wire rope diameter measurement pricelist

Mark-10 defines accuracy as a percentage of full scale of the instrument. To determine the measurement error as an actual load value, multiply the accuracy percentage by the instrument’s capacity.

Since our inception, we are offering industry standard PVC coated wire ropes to various clients based in domestic as well as global market. Presence of latest machines and modern technology assists in manufacturing the PVC coated wire ropes in various dimensions and sizes, as per the drawings provided byread more...

Owing to the knowledge of this domain, we are offering to our patrons a broad spectrum of Galvanized Wire Rope. These ropes can operate in demanding conditions and must resist crushing, bending fatigue and abrasion. Apart from this, these ropes are available in different sizes and thickness.

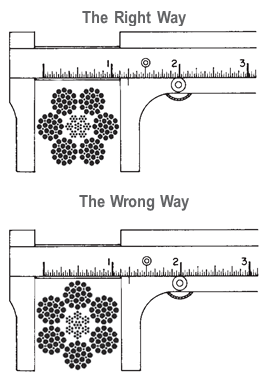

The actual diameter of a wire rope is the diameter of a circumscribed circle that will enclose all the strands. It’s the largest cross-sectional measurement as shown here. You should make the measurement carefully with calipers.

The rope diameter should be measured on receipt for conformity with the specification. British Standard (B.S. 302:1987, standard steel wire rope, Part 1. Clause 5.1) allow for a tolerance of - 1% to 4 % of the nominal rope diameter.

The generally accepted method of measuring rope diameter for compliance with the standard is to use a caliper with jaws broad enough to cover not less than two adjacent stands. The measurement must be taken on a straight portion of rope at two points at least 1 meter apart. At each point two diameters at right angles should be measured. The average of the four measurement is the actual diameter.

After the rope has made the first few cycles under low load, the rope diameter should be measured at several points. The average value of all the measurements at each point must be recorded and will form the basis of comparison for all future measurements.

The measurements of the rope diameter an essential part of all inspections and examinations. It ensures the maximum diameter reduction does not exceed the recommended figure. As stated in 5.2 British standard 6570 recommends that a wire rope should be discarded when the diameter of the rope is reduced to 90% of the nominal diameter.

A comparison of the measured data with the recorded previous values can detect an abnormal rate of reduction in diameter. Coupled with assessment of previous rope examination data, the probable date of rope renewal can be predicted.

If we examine the cross-section of a six-stand wire rope, we will find that measuring the thickness of the rope over the crowns (Fig-a) will produce a higher value than measuring it over the valleys (Fig-b). The actual diameter of the rope is defined as the diameter of the circumscribing circle.

When using a conventional caliper, wire rope with an even number of outer strands (four-, six, eight-, and multi strand) ropes must be measured from crown to crown. The advantage of a proper wire rope caliper with measuring plates is that even if the measurement is carried out "incorrectly", adjacent crowns are always included, so that the actual diameter is determined at any section. (Fig-c)

Measuring the diameter of wire rope with an uneven number of outer strands (three, five, seven, or nine-strand ropes) is more complicated: a crown on the one side of the wire rope always has a valley as a counterpart on the other side of the wire rope. A conventional caliper, therefore, has to be applied diagonally to the axis of the rope, so that at any time a crown adjacent to a valley is covered. Again a wire rope caliper with measuring plate is definitely to be preferred as it always includes strands crowns.

In all cases during periodic examinations where the measurements are to be recorded, the rope should be measured as already described. Where the roundness is being checked to detect potential faults, two diameters, one at right angles to the other can be taken and noted in the records. The entry into the records might read rope diameter : 20.4/20.5mm.

After a rope has been fitted to the appliance, its length cannot be measured again accurately, with out a great deal of trouble. The purpose of measuring the length of lay is to detect any increase in the rope length which may have been caused by corrosion, core deterioration or rope rotation (unlaying). With n new rope the wire and strands should be allowed to settle into their permanent position. Six or seven lifting cycles with a light to medium load are recommended before measuring error, the measurement should be made over four lays and the length divided by four lays and the length divided by four to find the average lay length.

On eight strand ropes the eight, sixteen, twenty-four and thirty-second strands must be marked. Using a straight length of the rope and with the rope under no load, first mark any strand on the crown with a piece of chalk; this strand now become"" crown zero"". Excluding this strands, count the next eight strands and mark the eight strand with chalk. Exclude the eight strand and repeat the procedures further two times. The measured length between the outer chalk marks is then divided by four to give the lay length.

