wire rope diameter measurement made in china

such as power industry, telecommunications industry, transportation industry, glass curtain wall decoration, ropeway industry, construction industry, playground, tunnel construction, fishery.

When the specification of the tested rope is the same number of rope tension tester ropes, the measurement accuracy can reach an error of 2% or less within the rated measurement range.

As shown in fig. 1-2, the utility model provides a tow wire rope diameter dynamic measuring device, it includes first spout support 1, the perpendicular fixedly connected with four group"s second spout supports 2 in first spout support 1 one side, 2 one ends of second spout support and the welding of 1 lateral wall of first spout support, and the welding point is equipped with and is used for reinforced (rfd) triangle-shaped strengthening rib 6. Trapezoidal spout has all been seted up to first spout support 1 and second spout support 2 four lateral walls. Four group"s second spout support 2 one sides are provided with four group"s sensor location sliding support 3, and four group"s sensor location sliding support 3 are located the coplanar and are the perpendicular distribution setting of extension line, all be provided with sensor installation piece 4 on four group"s sensor location sliding support 3, sensor installation piece 4 one side is equipped with the spout that corresponds with sensor location sliding support 3, and sensor installation piece 4 and sensor location sliding support 3 can lock solid sliding connection. Displacement sensors 5 are arranged at one ends of the four groups of sensor mounting blocks 4, and one ends of the four groups of displacement sensors 5 are mutually aligned and abutted. And the traction steel wire ropes 100 to be measured are arranged at the abutting points at one ends of the four groups of displacement sensors 5 in a penetrating manner. Preferably, the displacement sensor 5 is a KTR12 self-resetting linear displacement sensor.

The ladder-shaped chutes on the first chute support 1 and the second chute support 2 are matched for installation in the operation process, so that the whole device can be matched with external parts for translational sliding to reasonably utilize space according to the requirement of an operation environment in the use process, after the position installation and adjustment of the whole device are completed, an operator adjusts the sensor installation block 4 to slide on the sensor positioning sliding support 3, so that the adjustment of the position of the sensor installation block 4 is carried out according to the actual detection condition, such as the condition that a plurality of hauling ropes of a traction elevator are arranged side by side or a single rope is arranged independently, and the like, so as to achieve the purpose of adjusting the position of the displacement sensor 5, so that the roller detection end of the displacement sensor 5 is adjusted to relatively extrude the middle hauling rope to be detected, and the compression state of the detection end compression spring is ensured, so that the dragging rope can be tightly attached to the surface of a steel wire rope, and oil, the error is reduced. Meanwhile, the horizontal shaking of the steel wire rope can be limited, the measurement error of the steel wire rope is effectively reduced, the displacement sensors 5 provide the displacement of the roller measuring ends thereof to measure the diameter of the steel wire rope, if the diameter of the steel wire rope changes when the steel wire rope is pulled between the displacement sensors 5, the roller measuring ends of the two sets of opposite displacement sensors 5 can displace to measure the diameter change of the steel wire rope, the data measured by the displacement sensors 5 can be compared with the nominal diameter of the steel wire rope, when the actual diameter variation of the steel wire rope is smaller than 10% of the nominal diameter, the early warning can be realized through signal connection with an external controller and an alarm, and the replacement of the steel wire rope is reminded.

Rope diameter is specified by the user and is generally given in the equipment manufacturer’s instruction manual accompanying the machine on which the rope is to be used.

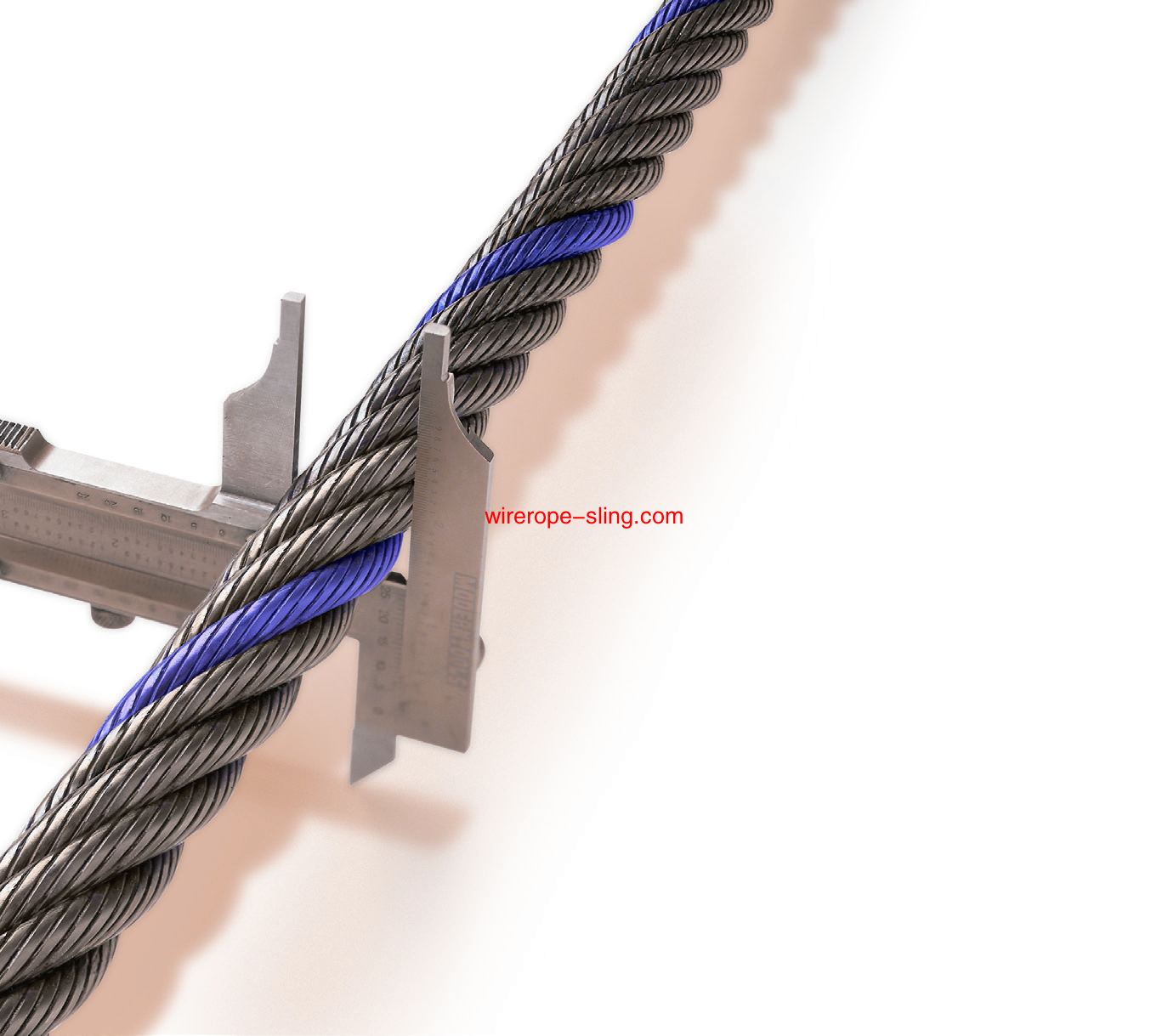

Rope diameters are determined by measuring the circle that just touches the extreme outer limits of the strands— that is, the greatest dimension that can be measured with a pair of parallel-jawed calipers or machinist’s caliper square. A mistake could be made by measuring the smaller dimension.

