wire rope drum capacity calculator supplier

With nearly 4,000 employees worldwide, WireCo WorldGroup is a great place for you to build a rewarding career. Our professionals enjoy the opportunities of a global manufacturing and distribution leader as well as a culture of open communication, professional growth, and friendly camaraderie that fosters innovation and problem solving.

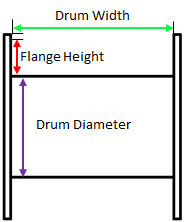

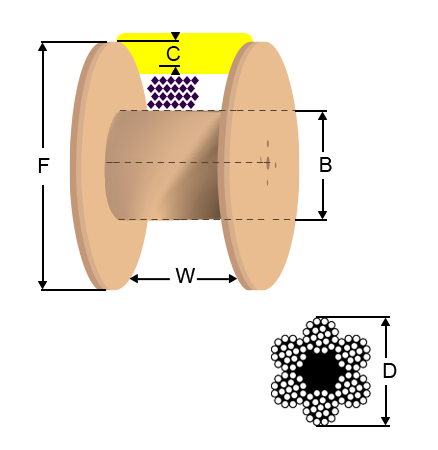

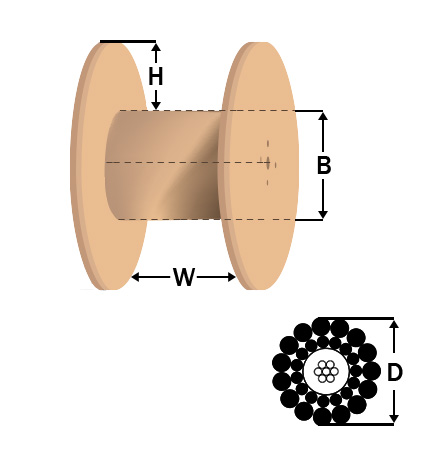

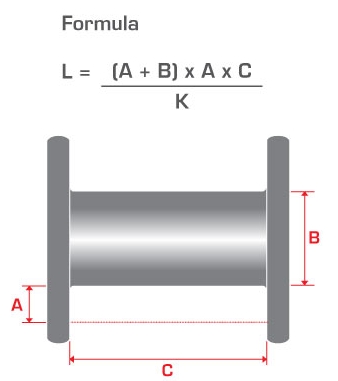

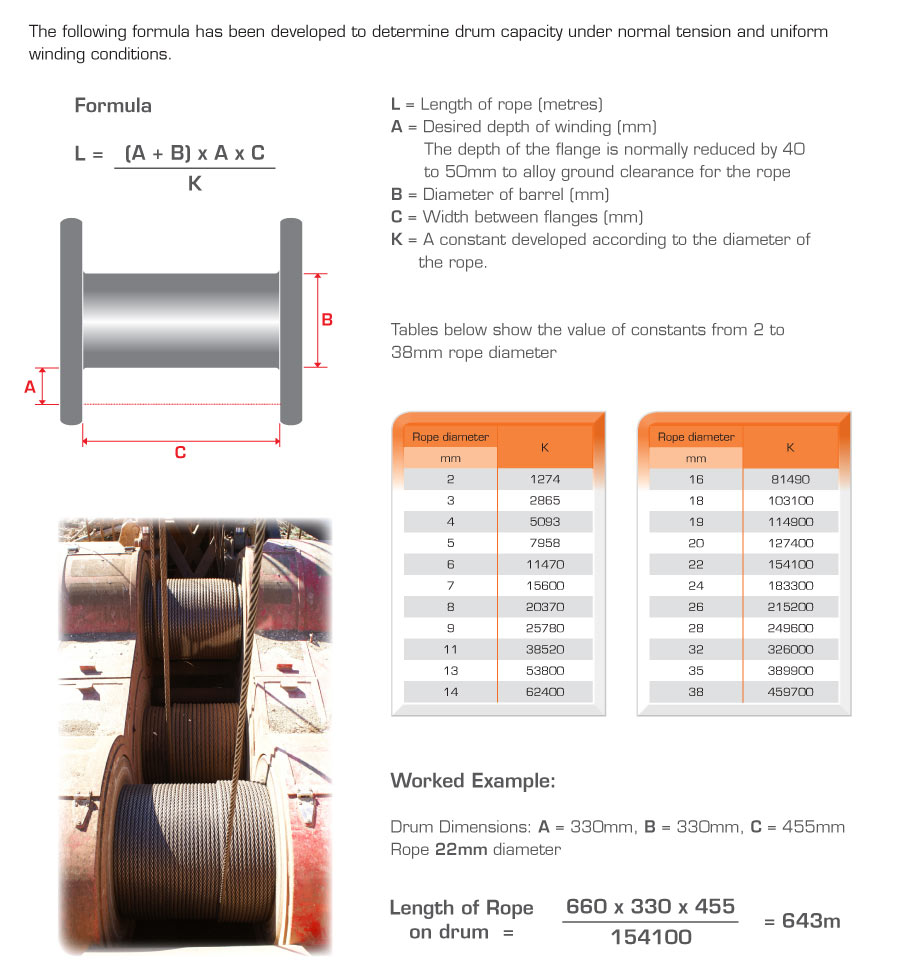

While it is virtually impossible to calculate the precise length of wire rope that can be spooled on a reel or drum, the following provides a sufficiently close approximation.

* This formula is based on uniform rope winding on the reel. It will not give correct results if the winding is non-uniform. The formula also assumes that there will be the same number of wraps in each layer. While this is not strictly correct, there is no appreciable error in the result unless the traverse of the reel is quite small relative to the flange diameter (“H”).

** The values given for “K” factors take normal rope oversize into account. Clearance (“x”) should be about 2 inches unless rope-end fittings require more.

A handy tool for finding a cable drum that suits your needs - just enter your cable diameter and required length and it will return a list of matching cable drums.

All figures given are based upon a theoretical ‘tight pack’. It is recommended that an allowance of up to 30% be made to accommodate loose winding. A lower percentage could be used if the crew are known to always wind the drums neatly!

The combined weight of cable and drum is highlighted in orange when the weight exceeds 16kg. At this weight a user may need to make a risk assessment with respect to moving and/or carrying such without assistance.

† Drums with CTS suffix have an open hub "Cable Tail Support" on their flange. This would accommodate a further couple of metre"s of cable to allow the

