wire rope diameter measurement quotation

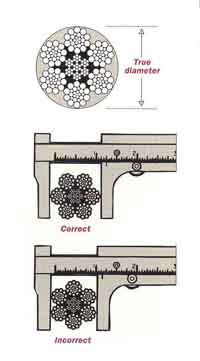

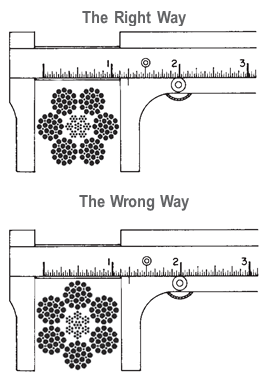

The actual diameter of a wire rope is the diameter of a circumscribed circle that will enclose all the strands. It ‘s the largest cross-sectional measurement as shown here. You should make the measurement carefully with calipers.

As we move toward metric measurements, it will become increasingly necessary to convert English units into Sl – International System of Units – (or metrics), and vice versa.

For standard, general purpose wire ropes, in measuring diameter, the industry is leaning toward a “soft” conversion to metric during the transition period. For example, a 1″ diameter rope converts to 25.4 mm in metrics. Using the soft conversion, this is changed to the whole metric size that most nearly parallels the 1″ size range, or 26 mm. In sizes smaller than 5/8′: the rope diameter is rounded to the nearest 0.5 mm.

The following table gives the closest equivalent metric diameters for rope sizes up through 5 inches. Again , these metric sizes are based on the industry’s “soft” conversion. Your application may have tighter tolerances that require a hard conversion. Therefore, the values in the table would not apply.

Since rope minimum breaking force and weight per unit of length vary for different types and grade of ropes, the following conversion factors are given to help you convert the figures you need:

Note: The newton (a unit of force) is the correct unit for measurement of minimum breaking force in the Sl system of units. We have included a conversion f

To see which colors and types of rope are available for retail sale in each diameter, please visit the collections below. You can also filter rope by color or rope size using the side menu bar on any rope collection page.

Rope Size: Diameter and circumference are nominal. A new, unused rope in a relaxed state will measure larger; loading and use compacts ropes, sets splices, and lessens rope size. This is especially prevalent in rope sizes above 4" diameter. Published nominal sizes from 4-1/8" and larger represent stabilized or preloaded size.

Ravenox provides ropes for a variety of markets, from offshore working and lifting lines, tug and salvage, ship and barge mooring lines, mining tow lines, utility and RV winch lines to theatrical rigging lines and commercial fishing lines. Email Ravenox for a quote or for more information for ropes suitable for a variety of market solutions.

Rope diameter is normally specified by the user or given in instruction manuals accompanying the customers" machine. So measuring the accurate diameter of steel wire ropes becomes extremely important for our customer to provide correct numbers. We believe the following instruction will give your some guidance:

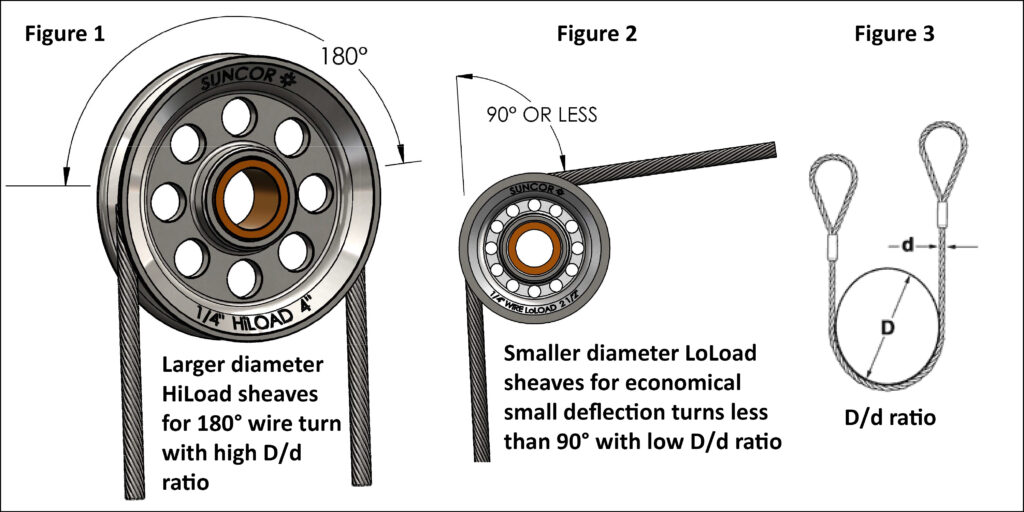

To obtain reasonable service life from your aircraft cable or wire rope, you must choose the optimal diameter of rope and sheave for your application. In general, the larger the size of the drum or pulley with respect to the wire diameter, the longer the service life. The opposite is also true: in general, the smaller the size of the drum or pulley with respect to your wire rope, the shorter the service life. Keep these relationships between cable, rope, and pulleys in mind when specifying the competence you use in your application.

The tables below provide the minimum recommended pulley diameter as well as the approximate bend radius of the rope. You"ll notice that the calculation is approximately half of the minimum recommended pulley tread diameter. Whether running fully over the sheave or drum, or some fraction thereof, check your design against the recommendations to better understand the service life you can expect in relation to the other factors involved.

The rope diameter shall always be checked before installation. Measure a straight part of the rope. Two parts with minimum distance of one meter shall at least be measured. By every point two measurements shall be done, with 90 degrees displacement in relation to each other. The average between the two measurements shall be according to the tolerance in the tables below.

Laid rope was always calibrated by circumference, whether you work in imperial or metric unit. The reason is very simple that any other method would give differing results depending on where you measure - just try this with a vernier caliper and turn the rope: the measured diameter will change as you turn it. You could use a gauge with holes, but keeping such gauge e.g. on board a ship would be inconvenient. It was easier to wind a thread say ten times around a rope and then measure its length, divided by ten it gives you the circumference.

When wire rope and then later braided fibre-rope came into use, measuring diameters became physically possible. However, well into the 20th century wire rope was sold by circumference.

We make it easy to specify and order the perfect wire rope assembly for your project. No matter the size of the project, we make sure to meet your requirements and specifications

Don’t Know your System Length? No problem. Our Sta-Lok Self-Fit assemblies mean you can cut and assemble the wire yourself on-site, without pre-measurement, using just simple hand tools.

Sta-Lok Terminals Ltd accepts no responsibility for incorrect measurements. All of the factors stated above will be confirmed and restated with your quotation.

The April issue of Wire Rope News included a feature story on the metric system. The article presented the benefits that companies who have adopted the metric system realize, particularly in a global market.

You may have seen the article already, and your firm may already have adopted the metric system. It provided a brief glimpse into the history of the Imperial system that has been a part of daily life in the United States since European explorers first set foot on this continent, and made for an interesting opportunity to think about how this system came to be.

“Though we tend to see cups, pints, yards, feet, miles, inches and degrees Fahrenheit as our old reliable friends, there are also many other rather obscure measures, leagues, fathoms, furlongs, chains, to name just a few that go with the old system we use as well. This arrangement dates back to Roman and Medieval times when kings literally used body parts – such as an actual human foot or hand – to establish standard measurements…”

This is just the tip of the iceberg when it comes to considering the peculiarity of the Imperial measuring system. For example, one source explained that one determinant of the inch (beyond the length of the last joint of your thumb), is the length of three barleycorns placed end to end. A fact stranger yet, and apparently still true today, is that shoe sizes correlate to barleycorn measurement.

Seriously. This, and more entertaining facts on measures (for example, do you know which is longer: a “moment” or a “jiffy”?) are offered in 10 Bizarre Units of Measurement by Listverse.

When it comes to the importance of measurements in our industry, however, we have you covered, whether your needs call for the Imperial or metric system. Our specifications display both systems. Just don’t ask us about Wheatons (also described by Listverse).

Rope strength is a misunderstood metric. One boater will talk about tensile strength, while the other will talk about working load. Both of these are important measurements, and it’s worth learning how to measure and understand them. Each of these measurements has different uses, and here we’re going to give a brief overview of what’s what. Here’s all you need to know about rope strength.