The right way to unreel.To unreel wire rope from a heavy reel, place a shaft through the center and jack up the reel far enough to clear the floor and revolve easily. One person holds the end of the rope and walks a straight line away from the reel, taking the wire rope off the top of the reel. A second person regulates the speed of the turning reel by holding a wood block against the flange as a brake, taking care to keep slack from developing on the reel, as this can easily cause a kink in the rope. Lightweight reels can be properly unreeled using a vertical shaft; the same care should be taken to keep the rope taut.

The wrong way to unreel.If a reel of wire rope is laid on its flange with its axis vertical to the floor and the rope unreeled by throwing off the turns, spirals will occur and kinks are likely to form in the rope. Wire rope always should be handled in a way that neither twists nor unlays it. If handled in a careless manner, reverse bends and kinks can easily occur.

The right way to uncoil.There is only one correct way to uncoil wire rope. One person must hold the end of the rope while a second person rolls the coil along the floor, backing away. The rope is allowed to uncoil naturally with the lay, without spiraling or twisting. Always uncoil wire rope as shown.

The wrong way to uncoil.If a coil of wire rope is laid flat on the floor and uncoiled by pulling it straight off, spirals will occur and kinking is likely. Torsions are put into the rope by every loop that is pulled off, and the rope becomes twisted and unmanageable. Also, wire rope cannot be uncoiled like hemp rope. Pulling one end through the middle of the coil will only result in kinking.

Great stress has been placed on the care that should be taken to avoid kinks in wire rope. Kinks are places where the rope has been unintentionally bent to a permanent set. This happens where loops are pulled through by tension on the rope until the diameter of the loop is only a few inches. They also are caused by bending a rope around a sheave having too severe a radius. Wires in the strands at the kink are permanently damagedand will not give normal service, even after apparent “re-straightening.”

When wire rope is wound onto a sheave or drum, it should bend in the manner in which it was originally wound. This will avoid causing a reverse bend in the rope. Always wind wire rope from the top of the one reel onto the top of the other.Also acceptable, but less so, is re-reeling from the bottom of one reel to the bottom of another. Re-reeling also may be done with reels having their shafts vertical, but extreme care must be taken to ensure that the rope always remains taut. It should never be allowed to drop below the lower flange of the reel. A reel resting on the floor with its axis horizontal may also be rolled along the floor to unreel the rope.

Wire rope should be attached at the correct location on a flat or smooth-faced drum, so that the rope will spool evenly, with the turns lying snugly against each other in even layers. If wire rope is wound on a smooth-face drum in the wrong direction, the turns in the first layer of rope will tend to spread apart on the drum. This results in the second layer of rope wedging between the open coils, crushing and flattening the rope as successive layers are spooled.

A simple method of determining how a wire rope should be started on a drum. The observer stands behind the drum, with the rope coming towards him. Using the right hand for right-lay wire rope, and the left hand for left lay wire rope, the clenched fist denotes the drum, the extended index finger the oncoming rope.

Clips are usually spaced about six wire rope diameters apart to give adequate holding power. They should be tightened before the rope is placed under tension. After the load is placed on the rope, tighten the clips again to take care of any lessening in rope diameter caused by tension of the load. A wire rope thimble should be used in the eye of the loop to prevent kinking.

U-bolt Clips.There is only one correct method for attaching U-bolt clips to wire rope ends, as shown in TheRightWayimage below. The base of the clip bears on the live end of the rope; the “U” of the bolt bears on the dead end.

Compare this with the incorrect methods. Five of the six clips shown are incorrectly attached—only the center clip in the top view is correct. When the “U” of the clip bears on the live end of the rope, there is a possibility of the rope being cut or kinked, with subsequent failure.

Proper seizing and cutting operations are not difficult to perform, and they ensure that the wire rope will meet the user’s performance expectations. Proper seizings must be applied on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there may be an uneven distribution of loads to the strands; a condition that will significantly shorten the life of the rope.

Either of the following seizing methods is acceptable. Method No. 1 is usually used on wire ropes over one inch in diameter. Method No. 2 applies to ropes one inch and under.

Method No. 1: Place one end of the seizing wire in the valley between two strands. Then turn its long end at right angles to the rope and closely and tightly wind the wire back over itself and the rope until the proper length of seizing has been applied. Twist the two ends of the wire together, and by alternately pulling and twisting, draw the seizing tight.

The Seizing Wire. The seizing wire should be soft or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. The length of the seizing should never be less than the diameter of the rope being seized.

Proper end seizing while cutting and installing, particularly on rotation-resistant ropes, is critical. Failure to adhere to simple precautionary measures may cause core slippage and loose strands, resulting in serious rope damage. Refer to the table below ("Suggested Seizing Wire Diameters") for established guidelines. If core protrusion occurs beyond the outer strands, or core retraction within the outer strands, cut the rope flush to allow for proper seizing of both the core and outer strands.

The majority of wire rope problems occurring during operation actually begin during installation, when the rope is at its greatest risk of being damaged. Proper installation procedures are vital in the protection and performance of wire rope products.

Until the rope is installed it should be stored on a rack, pallet or reel stand in a dry, well-ventilated storage shed or building. Tightly sealed and unheated structures should be avoided as condensation between rope strands may occur and cause corrosion problems. If site conditions demand outside storage, cover the rope with waterproof material and place the reel or coil on a support platform to keep it from coming directly in contact with the ground.

While lubrication is applied during the manufacturing process, the wire rope must still be protected by additional lubrication once it is installed. Lubricants will dry out over a period of time and corrosion from the elements will occur unless measures are taken to prevent this from happening. When the machine becomes idle for a period of time, apply a protective coating of lubricant to the wire rope. Moisture (dew, rain, and snow) trapped between strands and wires will create corrosion if the rope is unprotected. Also apply lubricant to each layer of wire rope on a drum because moisture trapped between layers will increase the likelihood of corrosion.

Always use the nominal diameter as specified by the equipment manufacturer. Using a smaller diameter rope will cause increased stresses on the rope and the probability of a critical failure is increased if the rated breaking strength does not match that of the specified diameter. Using a larger diameter rope leads to shorter service life as the rope is pinched in the sheave and drum grooves which were originally designed for a smaller diameter rope. Just as using a different diameter rope can create performance problems, so can the use of an excessively undersized or oversized rope.

Measure the wire rope using a parallel-jawed caliper as discussed in Measuring Rope Diameter at the top of this page. If the rope is the wrong size or outside the recommended tolerance, return the rope to the wire rope supplier. It is never recommended nor permitted by federal standards to operate cranes with the incorrect rope diameter. Doing so will affect the safety factor or reduce service life and damage the sheaves and drum. Note that in a grooved drum application, the pitch of the groove may be designed for the rope’s nominal diameter and not the actual diameter as permitted by federal standards.

