wire rope diameter measurement supplier

Rope diameter is specified by the user and is generally given in the equipment manufacturer’s instruction manual accompanying the machine on which the rope is to be used.

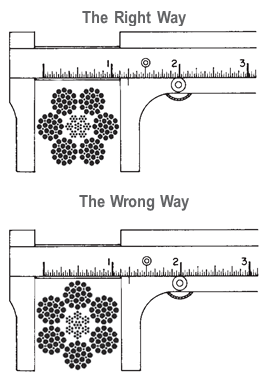

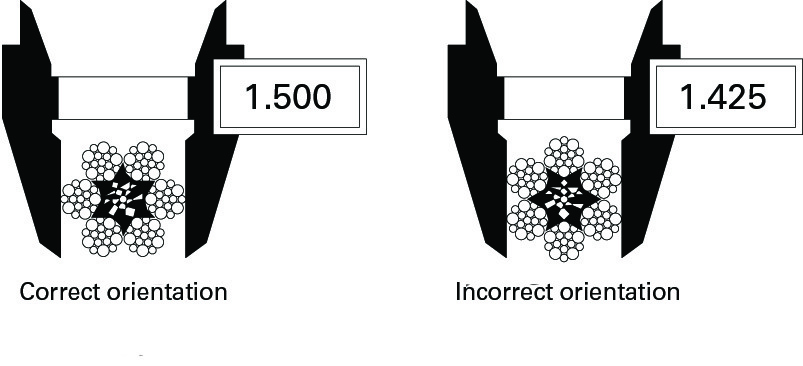

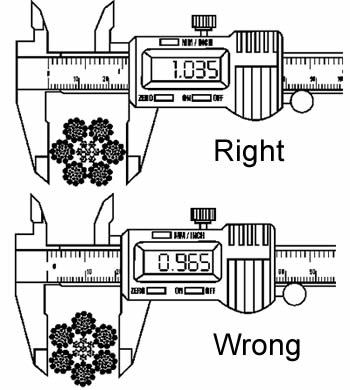

Rope diameters are determined by measuring the circle that just touches the extreme outer limits of the strands— that is, the greatest dimension that can be measured with a pair of parallel-jawed calipers or machinist’s caliper square. A mistake could be made by measuring the smaller dimension.

You should make the measurement carefully with calipers. The illustrations at left show the correct and incorrect methods of measuring a wire rope’s diameter.

As we move toward metric measurements, it will become increasingly necessary to convert English units into SI – International System of Units – (or metrics), and vice versa. The following table and conversion factors are included in this handbook to help you.

In measuring rope diameter, the industry is leaning toward a “soft” conversion to metric during the transition period. For example, a 1” diameter rope converts to 25.4 mm in metrics. Using the soft conversion, this changes to the whole metric size that most nearly parallel the 1” size range, or 26 mm. In sizes smaller than 5/8”, the rope diameter is rounded to the nearest 0.5 mm.

The following table gives the closest equivalent metric diameters for rope sizes up through 5 inches. Again, these metric sizes are based on the industry’s “soft” conversion.

Since rope minimum breaking force and weight per unit of length vary for different types and grade of ropes, the following conversion factors are given to help you convert the figures you need:

Note: TheNewton(a unit of force) is the correct unit for measurement of minimum breaking force in the SI system of units. We have included a conversion factor from tons to kilograms because a rope’s minimum breaking force is often referred to regarding kilograms (a unit of mass).

Use of design factors provides rope installations with reasonable assurance of adequate capacity for the work to be done throughout a rope’s service life. Considerations in establishing design factors include the type of service, the design of equipment and consequences of failure.

In most applications, the selection of a rope based on the proper design factor has been made by the equipment manufacturer. In an application where a different rope is to be used, or in a new application, check government and industry regulations for the required design factor. Different rope types on the same application may have different design factor requirements.

