wire rope drum capacity calculator quotation

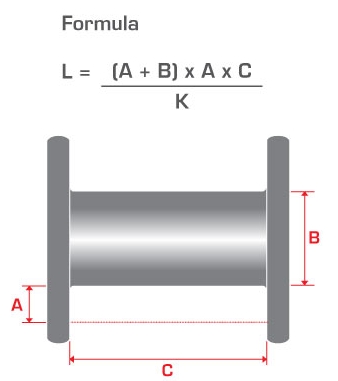

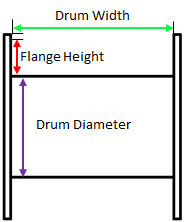

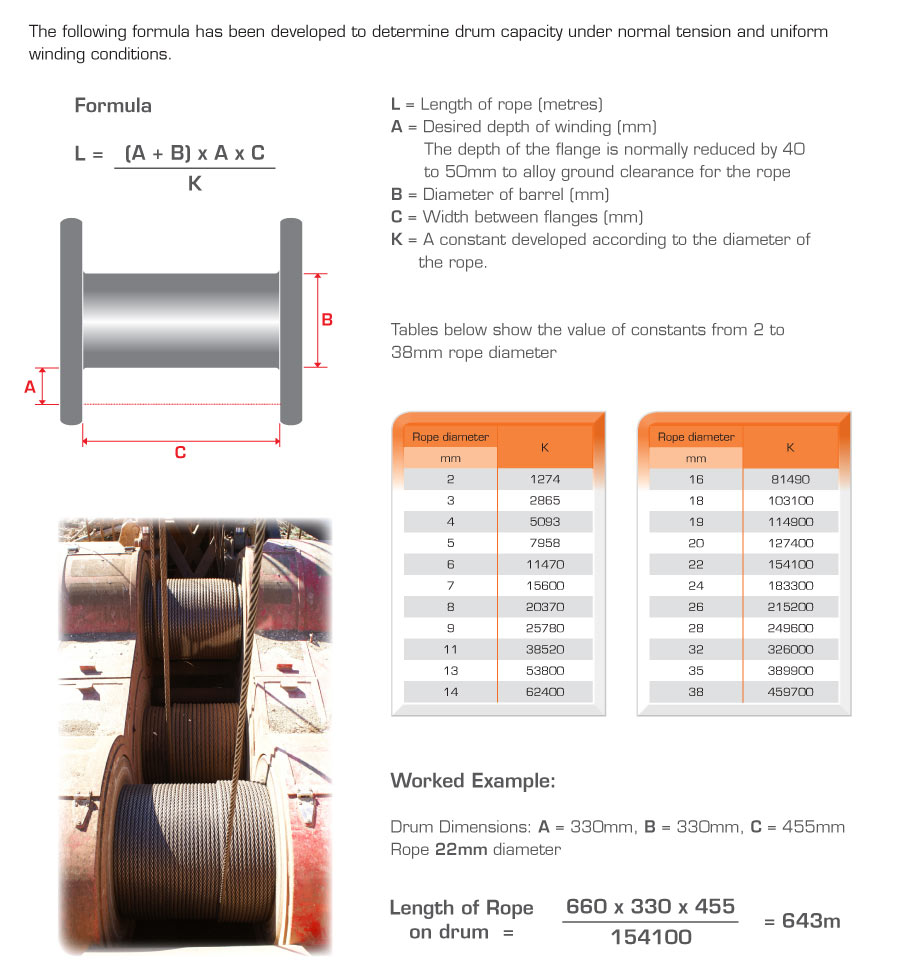

While it is virtually impossible to calculate the precise length of wire rope that can be spooled on a reel or drum, the following provides a sufficiently close approximation.

* This formula is based on uniform rope winding on the reel. It will not give correct results if the winding is non-uniform. The formula also assumes that there will be the same number of wraps in each layer. While this is not strictly correct, there is no appreciable error in the result unless the traverse of the reel is quite small relative to the flange diameter (“H”).

** The values given for “K” factors take normal rope oversize into account. Clearance (“x”) should be about 2 inches unless rope-end fittings require more.

When placing an order, it"s important to know how many reels you can expect. To know how much wire or cable will fit on a shipping reel, enter the diameter of your cable in inches below. Our Reel Capacity Calculator will show how many feet or meters of that cable will fit on our different reels.

To obtain reasonable service life from your aircraft cable or wire rope, you must choose the optimal diameter of rope and sheave for your application. In general, the larger the size of the drum or pulley with respect to the wire diameter, the longer the service life. The opposite is also true: in general, the smaller the size of the drum or pulley with respect to your wire rope, the shorter the service life. Keep these relationships between cable, rope, and pulleys in mind when specifying the competence you use in your application.

The tables below provide the minimum recommended pulley diameter as well as the approximate bend radius of the rope. You"ll notice that the calculation is approximately half of the minimum recommended pulley tread diameter. Whether running fully over the sheave or drum, or some fraction thereof, check your design against the recommendations to better understand the service life you can expect in relation to the other factors involved.

Winching is a popular term among the 4X4 off-road driving buffs. While a winch can be a lifesaver when your vehicle gets stuck in mud or sand, every winching situation can be a potential accident risk. Using a winch without proper safety precautions and user practices can cause severe injuries or may even lead to fatal mishaps.

A winch is a simple mechanical device that allows you to pull in or let out a wire rope. It essentially helps you to adjust the tension of a winch line, usually made from steel. Although manually operated winches are still in use, electrical models are now more prevalent.