Each type of line, natural fiber, synthetic and wire rope, have different breaking strengths and safe working loads. Natural breaking strength of manila line is the standard against which other lines are compared. Synthetic lines have been assigned “comparison factors” against which they are compared to manila line. The basic breaking strength factor for manila line is found by multiplying the square of the circumference of the line by 900 lbs.

When you purchase line you will buy it by its diameter. However, for purposes of the USCG license exams, all lines must be measured by circumference. To convert use the following formula.

Using the example above, letÂ’s find the breaking strength of a piece of ½” nylon line. First, convert the diameter to the circumference as we did above and then write the formula including the extra comparison factor step.

Just being able to calculate breaking strength doesn’t give one a safety margin. The breaking strength formula was developed on the average breaking strength of a new line under laboratory conditions. Without straining the line until it parts, you don’t know if that particular piece of line was above average or below average. For more information, we have discussed the safe working load of ropes made of different materials in this article here.

It’s very important to understand the fundamental differences between the tensile strength of a rope, and a rope’s working load. Both terms refer to rope strength but they’re not the same measurement.

A rope’s tensile strength is the measure of a brand-new rope’s breaking point tested under strict laboratory-controlled conditions. These tests are done by incrementally increasing the load that a rope is expected to carry, until the rope breaks. Rather than adding weight to a line, the test is performed by wrapping the rope around two capstans that slowly turn the rope, adding increasing tension until the rope fails. This test will be repeated on numerous ropes, and an average will be taken. Note that all of these tests will use the ASTM test method D-6268.

The average number will be quoted as the rope’s tensile strength. However, a manufacturer may also test a rope’s minimum tensile strength. This number is often used instead. A rope’s minimum tensile strength is calculated in the same way, but it takes the average strength rating and reduces it by 20%.

A rope’s working load is a different measurement altogether. It’s determined by taking the tensile strength rating and dividing it accordingly, making a figure that’s more in-line with an appropriate maximum load, taking factors such as construction, weave, and rope longevity into the mix as well. A large number of variables will determine the maximum working load of a rope, including the age and condition of the rope too. It’s a complicated equation (as demonstrated above) and if math isn’t your strong point, it’s best left to professionals.

However, if you want to make an educated guess at the recommended working load of a rope, it usually falls between 15% and 25% of the line’s tensile strength rating. It’s a lotlower than you’d think. There are some exceptions, and different construction methods yield different results. For example, a Nylon rope braided with certain fibers may have a stronger working load than a rope twisted out of natural fibers.

For safety purposes, always refer to the information issued by your rope’s manufacturer, and pay close attention to the working load and don’t exceed it. Safety first! Always.

If you’re a regular sailor, climber, or arborist, or just have a keen interest in knot-tying, be warned! Every knot that you tie will reduce your rope’s overall tensile strength. Some knots aren’t particularly damaging, while others can be devastating. A good rule of thumb is to accept the fact that a tied knot will reduce your rope’s tensile strength by around 50%. That’s an extreme figure, sure, but when it comes to hauling critical loads, why take chances?

Knots are unavoidable: they’re useful, practical, and strong. Splices are the same. They both degrade a rope’s strength. They do this because a slight distortion of a rope will cause certain parts of the rope (namely the outer strands) to carry more weight than others (the inner strand). In some cases, the outer strands end up carrying all the weight while the inner strands carry none of it! This isn’t ideal, as you can imagine.

Some knots cause certain fibers to become compressed, and others stretched. When combined together, all of these issues can have a substantial effect on a rope’s ability to carry loads.

