wire rope diameter measurement brands

To see which colors and types of rope are available for retail sale in each diameter, please visit the collections below. You can also filter rope by color or rope size using the side menu bar on any rope collection page.

Rope Size: Diameter and circumference are nominal. A new, unused rope in a relaxed state will measure larger; loading and use compacts ropes, sets splices, and lessens rope size. This is especially prevalent in rope sizes above 4" diameter. Published nominal sizes from 4-1/8" and larger represent stabilized or preloaded size.

Ravenox provides ropes for a variety of markets, from offshore working and lifting lines, tug and salvage, ship and barge mooring lines, mining tow lines, utility and RV winch lines to theatrical rigging lines and commercial fishing lines. Email Ravenox for a quote or for more information for ropes suitable for a variety of market solutions.

The rope diameter shall always be checked before installation. Measure a straight part of the rope. Two parts with minimum distance of one meter shall at least be measured. By every point two measurements shall be done, with 90 degrees displacement in relation to each other. The average between the two measurements shall be according to the tolerance in the tables below.

As already discussed on the ‘Measuring the rope diameter‘ page and on the ‘Break-In-Period‘ page, shortly after installation, the wire rope diameter will slightly decrease. This is normal and is caused by the adjustment of all rope elements when loaded the first time. To evaluate the diameter reduction, you have to measure the rope when new, and you also have to measure the rope after the break in period at a specified load. This gives you a good indication of the magnitude of the initial diameter reduction in your specific application. The diameter reading you took after the break in period should now become your ‘gauge’. Do not compare the rope diameter you are about to take with the ‘catalogue’ diameter. It may give you a false indication, since wire rope may have a plus tolerance of up to 4% to 5% over the ‘catalogue’ diameter.

If you detect a further diameter reduction when measuring the rope under the same load condition as after the break in period, it is often due to excessive abrasion of the outside wires, loss of core support, internal or external corrosion, inner wire failures, and/or inner wire abrasion. However, there will always be a normal continuous small decrease in diameter throughout the rope’s service life.

Deciding whether or not a rope is safe is not always a simple matter. A number of different but interrelated conditions must be evaluated. It would be dangerously unwise for an inspector to declare a rope ‘safe’ for continued service simply because its diameter had not reached a certain minimum diameter if, at the same time, other observations led to a different conclusion.

However, ASME, ISO 4309, CSA, other Canadian Provincial H&SA and USA OSHA Regulation have various values published for maximum allowable diameter reductions. They are somewhat confusing as they show diameter reduction values from 3.5% to 9%, and some give reduction values in inch fractions depending on rope nominal diameter.

CLEVELAND, OH – Wire rope inspection is a vital part of the maintenance process for any company using mobile crane equipment because the safety of your workers and secure delivery of lifted loads is of utmost importance.

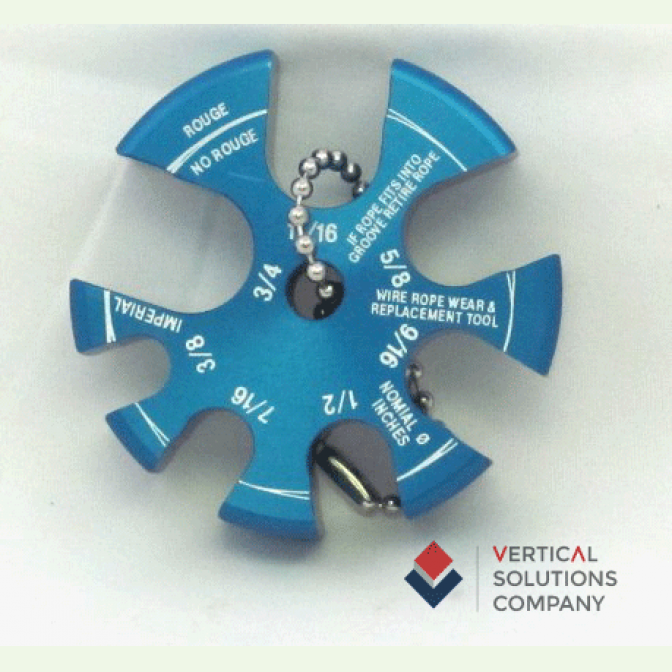

“The reason we decided to make our own inspection kit is because there really wasn’t anything like this on the market,” said Tyler Henley, a Mazzella crane ropes specialist. “We had a lot of customers that requested inspection kits like the kits our inspectors use in the field.

