wire rope crane hoist factory

Our overhead crane hoist line complies with all of the North American electrical and mechanical regulations and standards for lifting equipment. Our hoists are being actively used for a broad range of applications including but not limited to:

Munck Cranes is committed to understanding the requirements and challenges of our customers, building insight into your hoisting and material handling requirements so that we can guide these solutions with the proper hoist configuration, capcity, rating, and duty cycle. Our technical sales engineers take pride in this process so that our customers receive the best electric trolley hoist solution that will exceed your expectations now and for years to come.

Below are some of our standard bridge & gantry hoist configurations. If you think that your application may require a low headroom hoist, our team of professionals sales engineers are eager to understand and design a solution for you.

Munck Cranes uses the double girder electric hoist trolley on our standard two-rail overhead cranes as they allow for controlled hook travel. The capacity of this standard trolley hoist line ranges from 5-100 metric tons. For applications that require a capacity over 108 tons; a custom engineered built up hoist will be designed to meet the needs of your lifting application.

The common foot mounted hoist has a basic mounting arrangement so that it can easily be affixed to an existing trolley, a raised platform, or suspended from above. With 5 different hoist drum configurations and multiple reeving configurations, the Munck foot mounted hoist offers a vast array of options for all of your height of lift requirements.

All of our monobox cranes are equipped with the monorail hoist. This series hoist can achieve a remarkable HOL (height of lift) as they have a low headroom design. The image above does not show the electrical panel however the hoist panels can be easily mounted to the trolley in a safe location that is easy to access for routine service work and inspections.

If you are looking for a hoist that has an extremely high height of lift then a twin hoist trolley may be just what you need. This style hoist line can enable true vertical lift and it can also be programmed for individual lifting or dual synchronization lifting. Our hoists are custom engineered to meet all of your material handling and lifting requirements.

Whenever you are putting a hoist on an electric travelling bridge crane 2-ton or above, you should apply a wire rope hoist unless some circumstance specifically dictates the use of chain.

Whenever you have any application requiring an electric hoist, with capacity of 5-ton or above, use wire rope unless some circumstance dictates chain. One circumstance that might dictate chain would be a requirement for hook mounting. This is not normally available for wire rope.

Use one with a rope guide if the hook block is ever allowed to rest on the floor or some other object causing slack in the cable that might cause the wire rope to jump out of the drum grooves.

Electrolift is the oldest manufacturer of wire rope worm driven hoists in the world, highly innovative and a step ahead of the competition since the company was founded in 1932. Engineered and manufactured to be tough and reliable, today the product line has grown to Single Hook, Twin Hook, Base Mounted and Specialized Hoists that meet every type of application requirement. Customers who demand the very best receive a manufacturing integrity that begins with tried and true reliable designs and ends with installations that operate for decades with minimal maintenance, virtually eliminating downtime.

When getting into a higher capacity, electric wire rope hoists are your best bet. They are ideal for very fast lifting speeds, true vertical lift applications, and high cycle (H5 Duty rating) applications. Tri-State Overhead Crane offers 10 Ton, 20 Ton, 30 Ton, and 50 Ton Electric Wire Rope Hoists available from the top wire rope hoist manufacturers.

R&M Materials Handling has over 85 years of experience in the overhead manual, electric chain hoists and wire rope hoists history. Headquartered in Springfield, OH, R&M has parts and service centers located throughout North America, Central America, and South America.

Tri-State Overhead Crane is a highly trusted Yale wire rope hoist distributor and Yale hoist parts. Yale is well-known for their market-leading technology that goes into their YK, Cable King and LodeKing as well as their high safety and performance ratings.

Products under the Shaw-Box brand feature capacities ranging from a 1/2 ton wire rope hoist to a 100 ton capacity trolley/hoist. Whether the job calls for electric or air-power, indoor or outdoor duty, general or severe industrial service, a Shaw-Box hoist meets the needs of the workforce.

