wire rope crane hoist supplier

Full service distributor of new and used material handling low headroom, electric, chain and wire rope hoists. Variable capacity electric chain hoists can be mounted on overhead cranes including single, double or box girder types. Speed controls, radio control and hazardous environment options are available for chain hoists. Heavier capacity electric wire rope hoists can be used for industrial applications, and can be fitted with speed controls, radio remote control and other custom features. replacement or performance parts. Capabilities include turnkey installation and CAD designing. Crane maintenance, rebuilding, upgrades, inspection, retrofitting and safety training services are available. 24-hour emergency services are available. Meet ASME standards.

When getting into a higher capacity, electric wire rope hoists are your best bet. They are ideal for very fast lifting speeds, true vertical lift applications, and high cycle (H5 Duty rating) applications. Tri-State Overhead Crane offers 10 Ton, 20 Ton, 30 Ton, and 50 Ton Electric Wire Rope Hoists available from the top wire rope hoist manufacturers.

R&M Materials Handling has over 85 years of experience in the overhead manual, electric chain hoists and wire rope hoists history. Headquartered in Springfield, OH, R&M has parts and service centers located throughout North America, Central America, and South America.

Tri-State Overhead Crane is a highly trusted Yale wire rope hoist distributor and Yale hoist parts. Yale is well-known for their market-leading technology that goes into their YK, Cable King and LodeKing as well as their high safety and performance ratings.

Products under the Shaw-Box brand feature capacities ranging from a 1/2 ton wire rope hoist to a 100 ton capacity trolley/hoist. Whether the job calls for electric or air-power, indoor or outdoor duty, general or severe industrial service, a Shaw-Box hoist meets the needs of the workforce.

Harrington Hoists is recognized as an innovator and market leader in the hoist and crane industry. Harrington Hoists manufactures revolutionary manual, electric, and air chain hoists, wire rope hoists and crane products. TSOC carries a full line of Harrington Hoist world class products including the NER, NERP and SNER electric chain hoists with capacities of 1/8 Ton to 5 Ton.

Demag offers a complete line of cranes and handling technology, focusing on the benefits to their customers and providing high levels of safety, reliability and outstanding performance. Demag offers a wide range of electric hoists that include many standard features that are considered optional from other manufacturers.

Detroit hoist has been designing and manufacturing wire rope hoists since 1905. Based in Michigan, Detroit Hoist strives to be the best while delivering products on time and at competitive prices. In-house product research and development enables the company to retain the flexibility of applying standardized designs, simplicity and economies of time-proven serial components for more value and increased reliability.

STAHL Crane Systems" wire rope hoists range in capacity from 1,100 pounds to 175 tons. STAHL wire rope hoists have a compact, sturdy construction which is extremely low-maintenance. Their reliability, power and long service life are above average. The particularly smooth, precise starting and braking characteristics are common to all.

TSOC stocks several brands of electric chain hoists from CM, Coffing, Budgit, Yale, Harrington, and Demag. Typically ranging in capacity from 1/4 Ton to 5 Tons, these electric powered hoists are ideal for manufacturing and industrial facilities.

Hand chain hoists and lever hoists are the two styles of manual chain hoists that TSOC offers. These are perfect for low duty cycle applications. Another feature that makes these a good solutions is their ability to be portable. Capacities typically range from 1/8 Ton to 5 Ton, but we do offer some heavier capacities up to 25 Ton.

True vertical lift is the lack of any lateral hook drift as the hook moves vertically throughout the full range of motion. Single reeved wire rope hoists cause slight lateral movement of the hook, generally around a 1/4 of an inch lateral movement, for every 12 inches of vertical movement. For most jobs, this lateral movement will not cause a problem, but for some applications this movement can be damaging. If true vertical lift is required, a double reeved configuration will be needed. You will often pay a premium for true vertical lift at lower capacities, so it is important to understand if you really need this feature. By nature of their design, chain hoists provide true vertical lift by the nature of their design. Chain hoists for capacities up to 20 tons may be a more economical choice.

