase in the hardness and strength of wire rope cable clamps. G, but stainless steel wire rope clamps are the best choice for corrosion-resistant applications that can be used for saltwater environments.

Commonly wire rope clamp installation is very simple, there’s a well-known saying can help you remember how to attach wire rope clips, that reads “never saddle a dead horse.” Just follow the recommendation ways:

Keep three or more wire rope clips attached at the end of the wire rope dead end, space between each wire rope clip should be at least 6 times the wire rope diameter.

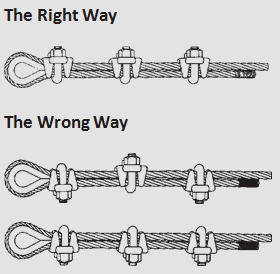

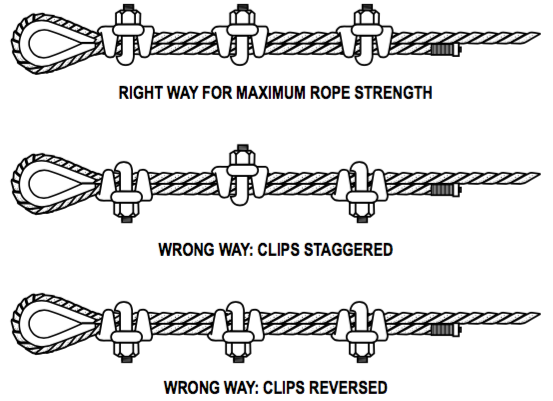

You can see the correct and incorrect ways of installation from the following pictures and find how many wire rope clips to use at one wire rope loop.

The saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—Remember the well-known saying: “Never saddle a dead horse.” Use at least two or three wire rope clips to secure the ends properly to the length of the rope, and tighten nuts evenly one by one until reaching the recommended torque.

If you have any wire rope clips questions, you can contact us by email at info@hilifting.com. We will be glad to share with you more useful information.

U-bolt Clips.There is only one correct method for attaching U-bolt clips to wire rope ends, as shown in TheRightWayimage below. The base of the clip bears on the live end of the rope; the “U” of the bolt bears on the dead end.

Compare this with the incorrect methods. Five of the six clips shown are incorrectly attached—only the center clip in the top view is correct. When the “U” of the clip bears on the live end of the rope, there is a possibility of the rope being cut or kinked, with subsequent failure.

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. Whether for use on cranes or for other lifting applications, it’s important to have a solid understanding of the rigging components that are being used to attach to and lift a load.

As a rigger or end-user of wire rope, it’s necessary to understand the types of wire rope end termination, or treatments that can be used at the ends of a length of wire rope—one of the most common being wire rope clips.

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80-90% efficiency of the rope breaking strength, depending on the diameter of the wire rope.

As a general guideline, they are NOT to be used for making slings, as ASME B30.9 Slingsstandard states: “Mechanical wire rope terminations requiring periodic adjustment to maintain efficiency shall not be used to fabricate slings.”

There are two main types of wire rope clips—U-Bolt and double saddle clips. U-Bolt wire rope clips are the most common and may be made of forged or malleable metal.

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

Unfortunately, it is not uncommon to see a wire rope clip applied incorrectly. Some of the most common mistakes include:Not torquing to the manufacturer’s expectations

Wire rope clips require the use of a torque wrench in order to function properly. Torquing the nuts on the clips too much or too little can cause the clip to fail. If the clip is over-torqued, it could damage the threads of the wire rope. If the clip is under-torqued, the holding power of the clip is diminished and the wire rope could slip through.

There are a minimum number of clips required for use related to the wire rope diameter. Using less than the number of specified clips could result in decreased efficiency and possible failure.

Depending on the number and size of the wire rope clips, there is a proportional amount of space required between the placement on each clip on the rope.

There are two sides of a U-Bolt style wire rope clip: the saddle and the U-Bolt. When securing a wire rope eye, it is important to place the clip on the correct end of the rope.

A saying commonly used in rigging to help remember this is: “Never saddle a dead horse!” In other words, never put the saddle on the dead end of the rope.

The turnback is the portion of the wire rope eye that runs from the end of the bearing eye to the live end. Having less than the suggested amount of turnback will decrease the efficiency of the wire rope eye and could lead to failure.

It is important to be sure you are using the correct wire rope clip—forged or malleable wire rope clips—for the application. Malleable clips can only be used for non-critical uses, such as tension rope to form a perimeter around a parking lot.

If the use is critical—an application where, if there is a failure, you have potential injury or loss of life or damage to property—a forged clip must be used.

