wire rope diameter measurement for sale

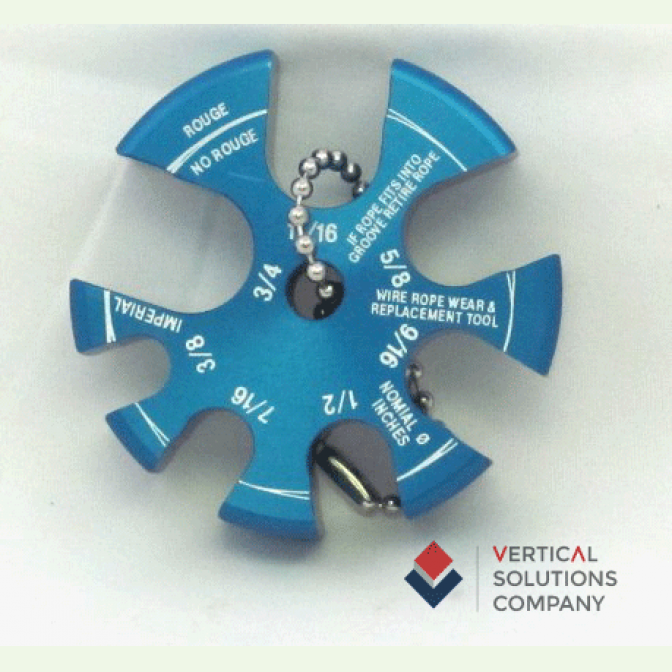

Made of Marine-grade 316 Stainless steel for years of reliable service. With this pocket sized tool you can measure rope, wire, cable and fasteners quickly and accurately. Metric and imperial scales are etched into the surface for an accurate measurement ship or shore.

Straightforward design and use: As a universal go-no-go gauge, if a specific portion of wire is suspected of wear, or rouging, simply place the gauge slot for that particular original diameter over the rope crowns on a straight section. If the rope will not enter the slot, its diameter is considered satisfactory.

Mainly used in a variety of wires, cables, pipe production line, the measurement ofouter diameter and adjust the extruder screw speed or traction speed, to control thepurpose of OD. Can also be applied to the outer diameter of workpiece and sizemeasurements.

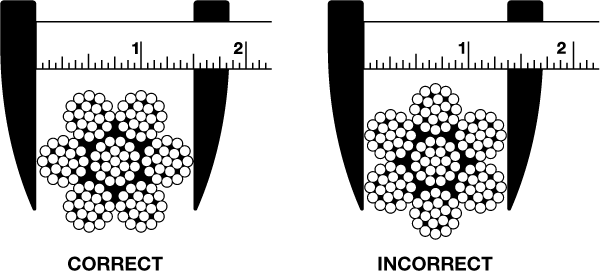

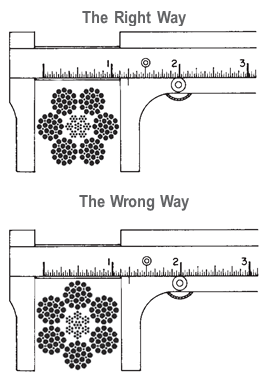

The actual diameter of a wire rope is the diameter of a circumscribed circle that will enclose all the strands. It ‘s the largest cross-sectional measurement as shown here. You should make the measurement carefully with calipers.

As we move toward metric measurements, it will become increasingly necessary to convert English units into Sl – International System of Units – (or metrics), and vice versa.

For standard, general purpose wire ropes, in measuring diameter, the industry is leaning toward a “soft” conversion to metric during the transition period. For example, a 1″ diameter rope converts to 25.4 mm in metrics. Using the soft conversion, this is changed to the whole metric size that most nearly parallels the 1″ size range, or 26 mm. In sizes smaller than 5/8′: the rope diameter is rounded to the nearest 0.5 mm.