As a rough check on the overall accuracy of the chalk marking, the length of lay for eight strand ropes is approximately between 6.25 and 6.5 x the diameter of the rope e.g. using a lay length of 6.5 x rope diameter, four lay length of a 32mm diameter rope will be 32mm x 6.5 x 4=832mm.

An alternate method of measuring the rope lay is to secure the free end of the roll of adding machine paper to the rope with adhesive tape. The paper is rolled out over the rope and simultaneously the wax pencil is drawn over the paper, providing a clear print of the outer wires of the rope. The finished print can be field for comparison with later measurements.

A third method is to wrap typing carbon papers round the rope under the roll of paper. By rubbing along the paper with a piece of cardboard, the carbon marking on the underside of the paper can be confined to the tops of the strand crowns.

Wire ropes are used on a regular basis in several industrial and home-based applications. To meet the needs of customers, Moglix has introduced a wide range of wire ropes for sale. The products that are available in this category are ungalvanised and are ideal for use in engineering. These steel wire ropes can be used in cranes, excavators and other items that are used in engineering projects. These ropes have been manufactured under the supervision of experts and comply with the existing quality standards in the industry.

At Moglix, we stress on creating trustworthy, mutually beneficial relationships with customers. In order to do so, we have sourced the best quality of wire ropes from leading brands in the market such as Mahadev. We also deal in all types of hand & power tools, cutting and machining tools, measurement & testing tools, welding tools, abrasives, adhesives, tapes and sealants, oils & paints, industrial oils & lubricants, electrical equipment, cleaning tools, personal protection equipment etc. To acquire some of the best online deals on wire ropes, select from the new range offered by Moglix.

Choosing the right wire rope for a job will be based on many factors: application, required strength, and environment, to name a few. Understanding the basic terminology and the abbreviations associated with wire rope can help you decide which will work best for you.Size

Displayed as inch or fractional inch measurements, the size indicates the diameter of the rope. Industry standards measure the rope at its widest point. A wide range of sizes are available.

The numbers used in describing wire rope indicate its construction. For example: a 6 x 19 construction wire rope, the first number is the number of strands (6); the second number is how many wires make up one strand (19).

Regular lay:Also known as a right lay or ordinary lay, this indicates that the strands pass from left to right across the rope and the wires in the rope are laid in opposite direction to the lay of the strands. This type of construction is the most common and offers the widest range of applications for the rope.

Lang lay:This indicates that the wires are twisted in the same direction as the strands. These ropes are generally more flexible and have increased wearing surface per wire than right lay ropes. Because the outside wires lie at an angle to the rope’s axis, internal stress is reduced making it more resistant to fatigue from bending. This type of rope is often used in construction, excavating, and mining applications.

Fiber cores are made of vegetable (sisal, etc.) or synthetic (polypropylene, etc.) fiber and offer more elasticity. Independent wire rope cores offer more support to the outer strands, and has a higher resistance to crushing and heat. Independent wire rope core also has less stretch and more strength.

Buy Bharat Ropes Ungalvanized Fiber Core(Dia-6mm, Size-6x36 mm) Steel Wire Rope online in India at wholesale rates. If you have been looking for Bharat Ropes Ungalvanized Fiber Core(Dia-6mm, Size-6x36 mm) Steel Wire Rope dealers, your search ends here as you can get the best Bharat Ropes Ungalvanized Fiber Core(Dia-6mm, Size-6x36 mm) Steel Wire Rope distributors in top cities such as Delhi NCR, Mumbai, Chennai, Bengaluru, Kolkata, Chennai, Pune, Jaipur, Hyderabad and Ahmedabad. You can purchase Bharat Ropes Ungalvanized Fiber Core(Dia-6mm, Size-6x36 mm) Steel Wire Rope of the finest quality and rest assured to get the best in terms of both durability and performance. If you are bothered about the Bharat Ropes Ungalvanized Fiber Core(Dia-6mm, Size-6x36 mm) Steel Wire Rope prices, you can be totally sure to get the best rates as Industrybuying brings you genuine Bharat Ropes Ungalvanized Fiber Core(Dia-6mm, Size-6x36 mm) Steel Wire Rope rates and quality assured products only from the best of brands with exclusive brand discounts you won’t find anywhere else. Procure Bharat Ropes Ungalvanized Fiber Core(Dia-6mm, Size-6x36 mm) Steel Wire Rope today and avail the best offers on your purchase.

8613371530291

8613371530291