Harrington Hoists is recognized as an innovator and market leader in the hoist and crane industry. Harrington Hoists manufactures revolutionary manual, electric, and air chain hoists, wire rope hoists and crane products. TSOC carries a full line of Harrington Hoist world class products including the NER, NERP and SNER electric chain hoists with capacities of 1/8 Ton to 5 Ton.

Demag offers a complete line of cranes and handling technology, focusing on the benefits to their customers and providing high levels of safety, reliability and outstanding performance. Demag offers a wide range of electric hoists that include many standard features that are considered optional from other manufacturers.

Detroit hoist has been designing and manufacturing wire rope hoists since 1905. Based in Michigan, Detroit Hoist strives to be the best while delivering products on time and at competitive prices. In-house product research and development enables the company to retain the flexibility of applying standardized designs, simplicity and economies of time-proven serial components for more value and increased reliability.

STAHL Crane Systems" wire rope hoists range in capacity from 1,100 pounds to 175 tons. STAHL wire rope hoists have a compact, sturdy construction which is extremely low-maintenance. Their reliability, power and long service life are above average. The particularly smooth, precise starting and braking characteristics are common to all.

TSOC stocks several brands of electric chain hoists from CM, Coffing, Budgit, Yale, Harrington, and Demag. Typically ranging in capacity from 1/4 Ton to 5 Tons, these electric powered hoists are ideal for manufacturing and industrial facilities.

Hand chain hoists and lever hoists are the two styles of manual chain hoists that TSOC offers. These are perfect for low duty cycle applications. Another feature that makes these a good solutions is their ability to be portable. Capacities typically range from 1/8 Ton to 5 Ton, but we do offer some heavier capacities up to 25 Ton.

True vertical lift is the lack of any lateral hook drift as the hook moves vertically throughout the full range of motion. Single reeved wire rope hoists cause slight lateral movement of the hook, generally around a 1/4 of an inch lateral movement, for every 12 inches of vertical movement. For most jobs, this lateral movement will not cause a problem, but for some applications this movement can be damaging. If true vertical lift is required, a double reeved configuration will be needed. You will often pay a premium for true vertical lift at lower capacities, so it is important to understand if you really need this feature. By nature of their design, chain hoists provide true vertical lift by the nature of their design. Chain hoists for capacities up to 20 tons may be a more economical choice.

TSOC distributes wire rope hoists; serving clients from coast to coast, Canada, Mexico and especially focused in Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

Whether you"re looking for a wire rope hoist with state-of-the-art or standard functionality, we offer wide solutions to meet our customers" needs. Our Demag wire rope hoists include excellent safety features, high handling rates, and cost-effective operation up to 100 tonnes.

As basic hoist units for integration into plant and machinery, or as lifting solutions with electronic controls that are optimized forcrane applications, with our wide range of wire rope hoists we offer the optimum solution to meet our customers’ specific requirements for efficiently lifting loads weighing up to 100 tonnes.

Our DMR modular wire rope hoists offer groundbreaking flexibility for diverse applications. With our DMR wire rope hoists, we can produce either a C-design or co-axial design. Some of the features include:

Our DH hoist units are utilized for a range of applications, including as traveling hoists on cranes or monorails and stationary solutions. These units provide reliable operation even in harsh environments with high ambient temperatures, high dust levels, and aggressive atmospheres. Additional features include:

Engineered Material Handling (EMH) sets the standard for wire rope hoists. EMH manufactures its own single and double girder wire rope hoists for standard industrial applications, with standard capacities of from 2 to 50 tons. The EMH wire rope hoist provides a price to performance ratio that compares favorably with the best the industry has to offer.

Standard features include two lifting and trolley speeds, two upper and one lower precision limit switches, overload limit, heavy duty wear resistant rope guide, DC rectified brakes, and lifetime lubricated bearings and gear reducers.

Hoists are one of the most essential components within an overhead crane system. After all, hoists are the devices that perform the lifting and lowering of a load. Allied Crane offers a variety of pneumatic, electric, and manual hoists to best suit the needs of your application. Whether you’re looking for a high-performance wire rope hoist or a standard chain hoist, we can assist you with finding the right hoist for every job.

