wire rope crash barrier quotation

Established in2014, V. A. Engg. & Infrais a leading organization affianced in the area of manufacturing a broad plethora of Cats Eyes Road Marking Stud, Guard Rails and Crash Barrier. In their development process, we assure that only top notch basic material is used by our professionals along with ultra-modern tools and machinery. Besides this, we check these on a variety of grounds before finally shipping them at the destination of our customers. Together with this, our offered facility of customization in order to attain high level of customer satisfaction has earned us huge number of satisfied customers.

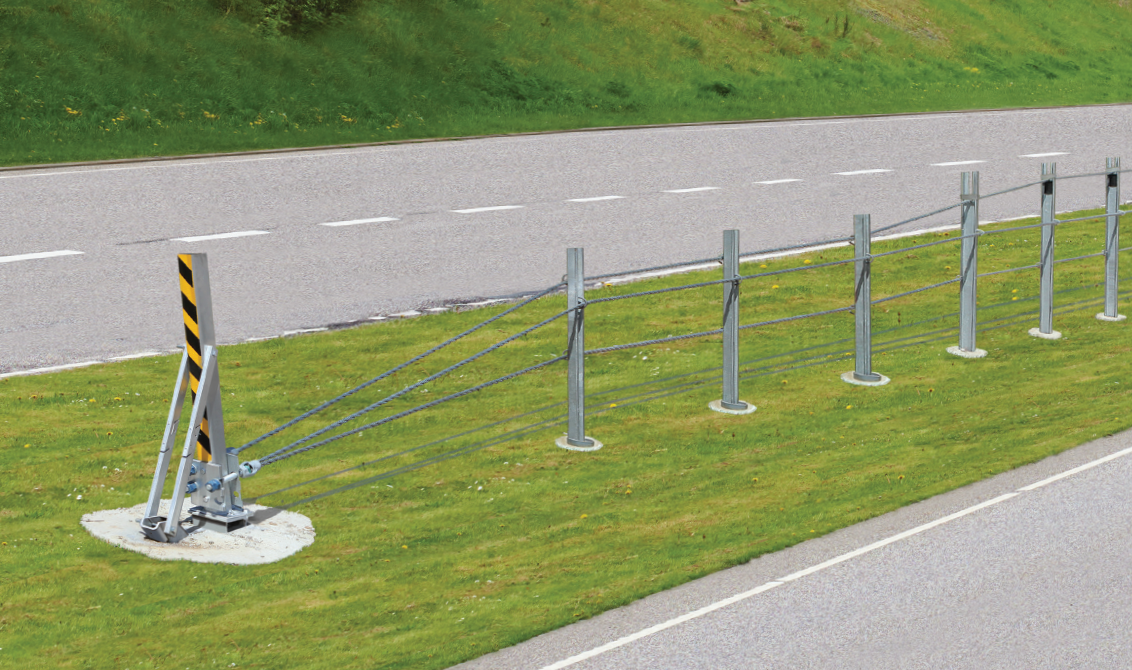

CASS™ wire rope safety barrier is a flexible type crash barrier that meets requirements of IRC-119: 2015 and is crash tested to EN-1317:2 for H2, H1 and N2 containment level. Wire rope safety barrier addresses the issue of median or shoulder crossover accident on highway systems throughout the world.

The newly designed post has no sharp edges or hooks that could present a hazard to unprotected road-users, e.g.motorcyclists.The patented shape of the slot keeps the cables in position during impact, resulting in noticeably lower deflections during crash tests. The deep slot in the post allows for a widened spread of the cables, which highly increases the system’s ability to retain different types of vehicles. Spacers of recycled plastic keep the cables correctly positioned. Each of the three 19 mm pre-stretched cables has a minimum breaking load of 16.7 tonnes and are fitted with turnbuckles for tension adjustment. In unison, these features effectively make CASS the safest solution for cable guardrails of today.

The proprietary shape of the post allows for lower deflections during crash tests by minimizing the length of unsupported cables. Additionally, the widened cable spread works to retain different types of vehicles.

SAFENCE® is the tensioned wire rope cable barrier system from Gregory Industries. As a "soft" barrier, SAFENCE is designed to safely absorb energy while redirecting the impacting vehicle along the barrier. SAFENCE also saves money because it is the only cable fence barrier system that meets TL-3 and TL-4 standards with either three or four wire rope cables.

It is available in 3 or 4-wire rope cable configurations with non-releasable anchors. This is a preferred system because wire cables remain under tension after vehicle impact.