TSOC distributes wire rope hoists; serving clients from coast to coast, Canada, Mexico and especially focused in Missouri, Illinois, Indiana, Iowa, Kansas, Nebraska, Arkansas, Mississippi, Tennessee, Kentucky, South Carolina, Florida, and Oklahoma.

Wire rope hoists lift loads by utilizing a grooved drum around which the wire rope is wrapped. Wire rope hoists are the ideal hoist option for very high-capacity lifting applications where frequent use throughout the day will occur. Industrial wire rope hoists offer a much wider selection of options compared to chain hoists, with the added benefit of extremely fast lifting speeds and reduced wear. Additionally, the larger components of a wire rope hoist allow them to withstand the intense heat created by constant lifting. Crane Depot is a leading supplier of industrial wire rope hoists and we are ready to help you select the right hoist for your application. Whether you need to lift very high-capacity loads in a foundry or need a durable hoist to withstand the harsh and frequent lifting environment of a lumber mill, Crane Depot is here for you.

Engineered Material Handling (EMH) sets the standard for wire rope hoists. EMH manufactures its own single and double girder wire rope hoists for standard industrial applications, with standard capacities of from 2 to 50 tons. The EMH wire rope hoist provides a price to performance ratio that compares favorably with the best the industry has to offer.

Standard features include two lifting and trolley speeds, two upper and one lower precision limit switches, overload limit, heavy duty wear resistant rope guide, DC rectified brakes, and lifetime lubricated bearings and gear reducers.

We provide solutions for your lifting needs. Whether you need a standard wire rope hoist, or a specially designed heavy lifting winch, R&M can serve you.

We are the most experienced custom wire rope hoist manufacturer in the world. At Ace World Companies we design and build specifically for your material handling needs and therefore there is virtually no limit in capacity. Our crane components are designed to be heavy-duty and long-lasting and as a result, our hoists meet the challenges that you put before them.

Our wire rope hoists are engineered to be the most reliable and cost-effective solution for our customers. We consider both your short and long-term needs before we identify design criteria and engineer a solution for your industrial wire rope hoist. As a result, every crane component we design must meet the critical issues of quality, durability, and furthermore ease of maintenance to be considered reliable. We’ve been guided through the years by the following customer-driven value principles: Low cost of ownership is even more valuable than low cost.

Our unwavering commitment to quality makes Ace Hoists the best value on the market today. Be sure to visit our Photo Gallery for a sampling of our custom hoists.

The CXT electric wire rope hoist is the most widely-used Konecranes product. Anywhere people want to lift up to 80 tons, you can often find a CXT hoist doing the job. The reliability and versatility of the CXT has made Konecranes the largest supplier of wire rope hoists in the world.

Versatility means custom-tailored solutions for your every lifting need. Choose a normal headroom hoisting trolley when you have the space, or a low headroom model when you don"t. Available in monorail or double girder models, flexibility is key. The CXT electric wire rope hoist adapts for the requirements of your runway and your building.

Do you need a swivel trolley for greater ease of movement? What about a fixed hoist, when movement is more restricted? The wire ropes are strong, highly flexible, and optimized to your specific reeving requirements. Tell us your needs, and we will give you a hoist to match them.

Ideally, you should buy a full CXT crane, to ensure the quality of all of your lifting equipment. But if your budget is tight, you may wish to modernize your existing crane with the CXT hoist. Even if you only buy the hoist, we still service your whole crane, not just the Konecranes part.

Ensure your hoist stays safe and lasts longer with our unique TRUCONNECT® remote monitoring and reporting service. The condition monitoring unit on your hoist sends usage data to Konecranes. Periodic reports make it easy to manage safety, usage, and maintenance.

