wire rope failure causes quotation

Safety should be the top concern of anyone employed in rigging. When working a job where so many lives could be cut short due to carelessness, there is no excuse for laziness or distraction. Rigs should be inspected thoroughly for any potential areas of breakage. It is important for employees to gain a fluency in the causes of wire rope damage and failures so they can spot areas of weakness and fix them before they grow into a dangerous problem.

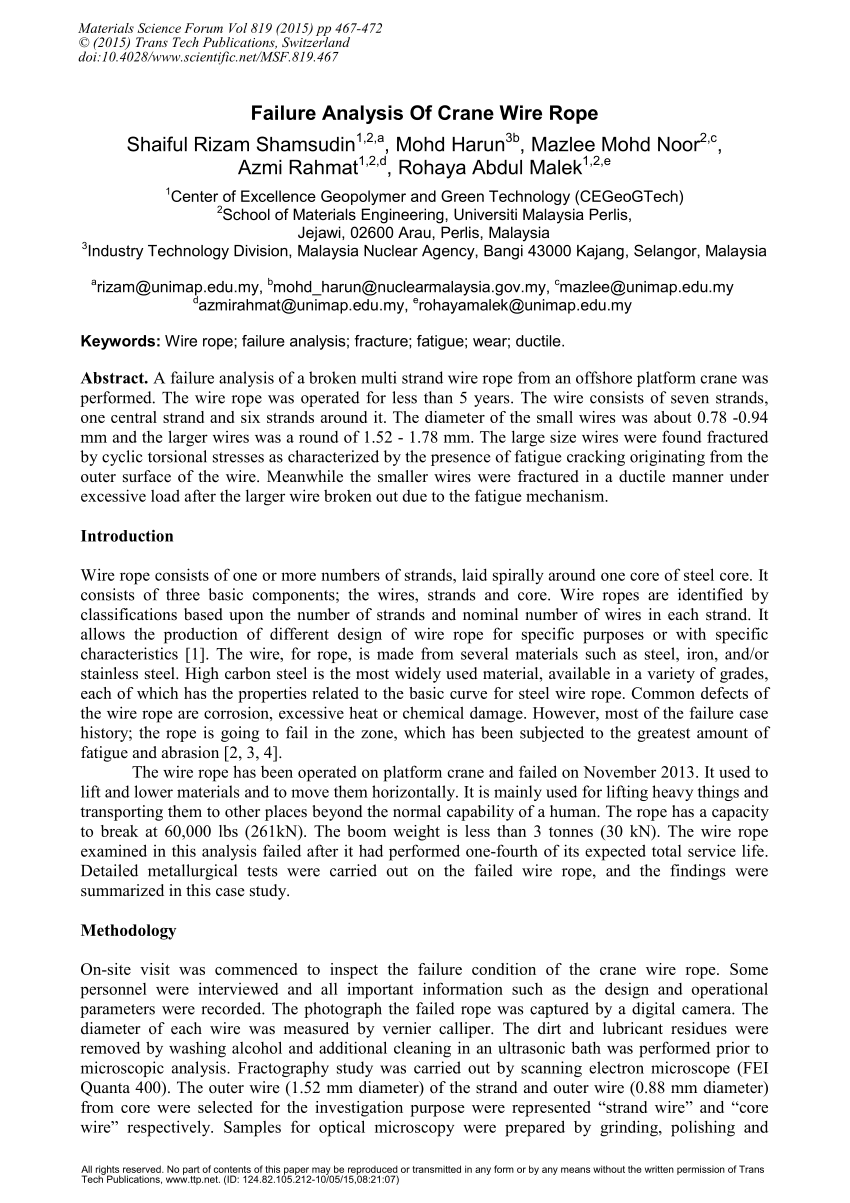

Corrosion issues in wire ropes are one of the most difficult causes of wire rope damage and failures to identify, which is why it is one of the most dangerous. Wire rope failures due to corrosion are typically the result of poor lubrication. You can measure some amount of the lubrication by looking at the pitted surface of every individual rope, but this tells us little of the damage done to the core. Since it is difficult to identify the full spectrum of corrosion, this break stands apart as mysterious and deadly.

Abrasion-caused failure occurs when the wire rope has been damaged by irregular contact with hoist sheaves and drums or when it awkwardly rubs against an object such as shelving or a crane girder. It is also often caused by poorly grooved drums and sheaves. You know the wire ropes have experienced abrasions when the wire ends are worn thin.