‡Drums with CTF suffix have cable tail supports plus an additional flange, forming an 80mm wide extra section on the side of the drum to protect the tail. Calculated capacities are shown including and excluding the extra section.

Remember to allow for a bit of space on the drum for uneven wrapping etc, unless you think you can wrap it perfectly everytime all the time? Also the machinery handbook lists specs on about 300 different cables, from 1/8 to 3", and various make ups and weave patters, I think I grabbed the 7x19 standard hoisting specs but I didn"t write that down, There are by all means many variable with wire rope, please consult your local dealer about tonnage capacity and make up, this is purely meant to help with filling up yer spool...

At the basis of any equipment selection, winches or otherwise, is an assessment of what is required in terms of capacity and capability. To enable the correct selection of winch, motor and gearbox, it is essential that basic application parameters as Load and Speed are known and understood. Below a brief explanation is given about the data and calculations required for the primary winch selection. The essence of winching is to move objects from one position to another by means of a length of rope. The rope is fixed to the object at one end, and to the winch drum on the other.

This makes power more understandable, since we know the required Nm (line pull x effective drum radius) to move the load and the required speed at which the load has to be moved. The higher the speed (at a given load), the more power we need.

With the required amount of power (kW) determined, the amount of torque (Nm) involved in the application must be determined. Depending on the effective drum radius and the load the torque at gearbox and motor level can be calculated. The amount of torque at gearbox level is important to make sure a sufficiently strong gearbox is chosen, and at motor level to make sure the load can be actually moved.