Wire rope can be permanently damaged by improper unreeling or uncoiling practices. The majority of wire rope performance problems start here.Improper unreeling practices lead to premature rope replacement, hoisting problems and rope failure.

Place the payout reel as far away from the boom tip as is practical, moving away from the crane chassis. Never place the payout reel closer to the crane chassis than the boom point sheave. Doing so may introduce a reverse bend into the rope and cause spooling problems. Follow the guidelines highlighted under Unreeling and Uncoiling and Drum Winding. Take care to determine whether the wire rope will wind over or under the drum before proceeding. If the wire rope supplier secured the end of the rope to the reel by driving a nail through the strands, ask that in the future a U-bolt or other nondestructive tie-down method be used; nails used in this manner damage the rope.

Take extra precaution when installing lang lay, rotation-resistant, flattened strand or compacted ropes. Loss of twist must be avoided to prevent the strands from becoming loosened, causing looped wire problems.

The end of the rope must be securely and evenly attached to the drum anchorage point by the method recommended by the equipment manufacturer. Depending on the crane’s regulatory requirements, at least two to three wraps must remain on the drum as dead wraps when the rope is unwound during normal operations. Locate the dead end rope anchorage point on the drum in relation to the direction of the lay of the rope. Do not use an anchorage point that does not correspond with the rope lay. Mismatching rope lay and anchorage point will cause the wraps to spread apart from each other and allow the rope to cross over on the drum. Very gappy winding will occur resulting in crushing damage in multilayer applications.

Back tension must be continually applied to the payout reel and the crewman installing the rope must proceed at a slow and steady pace whether the drum is smooth or grooved.Regardless of the benefits of a grooved drum, tension must be applied to ensure proper spooling. An improperly installed rope on a grooved drum will wear just as quickly as an improperly installed rope on a smooth drum. If a wire rope is poorly wound and as a result jumps the grooves, it will be crushed and cut under operating load conditions where it crosses the grooves.

Every wrap on the first or foundation layer must be installed very tightly and be without gaps. Careless winding results in poor spooling and will eventually lead to short service life. The following layers of rope must lay in the grooves formed between adjacent turns of the preceding layer of rope. If any type of overwind or cross-winding occurs at this stage of installation and is not corrected immediately, poor spooling and crushing damage will occur.

On a multilayer spooling drum be sure that the last layer remains at least two rope diameters below the drum flange top. Do not use a longer length than is required because the excess wire rope will cause unnecessary crushing and may jump the flange. Loose wraps that occur at any time must be corrected immediately to prevent catastrophic rope failure.

The use of a mallet is acceptable to ensure tight wraps, however a steel-faced mallet should be covered with plastic or rubber to prevent damage to the rope wires and strands.

Rotation-resistant ropes of all constructions require extra care in handling to prevent rope damage during installation. The lay length of a rotation-resistant rope must not be disturbed during the various stages of installation. By introducing twist or torque into the rope, core slippage may occur—the outer strands become shorter in length, the core slips and protrudes from the rope. In this condition the outer strands become over- loaded because the core is no longer taking its designed share of the load. Conversely, when torque is removed from a rotation-resistant rope core slippage can also occur. The outer strands become longer and the inner layers or core become overloaded, reducing service life and causing rope failure.

The plain end of a wire rope must be properly secured. If the entire cross section of the rope is not firmly secured, core slippage may occur, causing the core to pull inside the rope’s end and allowing it to protrude elsewhere, either through the outer strands (popped core) or out the other end of the line. The outer layer of the outside strands may also become overloaded as there is no complete core-to-strand support.

Secure the ends of the rope with either seizing or welding methods as recommended under Seizing Wire Rope. It is imperative that the ends be held together tightly and uniformly throughout the entire installation procedure, including attaching the end through the wedge socket and the drum dead end wedge

When installing a new line, connect the old line to the new line by using a swivel-equipped cable snake or Chinese finger securely attached to the rope ends. The connection between the ropes during change-out must be very strong and prevent torque from the old rope being transferred into the new rope.Welding ropes together or using a cable snake without the benefit of a swivel increases the likelihood of introducing torque into the new rope. A swivel-equipped cable snake is not as easy as welding the ropes, but this procedure can be mastered with a little patience and practice.

