wire rope drum capacity calculator pricelist

A handy tool for finding a cable drum that suits your needs - just enter your cable diameter and required length and it will return a list of matching cable drums.

All figures given are based upon a theoretical ‘tight pack’. It is recommended that an allowance of up to 30% be made to accommodate loose winding. A lower percentage could be used if the crew are known to always wind the drums neatly!

The combined weight of cable and drum is highlighted in orange when the weight exceeds 16kg. At this weight a user may need to make a risk assessment with respect to moving and/or carrying such without assistance.

† Drums with CTS suffix have an open hub "Cable Tail Support" on their flange. This would accommodate a further couple of metre"s of cable to allow the

‡Drums with CTF suffix have cable tail supports plus an additional flange, forming an 80mm wide extra section on the side of the drum to protect the tail. Calculated capacities are shown including and excluding the extra section.

With nearly 4,000 employees worldwide, WireCo WorldGroup is a great place for you to build a rewarding career. Our professionals enjoy the opportunities of a global manufacturing and distribution leader as well as a culture of open communication, professional growth, and friendly camaraderie that fosters innovation and problem solving.

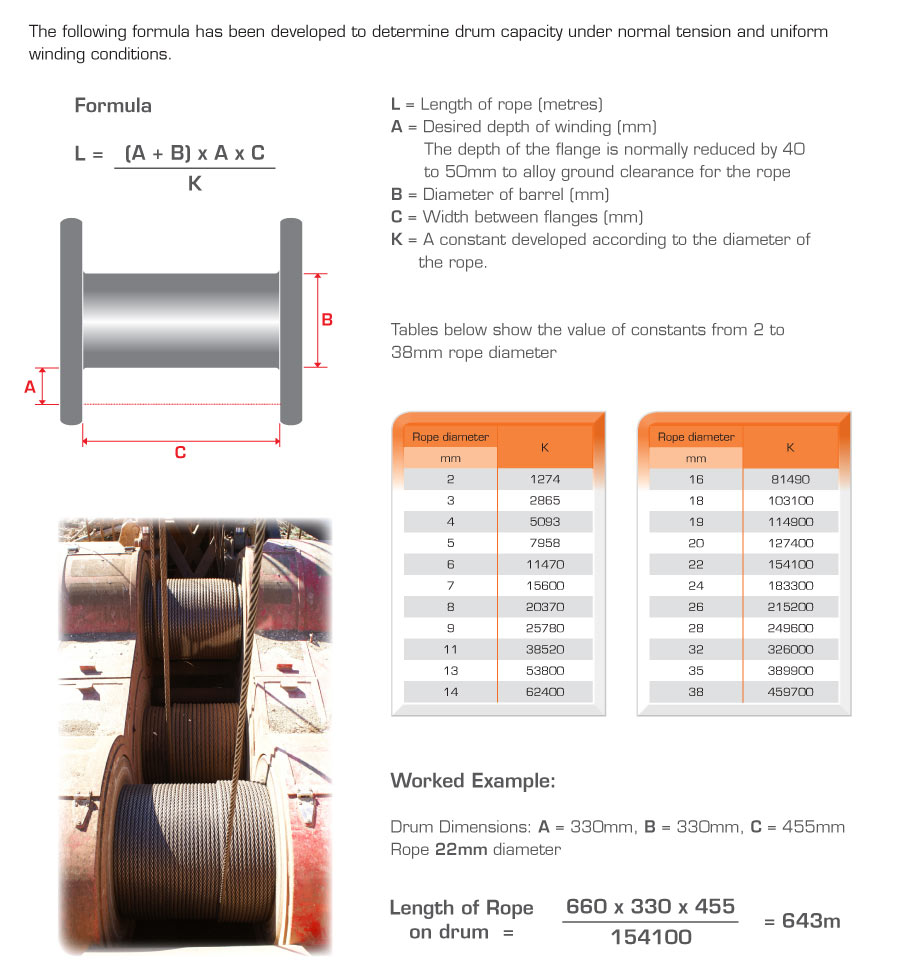

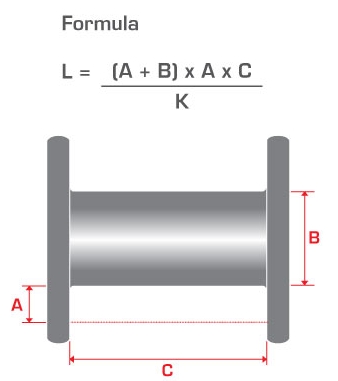

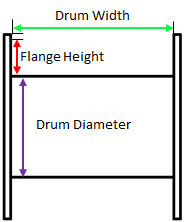

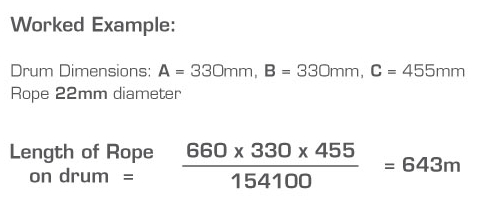

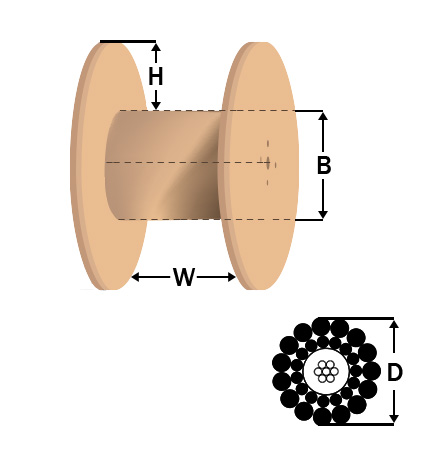

While it is virtually impossible to calculate the precise length of wire rope that can be spooled on a reel or drum, the following provides a sufficiently close approximation.

* This formula is based on uniform rope winding on the reel. It will not give correct results if the winding is non-uniform. The formula also assumes that there will be the same number of wraps in each layer. While this is not strictly correct, there is no appreciable error in the result unless the traverse of the reel is quite small relative to the flange diameter (“H”).