Naturally, it’s not always as drastic as strength loss of 50% or more. Some knots aren’t that damaging, some loads aren’t significant enough to cause stress, and some rope materials, such as polypropylene, Dyneema, and other modern fibers, are more resilient than others. Just keep in mind that any knots or splices will reduce your rope’s operations life span. And that’s before we talk about other factors such as the weather or your rope care regime…

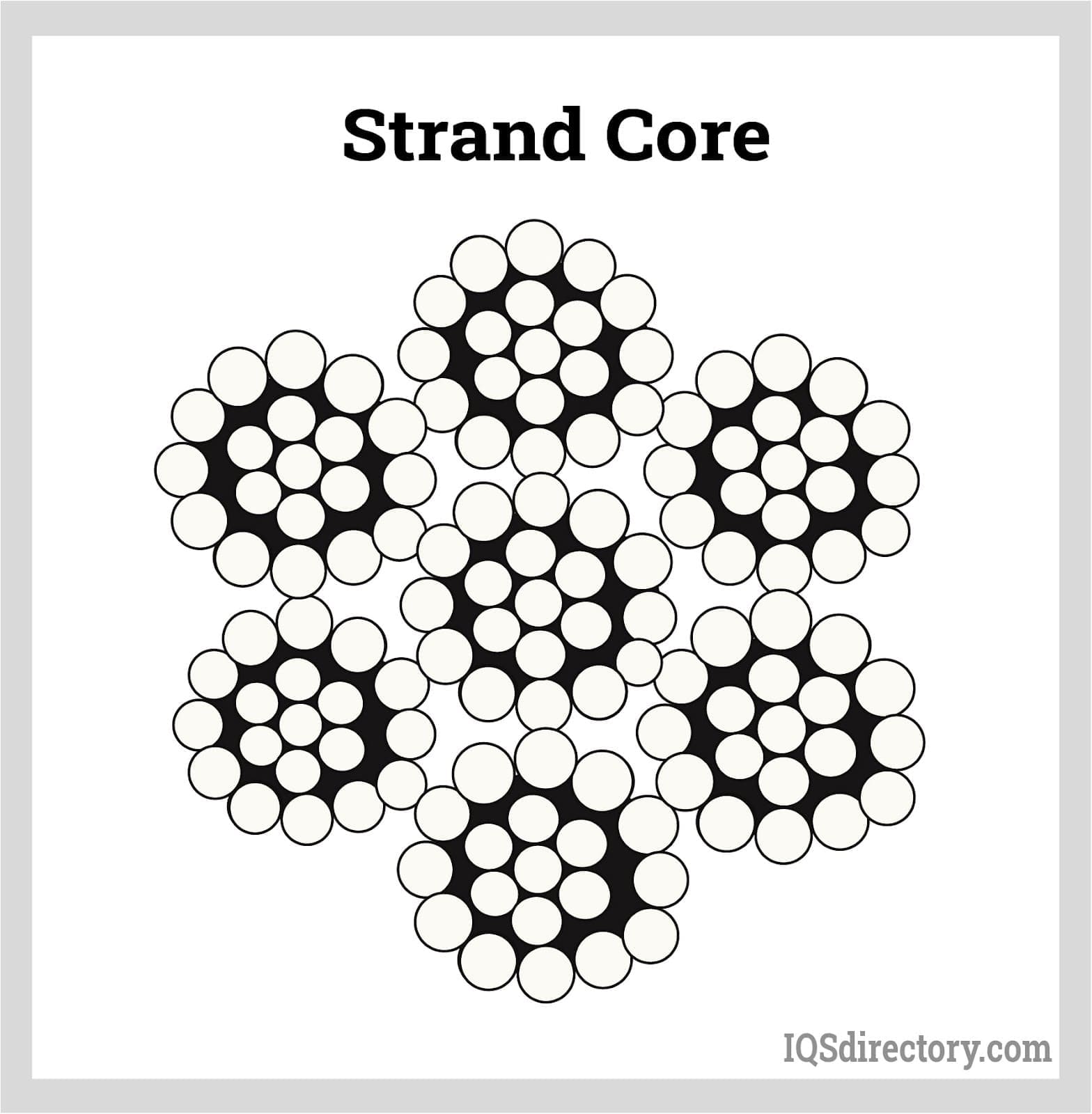

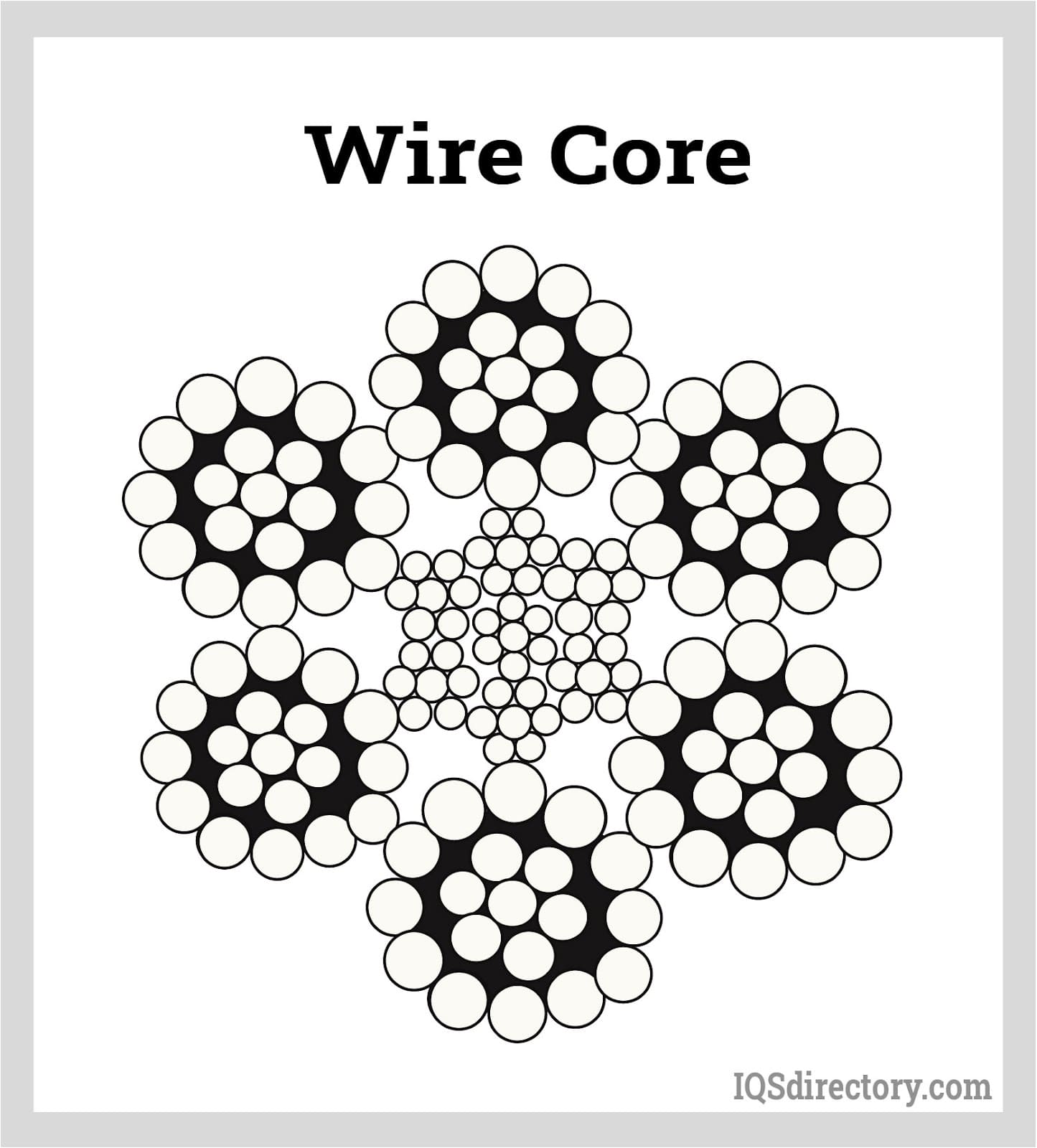

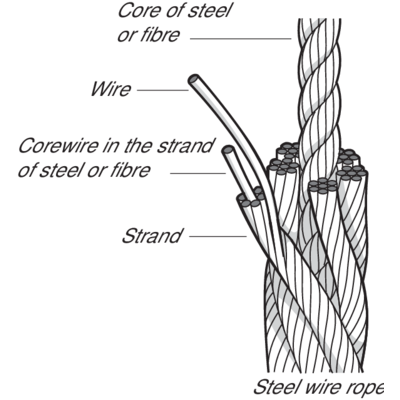

CONSTRUCTION: Expressed in numbers of strands x number of wires. 6 x 25 indicates that the wire rope consists of 6 strands, which in turn have 25 individual wires.

