wire rope cable fittings manufacturer

The majority of wire rope fittings are elements of a complete wire rope assembly designed for a specific task such as motion control or mechanical automation. Wire rope fittings are heavily implicated in a number of industrial processes and equipment such as mining equipment, braking, aircraft cables, levelers, hood latch releases, and more.

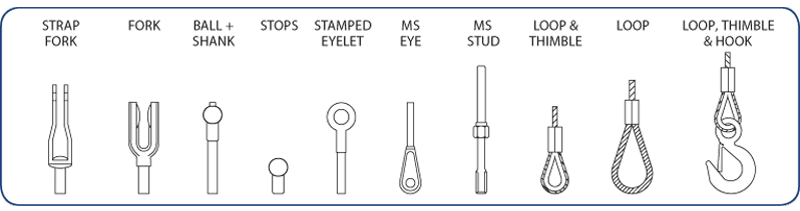

The versatility of fittings renders them essential to industries such as automotive, agriculture, construction, marine, aerospace, transportation, and virtually all applications where wire rope is used. Specific examples include clamps, clips, sleeves, links, hooks, forks, eyes, studs, and pins.

When used for heavy duty lifting, pulling, or other activities, fittings are often permanently attached or affixed to a given cable for added durability and security though change toolkits are sometimes available allowing for interchangeable fixtures. Wire rope manufacturers often provide a range of wire fitting options as well in order to accommodate the many different uses for the cables.

Fittings function by creating an endpoint to which other apparatus may more easily be affixed or which simply preserves the integrity of a given cable by preventing fraying, a common problem for unfitted stranded wire ropes. As aforementioned, the specifics of a fitting vary greatly as does their construction, shape, and size, all of which should be carefully considered in regards to their intended use.

Swaging, metal stamping, and die cutting are commonly used to create the metal forms needed for wire rope assemblies. Swaging involves compressing and deforming materials to achieve a permanent connection or bonding. While stamping and cutting are used to create additional hardware, swaging is performed when no additional hardware is desired, but instead the fitting requires the rope to be folded back onto itself to create a loop or eye.

Potted or poured sockets use both permanent and affixed elements as the rope end is inserted into a conical cavity that is then filled with molten zinc or an epoxy resin compound.

The materials used to create the fittings themselves vary with application, but often mirror that of the wire rope or cable. Copper, brass, bronze, steel, titanium, stainless steel, and other durable metals are among the most popular.

It is important to consider the integrity of the wire cable itself when selecting and applying a wire fitting as it may alter the strength, length, and dimensions of that particular section of rope.

Fittings known as sleeves and thimbles are often used in complete wire rope assemblies to protect the stranded wire from wear, tear, crimping, bending, pinching, or other damage.

Manufacturer of standard and custom wire rope fittings. Types include clevis, eye end, oval eye, drum socket, coupling, stud and antenna fittings. Products available include open body forged clevis/socket, open body double socket forged, closed body machined clevis/socket and closed body machined double socket/clevis turnbuckles, hooks and eye swivels, insulators and replacement sleeves. Capabilities include turning, milling, drilling, tapping, metal fabrication, welding and assembly. Serves the maritime, airport, amusement park, sports stadium, construction, architectural, utility, rigging, military and other industries. Made in the USA.

We offer a full line of wire rope and aircraft cable end fittings designed for installation by crimping, clamping, speltering, swageless connectors, or our specialty — machine swaging. Most fitting types are available in a variety of sizes and materials to meet the needs of nearly any application. To complete your assembly, you may also be interested in our wire rope hardware.

The majority of wire rope fittings are elements of a complete wire rope assembly designed for a specific task such as motion control or mechanical automation. Wire rope fittings are heavily implicated in a number of industrial processes and equipment such as mining equipment, braking, aircraft cables, levelers, hood latch releases and more. The versatility of fittings renders them essential to industries such as automotive, agriculture, construction, marine, aerospace, transportation and virtually all applications where wire rope is used. Specific examples include clamps, clips, sleeves, links, hooks, forks, eyes, studs and pins. When used for heavy duty lifting, pulling or other activities, fittings are often permanently attached or affixed to a given cable for added durability and security though change tool kits are sometimes available allowing for interchangeable fixtures. Wire rope manufacturers often provide a range wire fitting options as well in order to accommodate the many different uses for the cables.

