wire rope drum capacity calculator for sale

With nearly 4,000 employees worldwide, WireCo WorldGroup is a great place for you to build a rewarding career. Our professionals enjoy the opportunities of a global manufacturing and distribution leader as well as a culture of open communication, professional growth, and friendly camaraderie that fosters innovation and problem solving.

A handy tool for finding a cable drum that suits your needs - just enter your cable diameter and required length and it will return a list of matching cable drums.

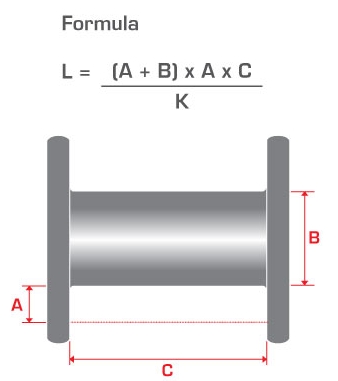

All figures given are based upon a theoretical ‘tight pack’. It is recommended that an allowance of up to 30% be made to accommodate loose winding. A lower percentage could be used if the crew are known to always wind the drums neatly!

The combined weight of cable and drum is highlighted in orange when the weight exceeds 16kg. At this weight a user may need to make a risk assessment with respect to moving and/or carrying such without assistance.

† Drums with CTS suffix have an open hub "Cable Tail Support" on their flange. This would accommodate a further couple of metre"s of cable to allow the

‡Drums with CTF suffix have cable tail supports plus an additional flange, forming an 80mm wide extra section on the side of the drum to protect the tail. Calculated capacities are shown including and excluding the extra section.

When cross winding, start with two layers of a level wound rope using the appropriate back tension. At the end of the second layer, pull the rope quickly across the drum, allow it to wind one full turn at the side of the drum, then quickly pull it back

to the opposite side of the drum. This will force the rope to cross in the middle and form a barrier that will prevent the rope from diving into the lower layers of the drum when placed under load. Follow the cross wound layer with two layers of level

To obtain reasonable service life from your aircraft cable or wire rope, you must choose the optimal diameter of rope and sheave for your application. In general, the larger the size of the drum or pulley with respect to the wire diameter, the longer the service life. The opposite is also true: in general, the smaller the size of the drum or pulley with respect to your wire rope, the shorter the service life. Keep these relationships between cable, rope, and pulleys in mind when specifying the competence you use in your application.

The tables below provide the minimum recommended pulley diameter as well as the approximate bend radius of the rope. You"ll notice that the calculation is approximately half of the minimum recommended pulley tread diameter. Whether running fully over the sheave or drum, or some fraction thereof, check your design against the recommendations to better understand the service life you can expect in relation to the other factors involved.

Cable drums come in many different sizes and weights depending somewhat on the materials they are made of. Usually materials include plywood, timber, plastic or metal, depending on the weight and type of cable they are expected to support and whether they are designed to be reusable and/or returnable. Additionally, the choice of material for the drums may depend on whether the drums and cables are being stored indoors or outdoors.

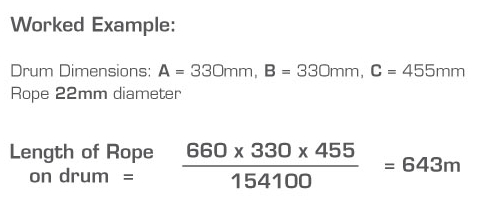

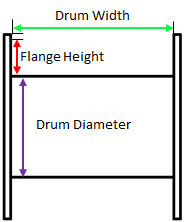

Drum sizes are typically determined by the flange height or drum diameter (D), the drum barrel or drum core (d), the width of the drum (B), and the inside width (b). See the diagram below for typical timber drums used by Eland Cables.

When placing an order, it"s important to know how many reels you can expect. To know how much wire or cable will fit on a shipping reel, enter the diameter of your cable in inches below. Our Reel Capacity Calculator will show how many feet or meters of that cable will fit on our different reels.

8613371530291

8613371530291