Electrolift is the oldest manufacturer of wire rope worm driven hoists in the world, highly innovative and a step ahead of the competition since the company was founded in 1932. Engineered and manufactured to be tough and reliable, today the product line has grown to Single Hook, Twin Hook, Base Mounted and Specialized Hoists that meet every type of application requirement. Customers who demand the very best receive a manufacturing integrity that begins with tried and true reliable designs and ends with installations that operate for decades with minimal maintenance, virtually eliminating downtime.

Whether you"re looking for a wire rope hoist with state-of-the-art or standard functionality, we offer wide solutions to meet our customers" needs. Our Demag wire rope hoists include excellent safety features, high handling rates, and cost-effective operation up to 100 tonnes.

As basic hoist units for integration into plant and machinery, or as lifting solutions with electronic controls that are optimized forcrane applications, with our wide range of wire rope hoists we offer the optimum solution to meet our customers’ specific requirements for efficiently lifting loads weighing up to 100 tonnes.

Our DMR modular wire rope hoists offer groundbreaking flexibility for diverse applications. With our DMR wire rope hoists, we can produce either a C-design or co-axial design. Some of the features include:

Our DH hoist units are utilized for a range of applications, including as traveling hoists on cranes or monorails and stationary solutions. These units provide reliable operation even in harsh environments with high ambient temperatures, high dust levels, and aggressive atmospheres. Additional features include:

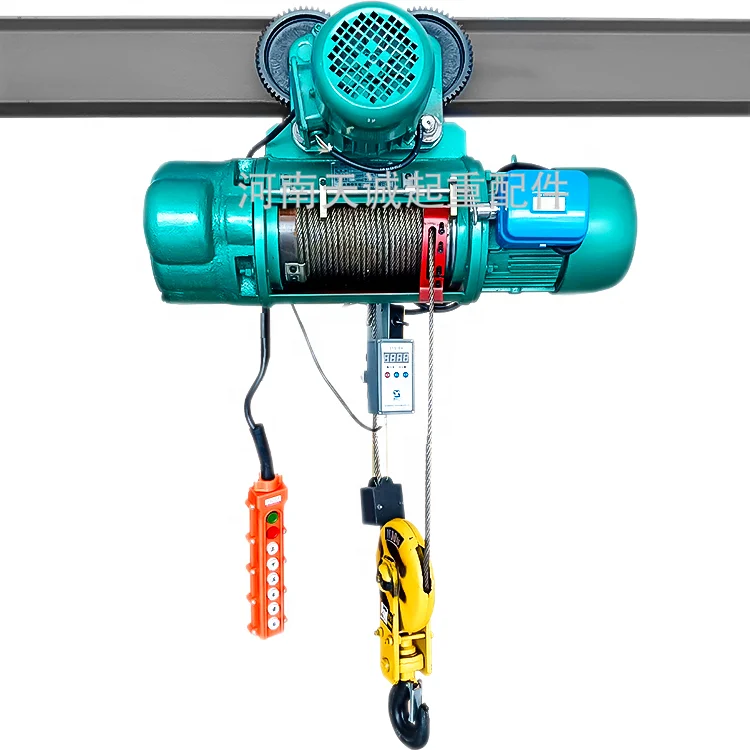

Electric wire rope hoists are a specific type of electrically powered hoists which use wire ropes as opposed to the usual steel chain used on standard electric hoists, which are often mounted on single girder overhead cranes and jib cranes, designed for widely used to lift heavy objects.

If you are looking for electric wire rope hoist manufacturer in China, Hilifting is the right one, our sales team can ensure you that we can understand your requirements well and deal with the projects immediately and professionally.

Numerous industries require lifting equipment to facilitate their operations. Out of those hundreds of sectors, the construction industry is the one whose operations rely the most on a diverse range of rigging solutions that have to be able to hoist light to heavy loads. All lifting operations, especially the heaviest ones, must be done with dependable and safe wire ropes. At Kennedy Wire Rope & Sling, we source our wire rope from manufacturers whose products meet, or exceed, industry standards. Our mission is to provide clients with a product that is nothing less than exceptional.