Continental Cable employs 65 people specializing in the manufacture of custom mechanical wire rope cable assemblies. Other product lines include stainless steel and galvanized aircraft cable, a complete line of cable related hardware and tools and plastic coated cable.

We offer competitive salary and benefits along with flexible scheduling, employee outings and holiday parties too. We pride ourselves on the fact that our employees enjoy working at Continental Cable. We believe a work environment should be enjoyable and we invest in good HR practices to ensure the right fit from management to our operators.

At Carl Stahl Sava Industries, manufacturing a comprehensive family of cable, stainless steel wire rope fittings and tools only explain a portion of what makes us so special as a cable assembly manufacturer. In addition to possessing an ISO 9001:2015 certification, Sava is also FDA and ITAR registered, as well as RoHS and REACH certified. Our wire rope manufacturing process leverages almost 50 years of engineering and manufacturing expertise that customers around the world have grown to depend upon every single day. Additionally, Sava’s sales professionals boast over 100 years of combined technical experience helping organizations just like yours meet the most complex and sophisticated application requirements.

Tap into our deep understanding of cable construction and application dynamics. We design, manufacture and test custom assemblies for highly complex application requirements.

A cable supplier for clients spanning the globe, everyday Sava meets the diverse needs of its customers with an extensive selection of product categories, ranging from precision miniature cables to large pulleys.

The functionality and working life of your applications depend on the quality of your cable fittings, whether you need custom aircraft cable fittings and aircraft cable connectors for rigging, aircraft cable thimbles, crimpable fittings, medical cable fittings or fittings for another industry. All of Sava"s miniature cable fittings are held to our unwavering commitment to quality assurance. That’s because we don’t simply possess expertise in custom cable assemblies, but also the design of the cable eyelet fittings, and the ball stops they include.

During the manufacturing process, each production run undergoes careful scrutiny to ensure our wire rope hardware and fittings demonstrate the precision, break strength, and reliability your applications require.

Additionally, we tailor our miniature wire rope fittings for industry-specific needs, a capability that has made us the global cable manufacturer we are today. Thanks to our in-house engineering expertise, Sava is easily able to design customized solutions, such as cable eyelet crimping and other wire crimping services, fittings for large-diameter cables in mechanical control cables, fittings made of specially requested materials, flexible wire rope fittings, cable pulley fittings, or fittings that meet other unique application requirements.

Turn to Sava for your fittings needs and ensure you achieve the performance demands of your products. Request a quote and get additional guidance from our fittings experts now.

Tyler Madison has earned its position as a leading custom cable manufacturer of wire rope assemblies through its commitment to quality and customer service. The company always carries an extensive inventory of stock components to meet their customers’ simpler needs. But with an extensive background in wire rope design, the company welcomes the opportunity to design, engineer, and manufacture wire rope solutions to perfectly match its customers’ more specific applications.

Industrial Wire Rope Fittings, SS Wire Rope Fittings, Wire Rope Cable End Fittings, Galvanised Wire Rope Fittings, Wire Rope Clips Provider & Exporter

Multinox Inc is the leading Manufacturer and Supplier of. You can use our Industrial Wire Rope Fittings for safely rigging your equipment to a support. The Wire rope fittings processed by us is used extensively in the marine, architectural, yacht ringing and other structural applications. The Stainless Steel Wire Rope manufactured by us is our prime best-sellers throughout the global market. The superior grade raw materials used in the manufacturing process by us result in the exceptional holding strength and lifting strength of wire and cable ropes. OurSS Wire Rope Fittingsare portable and lightweight for optimal usage by our customers worldwide.