When hoist ropes go through repetitive bending over sheaves, cracks will eventually develop in the individual wires. Sections of the wire that move over the sheaves develop the worst fatigue. The damage can often be seen by the naked eye. Whenever one broken wire appears due to fatigue, more will follow. Since these issues are essentially the result of wear and tear on the rope wire, they are considered a normal part of operating a crane.

Being fluent in safety measures is just as valuable to an employer as competency with cable rigging hardware. People who know how to spot areas for potential failures can keep themselves and their coworkers secure, which saves time, money, and even lives.

Unfortunately, many phone calls into ITI Field Services begins this way, “We have had an incident with a wire rope and we believe the rope failed. How do we determine the cause of failure?”

Fortunately, the calls come in because wire rope users want to determine cause of failure in an effort to improve their crane, rigging and lifting activities.

A wire rope distributor received a hoist rope and sockets from a rubber-tired gantry. The rope and sockets were returned by the customer who believed the rope and sockets failed. The distributor hired ITI Field Services to conduct an analysis on the rope and sockets to determine the cause of the failure and to produce written documentation.

Based on the findings of the examination, fatigue-type breaks in the wires indicated that the wire rope lost significant strength due to vibration. There was no indication that the rope was overloaded. The poured sockets showed no evidence of abnormalities in the pouring method, wire zinc bonding length or the materials used in the speltering process. The conclusion of the inspection is that rope failed due to fatigue.

Wire rope examination is just one of the many services that is offered by ITI Field Services. ITI has some of the most highly-regarded subject-matter experts in the crane and rigging industry with experience in performance evaluations, litigation, accident investigations, manual development and critical lift planning reviews.

Your rigging systems and rigging supplies are incredibly crucial for the upkeep of your business. The maintenance of your wires and ropes is essential to ensure the safety of you and your employees. When your rigging supplies fail, it could be catastrophic for business.

The best way to prevent rigging supply failure is to perform regular inspections. Before scheduling inspections, it’s essential to make sure all your employees using the equipment have proper training. The absence of adequate training leads to failure. All those using the equipment and performing inspections must know the ins and outs of how it works. Inspections are a chance to check on issues before they become a big problem.

Installation- The installation of your rigging system is incredibly important. If the installation is done incorrectly, then it will negatively affect everything after. Making sure of the proper installation of the equipment, in the beginning, avoids unnecessary failure going forward. Make sure you have a technically trained professional to install your systems.

When looking for rigging supplies for your business, call us. Our verope wires are top of the line and ensure your business is running efficiently and effectively.

But on one particular day in early May of 2009, it wasn’t a boom reaching toward the big Texas sky that was causing people to stop and stare; it was one that was lying in a heap just beside the water, lattice sections bent and lacings twisted into mess of mangled steel and frayed wire rope. “I got the call to investigate the cause of loss on a Manitowoc 888 that was being used to drive underwater pilings at a dock in Port Isabel,” says JR Bristow, of Bristow Truck and Equipment Specialists, an organization based in Ridgewood, NJ that provides failure analysis and appraisals, among other things, for heavy equipment. “The operator was hoisting the boom when it just sort of gave out and crashed to the ground. No one was hurt, but the boom was in bad shape. The initial reserve was set at $500,000.”

Though a half million dollars wasn’t a total loss – the crane was valued at $1.5 million – it was a pretty hefty price to pay for something that, as it turned out, could have been avoided. On lattice-type cranes, booms are raised and lowered using boom hoist wire rope, and when that wire rope shows surface wear or corrosion, or worse, has broken wires within the rope strand, it can fail. It’s usually just a matter of time.

The subsequent investigation that followed revealed that the wire rope used to hoist the boom of the Model 888 had been in an out-of-service condition for quite some time, due to lack of proper lubrication.

“An examination of the failed boom hoist wire rope revealed that the wire rope had gone without the proper lubrication, which was the responsibility of the insured per the attached lease agreement,” Bristow remembers. “I also noted significant broken wires within the rope strands at an average of six to 12 per strand lay. Clearly, if the insured had performed a daily inspection of the boom hoist wire rope as required, that incident would not have happened.”

The broken strand condition that Bristow observed was caused by load cycles that occurred during boom up and boom down functions that were part of the daily operation of the crane. Simultaneous compression and expansion of the wire rope usually occurs as it travels over the hoist sheaves, and that causes the gradual deterioration of the strand wires.

Like many other segments of the crane and rigging industry, the nuances of wire rope are complicated and varied. Considerable time, money and resources have been invested in new technology, new inspection suggestions and new manufacturers. And rightly so. As was the case in Bristow’s example earlier, there’s quite a bit at stake in terms of both human capital and equipment cost.