** The values given for “K” factors take normal rope oversize into account. Clearance (“x”) should be about 2 inches unless rope-end fittings require more.

There are a variety of cables and wires that are used for various purposes. They can either be hidden underground or pass overhead. Crane Cable is one such cable wire rope made out of several strands of metal wires that are twisted together into a helix form to make them into a single rope. Initially, wrought iron was used to make these Crane Cables however, these days steel is the primary material used. Apart from this high carbon steel and galvanized steel are also used in manufacturing these cables. Dents or flaws in the ordinary link chain can lead to severe failure whereas, damage in these EOT Crane Cablecan be easily covered up. Ther are ideally used for lifting elevators, in the transmission of mechanical power, and in cranes.

Crane Lifting Cables are resistant to corrosion and have excellent ductility for optimal fatigue. They have a high breaking strength compared to steel crane wire rope. The radially elastic rope structure absorbs the dynamic force thus giving it high impact resistance. Crane Cable Wires are said to be cost-effective as a strong and durable structure helps in reducing maintenance costs and downtime. They can be coated with bright phosphate or galvanized depending upon the customers’ requirements.

Crane Electrical Cable is available in rotating, rotation, compact, or non-compact structures. Most of the wire ropes have the tendency of developing torque and are thus prone to rotation. However, non-rotation wires are designed in a way that their outer rotation naturally counteracts the inner strands rotation. Crane Hoist Cable can be used in tower crane ropes or offshore crane ropes.

Overhead Crane Cable reel should be capable of winding it automatically. The drive torque of the crane cable should not be less than the max winding torque of the winding crane cable. The cable conductor should be as small as possible when the Crane Rope laying acts on the traction force.

The Crane Wire Rope does not have a reinforcement core, the maximum tension allowed on the copper conductor cross-section is 20N/mm2. We at Bhuwal Insulation Cable Pvt. Ltd. not only provide you the best quality Tower Crane Cable but also the parts required to assemble them. Our long-standing reputation in providing the best quality product at a competent price has made us one of the leading Crane Cable manufacturers in India.