Standards and regulations require that design factors be applied to the rope’s minimum breaking force to determine the maximum working load. To determine the maximum working load for which an operating rope may be used, divide the rope’s minimum breaking force by the required design factor. This equation is the rope’s maximum working load. There may be other limiting factors in an application that make the maximum load the equipment can handle less than the rope’s maximum working load.*

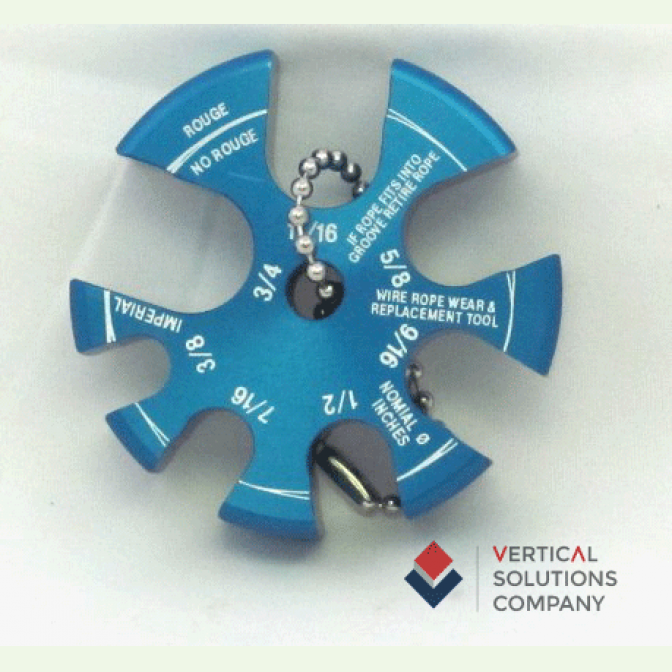

Made of Marine-grade 316 Stainless steel for years of reliable service. With this pocket sized tool you can measure rope, wire, cable and fasteners quickly and accurately. Metric and imperial scales are etched into the surface for an accurate measurement ship or shore.

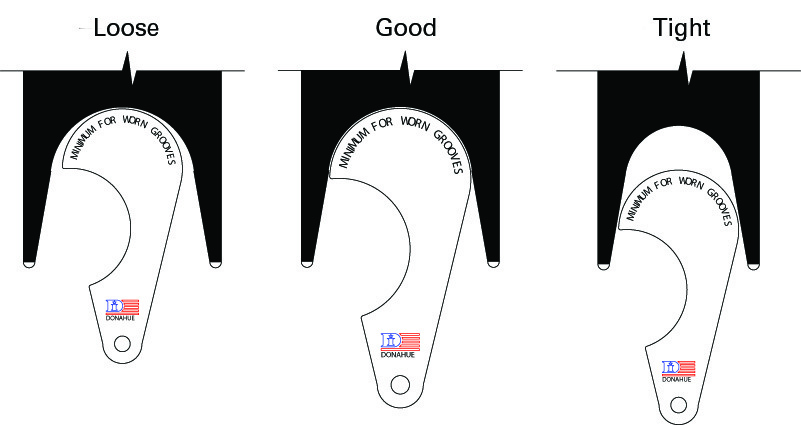

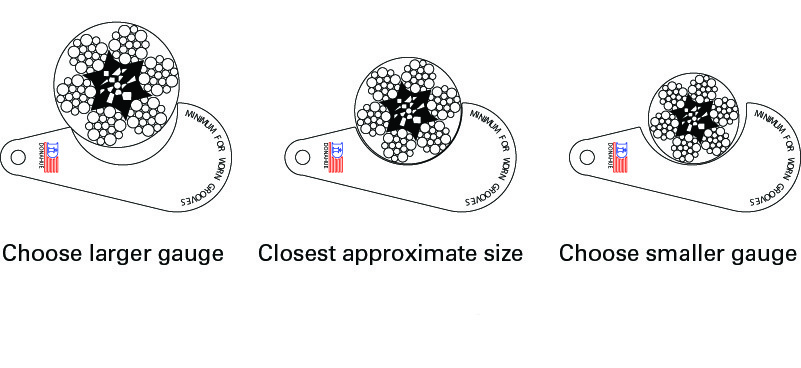

Stainless steel wire rope and sheave gauges for measuring worn sheave grooves on the end, together with a rope gauge on the shank. The gauges are produced in thick 18 gauge (0.05") Stainless Steel.Click here to Order

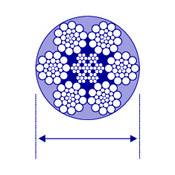

When measuring the wire rope diameter, it is important to measure around the widest part of the rope. The following diagram illustrates the correct way to measure the wire rope diameter:

The Nominal Diameter is the diameter that the manufacturer designates to a rope. The test certificate will provide this information. The nominal diameter is important during an inspection, as it used to determine the level of damage due to wear.