“Some of our certified wire rope inspectors that go on location to survey cranes and measure wire rope in the field have tools similar to this, but we never really had a dedicated kit that we could sell to customers or supply to our internal inspectors. This is very specific to mobile cranes and wire rope. Everything in the kit has a purpose, and is made for a particular reason.”

The four sets of custom-made sheave gauges measure between 16mm and 32.5mm, and are machined to specific tolerances to ensure accuracy. The special wide-jaw calipers help ensure proper measurement of wire rope’s diameter in the field.

The pick set is designed for inspecting between the wire rope strands and checking for tightness, while the metric steel rulers are used to measure waviness and kinks.

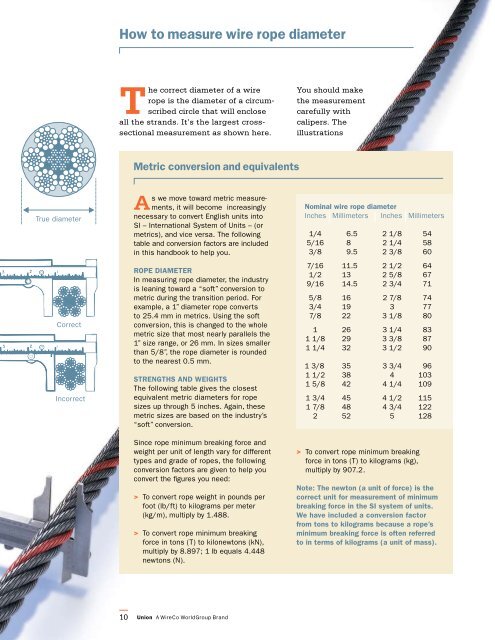

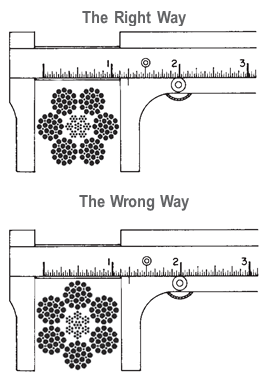

You should make the measurement carefully with calipers. The illustrations at left show the correct and incorrect methods of measuring a wire rope’s diameter.

As we move toward metric measurements, it will become increasingly necessary to convert English units into SI – International System of Units – (or metrics), and vice versa. The following table and conversion factors are included in this handbook to help you.

In measuring rope diameter, the industry is leaning toward a “soft” conversion to metric during the transition period. For example, a 1” diameter rope converts to 25.4 mm in metrics. Using the soft conversion, this changes to the whole metric size that most nearly parallel the 1” size range, or 26 mm. In sizes smaller than 5/8”, the rope diameter is rounded to the nearest 0.5 mm.

The following table gives the closest equivalent metric diameters for rope sizes up through 5 inches. Again, these metric sizes are based on the industry’s “soft” conversion.

Since rope minimum breaking force and weight per unit of length vary for different types and grade of ropes, the following conversion factors are given to help you convert the figures you need:

Note: TheNewton(a unit of force) is the correct unit for measurement of minimum breaking force in the SI system of units. We have included a conversion factor from tons to kilograms because a rope’s minimum breaking force is often referred to regarding kilograms (a unit of mass).

Use of design factors provides rope installations with reasonable assurance of adequate capacity for the work to be done throughout a rope’s service life. Considerations in establishing design factors include the type of service, the design of equipment and consequences of failure.

In most applications, the selection of a rope based on the proper design factor has been made by the equipment manufacturer. In an application where a different rope is to be used, or in a new application, check government and industry regulations for the required design factor. Different rope types on the same application may have different design factor requirements.

Standards and regulations require that design factors be applied to the rope’s minimum breaking force to determine the maximum working load. To determine the maximum working load for which an operating rope may be used, divide the rope’s minimum breaking force by the required design factor. This equation is the rope’s maximum working load. There may be other limiting factors in an application that make the maximum load the equipment can handle less than the rope’s maximum working load.*

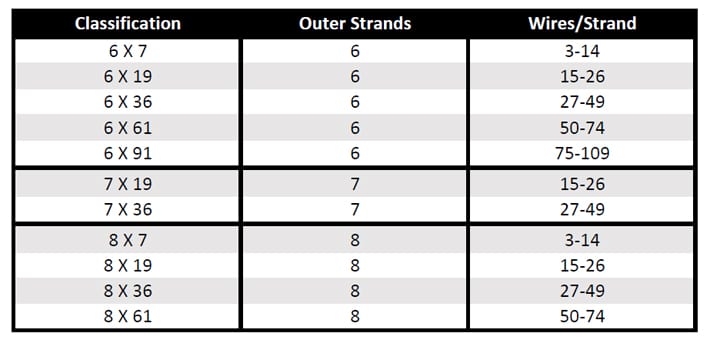

The 6 x 19 classification of wire ropes includes standard 6 strand, round strand ropes with 16 through 26 wires per strand. The 6 x 36 classification of wire ropes includes standard 6 strand, round strand ropes with 27 through 49 wires per strand. Although their operating characteristics vary, all have the same weight per foot and the same nominal strength, size for size.

