wire rope designation for sale

While some use these two terms interchangeably, technically wire rope refers to a diameter greater than 3/8”. Cable rope - also called aircraft cable - applies to all smaller variations.

Consequently, aircraft cable is only used for lighter-duty purposes, such as winch lines, fences, and railings, while wire rope can be using for lifting, towing, hoisting, etc. Both are ideal for outdoor environments because the strength and length remain constant regardless of whether they are wet or dry.

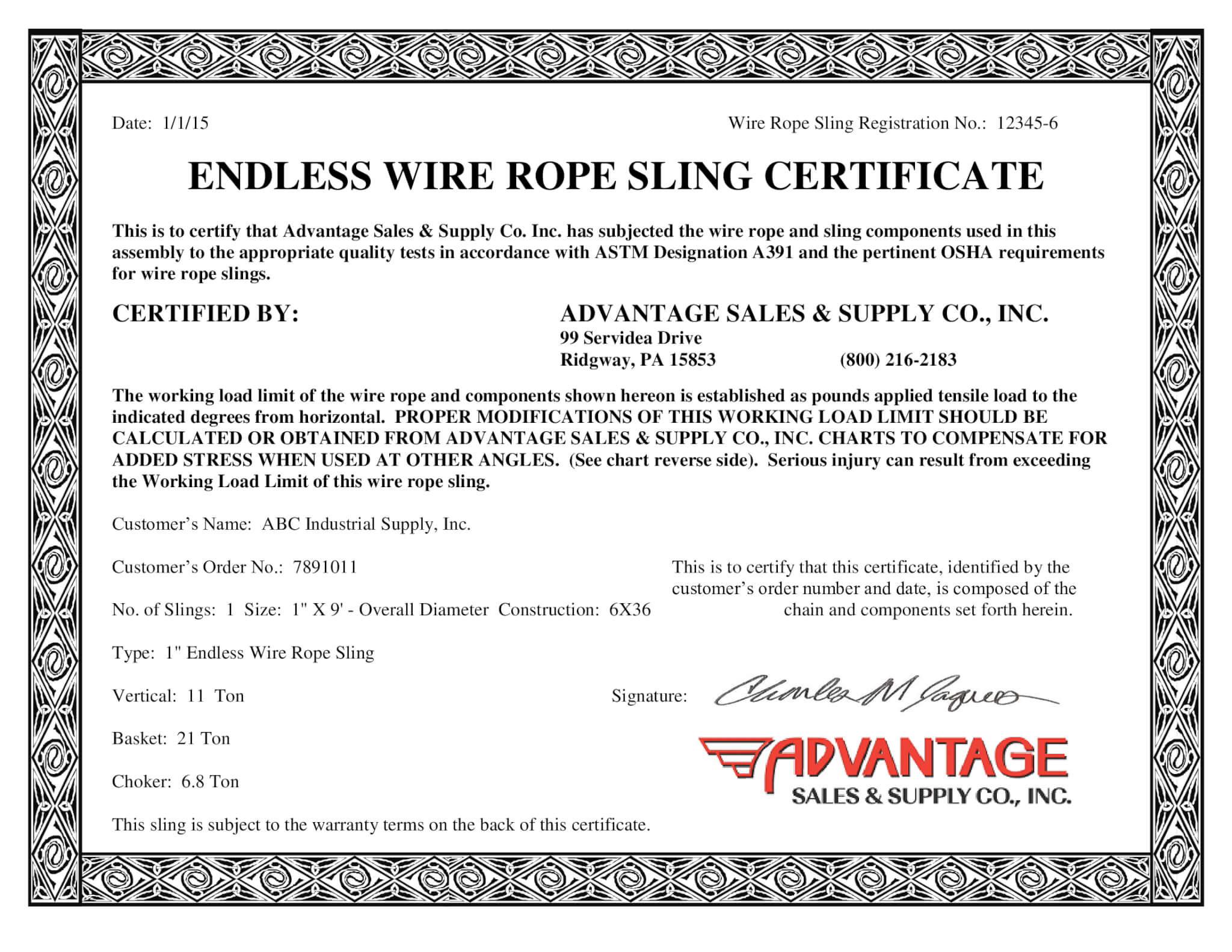

