wire rope diameter measurement in stock

Ropes come in many different diameters and there are guidelines to help you choose the right diameter for your purpose. But how do you know which diameter the halyards and sheets on your boat are? How do you measure the diameter?

The diameter of a rope is based on the combination between the construction of the rope and the amount of material used. A rope can be heavy and compact, or light and loosely braided. This influences the properties of the rope and therefore can affect the measurement of the size. A loosely braided rope gets thinner and flattens out under load, whereas a compact rope with more fibres will keep its shape. This is why measuring the diameter when the rope is under load will have different result as to when the rope is not loaded.

Due to this, the diameter of rope is less precise than with steel wire. Determining a diameter for ropes is an empirical process. This means that every manufacturer develops and adapts a rope, based on observation and experience. This causes the possibility for small differences between ropes with, according to the specification, the same diameter. A rope that is specified as a 10mm rope can therefore sometimes be 9mm or in other cases 11mm.

Made of Marine-grade 316 Stainless steel for years of reliable service. With this pocket sized tool you can measure rope, wire, cable and fasteners quickly and accurately. Metric and imperial scales are etched into the surface for an accurate measurement ship or shore.

Mainly used in a variety of wires, cables, pipe production line, the measurement ofouter diameter and adjust the extruder screw speed or traction speed, to control thepurpose of OD. Can also be applied to the outer diameter of workpiece and sizemeasurements.

In order to ensure optimal performance of sheaves and wire rope a complete range of sheave gauges should be used. We stock gauges in the following formats:

+5% Sheave Gauges are legacy format. They should fit snugly in new or re-machined sheaves. If correctly sized wire rope is run through the sheaves there will be a minimum of friction which should extend the life of the wire rope.

Laid rope was always calibrated by circumference, whether you work in imperial or metric unit. The reason is very simple that any other method would give differing results depending on where you measure - just try this with a vernier caliper and turn the rope: the measured diameter will change as you turn it. You could use a gauge with holes, but keeping such gauge e.g. on board a ship would be inconvenient. It was easier to wind a thread say ten times around a rope and then measure its length, divided by ten it gives you the circumference.

When wire rope and then later braided fibre-rope came into use, measuring diameters became physically possible. However, well into the 20th century wire rope was sold by circumference.

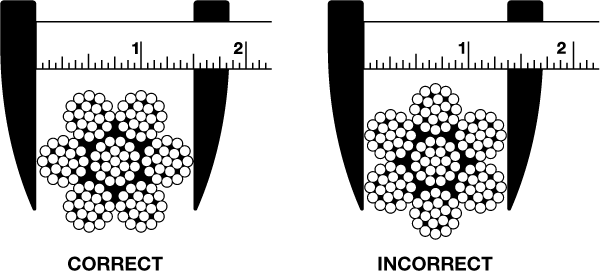

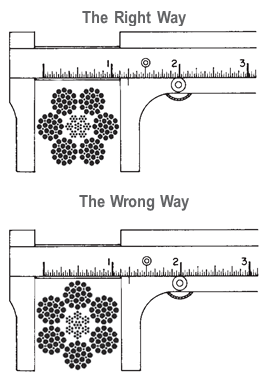

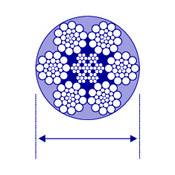

The actual diameter of a wire rope is the diameter of a circumscribed circle that will enclose all the strands. It ‘s the largest cross-sectional measurement as shown here. You should make the measurement carefully with calipers.

As we move toward metric measurements, it will become increasingly necessary to convert English units into Sl – International System of Units – (or metrics), and vice versa.

For standard, general purpose wire ropes, in measuring diameter, the industry is leaning toward a “soft” conversion to metric during the transition period. For example, a 1″ diameter rope converts to 25.4 mm in metrics. Using the soft conversion, this is changed to the whole metric size that most nearly parallels the 1″ size range, or 26 mm. In sizes smaller than 5/8′: the rope diameter is rounded to the nearest 0.5 mm.

The following table gives the closest equivalent metric diameters for rope sizes up through 5 inches. Again , these metric sizes are based on the industry’s “soft” conversion. Your application may have tighter tolerances that require a hard conversion. Therefore, the values in the table would not apply.