While the 6 x 19 ropes give primary emphasis to abrasion resistance in varying degrees, the 6 x 36 ropes are important for their fatigue resistance. This fatigue resistance is made possible by the greater number of small wires per strand.

Although there are exceptions for special applications, the constructions in 6 x 36 classification are primarily designed to be the most efficient for each rope diameter. As the rope size increases, for instance, a large number of wires can be used to achieve required fatigue resistance, and still those wires will be large enough to offer adequate resistance to abrasion.

In this construction, each strand has nine outer wires over nine smaller inner wires over one large center wire. A comparison of cross-sections shows that these outside wires are larger than those of the 6 x 25FW or 6 x 26WS. Therefore, its resistance to abrasion is increased, but its fatigue resistance is decreased. This is a good rope to withstand abrasion or crushing on the drum.

To most wire rope users, 6 x 19 means 6 x 25 filler wire. It is the most common rope in the 6 x 19 classification. This rope has a good balance between both abrasion resistance and fatigue resistance in relation to other ropes.

This construction has better resistance to abrasion than a 6 x 25FW. It also features a compact construction with solid support for the wires; hence, it has a high resistance to crushing. Its number and relative size of the inner wires add to the stability of the strand and gives it a fatigue resistance comparable to a 6 x 25FW.

A standard 6 x 26WS construction provides the best rope for a wide range of applications. In general, we recommend the use of a 6 x 26WS in any application where a 6 x 25FW is used.

In most rope sizes, only one 6 x 36 classification rope is made. These constructions were selected to provide fatigue resistance without having wires that are too small.

The greater number of wires in the 6 x 36 classification makes these ropes more susceptible to crushing. This can be minimized, however, by specifying an Independent Wire Rope Core (IWRC) and by using well-designed sheaves, grooved drums and proper operating techniques.

Rotation-resistant ropes can frequently provide the best and most economical service in specific applications when you choose, handle and use them properly.

Contra-helically laid, rotation-resistant ropes are different from standard ropes because they"re designed to reduce rope torque. Modes of failure and wear for rotation-resistant ropes can differ from those for standard rope constructions. The very nature of these ropes requires special handling, selection and usage not encountered with standard constructions. They are susceptible to kinking, crushing and unbalancing in the form of "core pops" and "birdcages" Use extreme care to avoid operational practices that can possibly lead to these conditions.

Rotation-resistant ropes should not be used with swivels that allow rope rotation -- or in single part lifts where the load can rotate. Rotation will cause a reduction in strength, unequal loading in the rope and possible rope unbalance. If any significant change in diameter is found in a short length of a rotation-resistant rope, the rope needs to be replaced.

These ropes should be replaced when you see two randomly distributed crown wire breaks in six rope diameters -- or four randomly distributed crown wire breaks in 30 rope diameters.

Because rotation-resistant ropes are special, there are separate design, maintenance, inspection and removal criteria established for them by applicable industry regulations and standards.

In an application where a single-part hoist rope is used to lift a free load -- or where rotation-resistant properties are essential for rope performance -- the 19 x 7 can be used. Its rotation-resistant characteristic is achieved by laying six strands around a core strand in one direction, then laying 12 strands around the first operation in the opposite direction. Thus, when the rope is in tension, opposing rotational forces are created between the inner and outer layers.

In addition, frequent and regular inspection for broken wires is critical when using this rope. Due to its design, the 19 x 7 construction has a relatively low reserve strength. This can result in short service life between the point in time when the broken wire removal criteria are met and when actual rope failure occurs.

In a multi-part wire rope system where the blocks have a tendency to twist -- or for a single-part hoist line that doesn"t require the degree of rotation-resistant properties found in a 19 x 7 rope -- the 8 x 25 Resistwist rope has found successful application. The rotation-resistant characteristic is achieved by laying the eight outer strands around an independent wire rope core so these strands are in the opposite direction to the lay of the core. Thus, when the rope is in tension, opposing rotational forces are created between the core and the outer strands.

Though not as rotation-resistant, the 8 x 25 Rotation Resistant rope is more stable than a 19 x 7 rope. It also has increased resistance to bending fatigue and crushing. This is achieved through the use of eight-strand construction with an independent wire rope core.