Python High Performance wire rope, a wire rope manufacturer that has produced a number of resources to assist people in understanding and ultimately purchasing wire rope, clarifies the structure of wire rope on its website www.pythonrope.com.

Python’s site explains that a typical wire rope can contain hundreds of individual wires. These wires are fabricated and formed to operate at close bearing tolerances to one another. When a wire rope bends, each of its many wires slides and adjusts in the bend to accommodate the difference in length between the inside and the outside bend. The sharper the bend, the greater the movement, and the greater capacity for stress on the wire rope.

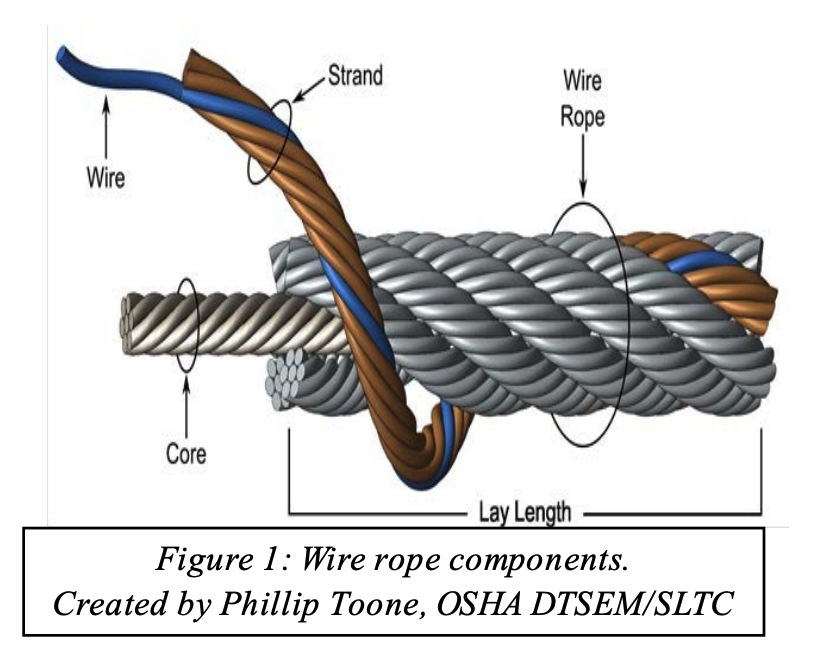

While manufacturers of wire rope are many and varied, each of the wire ropes they produce have three basic components:The wires, which form the strands and collectively provide the rope strength

According to Python’s site, the greatest differences in wire ropes are found in the number of strands, the construction of strands, the size of the core and the lay direction of the strand versus the core. But what does that mean for the layperson? What should he or she look for when purchasing wire rope?

Tony Fastuca, vice president Python America & High Performance Products, says that most people buy rope based on four ideal standards. “Abrasion resistance, fatigue resistance, flexibility and strength. Those four typical standards often weigh into a purchase decision: he says. “A buyer sometimes has to give a little in one area to get a bit more in another, but a lot of buyers are looking for a good balance of those four standards.”

Whereas other products usually come with an expected lifespan, wire ropes don’t really have an average operational life. “There are records that exist of wire ropes getting two to three years of use, sometimes longer,” says Fastuca. ”But it’s about the level of wear on the rope, not the length of time it’s been in service.”

Just as the crane itself needs to undergo frequent and period inspections, the wire rope does, too. Fastuca talks of the so called “A,B,Cs” of wire rope abuse – abrasion, bending, crushing.

The principle goal of a wire rope inspection is to find potential problems before they manifest into incidents or serious accidents. Inspections should be performed slowly and methodically, with a keen eye for corrosion or broken wires or sections of rope that look questionable. Because the reality of wire rope is that it will fail if it becomes worn out, overloaded, damaged, misused or improperly maintained. It can lead to huge headaches for companies that try to take shortcuts or don’t properly maintain it – a risk that just isn’t worth taking.

Like all industrial equipment, aircraft cables and wire ropes wear while in service, and will require replacement. Though the cycle life of each cable varies based on construction and application, factors such as load and pulley condition can actually reduce this lifespan by triggering wire breaks. Not all wire breaks look the same, and understanding these differences can help detect issues in your system before they damage additional cables, or put human lives in danger. Here is a quick guide to help you understand where wire breaks occur (crowns vs. valleys), and three common examples of wire breaks (tension, fatigue, and abrasion).