Detroit Hoist remains committed to providing our clients top quality, state-of-the-art wire rope hoists, and crane components. Customer satisfaction is paramount for our continued success. We strive to be the best at what we do and to deliver what we promise on time and at competitive prices.

At R&M Materials Handling, we prioritize the safety of our customers and take pride in the reliability and performance of our advanced lifting technology. With over 90 years of experience in the overhead crane, electric chain hoist and wire rope hoist industries, we have the experience to help you improve the flow and productivity of your operations.

The Street ZX wire rope hoist was first developed in the late 1990s and very quickly became the best selling hoist product that Street has ever produced, firmly establishing Street as a Global volume hoist manufacturer.

The ZX hoist very quickly developed a strong reputation for reliability and endurance with an unparalleled record in a vast range of applications and environments worldwide.

Every function of the latest generation ZX hoist has been reviewed and a whole series of innovations applied to provide new levels of user-friendliness and performance. The result is an easy to operate, high endurance hoist incorporating state-of-the-art technology. Our ZX range has recently been updated with higher lifting capacities for the

The ZX wire rope hoist has been designed to fulfill expectations and improve our customer’s productivity. With exceptionally safe and efficient lifting, the new ZX hoist sets the benchmarks in the crane industry and provides a series of unique benefits for the user.

The ZX hoist epitomises intelligent design for easy load handling and we think you will agree represents unbeatable value for money and a serious investment.

Now one of the world’s largest manufacturers of overhead cranes(or hoists and crane components, Street have a vast range of lifting solutions to suit all industrial applications. Products include

With 75 years of crane building experience and a strong focus on continuous product development, Street Crane is a name synonymous with quality and innovation. Street"s success is a result of a long standing strategy to invest our profits in

Model CD1/MD1 wire rope electric hoist is a small-sized lifting equipment, which can be mounted on single beam crane, overhead crane, gantry crane and jib crane. With slight modification, CD1/MD1 wire rope electric hoist can be also used as winch.

CD1/MD1 wire rope electric hoist is widely used in factories, mines, harbors, warehouses, cargo storage areas and shops. Model CD1 hoist has only one normal speed, which can satisfy normal application. Model MD1 hoist has 2 working speeds: normal and low speed. At low speed, it can do precise loading and unloading, mounding of sand box, maintenance of machine tools.

3. Installation and commissioning of the limiter (the limit is adjusted upward, the top of the hook and the drum shell are kept about 200mm space, when the limit is lower, the remaining total safety wire rope on the drum is kept at least 2 laps);

CD MD wire rope electric hoist is a small lifting equipment that can be installed on a single girder bridge crane. Gantry cranes can meet normal applications only as a normal speed. It is widely used in factories, mines, ports, cargo storage areas and shops, and is essential for improving work efficiency and improving working conditions.

The hoisting motor uses a cone motor with a large starting torque to brake the induction motor. No additional lightning arrester is needed. The load continuity factor of the motor is 25%; the motor uses B and F insulation, and the protection level is isIP44 / IP54 .

As the name suggests Electric Wire Rope Hoist utilizes Electricity to lift heavy workloads which are beyond human capacity. The Phenomenon lift loads by wrapping a cable around a grooved drum and then the load is attached to a hoist by the means of a lifting hook.

Electric Wire Rope Hoist is an invaluable asset for lifting and lowering a high amount of weight and reducing the efforts no matter what its unit is it can payback many times the investment made on it due to its efficiency for lifting purposes.