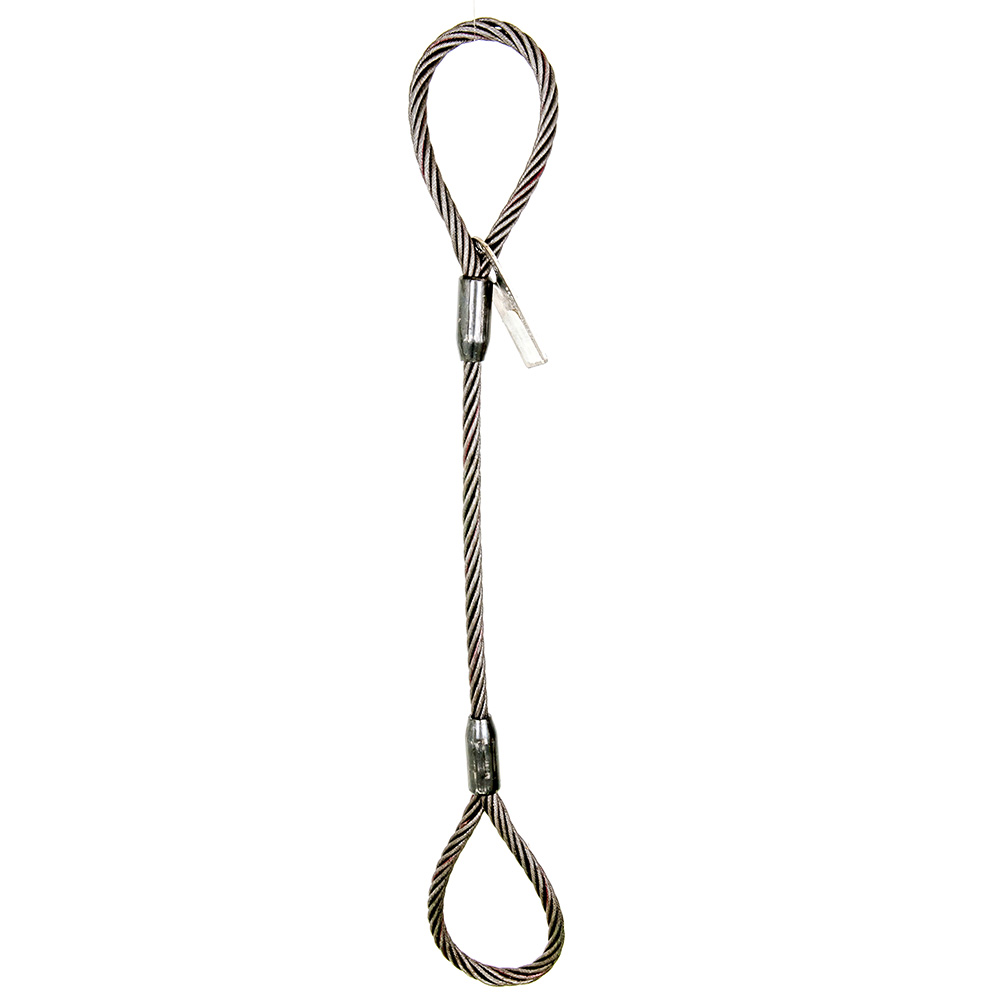

If you are looking for an option specifically designed for lifting, check out our wire rope slings. They come in a number of configurations - choices include leg count, end hardware, and more.

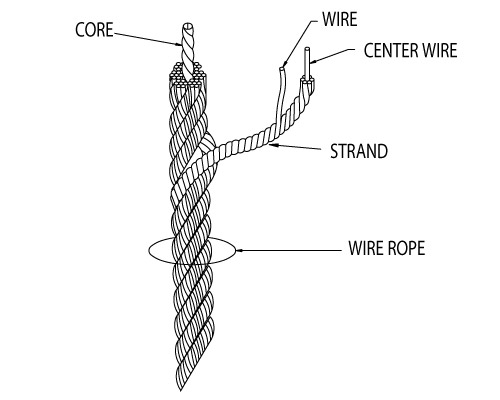

Generally composed of wires, strands, and a core shaped in a spiral pattern, wire rope is incredibly durable. Steel wires are aligned in a precise helix geometric pattern to form a strand in a process known as "stranding." A "closing" comes next, where the strands are laid around the core to form a wire rope.