Wire breaks typically occur in two different locations on the outside of wire rope or aircraft cable. The first location is on the crowns of the strands, which are the highest points with the most surface area exposure. The second location is the valleys, or the spaces between the strands. Though crown breaks typically result from normal wear and tear, valley breaks are more suspicious and may indicate issues with the pulley system or wire rope itself.

Wires that have been worn to a knife-edge thinness are characteristic of abrasion breaks. Abrasion can occur from a number of different sources, but sheaves are the most common. Remember to check sheaves for signs of wear, damage, or deformity and replace as necessary.

If you notice one end of a broken wire is cupped, and the other end resembles a cone, your wire rope likely experienced a tension break. Tension breaks result from excessive loading, causing the wires to stretch beyond their limits until they snap. Once one wire break appears, others will continue to occur if the cable is not addressed.

Once you have replaced your damaged pulleys, or removed sharp obstructions in your system, begin your quote for brand new wire rope at https://strandcore.com/contact/. Our wire rope craftsmen can help you select the ideal wire rope for your application, and oftentimes provide a better solution for your existing setup. Browse our selection ofwire rope and aircraft cableonline, and do not hesitate to contact our sales team at sales@sanlo.com if you have any questions.

A 3.8-cm diam 6 x 37 rope of improved plow steel wire failed in service during dumping of a ladle of hot slag. A heavy blue oxide extending 0.6 to 0.9 m back from each side of the break was revealed on examination of the rope. Tensile fractures were shown by the broken ends of the rope. Recrystallization of the steel was revealed during microscopic examination of the wires adjacent to the break which indicated that the wires had been heated in excess of 700 deg C (1292 deg F). The tensile strength of the wires in the rope...

Copyright © 2013 Sheila Devasahayam et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

A range of blends of polypropylene-polyethylene are investigated for their mechanical performances. These speciality polymer blends are chemically designed to suit high modulus/high load bearing mining wire rope applications subjected to continued bending and tensile stresses and fluctuating loads and are exposed to extreme weather conditions. In this paper we study the influence of different parameters on the performance of the wire ropes: chemistry of polymer, crystallinity of the polymer matrix, and the morphology. The FTIR and SEM studies revealed that the high fraction of polypropylene in polypropylene-polyethylene matrix lead to early failure as a result of incompatibility and phase segregation and high spherulite sizes of the polymer matrix.

Mining wire ropes are used for high modulus/high load bearing applications and are exposed to extreme weather conditions. The mining wire ropes are subjected to continued bending and tensile stresses and fluctuating loads, e.g., in drag rope, and shovel hoist rope applications. Historically wire ropes were made of only steel chains with a record of mechanical failure. The flaws in chain links or solid steel bars lead to catastrophic failure. Friction between the individual wires and strands, as a consequence of their twist, cause strand wear and heat resulting in accelerated rust and potential premature rope failure. Mining wire rope consists of several strands of steel wire laid (or “twisted”) into a helix featuring a 6 or 8 steel strand construction. The steel is normally made of non-alloy carbon steel with carbon content between 0.4% and 0.95%. The size and number of wires in each strand, as well as the size and number of strands in the rope greatly affect the characteristics of the rope. In general, a large number of small size wires and strands produce a flexible rope with good resistance to bending fatigue. The rope construction is important for tensile loading (static, live or shock), abrasive wear, crushing, corrosion and rotation. Plastic infusion helps achieve reduced rope fatigue from bending stresses by reducing the internal contact stresses between the strands and the core and provides improved fatigue and abrasion resistance and increased corrosion protection. A plastic-infused core provides a cushion for the outer strand and virtually eliminates interlayer contact wear. The plastic-infused core adds to the core support for the outer strands, further reducing internal stresses and promoting longer service life and under extreme conditions. Plastic-Infusion involves injecting specially engineered polymers under high temperature and pressure into the wire rope. Both the polymer and the wire rope are heated when the polymer is infused as the wire rope is drawn through specially designed dies. Passing the rope through a series of cooling troughs then solidifies the plastic. This plastic will not melt or soften from the heat of normal operating temperatures when in service and is also virtually unaffected by sunlight or cold weather during their life time (6 to 12 weeks). A set of plasticised ropes is expected to typically last between 6 - 12 weeks. Benchmark for these wire rope is identified visually as-all plastic still intact at the end of the ropes life, which only wears away due to mechanical abrasion to expose the crown of the strand (the highest point of the strand on a rope which has the thinnest plastic cover) on certain sections of the rope instead of peeling off entirely. Plastic delamination causes a hassle as it trips the machine off when the plastic pieces activate the slack rope indicator in the machine. A typical rope section is shown in