The effective drum radius used in this calculation is the distance between the centreline of the active rope layer and the centreline of the drum. For winches with only one layer of rope this is a constant factor. For winches with multiple layers the distance is a variable, and depends on the amount of rope wound on the drum. Please see Fig. 3-2 for the influence of the number of rope layers on the effective drum diameter.

Note:The rope diameter (required for the above calculation) follows from the nominal winch load, the required safety factor and the type of rope selected.

Selecting the correct gearbox, the maximum torque value during operation (or with an applied brake) is leading. In case of doubt go up one size of gearbox, the possibly too generous extra torque capacity of the gearbox will translate into a longer life. Make sure the calculated gearbox can be installed into or onto the winch and that it matches with the selected motor and resulting motor performance.

The winches found in the EMCÉ catalogue have drum diameters and lengths that have proven themselves during many years of real world use, and will be perfect for most standard applications. When special demands or requirements are present, it may be required to calculate with a non- standard drum. A few rules must be respected calculating a non-standard drum which are outlined below.

The minimum drum diameter follows from the minimum rope bending radius. Drum diameter/rope diameter ratio should not be too small since rapid rope wear will result, and for this reason the rope/drum ratio is stipulated in many regulations. The drum however may have a (much) larger diameter to enable storage of the required length of rope within a given drum width and number of rope layers. A larger diameter drum stores more rope for a given width, but also increases the effective drum radius and therewith the required torque for a given load. Make sure the diameter used in the calculation is an "existing" diameter i.e. a diameter that is available in the EMCÉ catalogue for (bigger) winches of the same model. Alternative dimensions can be specified, but will increase the cost of the modification unnecessary.

Note:Also make sure the drum flanges have a sufficiently large diameter to comply with the regulations. Depending on the regulation applicable the upper rope layer must remain 3-5 rope diameters below the edge of the flange. As with drum diameters it is advisable to use "existing" flange diameters. Again make sure an "existing" diameter is selected for the flanges, the same logic as for the drum diameter applies.

Drum width can be more or less chosen freely to suit the application, but increasing the drum width has a negative effect on the fleet angle of the winch rope, while at the same time winch footprint and winch cost increase. The EMCÉ standard drum dimensions as shown in the catalogue provide a sensible balance between rope storage, winch performance and winch dimensions.

Note:Make sure the drum width is sufficiently large to store at least an extra three safety wraps for steel wire rope and at least 6 safety wraps for man-made fibre ropes that will remain on the drum under all circumstances for safety reasons.

Frame dimensions usually result from the drum length and the combined length of transmission and motor. These dimensions can be derived from the catalogue information, and when a longer than standard drum is specified, the extra length can simply be added to the catalogue figures. Special care is required when bigger (longer) motors or gearboxes than standard are specified, or when extra equipment like clutches or band brakes are added to winches. Please contact the EMCÉ sales department for the effect this extra equipment will have on the frame dimensions. Make sure that the available space for installing the winch is sufficient for installing the winch itself and for the extra space required needed to operate and maintain the winch.

To obtain reasonable service life from your aircraft cable or wire rope, you must choose the optimal diameter of rope and sheave for your application. In general, the larger the size of the drum or pulley with respect to the wire diameter, the longer the service life. The opposite is also true: in general, the smaller the size of the drum or pulley with respect to your wire rope, the shorter the service life. Keep these relationships between cable, rope, and pulleys in mind when specifying the competence you use in your application.

The tables below provide the minimum recommended pulley diameter as well as the approximate bend radius of the rope. You"ll notice that the calculation is approximately half of the minimum recommended pulley tread diameter. Whether running fully over the sheave or drum, or some fraction thereof, check your design against the recommendations to better understand the service life you can expect in relation to the other factors involved.

8613371530291

8613371530291