The reference diameter is measured around a section of rope that is not subject to bending after a rope has been broken in. The reference diameter is also included in the calculation to determine the level of wear displayed by a rope.

The measured diameter is taken at a specific position during inspection. Unlike the other two forms of diameter, this value will change as the rope is subject to more extended wear.

Mainly used in a variety of wires, cables, pipe production line, the measurement ofouter diameter and adjust the extruder screw speed or traction speed, to control thepurpose of OD. Can also be applied to the outer diameter of workpiece and sizemeasurements.

Looking for proper measuring wire diameter measuring gauge just to find lots of cheek gauges, ear weights, tunnel plugs, earring gauges, ear gauge plugs, edgy small gauges, and other earlobe stretching tools? Well, while a shiny pair of diamond gauges may look incredibly cool on you, they might not exactly be what you"re looking for right now... To buy measuring and tools wire diameter measuring gauge, head straight here to Alibaba.com (you buy piercings too!). Here, you"ll find a large selection of wholesale wire diameter measuring gauge at amazingly affordable prices.

This listing includes the late hot picks and industry trends on wire diameter measuring gauge. Compare tons of popular suppliers with international shipping and nice products. Just browse through all the pictures, product descriptions, and details to find your match. These wire diameter measuring gauge are accurate and easy to use. They provide an exact measurement and reading, suitable for a range of activities and works. Search and filter to find the exact type of wire diameter measuring gauge that you need and check out all the discounts to save as much as you can on your purchase! The products shown here are often discounted with great promos and sales. Shipping options are also varied and widely convenient, you can find free shipping and other ways to get your order right at your door with zero hassle for you.

Straightforward design and use: As a universal go-no-go gauge, if a specific portion of wire is suspected of wear, or rouging, simply place the gauge slot for that particular original diameter over the rope crowns on a straight section. If the rope will not enter the slot, its diameter is considered satisfactory.

Industrial wire ropes are designed for extreme resilience and strength. They can withstand thousands of pounds of pressure and be used on all types of applications. However, issues with the wire rope installation process can significantly decrease its longevity and even its capacity and durability.

When wire ropes are not used properly, it can create an unsafe environment. The rope can snap, even if the load it’s supporting is below its maximum load limit. In anoted by the IMCA (International Marine Contractors Association), a wire rope sling rope broke due to improper installation. A crew member was seriously injured after the sling disconnected and hit the worker.

Many of these common accidents are easily avoidable through correct wire rope installation. Here are five of the most common mistakes made and how to prevent them on your worksite.

Determining the diameter of the wire rope is an essential step of the installation process. Installers are required to double-check that the correct diameter rope is being used, as this impacts the rope’s breaking strength and load limit.

Wire ropes are measured with a parallel-jawed caliper (also called a machinist’s caliper). This is placed over the wire rope to measure the diameter – but if the rope is inserted at the wrong angle, you will get an inaccurate result.

The strands of a wire rope must be flush against the measuring portion of the caliper. If a raised strand is at the top, the measurement will have a smaller dimension, which could affect breaking strength calculations.

Wire ropes are reeled onto these spools for easy handling and shipments, as it prevents the rope from getting tangled or crushed. But unreeling the wire rope incorrectly can cause severe damage, such as snagged wires, twists, kinks, or unraveled strands.

A common mistake that is often made is to unreel the wire rope by laying the spool vertically on its axis. The wire rope has to be yanked off of the spool, which increases the likelihood of it getting kinked or twisted. The wire rope should also not touch the ground as it is unreeled, as this could damage the wires as well.