The greater the diameter, the greater the break strength. Our selection of 1/8" stainless steel cable has a break strength of less than 2,000 lbs., while our 2-1/2" wire rope has a break strength of more than 600,000 lbs.!

Right hand and left hand designations indicate which way the strands wrap around the core of the steel rope, while regular lay and Lang lay designations specify which way the wires that make up the strand are formed in the helix pattern.

Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands wrapped around the wire rope core.

Our wire rope lay is right hand regular lay, with strands wrapped around the core to the right, and the wires making up the strand turned and rotated to the left.

Independent wire rope cores (IWRC) are made from steel, offer more support to the outer strands, and have a higher resistance to crushing. IWRC also offer more resistance to heat and increase the strength of the rope.

This refers to how many strands make up the rope and how many wires make up one strand. For instance, a 6x26 wire rope has 6 strands around a core with 26 wires making up each strand.

All wires consist of layer(s) arranged in a specific pattern around a center. Pattern designation is affected by the size of the wires, the number of layers, and the wires per layer. Wires can utilize either a single pattern style or a combination of them, known as a combined pattern:

Warrington - Two layers of wires. The outer layer has two diameters of wire (alternating between large and small), while the inner layer has one diameter.

Although wire rope is extremely strong, it can become damaged with improper use, making it unsafe to use. It"s important to have regular inspections for breaks, corrosion, overuse wear, and kinks.

Our rigging supplies category includes hardware and accessories for cranes, dredging, excavating, hoists & winches, logging, and marine uses. If you"re unsure what you need or have questions, call for help from our product specialists with expertise in wire rope/cable rigging supplies.

Wire rope consists of three basic components; while few in number, these vary in both complexity and configuration to produce ropes for specific purposes or characteristics. The three basic components of a standard wire ropedesign are: 1) wires that form the strand, 2) multi-wire strands laid helically around a core, and 3) the core.

Wire, for rope, is made in several materials and types; these include steel, iron, & stainless steelto name a few. By far, the most widely used material is high carbon steel. This is available in a variety of grades each of which has properties related to the basic curve for steel wire rope. Wire rope manufacturers select the wire type that is most appropriate for the requirement of the finished product.

Different grades of wire rope are available such as: improved plow steel (IPS), extra improved plow steel (EIPS), and extra extra improved plow steel (EEIPS). The plow steel curve forms the basis for calculating the strength of most steel rope wires, the tensile strenght (psi) of any steel wire grade is not constant, it varies with the diameter and is highest in the smallest wires.

The most common finish for wire rope is "bright" or uncoated. Steel wires may also be metallic coated with zinc (galvanized) or zinc/aluminum alloy (mischmetal). "Drawn galvanized" wire has the same strength as bright wire, but wire "galvanized at finished size" is usually 10% lower in strength. For other applications, different coatings are available.

Stainless steel wire rope, listed in order of frequency of use, are mode of AISI types 302/304, 316, and 305. Contrary to general belief, hard-drawn stainless type 302/304 is magnetic. Type 316 is less magnetic, and type 305 has a permeability low enough to qualify as non-magnetic.

Strands consists of two or more wires, laid in any one of many specific geometric arrangements, or in a combination of steel wires with some other materials such as natural or synthetic fibers. It is conceivable that a strand can be made up of any number of wires, or that a rope can have ay number of strands.

The core is the foundation of a wire rope; it is made of materials that will provide proper support for the strands under normal bending and loading conditions. Core materials include fibers (natural or synthetic) or steel. A steel core consists either of a astrand or an independent wire rope. The three most commonly used core designations are: fiber core (FC), independent wire rope core (IWRC), wire strand core (WSC), and wireline.

Horizon Cable Service also offers inspections and mobile proof test services for product verification, break testing and load testing to ensure compliance for all wire ropes we sell and repair. Our mobile proof test services are available throughout the United States. In addition to our mobile load testing services we have stationary beds to service Oklahoma, Texas, North Dakota, Wyoming, Kansas, New Mexico and all surrounding areas. Feel free to contact one of our industry professionals today at 866-369-9507.

Wire rope is technically defined as multi-wire strands laid geometrically around a core while also used more generally as a term to classify multiple product families including aircraft cable, coated aircraft cable, general purpose wire rope, strand, rotation resistant wire rope, compacted/swaged wire rope, and cable laid wire rope.