CASS™ wire rope safety barrier is a flexible type crash barrier that meets requirements of IRC-119: 2015 and is crash tested to EN-1317:2 for H2, H1 and N2 containment level. Wire rope safety barrier addresses the issue of median or shoulder crossover accident on highway systems throughout the world.

The newly designed post has no sharp edges or hooks that could present a hazard to unprotected road-users, e.g.motorcyclists.The patented shape of the slot keeps the cables in position during impact, resulting in noticeably lower deflections during crash tests. The deep slot in the post allows for a widened spread of the cables, which highly increases the system’s ability to retain different types of vehicles. Spacers of recycled plastic keep the cables correctly positioned. Each of the three 19 mm pre-stretched cables has a minimum breaking load of 16.7 tonnes and are fitted with turnbuckles for tension adjustment. In unison, these features effectively make CASS the safest solution for cable guardrails of today.

The proprietary shape of the post allows for lower deflections during crash tests by minimizing the length of unsupported cables. Additionally, the widened cable spread works to retain different types of vehicles.

A cable barrier, sometimes referred to as guard cable or wire rope safety barrier (WRSB), is a type of roadside or median safety traffic barrier/guard rail. It consists of steel wire ropes mounted on weak posts. As is the case with any roadside barrier, its primary purpose is to prevent a vehicle from leaving the traveled way and striking a fixed object or terrain feature that is less forgiving than itself.

Because these barriers are relatively inexpensive, as opposed to concrete step barriers to install and maintain, and are very effective at capturing vehicles, their use is becoming increasingly prevalent worldwide. By far, the most popular use of the cable barrier system occurs in the medians of divided highways.

Given the opposing directions of traffic on divided highways, cross median crashes are particularly severe. While median width plays a large role in the occurrence of these crashes, increased width alone does not eliminate them and quite often, the median must be shielded with a barrier. Cable barriers provide a cost-effective solution to the shielding issue.

The system is more forgiving than traditional concrete (Jersey) barriers or steel barriers used today and remains effective when installed on sloping terrain. The flexibility of the system absorbs impact energy and dissipates it laterally, which reduces the forces transmitted to the vehicle occupants.

Although cable barriers have been used since the 1960s it was not until the mid-1990s that many departments of transportation began to deploy them with any regularity.

In many countries of the European Union these cable barriers are not allowed to be used along highways as they are perceived to be especially hazardous for motorcyclists. However, a study of motorcyclist injury rates for several types of highway barrier did not find an appreciable difference in fatal and severe injuries between cable and W-beam barriers. Both were significantly more hazardous than concrete barriers but less hazardous than none.

There are two types of cable barrier systems in use today, low-tension and high-tension. Each system has its advantages and disadvantages, but in general, a high-tension system has a higher initial cost with lower long-term maintenance costs and concerns.

During the expansion of cable barrier use throughout the 1980s and 1990s, the low-tension system was specified almost exclusively. This system is also called the “generic” system, referring to the fact that it is not exclusively manufactured by any single producer.

Due to the low tension of the system, the cables tend to lie on the ground in the event that an impact damages multiple posts. As such, there is no residual safety value within the undamaged remainder of the 2,000 ft (600 metres) installation and that entire section of barrier will remain nonfunctional until repaired.

Despite these perceived shortcomings, low-tension cable barrier, until recently, was arguably the workhorse of the industry. Thousands of miles of the generic system remain in use today in countries worldwide.

At TL-3, an 1,800 pounds (820 kg) car is crashed at 60 miles per hour (97 km/h) on an impact angle of 20°. Also at this level, a 4,400 pounds (2,000 kg) pickup truck impacts at 60 miles per hour (97 km/h) and 25°. TL-4 includes both these tests but adds a 17,600 pounds (8,000 kg) single-unit truck impacting at 50 miles per hour (80 km/h) and 25°.

All cable barrier systems available today are approved at either TL-3 or TL-4. There is a great deal of anecdotal evidence, however, that many of these systems are performing at a higher level in the field capturing vehicles as large as semi truck-trailer combinations.

Cable barrier, is intended for use on slopes with a 1:6 vertical to horizontal ratio. The 1V:6H requirement is based in both computer modeling and full-scale crash testing and represents sound theory. In practice, however, slopes as flat as 1V:6H are often the exception.

Median Cable Barriers have been studied for safety, and they are arguably effective deterrents to serious highway accidents. However, a lack of proper installation and testing has led to severe collisions and even death.Arizona, there is indication that the state government agency in charge of highway regulation failed to follow proper installation procedures.Arizona Department of Transportation was aware of cable barrier problems, and they may have also rushed installation of these barriers on state highways.