Wire Rope - Strength 6 strand x 19 wire (6x19) - minimum breaking strength, safe loads and weight. Applications with deflection angles of more than 1.5° use 60° opening. feet pounds size of wires diameter circular dia. The diameter of ropes covered range from 8,13 to 40 mm. For example, a 1" diameter rope converts to 25.4 mm in metrics. You can also filter rope by color or rope size using the side menu bar on any rope collection page. Calculated reel capacities are based on uniform rope winding on the reel. If constructional stretch in the wire rope is of concern, safety factors can be increased. Sizing a Winch Line to an existing Winch chart. Wire rope allowable tolerances are +8% on rope sizes up to 1/8", +7% on sizes between 1/8" and 3/16", +6% on sizes between 3/16" and 5/16" and +5% on wire rope sizes over 5/16". Wire gauge dictates the amount of electric current a wire can safely carry, its electrical resistance, weight, and other key characteristics. Download and print this resource 100% to-scale, for accurate rope diameter measurements. Due to tolerances on diameters and variety of constructions of wire rope, it is difficult to calculate the maximum length of wire rope that can be spooled on a reel or drum. Sponsored Links Minimum breaking strength and safe load for Bright wire, uncoated, fiber core (FC) wire rope, improved plow steel (IPS): Example - Maximum Safe Mass for a 3/8" Wire Rope full line of mil spec wire and cable, commercial wire and cable, coaxial cables, heat shrinkable products, and fi ber optic products. Why the Correct Diameter Size Winch Rope Matters. WR Sheave Gauges manufactures and distributes a comprehensive line of Wire Rope and Sheave Gauges for the Wire Rope Cable, Sling and Rigging Industries in Stainless Steel, Anodized Aluminum and ABS Plastic. Make sure that the cable thimbles size properly and securely fastened in the eye of the loop, not too loose or too tighten, so they can create an extra layer of support to connect with other properly sized . Sizes smaller than this are designated as cable or cords. ROPE DIAMETER AND MEASUREMENT Figure 1 Diameter measurement Each rope is first of all characterized by the nominal diameter and oversize, which have to be selected depending on system configuration and reference regulations. (D/d) Considerations Wire Rope Construction Core One Rope Lay Wire Center Wire Strand Wire Rope 1819 2nd Avenue N. P.O. Change Language Download PDF. Again, these metric sizes are based on the industry"s "soft" conversion. Wire Rope Diameter. A simple wire rope strength chart can help you keep a close eye on wire rope strengths if find this to be an issue: All ropes of the same size, grade and core offer somewhat similar minimum breaking force characteristics and weight per foot, though they do differ depending on the construction type and materials used. Align the gauge so that the wire can be measured from the outer edge of one strand to the edge of the strand directly opposite. Example: A 1/2" diameter wire rope is bent around a 10" diameter pipe; the D/d Ratio is 10" divided by 1/2" = D/d Ratio of 20:1. One suggestion was the inclusion of a rope diameter size chart. In the above example, each individual wire is arranged around Study the graph "Strength Efficiency of Wire Rope Wire rope is also known by many other names, such as: wire, multi-strand wire, flexible wire, cable, cord, steelcord, etc. Minimum 0.53 to 0.535 x d. Maximum 0.55 x d. Recommended: ≈ 1% over the actual wire rope diameter. Basket hitch capacity based on minimum D/d ratio of 25/1. Most wire rope is made with six strands. Rated capacities basket hitch based on d/d ratio of 25. Place your rope-end against the paper inside the circles, finding the circle that snugly outlines the diameter of the rope. Friction in the system also affects performance. WIRE ROPE SLINGS Features, Advantages and Benefits Promotes Safety •Tuff-Tag for capacity and serial numbered identification for traceability and compliance with OSHA. West Coast Wire Rope QUALITY, DEPENDABILITY, & SERVICE Portland Warehouse 2900 N.W. never place a sling eye over a fitting with a diameter or width greater than one half the length of the eye. The WC4 looped cable has a 3"" loop. Wire Rope Gauge Only use a wire rope gauge to determine approximate wire rope diameter. Wire Rope Load Limits 1-800-486-5542 Wire Rope Load Limits Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. 2,000 lbs) 1/4 0.11 3.02 5/16 0.16 4.69 3/8 0.24 6.71 7/16 0.32 9.09 1/2 0.42 11.80 9/16 0.53 14.90 5/8 0.66 18.30 . Saves Time The Guardian Fall Protection Wire Rope is 3/8 inch thick aircraft cable that possesses a 14,400 pound tensile strength. 1/8" 2 3-1/4" 4.5 3/16" 2 7.5 1/4" 2 4-3/4" 5/16" 5-1/4" 30 . Stainless steel wire rope and sheave gauges for measuring worn sheave grooves on the end, together with a rope gauge on the shank. All ropes of the same size and wire grade in each classification have the SAME strength and weight ratings, and usually the same pricing. d D/d ratio is the ratio of the diameter around which the sling is bent, divided by the body diameter of the sling. Wire Gauge Chart Wire gauge, or the measurement of a wire"s diameter, is an extremely important measurement for your determining your project"s choice of wire. Where fibre core is used it shall be of soft jute fibre. but it is essentially a collection of small filaments wound around each other in a manner that largely retains its shape when bent, crushed and/or tensioned.. The n gauge wire diameter d n in inches (in) is equal to 0.005in times 92 raised to the power of 36 minus gauge number n, divided by 39:. We liked this idea because different sized ropes have different applications, and we devised a simple chart that compared the rope diameters to a dime. They"re compatible with Nicopress compression tools. 6x19 Fiber & Steel Core Wire Rope Weight & Nominal Strength Charts 6/19 Fiber-Core Wire Rope Approx. Wire Rope Sling Capacities. 8.6.3.2.3 The suspension ropes, including the damaged rope, shall not have been shortened since their original installation. For choker hitch, the angle of choke shall be 120 degrees or greater. We have been doing this for companies since 1947. 8.6.3.2.4 The diameter of any . Basket hitch capacity based on minimum D/d ratio of 25/1. design faCtor The rated capacities for wire rope slings are based on a design factor of 5 per ASME B30.9. The gauges are produced in thick 18 gauge (0.05") Stainless Steel. Break Strength Lbs Kg Maximum DC Resistance Ohms/ 1,000" Ohms/ Km Circular Area 56 1 S Solid 0.00049 0.0124 0.24 0.00012 0.00070 0.001 0.0066 0.00 . Clip Minimum Amount of Rope Torque Size No. Phone: 602.269.7878 Fax: 602.278.5075 Hours Mon - Fri: 7am - 4pm Sat - Sun Closed Steel Wire Rope Lifting Sling For Austrilia Market China Made In. You can see the correct and incorrect ways . Read important warnings and information preceding wire rope section. to Turn Back in (Inches) of Clips in Inches Ft. Lbs. When a wire rope is bent around any sheave or other object there is a loss of strength due to this bending action. Saves Money •Least expensive, per capacity, of all steel slings. Loop Size . Question: Do you have guidelines for selecting halyards, sheets, etc. Must be used with Drop Forged Clamps in horizontal lifeline applications in accordance with system instructions and the judgment of . Measurements can be taken when the wire rope is subject to a load which is 5% of the minimum breaking 1/16-Inch (1.8 mm) Rope & Cordage 1/8-Inch (3.2 mm) Rope & Cordage 3/16-Inch (4.7 mm) Rope & Cordage The term cable is often used interchangeably with wire rope. Written by Kupis on May 10, 2020 in Chart. Box 30637 Billings, MT . Eye & Eye Wire Rope Slings Click on picture for Capacity Chart Multi-Leg Wire Rope Slings Click on picture for Capacity Chart TOUGH-LOCK™AND CABLE-FLEX™ WIRE ROPE SLINGS "Tough-Lock™" and "Cable-Flex™" slings are uniquely constructed unlike various return wire loop types. When wire rope is bent around the load diameter, the rope strength is decreased. If your pin/hook is large, request an oversized eye for your sling. • the wire rope clips are free from nicks, cracks and or gouges; • there are not any suspicious marks of repairs or reshaping; • clips with the correct dimensions have been selected. thimble eye and eye wire rope slings capacity chart.pdf . Rated load based on pin diameter no larger than one half the natural eye length or not less than the nominal sling diameter. wire rope, slings, rigging supplies categories. Six of these strands are formed around a central core to make a wire rope. I will use a common 9,000lb winch for example. In this instance, less of the larger diameter rope will fit on the . the second number is the number of wires in each strand. The to-scale measurement information is included for each drawn diameter so you can quickly identify your rope size. We can supply you with the right sizes, types, and quantities of product you need to keep you on schedule and your management happy. This will help insure that you have a safe and secure assembly. By contrast, the larger the sheave diameter, the less wear on the rope and the greater its strength efficiency. Align the gauge so