We manufacture varieties of Wire Rope fittings that are pull-tested and proof-tested. There are numerous options available in the size, shape and further customizations of the products belonging to our catalog of Wire Rope Fittings. The Wire Rope Cable End Fittings provides nominal breakage strength and is best-suited for the aircraft cable fittings. However, ourGalvanised Wire Rope Fittingscan be crimped into many different shapes, like round, hex, square etc.

These Wire Rope Clips help in securing wire rope ends on turning back from a loop. They have a wide range of applications in the architectural and marine applications. We manufacture Wire Rope Fittings with extra threading and ultimately finished based on the requirements of our customers. The highly economical pricing of our products and affordability draws our customers towards us daily. TheSingle Wire Rope Fittingmanufactured by us is rightfully exercised in lifting lightweight air packed goods or equipment.

Engineered and manufactured at our facility, designed to meet all your fitting requirements. Assembly Specialty collaborates with you to design solutions for your most challenging applications and maintains an inventory of standard fittings for immediate delivery.

PersonalWe are on hand to personally guide you through the entire process, we translate the jargon, we recommend what’s best, and we are always here in person. No nonsense, just straight talking people who always exceed expectations through our extensive wire rope knowledge and superior service.

Reliability, experience and exceptional customer service for more than 50 years has made Sandin Manufacturing the leading supplier to the wire rope and cable industry in USA and Canada. With one of the most diverse inventories of bare galvanized and stainless steel wire rope, as well as the ability to extrude numerous thermo-plastic coatings, our capabilities are second to none.

Sandin Manufacturing specializes in custom-designed mechanical cable assemblies. Utilizing our extensive inventory of wire rope fittings in addition to our CNC machining capabilities, we have the ability to fabricate your custom cable solution quickly.

Consider Sandin Manufacturing for Galvanized and Stainless Steel cable, Mechanical Cable Assemblies, Can Conveyor Rope, Coiled Cable Assemblies, Cable Railings, Exercise Cable, and Marine Rigging.

Stock up on every variety of steel wire rods at the Alibaba metalworking store. Our listings feature wholesale steel rods from a network of dependable Chinese manufacturing partners. If you need to source steel rods for construction projects, you"ll find products that are robust and durable. And if you need welding rods, they are easy to find via our search engine. Track down the stainless steel wire rope fittings you need at affordable prices at Alibaba.com.

What can you do with the steel wire rods available from Alibaba"s wholesale store? One common use for steel rods is in the welding sector. Steel works well as a welding rod material thanks to its high ductility, meaning that welds are relatively strong and long-lasting. Choose a low carbon rod and you"ll be all set for successful welds in industrial settings and workshops alike. However, steel wire also has applications beyond welding. You can use it as wiring in electronic circuits and power distribution systems and it works especially well in high temperature settings as armored cabling. Find the ideal stainless steel wire rope fittings for every industrial use at Alibaba.com.

Steel wire rods also have applications in everyday life. For example, you can use coils of steel wire to construct fences and barriers both inside and outside homes. It"s a common material in agricultural businesses thanks to its toughness and resistance to oxidation. Use it to create reinforcement cages, enclosures for equipment, or add it to concrete to add extra strength where it really matters. From welding to concrete reinforcement, stainless steel wire rope fittings will always find a use. And whether you need small batches or huge bulk orders, our metallic materials catalog is the ideal place to look.

While some use these two terms interchangeably, technically wire rope refers to a diameter greater than 3/8”. Cable rope - also called aircraft cable - applies to all smaller variations.

Consequently, aircraft cable is only used for lighter-duty purposes, such as winch lines, fences, and railings, while wire rope can be using for lifting, towing, hoisting, etc. Both are ideal for outdoor environments because the strength and length remain constant regardless of whether they are wet or dry.

If you are looking for an option specifically designed for lifting, check out our wire rope slings. They come in a number of configurations - choices include leg count, end hardware, and more.