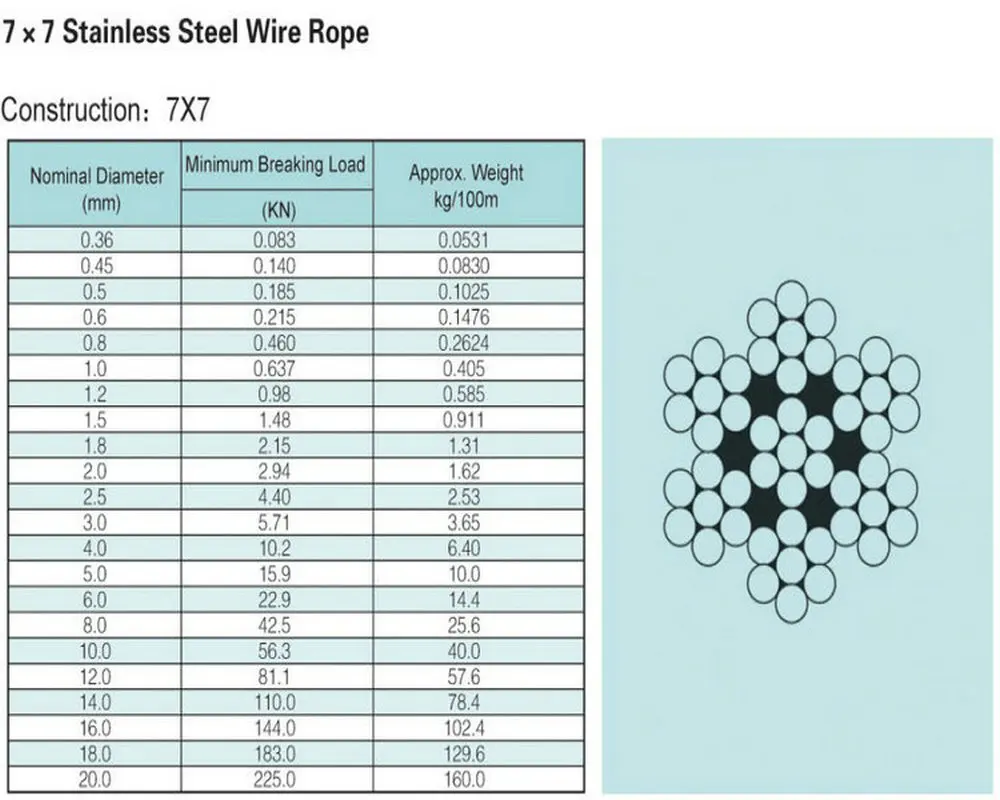

The following table gives the closest equivalent metric diameters for rope sizes up through 5 inches. Again , these metric sizes are based on the industry’s “soft” conversion. Your application may have tighter tolerances that require a hard conversion. Therefore, the values in the table would not apply.

Since rope minimum breaking force and weight per unit of length vary for different types and grade of ropes, the following conversion factors are given to help you convert the figures you need:

Note: The newton (a unit of force) is the correct unit for measurement of minimum breaking force in the Sl system of units. We have included a conversion f

To see which colors and types of rope are available for retail sale in each diameter, please visit the collections below. You can also filter rope by color or rope size using the side menu bar on any rope collection page.

Rope Size: Diameter and circumference are nominal. A new, unused rope in a relaxed state will measure larger; loading and use compacts ropes, sets splices, and lessens rope size. This is especially prevalent in rope sizes above 4" diameter. Published nominal sizes from 4-1/8" and larger represent stabilized or preloaded size.

Ravenox provides ropes for a variety of markets, from offshore working and lifting lines, tug and salvage, ship and barge mooring lines, mining tow lines, utility and RV winch lines to theatrical rigging lines and commercial fishing lines. Email Ravenox for a quote or for more information for ropes suitable for a variety of market solutions.

Rope diameter is normally specified by the user or given in instruction manuals accompanying the customers" machine. So measuring the accurate diameter of steel wire ropes becomes extremely important for our customer to provide correct numbers. We believe the following instruction will give your some guidance:

Ropes come in many different diameters and there are guidelines to help you choose the right diameter for your purpose. But how do you know which diameter the halyards and sheets on your boat are? How do you measure the diameter?

The diameter of a rope is based on the combination between the construction of the rope and the amount of material used. A rope can be heavy and compact, or light and loosely braided. This influences the properties of the rope and therefore can affect the measurement of the size. A loosely braided rope gets thinner and flattens out under load, whereas a compact rope with more fibres will keep its shape. This is why measuring the diameter when the rope is under load will have different result as to when the rope is not loaded.

Due to this, the diameter of rope is less precise than with steel wire. Determining a diameter for ropes is an empirical process. This means that every manufacturer develops and adapts a rope, based on observation and experience. This causes the possibility for small differences between ropes with, according to the specification, the same diameter. A rope that is specified as a 10mm rope can therefore sometimes be 9mm or in other cases 11mm.