Since rope minimum breaking force and weight per unit of length vary for different types and grade of ropes, the following conversion factors are given to help you convert the figures you need:

Note: The newton (a unit of force) is the correct unit for measurement of minimum breaking force in the Sl system of units. We have included a conversion f

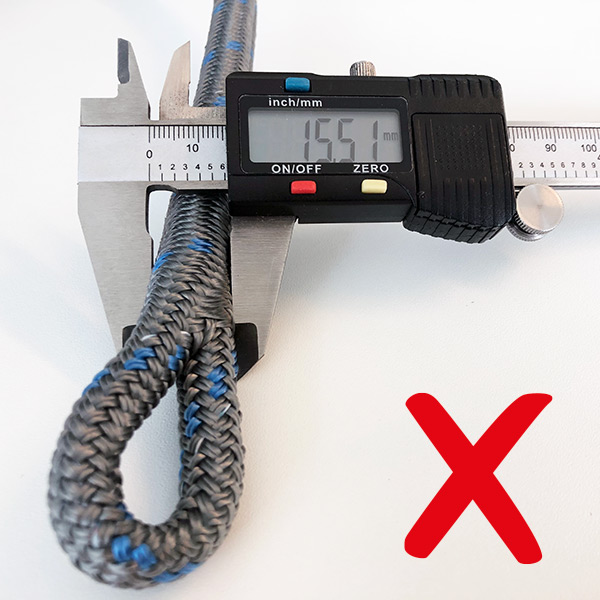

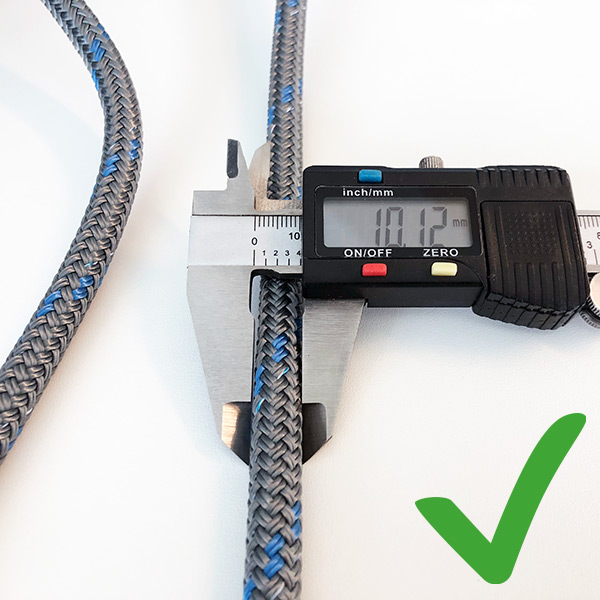

The rope diameter shall always be checked before installation. Measure a straight part of the rope. Two parts with minimum distance of one meter shall at least be measured. By every point two measurements shall be done, with 90 degrees displacement in relation to each other. The average between the two measurements shall be according to the tolerance in the tables below.

The greatest difference can be seen in the length of the measured rope when comparing it at a tensioned and untensioned state. Tests have shown an approximate 2% difference in length is found with 12-strand AmSteel®-Blue when tension is used during

measurement compared to an untensioned rope. Greater variability was seen with untensioned measurements, with as much as 2% of the same rope’s length but when tensioned that difference dropped to 0.5%. The amount of variation seen between tensioned

and untensioned ropes will also be affected by the material and construction of each rope.Necessary Rope Measuring Procedures:Supply constant, even tension (no more than 10 lb is needed) to all diameter ropes.

When no tensioning device is available, laying the rope to the complete required length on a flat surface, and tensioning it with hand force while measuring the full length will reduce the variability and difference in length.

Website designed & operated by DIELLE S.r.l. - Business Registration Office & Number: NA-483734 - European VAT Number: IT01523381216 - Fiscal Code: 06308490637 - Paid-up Capital: € 81.600 - D-U-N-S: 440178051.

Copyright 2020 by DIELLE SRL Industrial Automation. All product names, logos, and brands are property of their respective owners. All company, product and service names used in this website are for identification purposes only. Use of these names, logos, and brands does not imply endorsement.

8613371530291

8613371530291