A major problem alleged, that reduces the effectiveness of cable barriers, is the installation below grade, especially around slopes or dips.Washington state, numerous letters were submitted to the state Department of Transportation complaining of cable barrier installation.

Containment or Deflection – based WRSB. Deflection aimed WRSB could be tensioned to slightly higher tension and will most probably use 4 wires (ropes). The overall length of the barrier tends to be shorter. Containment based WRSB will have wire ropes spread further apart from each other (approximately 150mm - 60mm), to increase the catchment area.

Daniello, Allison; Gabler, Hampton C. (2011). "Effect of Barrier Type on Injury Severity in Motorcycle-to-Barrier Collisions in North Carolina, Texas, and New Jersey". Transportation Research Record: Journal of the Transportation Research Board. 2262 (2262): 144–151. doi:10.3141/2262-14.

Baxter, J.R. to B. Neusch. July 2006. Gibraltar Cable Barrier on 4:1 slope @ TL-3. Federal Highway Administration. Roadside Hardware: Acceptance Letters. HSA-10 / B137C.

The MASH compliant O-Post Wire Rope Barrier System (WRSF) offers a patented interweaving of the wire ropes to contain & redirect errant vehicles. This unique design helps to prevent vehicles from crossing the barrier or deflecting back into the traffic flow. The O-Post WRSF is designed to absorb the energy of an impact, minimizing injury to passengers and damage to vehicles.

Application of median wire rope safety barrier overseas had resulted in a reported 80% reduction in cross centre line casualty crashes. The key objective of the treatment is to prevent fatalities and serious injuries as a result of head-on crashes and other cross centre line crashes,� consistent� with� South� Australia’s� RoaStrategy – Towards Zero Together and Safe System principles. However, use of flexible barrier in a narrow median raises issues with maintenance monitoring and safety of…Expand

Standard End Terminals are designed to provide the necessary longitudinal support for a wire rope safety barrier ensuring the barrier is able to redirect a vehicle impacting its Length of Need. Although the design of these systems are such that they prevent snagging and vehicle launching, the terminals have not been subject to full scale crash testing.

TL3 end terminals are designed to provide a soft gating impact to prevent vehicles from launching or snagging upon impact. The release of the cables at the end anchor location (upon impact) is the most popular way this is achieved with various wire rope safety barrier systems.

A recent development has been the introduction of non-release terminals. These TL3 approved terminals have proven not to release the cables during full scale crash testing.

Non-release terminals ensure the barrier system remains tensioned and functional in the event of secondary impacts occurring downstream from the end anchor.

Wire Rope Safety Barriers are flexible systems that where developed as median barriers in order to prevent vehicles crossing over to the opposite side of the road. Increasingly Wire Rope Safety Barriers are being used in verge applications where the expected deflections of these systems can be accommodated, while still protecting motorists from the hazard.

Wire Rope safety Barriers provide softer ride-down decelerations for vehicle occupants in the event of a crash and are considered “more forgiving” than more rigid systems.

FLEXFENCE® is the most popular Wire Rope Safety Barrier in Australia. This parallel rope system can be installed to meet EN1317 standards, NCHRP Report 350 Test Level 3 or Test Level 4.

Are you looking for the best Safety Barrier importers and buyers? ExportHub has you covered. As a leading online B2B portal, we have ensured that you find the latest buy offers. With our help, you’ll never have to worry about getting your hands on your next order. Once you sign up and become our B2B member, you can connect with leading Safety Barrier buyers and importers to experience.

Get wholesale wire rope safety barrier at Alibaba.com at an affordable price. We carefully selected all the materials for your consideration. This product can be used for a long time, even outdoors under direct sunlight. It offers several advantages. The color will not easily fade and it is tougher and more durable than standard barriers. And because it uses stainless steel, it avoids corrosion and rust.

A special reflective sheet is used on wire rope safety barrier, which helps to get attention even at night. The color of the reflective outline is also eye-catching to achieve the goal of effectively preventing traffic accidents. While the design is simple to address most requirements, the paint color of the barrier should be selected based on the purpose or application under consideration. It is suitable for any type of environment.

Thicker materials are used to ensure durability over time. The base is also more stable and strong, so it will not fall over when the barrier gets hit. The installation process of wire rope safety barrier is convenient as the connections are well-designed and secure. Hurry and shop wholesale wire rope safety barrier at Alibaba.com. Tell us the colors and sizes you would like, and we’ll help you get everything you need for you and your business at Alibaba.com.