The clip size used—whether it be 1/8”, 3”, or otherwise—must match the diameter size of the wire rope. If it doesn’t, the wire rope could slip out of the clip.

After installing clips, it is necessary to regularly cycle the rope and retighten the clips. Monitoring the torque on the nuts is important, as they will loosen over repeated use.

Basic steps for installing a wire rope clip include:First, wrap the wire rope around the thimble or to form the eye, and turn back the correct amount of rope—as specified by the manufacturer.

Apply the first wire rope clip at the end of the dead end, with one base width of space. Use a torque wrench to tighten the nuts on the wire rope clip.

When applying the second clip (if required), place it as close to the eye loop or thimble as possible. Again, be sure to properly tighten the nuts of the clip with a torque wrench.

Wire rope clips are a common and necessary piece of rigging hardware when it comes to using wire rope and forming end terminations. They are used to form a wire rope eye or to connect two cables together. It’s important to understand how to correctly install a wire rope clip, as incorrect installation leads to decreased efficiency in the wire rope assembly.

While these clips are not designed to be used in an overhead lifting situation (swage sleeves should be used instead), wire rope clips are heavy-duty wire rope clips that used for sustaining overhead loads. Examples include guy lines, support lines, scaffolding, etc.

Install the first clip at the dead end side of the rope. The "U" side of the clip must always cover the dead end of the rope, and the "saddle" side of the clip on the live end of the rope. Place the nuts of the clip and tighten them using a torque wrench.

Place more clips on the rope if you need more than two on the wire rope. Be sure to space them evenly between the end clips. Finally, tighten the end clips and apply tension to reach the recommended torque for the wire rope.

With sincerity and hard work of our professionals, we have carved a niche for ourselves in this domain by manufacturing highly durable gamut of Wire Rope Clamp.

1.Turn back specified amount of rope from thimble or loop. Apply first clip one base width from dead end of rope. Apply U-Bolt over dead end of wire rope with live end resting in saddle. Tighten nuts evenly, alternating from one nut to the other until reaching the recommended torque.

3. When three or more clips are required, space additional clips equally between first two – take up rope recommended slack – tighten nuts on each U-Bolt evenly, alternating from one nut to the other until reaching recommended torque.

In accordance with good rigging and maintenance practices, the wire rope and termination should be inspected periodically for wear, abuse and general adequacy.

A termination made in accordance with the above instructions and using the number of dips shown, has an approximate 80% efficiency rating. This rating is based upon the nominal strength of wire rope. If a pulley is used in place of a thimble for turning back the rope, add one additional clip.

The number of clips shown is based upon using right regular or lang lay wire rope, 6×19 classification or 6×37 classification, fiber core or IWRC, IPS or EIP. If Seale construction or similar large outer wire type construction in the 6×19 classification, fiber core, IPS, sizes 11/2? and smaller; and right regular lay wire rope, 19×7 classification, IPS or EIP, sizes 1 3/4? and smaller.

If a greater number of clips are used than shown in the table, the amount of rope turnback should be increased proportionately. ABOVE BASED ON USE OF PROPER SIZE U-BOLT CLIPS ON NEW ROPE.

When it comes to lifting heavy objects, many people prefer to use wire rope. There is a good reason for this too. A wire rope consists of many steel wires twisted together around a core. This provides a strong, flexible rope that can withstand bending. We offer wire rope in a range of configurations for many applications.

We know that wire rope isn’t the only thing your company needs when you are moving loads. Murphy Industrial Products, Inc. also offers accessories that you can use with your wire rope, including hooks, swivels, shackles, and cable cutters. We have designed these products to help you get the job done as efficiently as possible. If you are looking for a cable supplier, then choose our company. Our wire rope offers benefits such as:

The Sabre C40-056-003 5/16 in wire rope clip meets Federal Specifications FF-C-450, Type 1, Class 1. Wire rope clips are used with guy strand or wire rope. The Sabre wire rope clips are forged and galvanized in accordance with ASTM A153. Designed to be used with 5/16 in EHS guy wire.

US based company with manufacturing in US and China. ISO 9001:9002, ISO 9001:2000 & ISO/TS 16949 certified manufacturer & distributor of clips including automotive clips, stainless steel clips & wire rope clips. Products are available in different sizes. Capabilities include aluminum die casting, investment casting, iron sand casting, steel forging, sheet metal stamping and forming, plastic injection molding and aluminum extrusion. Services include CAD model development, stress analysis, mechanical & chemical lab tests & prototyping service. Local US customer service handles project from beginning to end.

8613371530291

8613371530291