The 6X25 galvanized industrial wire rope is made of six strands of 25 wires, making it an exceptionally strong and durable choice for heavy-duty applications.

It features a drawn strand surface, which minimizes abrasions and friction. Drawn galvanized ropes have the same breaking strength as bright wire rope, with additional wear protection on the exterior.

The galvanized wire rope features an independent wire rope core (IWRC) for additional internal support that helps to increase the strength and longevity of the rope for heavy-duty applications.

For all wire rope, the best time to begin taking appropriate care and handling measures, is immediately upon receiving it. On arrival, the rope should be carefully checked to make certain that the delivered product matches the description on tags, requisition forms, packing slips, purchase order and invoice.

After these necessary preliminary checks, the next concern is that of providing weather-proof storage space. If wire rope is to be kept unused for a considerable time, it must be protected from the elements. The ideal storage area is, a dry, well-ventilated building or shed. Avoid closed, unheated, tightly sealed buildings or enclosures because condensation will form when warm, moist outside (ambient) air envelops the colder rope. Although wire rope is protected by a lubricant, this is not totally effective since condensation can still occur within the small interstices between strands and wires, thereby causing corrosion problems.

On the other hand, if the delivery site conditions preclude storage in an inside space nad the rope must be kept outdoors, it should be effectively covered with a waterproof material. Moreover, weeds and tall grass, in the assigned storage area, should be cut away; the reel itself should be placed on an elevated platform that will keep it from direct contact with the ground. Providing an adequate covering for the reel also prevents the original lubricant from drying out and thereby losing its protection.

Never store wire rope in areas subject to elevated temperatures. Dust and grit, or chemically laden atmospheres, are also to be avoided. Although lubricant applied at the factory offers some degree of protection, every normal precautionary measure should be taken with every coul or reel of wire rope.

Whenever wire rope remains in position on an idle machine, crane, hoist, etc., it should be coated with an appropriate protective lubricant. In these circumstances, as with ropes stored outside, moisture, in the form of condensation, rain or snow may form on the wire rope. Some of the moisture may easily become trapped inside the rope and cause corrosion problems.

If the wire rope is to be kept inactive for an extended period while wound on hte drum of the idle equipment, it may be necessary to apply a coating of lubricant to each layer as the rope is wound on the drum. Cleaning, inspection and re-lubrication should precede start-up of the equipment.

The greatest difference can be seen in the length of the measured rope when comparing it at a tensioned and untensioned state. Tests have shown an approximate 2% difference in length is found with 12-strand AmSteel®-Blue when tension is used during

measurement compared to an untensioned rope. Greater variability was seen with untensioned measurements, with as much as 2% of the same rope’s length but when tensioned that difference dropped to 0.5%. The amount of variation seen between tensioned

and untensioned ropes will also be affected by the material and construction of each rope.Necessary Rope Measuring Procedures:Supply constant, even tension (no more than 10 lb is needed) to all diameter ropes.

When no tensioning device is available, laying the rope to the complete required length on a flat surface, and tensioning it with hand force while measuring the full length will reduce the variability and difference in length.

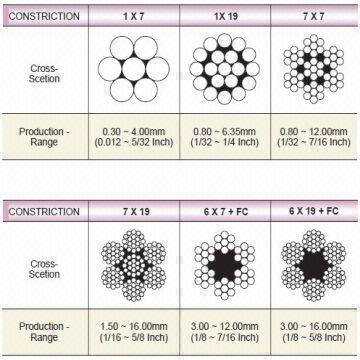

Galvanized wire rope is categorized by number of strands in its construction. We supply most of them but we concentrate on the two major categories of galvanized (and ungalvanized or bright) wire rope. These “classes” are referred to as 6x19 and 6x36. Within each category of galvanized wire rope there are different “constructions” illustrated in the tables below.

Wire rope, galvanized and ungalvanized is used for many kinds of projects and applications. No matter the application galvanized wire rope must be used properly to insure the safest working conditions. All of our galvanized wire rope is manufactured to meet or exceed Federal Specification RRW-410 and is mill certified.

All of these general purpose wire ropes are available in full reels, custom cut sizes or as part of a custom made wire rope sling. Contact us today for more information.

Galvanized wire rope also comes in different strength categories (IPS and EIPS) and different cores (FC or fiber core and IWRC or independent wire rope core). Relevant data for each is listed in the table below.

8613371530291

8613371530291