Wire rope is the best product for doing the heavy lifting for crane operations. Wire rope is made from multiple steel wires that are put together around a core. Steel wire offers strength, flexibility, the ability to handle stress, and works well for bearing heavy loads, which is the whole purpose of crane operations. Wire rope is also extremely resistant to corrosion, rotation, fatigue, crushing, and abrasion. Kennedy Wire Rope & Sling Company offers many different types of wire rope for your crane needs. Many industries, such as the construction, manufacturing, and oil and gas industry, rely on our crane products to meet their needs.

Flex-X 9: Features compacted strands and swaging for increased stability and extra drum crushing resistance. It’s designed for boom hoist applications and tubing line applications where drum crushing is a challenge.

19×19 Compacted: A very flexible rope with excellent resistance to rotation and high tensile strength. Best for use with choker ropes, trolley lines, winch lines, hoist ropes and boom lines. Applications include cranes, excavating, dredging, marine, oil and logging.

35×7 Class: Features a high strength-to-diameter ratio. Its unique design minimizes rotation and torque of the rope at normal load ranges of 0 to 20% of the rope’s minimum breaking force. Excellent when load control is vital.

8 x 19 Class: Is resistant to crush and built within ISO 9001 specifications. It has one of the most stringent testing processes of any rope. From creation to deployment, industry experts know what this rope can take.

Let our experienced on-site services team help you with your next wire rope slings installation, inspection, and maintenance procedure. This will ensure that you will get the most out of your equipment, with minimal downtime.

At Kennedy Wire Rope, our teams are dedicated to being and remaining the industry’s leading supplier of hardware used in rigging, construction, and oil and gas operations. We also have the licenses and insurances that our customers’ depend on. Call us today at 800-289-1445 and speak with a friendly representative. We welcome any questions concerning any of our products and rigging services.

Wire rope hoists use wire rope as the lifting medium and perform the lift by wrapping the cable around a grooved drum. They can be powered manually, electrically, or pneumatically.Wire rope can be used as the lifting medium in many industries but is especially popular in production environments because it can perform lifts at a faster speed, lift to higher heights, and can be rated for more severe duty cycle classifications when compared to chain hoists. They are also able to dissipate heat from extended usage with higher duty cycles in more demanding or severe lifting applications.

Findadistributor.com, the most comprehensive and reliable network of North America’s premier distributor and dealers to find quality and cost-effective electric wire rope hoists.

As a leading industrial directory, we’ve assembled a comprehensive list of wire rope distributors who caters for all your material handling and lifting needs.

Findadistributor.com is the trusted and premier vertical directory, containing all leading distributors and dealers, which allow end-users to have access to all their information available on the internet. We are here to bring together North America’s companies that supply manufacturing machinery and systems that are employed by the processing industries comprising but not confined to: wire rope hoist, electric hoist, hoist.

At Findadistributor.com, we leave no stone unturned in keeping every buyer updated with this highly competitive industry and its ongoing trends. Whether you are looking wire rope distributor, or electric wire rope hoist dealers, we provide you with the latest technology and the comprehensive data of North America’s distributors and dealers to enhance your sourcing performance in the business line of manufacturing and processing machinery. Our easy to use and easy to navigate search engine allows you to find wire rope distributors and dealers as per your business needs.

Whenever you are putting a hoist on an electric travelling bridge crane 2-ton or above, you should apply a wire rope hoist unless some circumstance specifically dictates the use of chain.

Whenever you have any application requiring an electric hoist, with capacity of 5-ton or above, use wire rope unless some circumstance dictates chain. One circumstance that might dictate chain would be a requirement for hook mounting. This is not normally available for wire rope.

Use one with a rope guide if the hook block is ever allowed to rest on the floor or some other object causing slack in the cable that might cause the wire rope to jump out of the drum grooves.

8613371530291

8613371530291