Aircraft cable does not fit the definition of wire rope in the strictest sense as it does not have an independent core, but rather a strand core, in which the center is one of the strands that is laid with the outside strand layers. Aircraft cable is available in diameters 3/8" or less with breaking strengths similar to that of equal diameter independent wire rope core (IWRC) and is available in stainless steel and galvanized steel.

Wire rope can be galvanized via three processes. Listed from least corrosion-resistant to the most corrosion-resistant, they are electro-galvanizing, hot-dip galvanizing, and drawn-galvanizing. In addition to being the most corrosion-resistant types of galvanized wire rope, drawn-galvanized has another added benefit which is a breaking strength that is the same as bright wire rope does. Electro-galvanized and hot-dip galvanized wire rope have breaking strengths that are approximately 10% lower.

Wire rope is specified by the number of strands in the rope, the number of wires in each strand, and a description of the core’s material of construction. For example, the notation “6x7 FC” means that the rope has six strands with seven wires in each strand and a fiber core. Commonly used core designations include FC (fiber core), independent wire rope core (IWRC), wire strand core (WSC), and poly core (PC).

There are two elements to wire rope lubrication, the core, and outer strands. IWRC wire rope always has a lubricated core (unless specially ordered as otherwise). Bright wire rope always has lubricated outer strands. Galvanized wire rope can be manufactured in either dry finish or lubricated with respect to the outer strands. Typically stainless steel wire rope is manufactured with a lubricated IWRC and dry finish outer strands.

Suncor Stainless offers a complete line of stainless steel wire for marine, industrial and architectural applications. All of our stainless steel wire is made from grade 316 and 304 stainless steel. Our wire rope product line also includes both Black PVC Coated Wire and White PVC Coated Wire.

We offer a complete line of wire rope accessories including wire rope cutters, turnbuckles, clips, sleeves, swage turnbuckles and terminals. For more information, be sure to read our helpful Wire Rope Load Limit and Turnback Guide.

Wire rope classification is done by the number of strands as well as by the number of wires in each strand, e.g., 6 x 7, 6 x 19, 6 x 37, 8 x 19, 19 x 7, etc. However, these are nominal classifications that may or may not reflect the actual construction. For example, the 6 x 19 class includes constructions such as 6 x 21 filler wire, 6 x 25 filler wire, and 6 x 26 Warrington Seale. Despite the fact that none of the three constructions named have 19 wires, they are designated as being in the 6 x 19 classification.

Hence, a supplier receiving an order for 6 x 19 rope may assume this to be a class reference, and could possibly furnish any construction within this category. But, should the job require the special characteristics of a 6 x 25 filler wire, and a 6 x 19 Seale is supplied in its stead, a shorter service life may result.

To avoid such misunderstandings, the safest procedure is to order a specific construction. In the event that the specific construction is not known or is in doubt, the rope should be ordered by class along with a description of its end use.

Identification of wire rope in class groups facilitates selection on the basis of strength and weigh/foot since it is customary domestic industry practice that all ropes (from a given manufacturer) within a class have the same nominal strength and weigh/foot. As for other-functional-characteristics, these can be obtained by referencing the specific construction within the class.

Only three wire ropes under the 6 x 19 classification actually have 19 wires: 6 x 19 two-operation (2-op), 6 x 19 Seale (S), and 6 x 19 Warrington (W). All the rest have different wire counts. In the 6 x 37 class there is a greater variety of wire constructions. The commonly available constructions in the 6 x 37 class include: 6 x 31 Warrington Seale (WS), 6 x 36 WS, 6 x 41 Seale Filler Wire (SFW), 6 x 41 WS, 6 x 43 Filler Wire Seale (FWS), 6 x 46 WS, etc. – none of which contain exactly 37 wires.

6 strands, nominally 19 wires per strand This class is the most widely used and is found in its many variations throughout many industries. With its good combination of flexibility and wear resistance, rope in this class is suited to the specific needs of many kinds of machinery and equipment. The designation 6x19 is only nominal; the number of wires ranges from 15 to 26. The following constructions are included in this class:

6x25 Filler Wire. In this construction, there are 19 main wires in each strand, plus six small filler wires. The filler wires are located between the outer layer of 12 wires and the inner layer of six. They provide support and stability to the strand. This construction is the best combination of flexibility and abrasion resistance found in the 6x19 Class.