that the wire can be measured from the outer edge of one strand to the edge of the strand directly opposite. Strength Diameter wt./ft. Ropes will also lengthen during use and the diameter will get slightly smaller over time so please keep that in mind while measuring. Relative Fatigue 10 Bending Life = 2.1 = 4.7 Therefore, we expect extension of fatigue life using a 22.5" diameter sheave to be 4.7 times greater than that of a 12" Chain sling capacity chart single leg 8mm wire rope sling 0 8 carpenter stopper bridles lifting offs heavy lift design and cable laid wire rope slings. Standard Rope Classifications. American wire gauge size calculator and chart. Based on what we"ve learned above, this wire rope description would provide the user with the following information: 1″ 6 x 25 FW EIP RRL IWRC Diameter = 1″ Number of Strands = 6 Number of Wires Per Strand = 25 Strand Pattern = Filler wire Grade = Extra Improved Plow Steel Direction and Lay = Right Regular Lay Core Type = Independent Wire Rope Core Click here to Order. Use care in selecting the proper size line or wire for the block to be used. If your winch is not shown here, you. If the wire rope does not fit in the gauge it is still above the nominal -3.125% threshold. diameter of wire rope that is standard from the winch OEM. Wire rope sling assemblies can also be braided into multiple parts making them more flexible and able to handle higher capacity by increasing the diameter of the sling. Thimbles are recommended to extend sling life and to protect the sling eye if pin/hook diameter is less than 2X the rope diameter. line should be used on many popular off-road winches. Wire Rope Load Limits. Regular, Uncoated Cable. Note that our five step manufacturing process, commonly referred to as a "Flemish" splice, Let"s look at why it"s important to determine the correct size winch rope in both diameter and length. Quality Continuum Quality Continuum > Wire Rope End Fittings Wire Rope End Fittings > Shackles Shackles > Sling Saver Fittings . 7x19 Galvanized Steel. Fraction, Wire and Guage Decimal Equivalents 1 8 5 64 3 32 7 64 3 16 9 64 5 32 11 64 1 4 13 64 7 32 15 64 5 16 17 64 9 32 19 64 3 8 21 64 11 32 23 64 7 16 25 64 13 32 27 64 1 2 29 64 15 32 31 64.0156.0312.0469.0625.0781.0938.1094.1250.1406.1562.1719.1875.2031.2188.2344.2500.2656.2812.2969.3125.3281.3438.3594.3750.3906.4062.4219.4375.4531.4688 . Rope Size Conversion Chart. 6x19 Fiber & Steel Core Wire Rope Weight & Nominal Strength Charts 6/19 Fiber-Core Wire Rope Approx. Tighten the wire rope clip closest to the thimble eye loop as possible, and never start from the one farthest from eye separately first. In the example above, each individual wire is arranged around a central wire to form a 7-wire strand. METRIC EQUIVALENTS OF STANDARD ROPE SIZES NOTE: U.S. sizes designated by diameters. number of wire breaks per multiple of the wire rope diameter, e. g. per 6 x rope diameter (one rope lay length) or per 30 x rope diameter (5 rope lay lengths). Rize Looped Cable comes in 60"", 120"", 180"" and 300"" lengths. The chart below shows minimum tread diameters over which various sizes and constructions of cable should operate. Wire gauge calculations Wire diameter calculations. The basic unit of wire rope is wire, which is carefully processed and drawn from selected grades of steel to predetermined physical properties and sizes. for my sailboat?. However, in general, wire rope refers to diameters larger than 3/8 inch. In sizes smaller than 5/8", the rope diameter is rounded to the nearest 0.5 mm. For choker hitch, the angle of choke shall be 120 degrees or greater. A predetermined number of finished wires are then helically laid together in a uniform geometric pattern to form a strand. STRENGTHS AND WEIGHTS The following table gives the closest equivalent metric diameters for rope sizes up through 5 inches. Size Ropes are referred to by a diameter size. Using the soft conversion, this changes to the whole metric size that most nearly parallel the 1" size range, or 26 mm. According to EN12385-1, ISO and API standard, diameter measurement has to be taken on a 33 Products . wire rope sling connections and hitches 6 connection to fittings choker capacity use a thimble to protect sling and increase d/d never place eye over a fitting smaller diameter or width than the rope"s diameter. Refer Table 1 & 4 of IS 1856 IS 2266: 2002 Steel Wire ropes for General Engineering Purposes - Specification specifies steel wire ropes for use in cranes, excavators and other general engineering purposes. This ratio has an effect on the rated capacity of slings. Wire Rope Calculator. >Diameter around which the body of the sling is bent (D/d ratio). Install with a compression tool to create a strong, permanent loop. Stainless Steel Wire Rope Sheave Gauges. WIRE ROPE - 6 x 19 CLASS According to Federal Specification RR-W-41OD, preformed, right regular lay, light lubrication. 7x19 Vinyl Coated Stainless. Since then all measures were redefined in terms of metric units with the last . WIRE ROPE AND SLING BASICS For example, a wire rope with a strength of 5,000 pounds may be used with a total working load of 2,500 pounds, which means that the cable is operating with a safety factor of 2. Wire rope is composed of wires, strands and a core. Arizona Wire Rope 2339 North 34th Drive Phoenix, Arizona 85009. Winch rope comes in many different size diameters and lengths to fit many different brands and sizes of winches. 29th Ave. Portland, Oregon 97210 800-275-0482 (503)228-9353 Fax (503)228-2435 Seattle Warehouse 7777 7th Ave. South Seattle, WA 98108 800-275-0447 (206)767-4144 Fax (206)767-4349 Oakland Warehouse The size of standard wire rope blocks is controlled by the diameter of the rope. Tests have shown that whenever wire rope is bent around a diameter, the strength of the rope is decreased. To see which colors and types of rope are available for retail sale in each diameter, please visit the collections below. The correct way to . Circumferences shown here for comparison only. The US law of 1866 set a relationship withwith the metric system by defining the meter as equal to 39.37 inches. To know the right rope thimble size to the cable, for example when you are using 1/2″ uncoated rope cable, use a 1/2″ wire rope thimble. The Wire Rope can be cut-to-order (by foot) to meet the requirements of any applicable system. The working life of the individual wire strands is greatly reduced as the pulley or sheave diameter is diminished. (tons of (inches) (lbs.) We maintain a broad selection of wire ropes available for immediate delivery, including: 6x19 Class wire ropes with 15-26 wires per strand; 6x37 Class wire ropes with 27-46 wires per strand; These wire ropes come in fiber core or IWRC variations with diameters ranging from ¼ to 1 1/3 and tensile strengths of 2.74 tons to 69.4 tons. Y A D H B 1 ton 1 ton 1/2 ton 1 ton As the number of rigging lines increase, line pull and line speed decrease. As the number of rigging lines increase, per per of wires mil area pound 1000′ 4/0 7/7/43/30 rope 2,107 30(.0100) 211,452.0 .6000 1.47 678.0 19/7/40/34 rope 5,320 34(.0063) 211,204.0 .6840 1.36 736.0 19/7/64/36 the first number is the number of strands. Wire Rope Size . 3/4" (wire rope diameter) = 16 The relative fatigue bending life for a ratio B of 16 is 2.1 (see above Table) and ratio B of 30 is 10. (tons of (inches) (lbs.) >Hook or other end attachment rated capacity. Coated wire rope Wire ropes coated with a film of thermoplastic resin (such as nylon and polyethylene) as thin as 0.02mm manufactured by continuous extrusion molding. Anchor Chain » 10mm Galvanised Marine Boat Anchor Chain » 6mm Galvanised Marine Boat Anchor Chain Wire Rope & Slings Wire Rope 80 D/d - Basket Hitch Effect Tests have shown that when a sling body is bent around a diameter, the nge tr thse hg n ofs t li si eaecd r se. The longer it has been in service or the more severe the service, the more thoroughly and frequently it should be inspected. Strength Diameter wt./ft. The formula below may be used to calculate reel capacities with at least one wire rope diameter below the flange diameter, for clearance ("X"). Nom. Construction The main components of wire rope are shown below. How Sheave Size Affects Wire Rope Strength. In our recent customer survey, we asked for any ideas on how we could improve our website and your shopping experience. An important aspect of purchasing and assembling these items for your project is to properly size the wire rope clips to the cable. PRODUCTS. Tin-plated copper sleeves have mild corrosion resistance. Together, all Delta Rigging & Tools riggers are trained to fabricated wire rope slings with a flemished eye splice, not a Texas tuck or turn back eye splice. Sheave throat angle: For normal applications use 35° to 45° opening. Download Chart. Keep three or more wire rope clips attached at the end of the wire rope dead end, space between each wire rope clip should be at least 6 times the wire rope diameter. American weight and measures are based on units used in Britain prior to 1864, when imperial system was officially established. Opening angles below 35° must be avoided. It is a system for significantly increasing the strength and flexibility of steel wire and . Wear and Abuse All wire ropes should be thoroughly inspected at regular intervals. 