Instead, the reeled wire rope should be placed on a shaft that allows the spool to turn 360°. It also should require two people, one to slowly pull the rope off of the spool in a straight line and another to regulate the speed by controlling the turn rate.

Occasionally ais added during wire rope installation to create a load-bearing eye or to connect two cables together. These small but mighty pieces only diminish a wire rope’s strength by around 10%, if they are added correctly.

These little issues can cause the wire rope to slip out of the clip. It is very important to follow the directions and use the right number of clips with the correct spacing in-between, depending on the rope’s diameter and approximate load weight.

Sometimes a damaged wire rope can be repaired through a method called seizing. First, the rope is cut at a straight angle, then a wire is tightly wound around this end to prevent the strands from unraveling.

Two methods can be used to securely seize a wire rope. First, it can be placed at a right angle between the starting and ending point of the seizing. The wire is then wrapped around this angled piece to hold it in place, and the ends are twisted together to secure it. Another option is to wrap the seizing wire around and twist the two end pieces together, creating a tourniquet type of attachment.

The type of end preparations recommended depends on several factors. This includes the diameter of the rope and the number of wires and strands. In some cases, double seizing and fuse welding is required for additional securement. Failing to follow these instructions could result in the core or strands of the wire rope to slip and unravel.

Although wire ropes are usually damaged due to improper use, they can get ruined during storage as well. Failing to follow through with routine maintenance and storage recommendations could cause the wire rope to rust, unravel, or kink. Further, keeping your wire rope on the ground, in wet areas, or directly in hot sunlight can cause it to break down faster.

the right way can improve their long-term performance and use. This includes following all instructions during wire rope installation, as well as storage and upkeep. Wire ropes should be cleaned before going into storage and may need lubricant from time to time to protect the wires from drying out.

Wire ropes are intended to be a strong, reliable piece of industrial hardware. There is no reason to compromise its durability due to simple installation mistakes. By avoiding these common mishaps, you can ensure a far safer work environment and also extend the use of your wire ropes.

Another tip is to start by purchasing top-quality hardware from a trusted wire rope supplier. Elite Sales is proud to carry a vast selection of wire rope sizes, styles, and finishes that are made to fit many applications.

Donahue Industries, Inc. is a full service international metal stamping manufacturer in Massachusetts specializing in parts for the grinding wheel and wire rope industries.

Donahue Industries, Inc. is a full service international metal stamping manufacturer in Massachusetts specializing in parts for the grinding wheel and wire rope industries.

Ropes come in many different diameters and there are guidelines to help you choose the right diameter for your purpose. But how do you know which diameter the halyards and sheets on your boat are? How do you measure the diameter?

The diameter of a rope is based on the combination between the construction of the rope and the amount of material used. A rope can be heavy and compact, or light and loosely braided. This influences the properties of the rope and therefore can affect the measurement of the size. A loosely braided rope gets thinner and flattens out under load, whereas a compact rope with more fibres will keep its shape. This is why measuring the diameter when the rope is under load will have different result as to when the rope is not loaded.

Due to this, the diameter of rope is less precise than with steel wire. Determining a diameter for ropes is an empirical process. This means that every manufacturer develops and adapts a rope, based on observation and experience. This causes the possibility for small differences between ropes with, according to the specification, the same diameter. A rope that is specified as a 10mm rope can therefore sometimes be 9mm or in other cases 11mm.

The greatest difference can be seen in the length of the measured rope when comparing it at a tensioned and untensioned state. Tests have shown an approximate 2% difference in length is found with 12-strand AmSteel®-Blue when tension is used during

measurement compared to an untensioned rope. Greater variability was seen with untensioned measurements, with as much as 2% of the same rope’s length but when tensioned that difference dropped to 0.5%. The amount of variation seen between tensioned

and untensioned ropes will also be affected by the material and construction of each rope.Necessary Rope Measuring Procedures:Supply constant, even tension (no more than 10 lb is needed) to all diameter ropes.

When no tensioning device is available, laying the rope to the complete required length on a flat surface, and tensioning it with hand force while measuring the full length will reduce the variability and difference in length.

8613371530291

8613371530291