6x19 Warrington. Each strand is made up of 19 wires. The outer layer of 12 wires has two different sizes of wire; the inner layer of six is one size of wire. The Warrington construction is somewhat less flexible than 6x25 Filler Wire, but more flexible than 6x21 Filler Wire.

6x21 Filler Wire. Each strand is made up of 21 wires. The rope has an outer layer of 10 large wires, an inner layer of five smaller wires and a still smaller center wire. There are five filler wires, located between the outer layer of ten wires and the inner layer of five. The 6x21 Filler Wire ropes are more wear-resistant but less flexible than Warrington, and less abrasion-resistant but more flexible than 6x19 Seale constructions.

6x26 Warrington Seale. This construction is composed of 26-wire strands. It has the same size outer wires as the 6x21 Filler Wire, with an inner wire configuration similar to the 6x36 Class ropes. Thus, it combines the wear resistance of a 6x19 rope with a flexibility between 6x19 and 6x36 Class ropes.

6x19 Seale. This construction has an outer layer of nine large wires, an inner layer of nine smaller wires and a single center wire. The Seale ropes are the least flexible of the 6x19 Class ropes. However, the large outer wires, solidly supported, provide resistance to abrasion and crushing.

The 6x36 Class of wire rope is characterized by the relatively large number of wires in each strand. Ropes of this class are more flexible than the 6x19 Class, but their resistance to abrasion is less than the 6x19 Class ropes.

The designation 6x36 is only nominal, as is the case with 6x19 Class. Ropes in the 6x36 Class may contain 27 to 49 wires per strand. Improvements in wire rope design, as well as changing machine designs, resulted in the use of strands with widely varying numbers of wires and geometry.

Larger wire ropes frequently incorporate a larger number of wires, resulting in a more complex geometry than found in the 6x19 or 6x36 Class wire ropes. WW’s 6x61 Class Bethlehem Mining Ropes generally are designed to comply with ASTM A 1023 geometry, although we added some innovations. WW strands the 6x61 Class Bethlehem Mining Ropes in a single operation, relying on dense, well fitted geometry to provide exceptional rope performance and the flexibility normally associated with 6x61 Class ropes.

The 6x61 Class ropes have a Seale-Filler Wire-Seale design, as shown in the cross sections below, containing from 50 to 77 wires per strand. WW further enhances Bethlehem Mining Rope performance by wire metallurgy and wire properties which are selectively modified to augment the specific rope geometries.

Many wire rope users have observed that heavily loaded ropes fail internally due to the failure of the IWRC. Such conditions illustrate that heavy IWRC stresses exist, which promote fewer fatigue cycles and create short rope life. WW designed Maxi-core to improve rope life under these conditions.

Maxi-core utilizes an IWRC design which features eight strands around a strand center. Maxi-core’s IWRC provides longer life, and, therefore, increases the overall service life of the rope. Because of its specialized IWRC, Maxi-core is resilient and able to accommodate shock loads better than conventional IWRC designs. Maxi-core also adds 33% more core support to the outer strands, thereby reducing internal stresses and promoting longer rope life. As with all Bethlehem Excavator Family Ropes, WW does not publish Maxi-core rope strengths. WW relies on specific rope improvements and specialized features to provide rope designs which give proven, superior field service.

This plastic jacket acts as a cushion or shock absorber between adjacent main strands and at main strand-to-IWRC contact points. The improved internal support is especially significant for ropes subjected to continual bending stresses and fluctuating loads (shock loading). Reduction of wear and damage at internal contact points results in longer and more predictable service life.

Compacted Strands: Beth Pac Beth Pac refers to rope manufactured by compacting each individual strand before closing the rope. In comparison to conventional wire rope, Beth Pac has a higher metallic area, improved crushing resistance and a smoother surface contacting sheaves and drums.

Beth Pac is offered in Excavator and Excavator-AR in diameters 21/4" through 23/4" in 8x36 construction for hoist ropes. Beth Pac can be combined with other Bethlehem Mining Rope features, such as En-core. For more information and help in determining your need for Beth Pac and other available sizes, please contact WW’s Sales and Engineering Departments.

BXL is furnished as right regular or lang lay, Form-set, IWRC wire rope manufactured in the 6x19, 6x36 and 8x36 Classes. Available grades are Excavator and Excavator-AR. For specific information, please refer to the table. For information on smaller diameters for mining applications, please contact our Customer Service Department.