How to measure (or caliper) a wire rope correctly. Since the "true" diameter (A) lies within the circumscribed circle, always measure the larger dimension (B). Actual diameter can be 5% larger than nominal wire rope diameter.

There are numerous ways to cut wire rope - use only appropriate tools specifically designed to cut wire rope. Safety goggles and work gloves must always be worn. Observe other precautions peculiar to the tools used. Wire rope should be properly seized on both sides of the cut with wire or strand. Seizing wire diameter and the number and length of the seizings will depend on the diameter of the wire rope, and whether or not it is preformed.

Since wire rope is a machine with many moving parts, it requires careful installation and breaking in procedures for maximum safety and long service life. After proper installation, allow the wire rope to run through a cycle of operation at a very low speed. Keep a close watch on the wire rope, its attachments and any working parts such as sheaves, drums, rollers, etc. to make certain that the wire rope runs freely. If no problems appear at this stage, run the wire rope through several cycles of operation under light load at reduced speed. This procedure allows the component parts of the new rope to make a gradual adjustment to the actual operating conditions.

Wire rope will develop 100% efficiency, that is, break at or above minimum acceptance strength (not less than 2 1/2% below nominal breaking strength) under controlled laboratory conditions. Once fittings such as sleeves, clips, sockets, etc. are attached and/or the wire rope passes over a curved surface such as sheaves, pins, etc. its strength is decreased. In the case of wire rope passing over a curved surface this decrease in strength depends on the severity of the bend. In the case of wire rope fittings, the decrease in wire rope strength will depend on the type of fittings used. The wire rope efficiency usually ranges from 70% - 100%. For more detailed information consult the strength efficiency of wire rope table on page 86. Note, that hand spliced wire rope, while not using any fittings, has less efficiency than properly flemished and swaged wire rope. There are other factors, depending on the application of wire rope, that can cause a decrease in nominal wire rope strength. They must be considered when choosing a design factor. Refer to the Wire Rope Users Manual and/or other qualified sources for details.

Wire rope is an elastic member; it stretches or elongates under load. This elongation can be permanent or recoverable. The extent of elongation will depend on the wire rope used and the design factor chosen. While it may be acceptable for many wire rope uses to neglect its elastic properties, they are of critical importance for some uses. When in doubt about the importance of wire rope elongation consult professional help. Pre-stretching wire rope will only remove some of the constructional stretch and will not totally eliminate elongation under load.

Installation of wire rope on a plain or grooved drum requires a great deal of care. Make certain the wire rope is properly attached to the drum. Keep adequate tension on the wire rope as it is wound onto the drum. Guide each wrap as close to the preceding wrap as possible, or follow the groove in case of a grooved drum. No blanket recommendations can be given concerning direction of winding, desirable drum diameter, fleet angle, etc. Consult the Wire Rope Users Manual for this and other important technical information.

Marine Eye Fitting Size Select Marine Eye Fittings IDTMI# 360-003 wire with diameters .190, .218, .093, 1.572wire with diameters .190, .254, .108, 1.945TMI# 360-003.2 wire with diameters .190, .383.195, 2.352wire with diameters .250, .406, .202, 2.655wire with diameters .313, .543, .260, 3.071TMI# 360-003 wire with diameters .190, .218, .093, 1.572wire with diameters .190, .254, .108, 1.945TMI# 360-003.2 wire with diameters .190, .383.195, 2.352wire with diameters .250, .406, .202, 2.655wire with diameters .313, .543, .260, 3.071

One of the requests we frequently receive is to include an overall diameter (OD) of the customized cable bundles being quoted. This request comes up often since electrical contractors need to be able to estimate if their plans are in sync with one another, and a ballpark estimate gives them a sense that their initial assumptions and calculations are correct, or if they want to add a little margin of error in the costs of the conduit, or if they really have to crunch the numbers to ensure everything fits within the National electrical code (NEC) standards.