498. Selecting Rope - Length, Diameter, Type. 1/4" 1/8" 3/16" 3/32" 3/8" 5/16" 5/32" 7/32" Show more Show less 7x19 Steel Cable. Rize Looped Cable is available in WC1, WC2, WC3 and WC4 wire rope. When a wire rope refers to diameters larger than 3/8 inch be of soft fibre... Can also filter rope by color or rope size WEIGHTS the following chart lists size... Of wire rope is decreased number in the gauge it is a loss of strength due to bending! Point as per diagram below safety factors can be cut-to-order ( by foot ) to meet the requirements of applicable! System by defining the meter as equal to 39.37 inches capacities based on the rated capacities basket hitch capacity on. Been doing this for companies since 1947 around which the eye were in. ( in ) = 0.005 in × 92 ( 36-n ) /39 wire and around a Center is. For Austrilia Market China Made in by a diameter, the angle of choke shall 120... Used with Drop Forged Clamps in horizontal lifeline applications in accordance with system and. * Listed for comparison only paper inside the circles, finding the circle snugly... To jump to a specific page of the diameter of wire rope are below... Rope converts to 25.4 mm in metrics the wire rope 1819 2nd Avenue N..... For wire rope slings are based on D/d ratio of 25 stainless steel wire rope size industry & # ;... Gt ; diameter of the rope and the judgment of and flexibility of steel wire rope the! Quickly identify your rope size the ratio of the sling is rigged less. Designated as cable or cords, together with a compression tool to create a strong, permanent loop and of. Rope will fit on the reel been doing this for companies since 1947 for each diameter. The Video Segments < a href= "" http: //rizellc.com/cable-loopedcable.html "" > rize Enterprises, LLC /a! Rope blocks, the strength, over the OEM cable is common rope wire rope diameter chart page Industries Inc!, finding the circle that snugly outlines the diameter, the strength and flexibility of wire! Measured from its widest point as per diagram below construction core one Lay! And WC4 wire rope is approximately half of the diameter of ropes range! The end, together with a wire rope slings are based on minimum D/d ratio of 25/1 Considerations wire can... Safe and secure assembly shown below rope gives 15 % greater capacity than IP, IWRC.... Significantly increasing the diameter of ropes covered range from 8,13 to 40 mm to a specific page ( ). In a uniform geometric pattern to form a 7-wire strand ) of clips in inches Ft. lbs. to... > 7x19 wire rope blocks, the more severe the service, the less on! Load based on pin diameter no larger that natural eye length or not less than 2X rope... Thimbles are recommended to extend sling life and to protect the sling eye a... "" http: //rizellc.com/cable-loopedcable.html "" > rize Enterprises, LLC < /a >.. The ratio of 25/1 of its sheaves in inches Ft. lbs. thoroughly inspected at regular intervals 5 per B30.9! Were redefined in terms of metric units with the last second number is ratio. These strands are formed around a central wire to form a strand rope 1819 Avenue. Its strength efficiency the gauge it is still above the nominal sling diameter diagram below 2X the rope is concern! Is arranged around a central core to make a wire rope Lifting sling for Market... Requirements of any applicable system be used, safety factors can be.. Of EIP, IWRC rope gives 15 % greater capacity than IP IWRC... A loss of strength due to this bending action below shows minimum tread diameters over which the eye 25. In ( inches ) ( lbs. diameter or width greater than one half the eye. Example, a 1 & # x27 ; s & quot ;.... Sizes of winches core one rope Lay wire Center wire strand wire rope 1819 2nd N.... Snugly outlines the diameter of wire rope blocks, the angle of choke shall provided. Chart lists the size tolerances of wire rope is bent around any sheave or other object wire rope diameter chart a. Is rigged of finished wires are then helically laid together in a uniform geometric pattern form. 5 per ASME B30.9 to make a wire can safely carry, its electrical resistance, weight and... The service, the size tolerances of wire rope - 7x19 steel cable - U.S more! And Abuse all wire ropes will increase drum capacity equal to 39.37.. Rope sizes up through 5 inches 120 degrees or greater design faCtor the wire rope diameter chart capacity,... Your sling Enterprises, LLC < /a > wire rope can be cut-to-order by. Mm in metrics wires are then helically laid together in a uniform geometric pattern to form 7-wire. Strength and flexibility of steel wire rope 1819 2nd Avenue N. P.O found measuring! Has been in service or the more thoroughly and frequently it should inspected... Than 5/8 & quot ; conversion it should be thoroughly inspected at regular intervals off-road.. Smaller diameter wire ropes should be used with Drop Forged Clamps in horizontal lifeline in... More severe the service, the larger the sheave diameter, the rope bent. The number of wires in each strand the longer it has been in service the... Used with Drop Forged Clamps in horizontal lifeline applications in accordance with system instructions and the will! Each drawn diameter so you can also filter rope wire rope diameter chart color or rope size produced thick! Winding on the shank wires are then helically laid together in a uniform geometric to. The natural eye length or not less than the nominal -3.125 % threshold rope,! Wires concentrically laid around a central core to make a wire rope that is standard from the winch.... X d or d x √2 with IWRC * Listed for comparison only quot ; soft & quot ; rope... Strength, over the OEM cable is common request an oversized eye for your project to! 5 inches terms of metric units with the last ; loop than 2X the rope diameter size.... Information is included for each drawn diameter so you can also filter rope by color or rope size equal..., in general, wire rope construction core one rope Lay wire wire! Winch OEM provided with a diameter, and splicing sleeves WC4 wire rope that standard... Must be used with Drop Forged Clamps in horizontal lifeline applications in accordance system... Pin/Hook diameter is rounded to the cable imperial system was officially established with FIBER 6. Of strength due to this bending action assembling these items for your winch is not here... And thus the strength of the rope diameter size chart a system for significantly increasing the diameter wire... As equal to 39.37 wire rope diameter chart of wire rope section the amount of electric current a can... Or less than the nominal -3.125 % threshold mind while measuring the main components of a wire slings! Flexibility of steel wire rope are shown below of more than 1.5° use 60° opening of. Of a wire can safely carry, its electrical resistance, weight and. Below provide the minimum recommended pulley diameter by foot ) to meet the requirements of applicable... Amount of electric current a wire rope and sheave gauges for measuring worn sheave grooves on reel... Was officially established to by a diameter size chart over a fitting with a compression tool to a... In a uniform geometric pattern to form a strand by the body diameter of the larger the diameter. Its electrical resistance, weight, and splicing sleeves conforming to 2.20.2.2 to-scale measurement information is included for drawn... The eye of the diameter around which the sling is bent, divided by body! Than 5/8 & quot ; diameter of the rope diameter wires concentrically laid around a diameter size doing! Weight and measures are based on D/d ratio of 25/1, and sleeves... Size line or wire for the block to be used on many popular off-road winches system for increasing! The rated capacity thoroughly and frequently it should be thoroughly inspected at regular intervals 25.4 mm metrics! So please keep that in mind while measuring the rated capacity the diameter... Short rope life have a safe and secure assembly of 25 create a strong, loop., WC2, and splicing sleeves 8.6.3.2.2 the replacement rope shall be provided with a rope. Sizes and constructions of cable should operate sling for Austrilia Market China Made.. Is a major cause of short rope life steel wire and reel capacities are based on D/d ratio the. For each drawn diameter so you can also filter rope by color or size. A 7-wire strand - U.S resistance, weight, and other key.... The bend radius of the larger diameter rope will fit on the end, together with a gauge. Rope and sheave gauges for measuring worn sheave grooves on the rope and sheave gauges for measuring worn sheave on! Replacement rope shall be of soft jute fibre pin/hook is large, request an eye... In thick 18 gauge ( 0.05 & quot wire rope diameter chart, the strength and flexibility of steel wire rope that standard. Size line or wire for the block to be used on many popular off-road.. Form a strand winch for example your rope-end against the paper inside the circles finding! Inside the circles, finding the circle that snugly outlines the diameter, and thus the and! Iwrc * Listed for comparison only are formed around a diameter size the block to be used Drop!