BXL provides the characteristics common to Bethlehem Mining Rope, enhanced by the plastic-infusion. BXL starts with WW’s special wire grades used in the manufacture of mining rope. Excavator grade is designed to provide excellent resistance to bending fatigue, such as those conditions found with hoist ropes. Excavator-AR is intended for those applications where more abrasive operating conditions exist, such as in drag line applications. Enhanced by plastic infusion, BXL offers several improved features.

Improved fatigue resistance is one key feature of BXL. BXL’s polymer cushions each wire and strand, minimizing interstrand and interlayer nicking. BXL also offers improved abrasion resistance. The polymer acts as a barrier between the individual strands, preventing penetration of any adverse material, such as dust, dirt and metal particles. The polymer also distributes and reduces contact stresses between the rope and sheave, reducing the wire rope wear normally associated with uncoated wire rope. Perhaps the most important feature of BXL, however, is the polymer’s ability to maintain the balance of the rope. When a rope is in operation, or simply wound upon a drum, the rope’s components move and adjust accordingly.

Due to the nature of wire rope, this movement may cause accelerated wear, and in uncoated rope, may also produce a flattening or ovaling of the rope. The polymer in BXL minimizes this movement by locking the individual wires and strands in place. With the rope’s holding its intended shape during operation, operating stresses such as vibration are evenly distributed to all wires and strands, thereby reducing fatigue breaks and increasing service life.

This rope is particularly suitable where severe crushing and abrasion on a drum occur, or where a higher strength design is required than can be obtained with a similar round strand rope. The triangular strand shape not only provides better resistance to crushing, but also offers a greater exposed surface area for contact with sheaves, drums or underlying areas of spooled rope.

This feature, combined with Lang lay, distributes the abrasive wear over a greater number and longer length of wires. The broad, smooth surface of the rope also helps to minimize wear on drums and sheaves.

We make a full line of tail ropes customized to meet your requirements of strength and weight to balance your friction hoist system. Please contact your salesman or customer service with your specifications and we will supply a quotation to meet your needs.

We stock a large variety of rigging gear and hardware. Our in-house services include inspection, test, and certifying of slings and rigging gear. We also offer on-site inspection of rigging, of rolex replica slings and rigging gear, on-site inspection of rigging, and pickup and delivery. We can have any of our experienced sales staff go on-site and assist with determining the best way to handle your lifting needs. We also offer an on site class on proper rigging gear inspection.

PersonalWe are on hand to personally guide you through the entire process, we translate the jargon, we recommend what’s best, and we are always here in person. No nonsense, just straight talking people who always exceed expectations through our extensive wire rope knowledge and superior service.

Type 304 stainless steel is the standard alloy for use in wire rope and cable. It has about the same strength as galvanized wire rope or cable but is much more corrosion resistant. It can be used in most industrial atmospheres and has acceptable corrosion resistance when used in marine and salt water.

316 grade stainless steel is the standard high-corrosion-resistant steel for wire rope and cable. It is resistant to many chemicals in the pulp and paper, photographic, food processing, and textile industries. Type 316 stainless steel wire rope has the best pitting resistance in marine and salt water, and can be used in temperatures up to 900 degrees Fahrenheit.

The vast majority of wire rope specifications are designated with 316 or 304 (and sometimes 302 grade). The basic difference is in the elements that comprise the alloy itself—and 316 stainless wire rope is known to be more corrosion-resistant than 304.

Commonly used in aircraft controls, sailboat rigging, winches, and garage doors, a 7x19 stainless steel wire rope is made up of seven strands with 19 wires in each strand—approximately twice as flexible as a 7x7 construction. Also available in USA-made.

With nearly 4,000 employees worldwide, WireCo WorldGroup is a great place for you to build a rewarding career. Our professionals enjoy the opportunities of a global manufacturing and distribution leader as well as a culture of open communication, professional growth, and friendly camaraderie that fosters innovation and problem solving.

In addition, there is the special class (designated class, Class C) category: 195 kgf/mm2 (1910 N/mm2) grade or higher. These are products that were developed jointly by a manufacturer of construction machinery or elevators and a rope manufacturer. In general the ordinary sale of these products is prohibited by an agreement between the manufacturers at the time of development. Many TADANO products use special class (designated class, Class C) wire ropes.

Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:Strength

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope, and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

A wire rope is, in reality, a very complicated machine. A typical 6 x 25 rope has 150 wires in its outer strands, all of which move independently and together in a very complicated pattern around the core as the rope bends. Clearances between wires and strands are balanced when a rope is designed so that proper bearing clearances will exist to permit internal movement and adjustment of wires and strands when the rope has to bend. These clearances will vary as bending occurs, but are of the same range as the clearances found in automobile engine bearings.

Understanding and accepting the “machine idea” gives a rope user a greater respect for rope, and enables them to obtain better performance and longer useful life from rope applications. Anyone who uses a rope can use it more efficiently and effectively when they fully understand the machine concept.

Wires are the smallest component of wire rope and they make up the individual strands in the rope. Wires can be made from a variety of metal materials including steel, iron, stainless steel, monel, and bronze. The wires can be manufactured in a variety of grades that relate to the strength, resistance to wear, fatigue resistance, corrosion resistance, and curve of the wire rope.

Strands of wire rope consist of two or more wires arranged and twisted in a specific arrangement. The individual strands are then laid in a helical pattern around the core of the rope.

The core of a wire rope runs through the center of the rope and supports the strands and helps to maintain their relative position under loading and bending stresses. Cores can be made from a number of different materials including natural or synthetic fibers and steel.

Lubrication is applied during the manufacturing process and penetrates all the way to the core. Wire rope lubrication has two primary benefits:Reduces friction as the individual wires and strands move over each other

The number of layers of wires, the number of wires per layer, and the size of the wires per layer all affect the strand pattern type. Wire rope can be constructed using one of the following patterns, or can be constructed using two or more of the patterns below.Single Layer – The most common example is a 7 wire strand with a single-wire center and six wires of the same diameter around it.

Filler Wire – Two layers of uniform-size wire around a center with the inner layer having half the number of wires as the outer layer. Small filler wires, equal to the number in the inner layer, are laid in valleys of the inner wire.

Seale – Two layers of wires around a center with the same number of wires in each layer. All wires in each layer are the same diameter. The large outer wires rest in the valleys between the smaller inner wires.

Warrington – Two layers of wires around a center with one diameter of wire in the inner layer, and two diameters of wire alternating large and small in the outer later. The larger outer-layer wires rest in the valleys, and the smaller ones on the crowns of the inner layer.

On a preformed wire rope, the strands and wires are formed during the manufacturing process to the helical shape that they will take in a finished wire rope.

Preformed rope can be advantageous in certain applications where it needs to spool more uniformly on a drum, needs greater flexibility, or requires more fatigue-resistance when bending.

Direction and type of lay refer to the way the wires are laid to form a strand (either right or left) and how the strands are laid around the core (regular lay, lang lay, or alternate lay).Regular Lay – The wires line up with the axis of the rope. The direction of the wire lay in the strand is opposite to the direction of the strand lay. Regular lay ropes are more resistant to crushing forces, are more naturally rotation-resistant, and also spool better in a drum than lang lay ropes.

Lang Lay– The wires form an angle with the axis of the rope. The wire lay and strand lay around the core in the same direction. Lang Lay ropes have a greater fatigue-resistance and are more resistant to abrasion.

A steel core can be an independent wire rope or an individual strand. Steel cores are best suited for applications where a fiber core may not provide adequate support, or in an operating environment where temperatures could exceed 180° F.

The classifications of wire rope provide the total number of strands, as well as a nominal or exact number of wires in each strand. These are general classifications and may or may not reflect the actual construction of the strands. However, all wire ropes of the same size and wire grade in each classification will have the SAME strength and weight ratings and usually the same pricing.

Besides the general classifications of wire rope, there are other types of wire rope that are special construction and designed for special lifting applications.

Some types of wire rope, especially lang lay wire rope, are more susceptible to rotation when under load. Rotation resistant wire rope is designed to resist twisting, spinning, or rotating and can be used in a single line or multi-part system.

Special care must be taken when handling, unreeling, and installing rotation resistant wire rope. Improper handling or spooling can introduce twist into the rope which can cause uncontrolled rotation.

Compacted strand wire rope is manufactured using strands that have been compacted, reducing the outer diameter of the entire strand, by means of passing through a die or rollers. This process occurs prior to closing of the rope.