Other plastics of interest in wire ropes include, HMPE (High Modulus Polyethylene), Nylon®, Perlon® (Polyamide), Dacron®, Terylene® (Polyester), Polyolefins: Polypropylene and Polyethylene; Kevlar®, Twaron®, and Technora® (Aramid): Vectran® (LCAP—(Liquid Crystal Aromatic Polyester)): Zylon® (PBO-Poly-pphenylenebenzobisoxazole), Poly Vinyl Chloride, Low Density Poly Ethylene, High Density Poly Ethylene, P, nylon 6 (PA6), nylon 11 (PA11), polyvinylidenedifluoride and more [1]. Properties of these wire rope materials based on manufacturer’s specifications have been summarised by Barry Cordage [2].

Homopolymer of polypropylene (PP) are homogeneous with single phase, exhibiting large spherulite dimension which affect their mechanical properties adversely. However, the polymer blends/copolymers e.g., polypropylene-polyethylene (PP-PE) are immiscible in each other, and show decline in their mechanical properties due to their incompatibility. They show remarkable phase separation during crystallization. Phase segregation hastens yielding and fracture at interphase boundaries. The micro structure of the polymer matrix greatly influences the mechanical behaviour of the polymer products. Higher crystallinity leads to brittle fracture in polymers as opposed to the amorphous nature of the polymer. The factors affecting the crystallinity include the polymer processing, e.g., during polymer extrusion the slow cooling or the rapid cooling greatly affects the crystallinity in polymers [3]. In this study we focus on if the crystallinity behaviour of the polypropylene-polyethylene blend affects the performance of the mining wire ropes.

The Moly-Cop Ropes supplied the mining wire rope samples and the information on their mechanical performance as listed below: wire rope A > wire rope B > wire rope C - wire rope D > wire rope E. The manufacturers of these wire ropes have not released chemical compositions, structures of these wire ropes.

The chemical composition and the crystallinity of the plastic component of the mining wire ropes were studied using Perkin Elmer Spotlight 400 FTIR Microscope, a Fourier Transform Infrared (FTIR) spectrometer fitted with Harrick Grazing Angle ATR accessories. This technique probes the surface of a sample (up to 2 microns deep) with infrared energy of varying wavelengths. The detection limit of IR has been noted to be between 2% and 3% by weight of the total analysed sample. The technique allows transmittance or absorbance to be measured. The spectra were accumulated for 4 scans at a resolution of 4 cm−1 over the spectral range 500 - 4000 cm−1 at ambient temperature.

three isotactic bands at 1165 cm−1, 997 cm−1 and 977 cm−1 confirmed the presence of the isotactic polypropylene component in all the wire ropes studies. The presence of following CH2 bands at 2917 cm−1, 2860 cm−1, 1464 cm−1 and 718 cm−1, and the CH3 band at 731 cm−1, and 1379 cm−1 confirmed the presence of polyethylene component of these wire ropes. A reference spectra of PE-PP from FTIR library is included in the figures to corroborate the presence of PP-PE in the wire samples.

The crystallinity, Xc, for isotactic polypropylene of the wire ropes showed following trend: B < E < C < A < D. The evolution of crystallinity and the associated mechanical properties during polymer processing in the extruded polymer samples are attributed to different cooling rates. The crystallinity increases when the polymer sample is slow cooled [3]. It is believed that in slow cooling, the polymer chains are exposed near the maximum crystallization temperature for a longer period, and therefore, the crystallization is activated. In fast cooling, the polymer melt go through the maximum crystallization temperature very quickly, leaving most of the molecular chains in amorphous form. What this means is higher crystallinity results in a harder and more thermally stable, but also more brittle material, whereas the amorphous regions provide certain elasticity and impact resistance. Samples cooled slowly from the melt state, form larger and denser microstructures. Based on the mechanical performance trend of the samples, where sample A performed better than sample B showing following trend, A > B > C - D > E, the trend observed in the crystallinity, Xc of the samples could not be correlated with the performance trend.