Cables or cords are the wire ropes which have diameters smaller than 3/8 inches, While wire ropes have diameters greater than 3/8 inches. if there are two or more wire concentrically laid then it is known as strand

Warrington: Two layers of wires around a center with one diameter of wire in the inner layer and two diameters of wire alternating large and small in the outer later

6 by 19 is a type of wire rope which can withstand fatigue resistance, abrasion and prevents crushing on drums. it is available in diatmeter range of 3mm to 6 mm. While 7 by 19 are wire rope which has diameters ranging between 3 mm to 16 mm which can be use in different applications.

According to the dead load of hook and max lifting height from rated lifting capacity to determine the motor model, pulley diameter, rope diameter, roll diameter, wall thickness, reducer Model and brake models;

Estimate the trolley dead load and maximum wheel load to determine the number of trolley wheels and wheel diameter, and with the rated lifting capacity to determine the main beam section size;

Wire rope selected: 36NAT-6×36WS+IWR1870,its nominal tension 863[KN],is greater than Max. breaking force. So 30NAT-6×19WS+IWR1870 meets the requirement。

2. The structural design of this crane is reliable and able to meet the requirements of the customer on rated lifting capacity, speed, and working life.

At Allied Wire and Cable, we provide our customers with quality copper at bargain prices. As industry experts, we can help customers combat high or volatile copper prices. As seen in the chart below, copper prices have fluctuated throughout history. At Allied Wire and Cable, we can help you avoid sticker shock when purchasing copper.

The International Wire Group, a manufacturer of a wide range of copper wire supplied the Omega-Camden Copper Index. This index prices copper after it’s been drawn down to size, rather than in its raw form. Rod copper is pulled through a series of dies during the drawing process, which stretches the copper out into a longer, thinner strand. These strands are bunched together to form a single-stranded conductor in the end.The Omega-Camden Index is only updated twice a month.

Copper moves around the world in a variety of forms such as copper ore, raw copper, refined copper and copper wire. There are five countries that sit on roughly 65% of the world’s copper deposits, including Chile, Australia, Peru, Mexico, and the United States. Roughly 700 million metric tons of copper have been mined and an estimated 2.1 billion tons of identified deposits remain in the ground, while undiscovered deposits are estimated to be around 3.5 billion tons.

Traction elevators, also known as machine room-less (MRL) elevators, use steel ropes or belts that roll over a grooved pulley powered by a motor to raise and lower the elevator cab. The traction elevator system uses a counterweight to offset the passenger weight in the cab for better energy efficiency. The motor in a traction elevator is located directly above the elevator in a hoistway, so there’s no need for a separate machine room in the house to contain the driving and control parts of the elevator. A traction elevator can access two to five floors.

Cable-driven elevators, also known as winding drum elevators, use two cables (wire rope) that wind and unwind on steel drums to raise and lower the cab. The steel drums and motor assembly can be located in a separate machine room. Cable-driven elevators can access up to five floors, depending on the model.

Hydraulic elevators use hydraulic fluid and a hydraulic pump connected to a cylinder and piston that moves the elevator cab up and down. Hydraulic elevators are heavy-duty, designed for frequent use and typically have a weight capacity ranging from 750 to 1,000 pounds. This type of home elevator typically requires a separate machine room for the pump and control system.

Pros: Because the pump and controller can be stored in a separate machine room, the elevator cab itself takes up less space. A hydraulic elevator can also fit in houses with ceilings as low as 8 feet. It’s typically quieter than other types of elevators, and it offers a higher weight capacity than some other options. A standard hydraulic elevator can travel up to six floors, or 50 feet.

Shaftless elevators are compact, averaging about 12 square feet in size. This type of elevator works with “winding drum” technology, where cables wind on a drum placed in the elevator overhead. Shaftless elevators are also available in hydraulic models. These elevators fit easily into tight spaces and—like the name suggests—don’t require an elevator shaft, which generally makes them easier to “retrofit” in existing homes. A shaftless elevator can access two floors and is typically installed in an open or semi-enclosed area. The elevator uses a “push and hold” button to move the cab between floors.

8613371530291

8613371530291