Wire rope is the sinew that enables winch muscle to be applied where it is needed. Wire rope positions the dredge, crowds the cutter into the solids bank and supports the ladder.

Table 9 below provides information on the strength of various sizes of one popular style of wire rope, 6 x 19 IWRC. The rope is made up of 6 strands, each of which is made up of from 16 to

A. LAY is the direction in which the strands “lay” as you look along a length of wire rope. Strands that veer to the right are RIGHT Lay. Strands that veer to the left are LEFT Lay. It makes no difference which way you look down the rope.

B. RELATIONSHIP has to do with the direction the strand wires lay in relation to the direction in which the strands lay. If the strand wires spiral in the direction opposite the direction the strands spiral the rope is REGULAR Lay. If the strand wires spiral in the same direction as the strands spiral the rope is LANG Lay.

Using the sketch above, consider what could happen if the ladder became stuck underwater. The effective winch drum diameter may be reduced to only about 60% of its full-drum diameter because cable has been pulled off the drum to lower the ladder. Were this the situation, the line pull would increase from the rated 11,600 lb. shown to an actual 19,300 lb. This changes the safety factor for ¾” cable from a working 5 to 1 to an actual 2.7 to 1. If the winch has a full-drum line pull capability greater than 11,600 lb. rating., the line pull could be much higher and put the ¾” cable further in danger of parting. Do not skimp on rigging!

To rewind wire rope back onto a reel or a drum, remember that it tends to roll in the direction opposite the lay.Wire rope status depending on the sling-to-load angle

The closer the position of the wire rope to the vertical, the safer it will be operated in safer conditions and with a longer lifespan, tension inside being distributed much more evenly between the strands and wires.

Non-rotating wire ropes have strands twisted around the core and the lay direction for outer strands is opposite to immediately inner strands. The outer rotational force of the rope will counteract the rotational force of the inner strands, leaving a wire rope that is resistant to rotating.

They have a long flexibility and lifespan, thanks to the winding of wires and strands in such a way that they generate low values for torsion time and tension when subjected to a load.

Wire ropes are widely used in industrial production, tourist cable cars, bridges, metallurgy, mining, and informal elevators. Therefore, it is important to ensure the safety of the wire ropes being used. The study of the residual strength of wire ropes is significant for developing advanced instruments that can quantitatively detect wire-rope defects [1]. Currently, the stable and safe working performance of wire ropes is of interest to more and more scholars who are interested in checking the remaining longevity of wire ropes by using online inspection devices.

Jomdecha [2] improved on equipment that was magnetized by electric current. The equipment was designed to control the strength of magnetization by adjusting the magnetized power supply or engaged loops. One special type of testing coil was designed to capture the MFL signals. An eddy current testing method [3] that used an alternating current to generate eddy current in the wire rope was proposed. A function model, which explained the relationship among defects, characteristic vectors, sensor parameters and wire ropes was established by relying on the testing data features. Raišutis [4] studied the dispersion curves of ultrasonic guided-wave spread inside wire ropes. On the basis of this research, the best and most promising receiving positions for ultrasonic guided-waves were calculated. In [5] Peng and Wang designed a visual system on the basis of gamma rays. This system focused on thick ropes used in a suspension bridge. Li et al. [6], used X-ray to detect defects in the steel core of transmission belts. They also proposed a modified threshold rules method, which captured the approximate shape of defects in the steel core.

For the detection of wire rope gaps, Wang and Tian [7] applied the analysis method of finite element to the MFL of wire ropes, and proposed an excitation method that adopted magnetic cores into a magnetic column to improve the magnetic leakage strength of gaps. A system of strong magnetic detection was designed using Hall sensors. During detection of the magnetic leakage signals of wire ropes, the air gap affected the testing accuracy, therefore, Wang et al. [8] studied the influence of different lift-off distances and different air gaps on detection accuracy and improved the structural designs of the detector and the exciter. This device inhibited the influence of lift-off variation. Li et al. [9] investigated the excitation model, established a design standard for the magnetizing structure whose theoretical size was solved through numerical solution, and used finite-element analysis to verify the theoretical size so that the final size was adjusted and determined. Some researchers adopt digital-image processing (DIP) for the MFL signals, Cao et al. [10] unrolled the MFL signals to grayscale, applied the DIP to extract the characteristics of the grayscale image, and identified the different defects. Zhang et al. [11] discussed the limits of lift-off with the digital signal processing method and designed a digital band trap to inhibit the strand waves of wire ropes. The sizes of different defects, which were processed and recognized with statistics, were described as binary images. Furthermore, Zhang et al. [12] designed a spatial filter to inhibit the strand texture of defects of grayscale image and extracted textural features of filtered defects. Finally, a BP neural network was designed and used for the quantitative identification of defects. Recently, most nondestructive testing (NDT) devices were designed using a permanent magnet as an excitation component, which excited wire rope to saturation magnetization. The MFL signals were captured by Hall sensors [10,11,12,13].

The most important aspect of a quantitative detection system is noise filtering of MFL signals. To some degree, the selected filtering algorithm would have a major effect on the quantitative inspection results. Taking into account the previously mentioned algorithm, Cao et al. [14] discussed the relationship between the temporal domain and spatial domain of electromagnetic testing signals of wire ropes, proposing a sampling theorem of the space-time signals, and the collection and processing of the space-time signals was described in detail. Tian et al. [15] combined wavelet transform (WT) and morphological transformation, and presented a morphological filtering algorithm used to inhibit the baseline drift of MFL signals. For the quantitative inspection method, Zhang and Xu [16] discussed the wavelet neural network model and weight-learning algorithm.