Like any application where an installation"s rope type is changed, the 8 x 25 Rotation Resistant rope should be substituted only after carefully comparing specifications and strength requirements.

You should make the measurement carefully with calipers. The illustrations at left show the correct and incorrect methods of measuring a wire rope’s diameter.

As we move toward metric measurements, it will become increasingly necessary to convert English units into SI – International System of Units – (or metrics), and vice versa. The following table and conversion factors are included in this handbook to help you.

In measuring rope diameter, the industry is leaning toward a “soft” conversion to metric during the transition period. For example, a 1” diameter rope converts to 25.4 mm in metrics. Using the soft conversion, this changes to the whole metric size that most nearly parallel the 1” size range, or 26 mm. In sizes smaller than 5/8”, the rope diameter is rounded to the nearest 0.5 mm.

The following table gives the closest equivalent metric diameters for rope sizes up through 5 inches. Again, these metric sizes are based on the industry’s “soft” conversion.

Since rope minimum breaking force and weight per unit of length vary for different types and grade of ropes, the following conversion factors are given to help you convert the figures you need:

Note: TheNewton(a unit of force) is the correct unit for measurement of minimum breaking force in the SI system of units. We have included a conversion factor from tons to kilograms because a rope’s minimum breaking force is often referred to regarding kilograms (a unit of mass).

Use of design factors provides rope installations with reasonable assurance of adequate capacity for the work to be done throughout a rope’s service life. Considerations in establishing design factors include the type of service, the design of equipment and consequences of failure.

In most applications, the selection of a rope based on the proper design factor has been made by the equipment manufacturer. In an application where a different rope is to be used, or in a new application, check government and industry regulations for the required design factor. Different rope types on the same application may have different design factor requirements.

Standards and regulations require that design factors be applied to the rope’s minimum breaking force to determine the maximum working load. To determine the maximum working load for which an operating rope may be used, divide the rope’s minimum breaking force by the required design factor. This equation is the rope’s maximum working load. There may be other limiting factors in an application that make the maximum load the equipment can handle less than the rope’s maximum working load.*

The amount of yarn per metre is accurately calculated and strictly controlled to produce a finished rope with the correct interacting tension (or lay) at a nominal diameter, normally in 2mm increments in even numbers e.g. 8mm, 10mm, 12mm

Importantly, the final break load of the rope for any given diameter is dependent on the quantity/weight of yarn per metre in the designated construction.

Rope manufacturers publish minimum (or average) break loads for their ropes and therefore all rope production is designed to achieve this rather than concentrating solely on the finished diameter.

Attempting to measure the diameter of a new rope - by eye, with a tape measure or even callipers - before it has stretched out to a working diameter isn"t likely to produce an accurate result.

The true diameter will be more apparent if you hold the rope firmly with one hand, take a firm grip with the other hand and run the rope through your grip without releasing the pressure - a leather glove will protect your hand if required.

Once you have used your new rope, and applied a light load, the interacting weave or lay will elongate to the manufacturer designed structure i.e. it will naturally become slightly thinner and consequently slightly longer. The effect varies across all ropes due to the complex variation of two factors: the construction of the rope and the elasticity of the fibre. This should result in your rope measuring more closely to the nominal diameter.

The amount that it relaxes also depends on the construction of the rope - a closer, tighter weave is generally less affected e.g. 32 plait and conversely, a looser construction will be more affected e.g. 3 strand and 8 strand

Jimmy Green Marine began selling rope in 1981, over 40 years ago, and very quickly realised that customers wouldn"t always appreciate the finer points of rope construction.

We therefore allow for the concertina effect when measuring your order by adding an appropriate percentage according to the elasticity of the rope i.e. the stretchier it is, the more we add on to compensate.

There are many different sizes, configurations, and materials that form wire rope, and these are different types including stainless steel wire rope, galvanized wire rope, and bright wire rope.

Looking for accessories to use with wire ropes? Our rigging supplies include hardware and accessories for use with cranes, hoists & winches, and oilfield applications.

Diameter:To properly measure the diameter of steel wire ropes, measure the rope at its widest point. This is an industry standard with wire cable manufacturers and steel cable suppliers.

Grade of Steel – EIPS, EEIPS: EIPS is Extra Improved Plowed Steel and has roughly 10% more strength than IPS. EEIPS is Extra Extra Improved Plowed Steel and is approximately 10% stronger than the EIPS. We offer every variety of EIPS Wire Rope and have a one day lead time on any EEIPS ropes.