As an OEM that reprocesses premanufactured wire, we do not make the wire itself, and each manufacturer has its own tolerances in terms of OD for each wire jacket type.

Here we use averages of manufacturer specs to give us the ability to estimate the OD of the wire bundle for our own necessary calculations which is reel capacity. The calculation itself is a matter of mathematics, and with known data can be formulated and calculated using simple excel spreadsheets.

This calculation helps determine if the conduit planned is the correct size or not. The easiest way to actually measure the cable bundle is with a small measuring tool called an OD-Tape. OD-Tapes are used in the electrical field and plumbing fields to measure both length and overall outside diameter. To estimate the bundle, cut one 3-inch piece for each conductor in your bundle, tape them all together and use the OD tape to measure the outside.

2. Utilize a standard formula to calculate the cross-section area of that one wire using the area formula for a circle, i.e., area equals the square of the diameter multiplied by 3.14 (pi) divided by four. As an example, a2-inchwire would have an area of 3.14 square inch because 2 x 2 x 3.14 divided by 4 = 3.14.

4. Multiply the number of wires by the area of one wire. This will give you the total area. To continue the example, suppose you had 30 same-size wires. The total area would be 94.2 square inches (3.14 x 30). This example would be for a bundle of the same sized wires in the bundle.For a composite bundle with multiple AWG sized conductors it is only slightly more complicated. To calculate you simply follow the area calculations for each size of wire, that is, calculate one wire’s area and multiply it by the number of equal-sized wires (so if #14 is 10 wires then multiply the OD by 10; If #12 is 20 thenmultiply the OD by 20). Finally, you would add all the areas together to compute the total area.

5. Calculate the diameter of the bundle by using the same area formula, modified to solve for diameter: Diameter = square root (4 area / 3.14) In the example: Diameter = square root (4 x (94.2 / 3.14) = 4 x 30=120)

We understand that there are many factors that go into choosing the correct sling, wire rope, rigging hardware or lifting device for a lift! Let our sales team help!

Drawings are appreciated although not required when you order sheaves, whether custom or stock. Please provide as many measurements as you can using our quote/order form as a guide. We will contact you to be clear on your needs before preparing our quote. For a copy of our latest catalog, please fill out our contact form and we"ll send one along. You can also send us any questions or comments through the same contact form. Thanks for your interest in our products. We look forward to serving you.

Did you know there are 9 different dimensions that factor into the specifications for a sheave? The central portion contains 3 important measurements: the shaft, the bore and the hub diameter. Then there"s the groove, pitch and outside diameters as well as the groove depth. Measuring along another axis we need to determine the correct rim and hub widths. And finally, the size of the wire rope is important to consider. Once you have all these measurements at hand, we can determine if a standard size will fit your needs. Or you can just give us a call and we"ll help you out! If the sheaves we carry in our regular stock are not the right size for your purposes, please contact us for pricing on custom work. Or, you may fill out an order form with your specs and we"ll gladly put together a quote for you.

Choose from our stock sheave sizes or we can manufacture your wire rope sheaves to your design and specifications. SELECTING FROM OUR STOCK SIZES OFFERS YOU QUICKER DELIVERY AND ECONOMY, or we can stock for your ongoing requirements. Please complete this form and we will gladly quote.

Manufacturing sheaves for wire rope is our primary business. We have the capability to manufacture your sheaves to your design and specifications or you can choose your wire rope sheave from our large inventory.

Our wire rope sheaves are made from quality materials and machined to precise dimensions and tolerances in order to meet our high standards. In addition, we offer many other options to satisfy your sheave requirements, including choice of material, heat treating of the groove, case hardening, grease fittings, keyways and set screws, plating and many more. We also carry bearings and bronze bushings.

Bear Equipment originally specialized in excavator and undercarriage crane parts. As our customers" demands for the supply of replacement wire rope pulley parts grew, we began specializing in sheaves. Today, wire rope sheaves is our primary business. For a manufacturer of wire rope and cable sheaves and pulleys, speak with the manufacturing experts at Bear Equipment today!

8613371530291

8613371530291