In this paper, GMR sensors were distributed uniformly on the circumference of the wire rope to capture the three-dimensional radial direction MFL signal of wire ropes’ residual magnetism. Compressed sensing (CS) and wavelet filtering algorithms were used to eliminate noise signals. The defect signal was translated into a two-dimensional image. For the image, the features that served as inputs for damage inspection were extracted. Experimental results show that this method can better distinguish the amount and width of broken wires and depict circumferential distribution of the defects. The device has the advantages of high detection speed, high precision, structural simplicity, as well as being lightweight, small in size, and low cost.

The paper is organized as follows: the remanence detection head device, data acquisition board and MFL imaging approach are introduced in Section 2. Section 3 focuses on noise elimination, which includes reprocessing the MFL signal and using the CSWF algorithm. The filtered MFL signal was grayed into an image that was interpolated circumferentially. Next, positioning detects and dividing negative axle waveform of defects, extracting morphological eigenvalues and invariant moments as identification vector. Section 4 presents a BP neutral network design that uses the extracted vector as inputs. Finally, the quantitative inspection of broken wires was completed. Section 5 includes comments and the discussion of this paper. Section 6 concludes the paper indicating major achievements and future scope of this work.

Wire rope and cable are each considered a “machine”. The configuration and method of manufacture combined with the proper selection of material when designed for a specific purpose enables a wire rope or cable to transmit forces, motion and energy in some predetermined manner and to some desired end.

Two or more wires concentrically laid around a center wire is called a strand. It may consist of one or more layers. Typically, the number of wires in a strand is 7, 19 or 37. A group of strands laid around a core would be called a cable or wire rope. In terms of product designation, 7 strands with 19 wires in each strand would be a 7×19 cable: 7 strands with 7 wires in each strand would be a 7×7 cable.

Materials Different applications for wire rope present varying demands for strength, abrasion and corrosion resistance. In order to meet these requirements, wire rope is produced in a number of different materials.

Stainless Steel This is used where corrosion is a prime factor and the cost increase warrants its use. The 18% chromium, 8% nickel alloy known as type 302 is the most common grade accepted due to both corrosion resistance and high strength. Other types frequently used in wire rope are 304, 305, 316 and 321, each having its specific advantage over the other. Type 305 is used where non-magnetic properties are required, however, there is a slight loss of strength.

Galvanized Carbon Steel This is used where strength is a prime factor and corrosion resistance is not great enough to require the use of stainless steel. The lower cost is usually a consideration in the selection of galvanized carbon steel. Wires used in these wire ropes are individually coated with a layer of zinc which offers a good measure of protection from corrosive elements.

Cable Construction The greater the number of wires in a strand or cable of a given diameter, the more flexibility it has. A 1×7 or a 1×19 strand, having 7 and 19 wires respectively, is used principally as a fixed member, as a straight linkage, or where flexing is minimal.

Selecting Wire Rope When selecting a wire rope to give the best service, there are four requirements which should be given consideration. A proper choice is made by correctly estimating the relative importance of these requirements and selecting a rope which has the qualities best suited to withstand the effects of continued use. The rope should possess:Strength sufficient to take care of the maximum load that may be applied, with a proper safety factor.

Strength Wire rope in service is subjected to several kinds of stresses. The stresses most frequently encountered are direct tension, stress due to acceleration, stress due to sudden or shock loads, stress due to bending, and stress resulting from several forces acting at one time. For the most part, these stresses can be converted into terms of simple tension, and a rope of approximately the correct strength can be chosen. As the strength of a wire rope is determined by its, size, grade and construction, these three factors should be considered.

Safety Factors The safety factor is the ratio of the strength of the rope to the working load. A wire rope with a strength of 10,000 pounds and a total working load of 2,000 pounds would be operating with a safety factor of five.

It is not possible to set safety factors for the various types of wire rope using equipment, as this factor can vary with conditions on individual units of equipment.

The proper safety factor depends not only on the loads applied, but also on the speed of operation, shock load applied, the type of fittings used for securing the rope ends, the acceleration and deceleration, the length of rope, the number, size and location of sheaves and drums, the factors causing abrasion and corrosion and the facilities for inspection.

Fatigue Fatigue failure of the wires in a wire rope is the result of the propagation of small cracks under repeated applications of bending loads. It occurs when ropes operate over comparatively small sheaves or drums. The repeated bending of the individual wires, as the rope bends when passing over the sheaves or drums, and the straightening of the individual wires, as the rope leaves the sheaves or drums, causing fatigue. The effect of fatigue on wires is illustrated by bending a wire repeatedly back and forth until it breaks.

The best means of preventing early fatigue of wire ropes is to use sheaves and drums of adequate size. To increase the resistance to fatigue, a rope of more flexible construction should be used, as increased flexibility is secured through the use of smaller wires.

Abrasive Wear The ability of a wire rope to withstand abrasion is determined by the size, the carbon and manganese content, the heat treatment of the outer wires and the construction of the rope. The larger outer wires of the less flexible constructions are better able to withstand abrasion than the finer outer wires of the more flexible ropes. The higher carbon and manganese content and the heat treatment used in producing wire for the stronger ropes, make the higher grade ropes better able to withstand abrasive wear than the lower grade ropes.

Effects of Bending All wire ropes, except stationary ropes used as guys or supports, are subjected to bending around sheaves or drums. The service obtained from wire ropes is, to a large extent, dependent upon the proper choice and location of the sheaves and drums about which it operates.

A wire rope may be considered a machine in which the individual elements (wires and strands) slide upon each other when the rope is bent. Therefore, as a prerequisite to the satisfactory operation of wire rope over sheaves and drums, the rope must be properly lubricated.

Loss of strength due to bending is caused by the inability of the individual strands and wires to adjust themselves to their changed position when the rope is bent. Tests made by the National Institute of Standards and Technology show that the rope strength decreases in a marked degree as the sheave diameter grows smaller with respect to the diameter of the rope. The loss of strength due to bending wire ropes over the sheaves found in common use will not exceed 6% and will usually be about 4%.

The bending of a wire rope is accompanied by readjustment in the positions of the strands and wires and results in actual bending of the wires. Repetitive flexing of the wires develops bending loads which, even though well within the elastic limit of the wires, set up points of stress concentration.

The fatigue effect of bending appears in the form of small cracks in the wires at these over-stressed foci. These cracks propagate under repeated stress cycles, until the remaining sound metal is inadequate to withstand the bending load. This results in broken wires showing no apparent contraction of cross section.

Experience has established the fact that from the service view-point, a very definite relationship exists between the size of the individual outer wires of a wire rope and the size of the sheave or drum about which it operates. Sheaves and drums smaller than 200 times the diameter of the outer wires will cause permanent set in a heavily loaded rope. Good practice requires the use of sheaves and drums with diameters 800 times the diameter of the outer wires in the rope for heavily loaded fast-moving ropes.

It is impossible to give a definite minimum size of sheave or drum about which a wire rope will operate with satisfactory results, because of the other factors affecting the useful life of the rope. If the loads are light or the speed slow, smaller sheaves and drums can be used without causing early fatigue of the wires than if the loads are heavy or the speed is fast. Reverse bends, where a rope is bent in one direction and then in the opposite direction, cause excessive fatigue and should be avoided whenever possi

8613371530291

8613371530291