Generally composed of wires, strands, and a core shaped in a spiral pattern, wire rope is incredibly durable. Steel wires are aligned in a precise helix geometric pattern to form a strand in a process known as "stranding." A "closing" comes next, where the strands are laid around the core to form a wire rope.

The greater the diameter, the greater the break strength. Our selection of 1/8" stainless steel cable has a break strength of less than 2,000 lbs., while our 2-1/2" wire rope has a break strength of more than 600,000 lbs.!

Right hand and left hand designations indicate which way the strands wrap around the core of the steel rope, while regular lay and Lang lay designations specify which way the wires that make up the strand are formed in the helix pattern.

Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands wrapped around the wire rope core.

Our wire rope lay is right hand regular lay, with strands wrapped around the core to the right, and the wires making up the strand turned and rotated to the left.

Independent wire rope cores (IWRC) are made from steel, offer more support to the outer strands, and have a higher resistance to crushing. IWRC also offer more resistance to heat and increase the strength of the rope.

This refers to how many strands make up the rope and how many wires make up one strand. For instance, a 6x26 wire rope has 6 strands around a core with 26 wires making up each strand.

All wires consist of layer(s) arranged in a specific pattern around a center. Pattern designation is affected by the size of the wires, the number of layers, and the wires per layer. Wires can utilize either a single pattern style or a combination of them, known as a combined pattern:

Warrington - Two layers of wires. The outer layer has two diameters of wire (alternating between large and small), while the inner layer has one diameter.

Although wire rope is extremely strong, it can become damaged with improper use, making it unsafe to use. It"s important to have regular inspections for breaks, corrosion, overuse wear, and kinks.

Our rigging supplies category includes hardware and accessories for cranes, dredging, excavating, hoists & winches, logging, and marine uses. If you"re unsure what you need or have questions, call for help from our product specialists with expertise in wire rope/cable rigging supplies.

Loos & Co., Inc. has long been a manufacturer of high-quality wire rope fittings and accessories for a variety of industries. Our most successful wire rope products are our wire rope terminals. Our domestically manufactured wire rope terminals come in many milspec (MS) and commercial hardware styles for a range of applications. And are Made in the USA at our Naples, Florida facility. By buying our Made in the USA terminals, you are ensured a high-quality product from our craftsmen, with each purchase directly supporting the American workforce and the America manufacturing sector. If you would like to speak with one of our experts of wire rope terminals, or learn more about our other domestically manufactured products, please contact us via one of the methods below, and we will reach out to you directly.

Aero Assemblies has over 45 years of experience fabricating wire rope cable assemblies for the aerospace, industrial and commercial industries. From simple to intricate applications, we partner with our customers to fabricate their assemblies to their required specifications using cost effective solutions.

Our team will work with you from your initial design through the prototyping process until the final approval for production is achieved. We can print the unique components required for your small production runs or for rapid proto typing.Wire Rope Options

Additive Manufacturing services are available in many materials from plastic to stainless steel. This process allows Aero to print the unique components required for prototyping, repair cable assemblies or small production runs.

We offer solutions for your Industry. No application is the same and each may require some modification. The majority of the cable assemblies we manufacture for our clients are made to their print with customized fittings and components. Pre-production samples are available during the procurement stage.

There is no such thing as a standard lanyard or safety cable. Each application has different requirements such as a loop size, the length or a release point. We offer a variety of end fittings and components to meet your requirements.

NextControl cables are used in any application where mechanical actuation or mechanical force needs to be used to actuate something between 2 fixed points. There are 4 main components used in the manufacturing of these assemblies. Conduit/Casing, Conduit Fittings, Wire/Wire Rope and Wire Rope End Fittings.

At U.S. Rigging, we offer a wide selection of wire rope and wire rope fittings. Whether you"re in need of hand swagers, wire rope cutters, or wire rope and custom cable assemblies, we offer the best rigging hardware in our DuraBrite™ brand.

8613371530291

8613371530291