We manufacture and supply our clients a broad array of Crash Barriers. Designed for installation at the roads, these are used to keep away the motorists from the edges. These are designed and manufactured using pristine quality basic materials and sophisticated techniques in tandem with industry standards. Also, our quality inspectors test all types of crash barriers / safety barriers on set quality parameters to assure their durability and rugged design. We offer these road safety equipment to the clients in different lengths, thicknesses and designs at nominal prices.

With several types of barriers available to improve road conditions, why and when should you choose the wire rope safety fence? These and other questions regarding the barrier type are answered below to help you make an informed buying decision.

It’s a type of road barrier that is installed to improve road safety and reduce the severity of injury upon a vehicle’s collision with the barrier. The design includes wire rope cables attached to steel posts. The ropes are tensioned to create an effective barrier. Typically, it consists of three to four parallel wire ropes or two intertwined and two parallel wire ropes tensioned between posts.

The results of full-scale vehicle crash tests have shown that wire rope safety fences perform better in terms of lower vehicle occupant injury levels than rigid road barriers.

Although it’s not possible to guarantee zero injuries for any type of road safety product, the injuries road users suffer tend to be less severe in most instances in comparison with injuries suffered in collisions with other types of barriers.

The claim is supported by the results of research conducted at the Monash University Accident Research Centre. The researchers based their findings on the performance of the road safety fences next to the roads of Victoria. The study scope included a 100-km stretch of road. The results showed that the barriers reduce collision incidents and vehicles from leaving the safe travel path by up to 87%.

The report noted that rigid concrete road barriers are less effective in reducing the level of injuries. Wire rope safety fences outperform other barriers in terms of the reduction of the severity of injuries.

The design of these barriers makes it possible for the wire ropes to give way significantly, thereby reducing the impact force on the colliding vehicle and its occupants. The risk of vehicle penetration is drastically reduced whereas the risk is more notable with rigid barriers.

These barriers are installed in urban areas, next to highways and national roads. The barriers are best suited for sections with few or no extreme curves. Also, where these barriers are installed on the median of two highways or lanes, there is the risk of accidents spilling over into the opposite lane because the posts give way to deflect the impact.

Thus, it’s essential to factor in the clearance space required behind the barrier. This is also true for installation to protect motorists from colliding with unforgiving objects. Enough clearance space is crucial to ensure the wire rope can stop the straying vehicle before it hits the rigid object.

Any type of barrier poses a risk for road users. The question is rather whether a collision with the barrier reduces the impact and is safer than colliding with the unforgiving object against which it protects.

Whenever there is the likelihood of a vehicle being able to return to the safety of the road or to come to a controlled stop without crashing, then it’s favourable not to have a barrier.

However, each type of barrier carries its own set of risks for road users. In isolated cases, the wire rope safety fence can give way too much and might be unable to stop a vehicle travelling at a high speed. The risk of vehicle body penetration upon impact is extremely low, making it safer in this regard than a steel-type barrier.

The risk of roll and pitch occurring when a vehicle hits a kerb at a speed of, for instance, 70km per hour should be taken into account. The impact with the kerb can influence how the vehicle interacts with the safety fence. If a kerb is needed, the barrier offset must be at a sufficient distance after the kerb to enable the straying vehicle to regain control before it hits the barrier.

Alternatively, it must be installed close enough to the kerb that there isn’t sufficient time for roll or pitch to take place after the vehicle has hit the kerb. If a fence is installed on a kerb, the height of the ropes must be adjusted accordingly. Considering the importance of correct barrier placement, it becomes clear why expert installation is required.

Each road safety barrier type has its own characteristics and performance profile. Therefore, sufficient clearance between barriers is essential to allow for impact absorption, deflection and redirection performance.

It’s a road safety fence from Blue Systems, which Armco Superlite has developed along with Brdr. Markussens Metalvarefabrik (BMM). The barrier has been designed to meet the new European CEN standards and the requirements of NCHRP 350-TL3.

We install these barriers in accordance with strict requirements regarding clearance space, soil type, the distance between poles, and the tension required for the cables to meet the requirements of Blue Systems.

The fittings are made from grade 316 stainless steel, giving them optimal corrosion resistance and longevity. The rest of the steel components are galvanised to meet the requirements of SABS ISO 1462, also ensuring durability and resistance. View more information on the Safence barrier here.

8613371530291

8613371530291