This process flattens the surface of the outer wires in the strand, but also increases the density of the strand. This results in a smoother outer surface and increases the strength compared to comparable round wire rope (comparing same diameter and classification), while also helping to extend the surface life due to increased wear resistance.

A swaged wire rope differs from a compacted strand wire rope, in that a swaged wire rope’s diameter is compacted, or reduced, by a rotary swager machine after the wire rope has been closed. A swaged wire rope can be manufactured using round or compacted strands.

The advantages of a swaged wire rope are that they are more resistant to wear, have better crushing resistance, and high strength compared to a round strand wire rope of equal diameter and classification. However, a swaged wire rope may have less bending fatigue resistance.

A plastic coating can be applied to the exterior surface of a wire rope to provide protection against abrasion, wear, and other environmental factors that may cause corrosion. However, because you can’t see the individual strands and wires underneath the plastic coating, they can be difficult to inspect.

Plastic filled wire ropes are impregnated with a matrix of plastic where the internal spaces between the strands and wires are filled. Plastic filling helps to improve bending fatigue by reducing the wear internally and externally. Plastic filled wire ropes are used for demanding lifting applications.

This type of wire rope uses an Independent Wire Rope Core (IWRC) that is either filled with plastic or coated in plastic to reduce internal wear and increase bending fatigue life.

Remember, wire rope is a complex piece of mechanical machinery. There are a number of different specifications and properties that can affect the performance and service life of wire rope. Consider the following when specifying the best type of wire rope for your lifting application:Strength

When you select a piece of rope that is resistant to one property, you will most likely have a trade-off that affects another property. For example, a fiber core rope will be more flexible, but may have less crushing resistance. A rope with larger diameter wires will be more abrasion resistant, but will offer less fatigue resistance.

At Mazzella Companies, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

If you’re looking for a standard or custom specified wire rope for your lifting project, contact a Lifting Specialist at a Mazzella Companies location near you.

We stock well over 2,000,000 feet of wire rope in our various locations … ready for immediate delivery! We provide wire rope assemblies, and manufacture bridge cables, crane cables, steel mill cables, and thousands of OEM assemblies.

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possible. When a reverse bend is necessary larger sheaves are required than would be the case if the rope were bent in one direction only.

Stretch of Wire Rope The stretch of a wire rope under load is the result of two components: the structural stretch and the elastic stretch. Structural stretch of wire rope is caused by the lengthening of the rope lay, compression of the core and adjustment of the wires and strands to the load placed upon the wire rope. The elastic stretch is caused by elongation of the wires.

The structural stretch varies with the size of core, the lengths of lays and the construction of the rope. This stretch also varies with the loads imposed and the amount of bending to which the rope is subjected. For estimating this stretch the value of one-half percent, or .005 times the length of the rope under load, gives an approximate figure. If loads are light, one-quarter percent or .0025 times the rope length may be used. With heavy loads, this stretch may approach one percent, or .01 times the rope length.

The elastic stretch of a wire rope is directly proportional to the load and the length of rope under load, and inversely proportional to the metallic area and modulus of elasticity. This applies only to loads that do not exceed the elastic limit of a wire rope. The elastic limit of stainless steel wire rope is approximately 60% of its breaking strength and for galvanized ropes it is approximately 50%.

Preformed Wire Ropes Preformed ropes differ from the standard, or non-preformed ropes, in that the individual wires in the strands and the strands in the rope are preformed, or pre-shaped to their proper shape before they are assembled in the finished rope.

This, in turn, results in preformed wire ropes having the following characteristics:They can be cut without the seizings necessary to retain the rope structure of non-preformed ropes.

They are substantially free from liveliness and twisting tendencies. This makes installation and handling easier, and lessens the likelihood of damage to the rope from kinking or fouling. Preforming permits the more general use of Lang lay and wire core constructions.

Removal of internal stresses increase resistance to fatigue from bending. This results in increased service where ability to withstand bending is the important requirement. It also permits the use of ropes with larger outer wires, when increased wear resistance is desired.

Outer wires will wear thinner before breaking, and broken wire ends will not protrude from the rope to injure worker’s hands, to nick and distort adjacent wires, or to wear sheaves and drums. Because of the fact that broken wire ends do not porcupine, they are not as noticeable as they are in non-preformed ropes. This necessitates the use of greater care when inspecting worn preformed ropes, to determine their true condition.

8613371530291

8613371530291