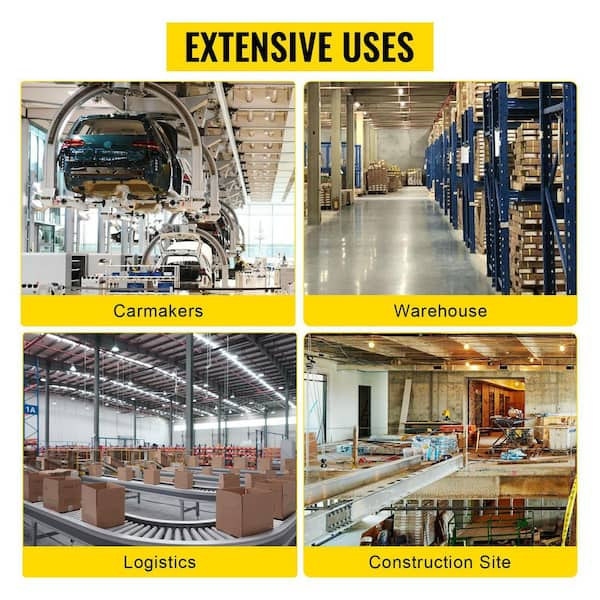

Electric Wire Rope Hoists are commonly seen at manufacturing units, large-scale factories, and construction sites. It gives workers a helping hand and makes their work hassle-free.

Electric Wire Rope Hoists shortens the Amount of work time for a certain period which takes hours and days to complete. They are simple and easy to use solution which will increase the productivity in your operation.

Electric Wire rope hoist is a fast speed lifting equipment in comparison to Electric Chain hoist. The lifting mechanism of the Electric Wire rope hoist is driven by a motor to complete the lifting action of the wire rope drum.

Electric Wire rope hoists use wire to lift which is wrapped around a grooved drum they move load slightly laterally and not precise or accurate in lifting. Although the lateral movement is negligible.

These hoists are made to carry heavy objects in a variety of conditions like heat, furnaces, and over the burners. These hoists can lift ranging from pounds to tones. But at the same time, it is required to maintain proper safety measures to ensure the safety of the Hoist, load, and the operator.

Electric Wire Rope Hoists are made using strands and wires which assures the spreading of pressure, stress, and weight on the overall length rather than being distributed on a single strand alone which decreases the chances of breaking factor.

Even if one of the strands breaks, there are chances that the lifting work will be completed without any problems. But a professional would suggest not to use the wire rope which has suffered any such issue but still the current operation can be completed irrespective of the broken strand. So always consider the rope material, wire, and strand structure as they go through more wear and tear than they are subjected to.

Electric Wire Rope hoists come with an instruction guide where you will have all the operating information. There are a few checks which are suggested to perform you put Electric Wire Rope hoist into use.

Wire Rope: – 6×37 construction which is a special flexible steel wire rope, having a safety factor of 6 for class-II and 7 for class-II duty cycle is provided on the hoist.

Rope Drum: – Main component is the rope drum which is made of sturdy seamless pipe or fabricated from steel plated and is grooved to take the full lift without over-winding.

Motor: – Motors are enclosed with half-hour rated with high starting torque, which is specially designed and built for hoist duty. The motors are provided with class-F insulation.

Limit Switch: – To avoid over winding of wire rope, limit switches are provided with each hoist, which ensures the highest and lowest position of the load hook.

Controls: – Every hoist is provided with a control panel comprising of Siemens/L&T/Schneider to make the heavy-duty, directed-on line reversing type airbrake connector, transformers, and fuses which helps in preventing an accident.

Wire rope hoists use wire rope as the lifting medium and perform the lift by wrapping the cable around a grooved drum. They can be powered manually, electrically, or pneumatically.Wire rope can be used as the lifting medium in many industries but is especially popular in production environments because it can perform lifts at a faster speed, lift to higher heights, and can be rated for more severe duty cycle classifications when compared to chain hoists. They are also able to dissipate heat from extended usage with higher duty cycles in more demanding or severe lifting applications.

Our SEQ hoists are the industry"s first dual speed via VFD, single phase electric chain hoists. The variable frequency drive furnishes smooth starts and stops, adjustable speeds, and unbeatable precision. The added benefit of a no-load high speed function that automatically increases hoist speed up to 130 percent when the load is less than 30 percent of working load limit takes lifting to new heights.

8613371530291

8613371530291