Direction of Lay: Right hand and left hand designates which way the strands wrap around the core of the steel rope. Regular lay and Lang lay specify which way the wires are formed in the helix pattern. Regular lay means the wires are rotated opposite the direction of the strands around the core. Lang lay means the wires are twisted in the same direction as the strands are wrapped around the wire rope core.

Finish – Bright Wire, Galvanized Wire, and Stainless Steel: Most wire ropes have a bright, self-colored finish hence the name. Wire ropes generally have a coating of lubricant to reduce friction and protect from corrosion. However, there are wire ropes that are galvanized, stainless steel, or coated in vinyl and other plastics.

Material of the Core: Fiber Core (FC) or Independent Wire Rope Core (IWRC) – Fiber cores are made of natural (sisal, etc.) or synthetic (polypropylene, etc.) fibers and allow for increased flexibility. IWRC offers more support to the outer strands, and have a higher resistance to crushing. IWRC also offers more resistance to heat, reduces the amount of stretch, and increases the strength of the rope.

Strands: Another variable in wire rope is how many strands make up the rope and how many wires make up one strand. For instance, a 6×26 wire rope has 6 strands around a core with 26 wires making up each strand. The 6×19 class is the most common and offers higher resistance to abrasion whereas the 6×37 class offers higher flexibility.

Although there are exceptions for special applications, the constructions in 6×36 classification are primarily designed to be the most efficient for each rope diameter. As the rope size increases, for instance, a large number of wires can be used to achieve required fatigue resistance, and still those wires will be large enough to offer adequate resistance to abrasion.

The 6×19 classification of wire ropes includes standard 6 strand, round strand ropes with 16 through 26 wires per strand. This is a good rope to withstand abrasion or crushing on the drum. Ropes with independent wire rope strands and a core (IWRC) in general, are more crush resistant than fiber core ropes.

When you purchase our 6×19 Class of wire ropes, you get more than just another rope. Manufactured in an ISO 9001 certified factory and backed by the industry’s largest staff of professional engineers, we do more than meet published specifications.

The 6×26 WS has better resistance to abrasion than a 6x25FW. It features a compact construction with solid support for the wires; therefore it has a high resistance to crushing. Its number and relative size of the inner wires add to the stability of the strand and gives it a fatigue resistance comparable to a 6×25 FW. A standard 6×26 WS construction provides the best rope for a wide range of applications. In general, we recommend the use of the 6x26WS in any application where a 6x25FW is used.

Mast Raising Lines, also called Bull Lines or Bridle Lines, are usually two pieces: each having sockets on both ends. These lines can be fabricated from either right regular lay rope or right lang lay rope. They must be fabricated from IWRC ropes.

Premium ropes may be used for specific applications. PFV cushions the strands, distributes internal stresses, keeps in wire rope lubricant and keeps out dirt and debris, extending the service life.

Flex-X® 9 features compacted strands and swaging for extra drum crushing resistance and increased stability. Its high-density strands deliver extra strength and resistance to abrasion. Flex-X® 9 is manufactured with a dual compaction process to produce a compact cross-section with minimum voids and greater surface area on outer wires that contact drums, sheaves and the rope, itself during operation. The high-density compacted strands minimize nicking at strand-to-strand contact points. Flex-X® 9 was specifically designed for boom hoist applications and tubing line applications where drum crushing is a challenge.

Flex-X® 6 users receive superior performance and increased service life in many applications compared to the ropes they had previously employed. When compared to conventional six-strand ropes, Flex-X® 6 ropes provide greater surface area and more steel per given diameter. This increases rope stability and strength. This results in a longer service life and less sheave and drum wear.

Flex-X® 19, a Category 2 rotation resistant rope, is made from 19 strands. Six strands are laid around a core strand in one direction, and then 12 strands are laid around this first operation in the opposite direction. Because of its tightly compacted smooth design, Flex-X® 19 offers more crushing resistance than standard 19×7 rope, higher strength-to-diameter, resistance to bending fatigue, exceptional stability, reduced wear to sheaves and drums, and improved handling, operating and spooling characteristics.

Website designed & operated by DIELLE S.r.l. - Business Registration Office & Number: NA-483734 - European VAT Number: IT01523381216 - Fiscal Code: 06308490637 - Paid-up Capital: € 81.600 - D-U-N-S: 440178051.

Copyright 2020 by DIELLE SRL Industrial Automation. All product names, logos, and brands are property of their respective owners. All company, product and service names used in this website are for identification purposes only. Use of these names, logos, and brands does not imply endorsement.

8613371530291

8613371530291