2) Clutch: The clutch allows you to control the winch drum rolling. When you disengage the clutch, the drum detaches from the gear train, letting it rotate freely (free spooling). After engaging the clutch, the drum locks into the gear train again, stopping it from free-spooling. Once the clutch gets engaged, you can start winching.

4) Drum: It is a hollow metal cylinder. When you turn on the motor, the drum starts rolling, wrapping the wire rope around it. You can use the remote to change the direction in which the drum rolls.

5) Fairlead or Wire Lead: As the name suggests, fairlead or wire lead guides the wire rope as it wraps around the drum. The purpose of a fairlead is to minimize the damage to the wire rope as it goes through a winch mount or bumper. The two most common winch leads are roller fairlead and hawse fairlead.

7) Motor: The purpose of an electric motor is to power the gear system in a winch. The gear system is connected to the winch drum, which winds the wire rope when you turn on the motor. Usually, you can use your vehicle’s battery to power the motor.

8) Remote Control: The remote control helps you control the winching process (the directions in which the drum rolls). Furthermore, the remote control allows you to stand clear of the winch and the wire rope, reducing the risk of an accident. Modern winch systems come with a wired or wireless remote control.

9) Winch Line or Wire Rope: The wire rope or winch line is usually made of a steel cable or synthetic ropes. The type of rope material, diameter, and length will determine how much load the winch machine can pull. The wire rope is looped at the end to attach a hook.

Before stepping out, move your vehicle forward gently. It will release the tension from the taut wire rope. You can now step out and start un-rigging the winch.

• Make sure to re-spool the winch rope under load, especially if you are using the winch for the first time. It will prevent the outer layers of the steel rope from getting pulled down between the inner layers.

• Never use a winch with less than five rounds of steel rope wrapped around the drum. It can damage the winch system as the rope attachment is not strong enough to hold the load.

3) Protective Gloves: Gloves will protect your hands from barbed steel winch wires. Make sure to use gloves that fit perfectly. Loose gloves can get entangled in a winch, resulting in injuries.

7) Tree Trunk Protector: Usually made from high-quality nylon, a tree trunk protector is essentially a strap that you can wrap around tree trunks. You can connect it to a steel rope using a D-shackle.

9) Winch Line Damper: You will need to use a winch line damper or a heavy blanket to prevent the wire rope from recoiling if it snaps. Make sure to place it on the winch rope (in the middle) before it goes under tension.

You need to stand at a safe distance away from the wire rope if you are not handling the winch, preferably behind a tree or a rock. Never mount the winch rope or touch it after it is tout. Also, don’t stand between the anchor point and your vehicle once the wire rope is under tension. If you are operating a winch, stay in your driver’s seat with the remote control in your hand.

Generally, the bigger the winch, the better. However, you can find several online calculators to help you find the suitable winch size. Make sure to take manufacturer’s guidelines into account as well.

As you can probably see, winching is a vast topic. Learning different winching techniques requires time, patience, and practice. While this guide will help you clarify your winching basics, you will need to rely on your cognitive skills to assess the situation carefully. Make sure to pay careful attention to every possible detail before proceeding with the winching. If you still have doubts or want to know more about winching process and accessories like wire ropes and hooks, contact our experts right away.

Higher strength-to-diameter due to compacted wires in the strands. With increased metallic area, it provides rope strengths equal to 6-strand XXIP IWRC ropes of the same diameter.

Resistance to bending fatigue due to the uniformity of the wires within each strand. The strand’s outer surface is smooth, reducing contact pressures between the rope’s strands and radial pressures as it operates over sheaves and drums. This substantially cuts rope expense and extends service life.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #4. Loading W at θ relative to x angle. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms #4.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #7. Ring under any number of equal radial forces equally spaced. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms #7.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #8. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms #8. Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms #9. Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #10 Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms #10. Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #11. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms #11. Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #12. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms #12. Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #13. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms # 13. Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #14. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms #14. Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Analysis No 15 Roarks Formulas for Stress and Strain Equations and Calculator Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Analysis No 16 Roarks Formulas for Stress and Strain Equations and Calculator. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms. Formulas for moments, loads, and deformations and some selected numerical values. Unit axial segment of pipe filled with liquid of weight per unit volume ρ and supported at the base.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #17. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms. Formulas for moments, loads, and deformations and some selected numerical values. Unit axial segment of pipe partly filled with liquid of weight per unit volume ρ and supported at the base.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #18 Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms. Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #19. Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms. Formulas for moments, loads, and deformations and some selected numerical values.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #20. Per. Roarks Formulas for Stress and Strain Formulas Section 9, Reference, loading, and load terms #20. Bulkhead or supporting ring in pipe, supported at bottom and carrying total load W transferred by tangential shear v distributed as shown.

Circular Ring Moment, Hoop Load, and Radial Shear Equations and Calculator #21 Per. Roarks Formulas for Stress and Strain Formulas for Circular Rings Section 9, Reference, loading, and load terms. Formulas for moments, loads, and deformations and some selected numerical values. Ring rotating at angular rate ω rad/s about an axis perpendicular to the plane of the ring. Note the requirement of symmetry of the cross section.

Capital Recovery Factors Formula and Calculator The future equal payments to repay a present value of money is determined by the capital recovery factor, which is the reciprocal of the present worth factor for a series of equal payments.

Life Cycle Costs Formula and Calculator A representation in present dollars of the cost of an investment over its lifetime is useful for evaluating mutually exclusive alternatives that have the same anticipated lifetime.

Meeting Cost Calculator - How does the estimate work? We calculate the average hourly cost of each attendee and multiply it by the number of attendees and the duration of the meeting. You can help make the estimate more accurate by..

8613371530291

8613371530291