Though the samples were identified to be copolymer of PP and PE, the ratio of the PP and PE in the wire rope samples have not been released. In order to investigate if the PP:PE could have bearing on the mechanical performance of the wire ropes, the proportion of polypropylene (PP) in the copolymer (Figures 9 and 10) was determined using the ATR-FTIR technique. The relative ratio of the absorbance (integrated area) of two peaks in the rocking wagging region, a peak at 1168 cm−1 characteristic for methyl group wagging in PP and a peak at 720 cm−1 arising from ethylene rocking and typical for HDPE were chosen [6,7].

est PP content compared to the other samples, followed by sample B and A leading to the proposition that the amount of PP could perhaps affect the performance of these wire ropes, that is high PP content as found in sample E could lead to the early failure in these samples.

The results indicate that perhaps the PP content of the matrix could be responsible for the observed differences in the behaviour in different mining wire ropes. In the present study it is observed from the SEM images (Figures 12-14) that as the % PP increased, the spherulite size increased, the crystallinity (

High modulus applications of homopolymer of polypropylene exhibiting homogeneous single phase, is limited by their large spherulite dimension affecting their mechanical properties adversely. This has led to a great deal of commercial interest In recent years in blends based on isotactic polypropylene and other polyolefins in nature due to improved mechanical strength, tensile strength, enivironmental stress cracking, low temperature impact properties exhibited by these blends.

chanical properties, including impact strength, strain at break and ductile to brittle transition, especially related to morphology are attributed to the strong phase separation leading to a coarse phase structure and low interfacial adhesion between the two phases. Previous studies on mechanical properties of the PE-PP blends reveal direct

correlation between the morphology and the tensile properties, the spherulite size and the crystallinity being controlled by the PE-PP ratio. The impact strength and adhesion are improved when the particles are smaller with narrower particles size distributions, and when there is stronger adhesion between particle and the matrix [10- 17]. Lovinger and Williams [18] correlated the morphological effects, such as spherulite sizes, inter crystalline links between lamellae, and the detailed structure of the two incompatible phases and of their mutual boundaries, with the tensile behaviour of PE/PP blends. They reported deterioration of mechanical properties as a result of incompatibility and phase segregation which hastens yielding and fracture at interphase boundaries. Studies have shown that yield stress and ultimate strength are improved with decreasing spherulite size, primarily because yielding and failure are commonly initiated at inter spherulitic boundaries. The PE in the blends reduce the average spherulite size, increase the overall crystallinity, promoting formation of intercrystalline links, and increases modulus and strength [13,19-21].

In present study the higher PP content in the sample E, with lower crystallinity but larger spherulite size is determined to be contributing to the observed early failure, as well as the higher void fraction compared to samples with lower polypropylene content (e.g., samples A and B).

The study pertaining to failure in mining wire ropes revealed all the samples were made of copolymer of polyethylene and Polypropylene, with different PP:PE content. Sample E exhibited higher polypropylene content, lower crystallinity and bigger spehrulite size compared to the other samples. The SEM results showed highly ruptured and segregated morphology for sample E. SEM images of samples A and B with lower % PP are ordered/ homogenised and well plasticised with uniformly distributed microcellular structures. Even though the crystallinity (crystalline content) results from FTIR study of all the samples appear to be comparable and not correlated to their performance characteristics, the spherulite size of samples could be directly correlated to their performance behaviour. The % PP had direct influence on the spherulite size with higher % PP showing larger spherulite structure and lower crystallinity while the higher PE content increased the crystallinity of the samples. It is concluded the larger spherulite size of sample E compared to the samples A and B, which showed smaller spherulite structures and relatively homogenised morphology samples contributes to the early failure in the sample E, as the higher PP content increases the viscosity and void fraction in samples. Performance characteristics of samples A and B are superior to sample E attributable to higher PE content resulting in smaller spherulite size. It is also concluded that sample with 50:50 PP: PE performed the best (sample A), where the microcellular structure uniformly distributed.

D. C. Yang, B. L. Zhang, Y. K. Yang, Z. Fang, G. Sun and Z. L. Feng, “Morphology and Properties of Blends of Polypropylene with Ethylene-Propylene Rubber,” Polymer Engineering and Science, Vol. 24, No. 8, 1984, pp. 612-617. doi:10.1002/pen.760240814

A. J. Lovinger and M. L. Williams, “Tensile Properties and Morphology of Blends of Polyethylene and Polypropylene,” Journal of Applied Polymer Science, Vol. 25, No. 8, 1980, pp. 1703-1713. doi:10.1002/app.1980.070250817

P. J. Phillips and J. Patel, “The Influence of Morphology on the Tensile Properties of Polyethylenes,” Polymer Engineering and Science, Vol. 18, No. 12, 1978, pp. 943- 950. doi:10.1002/pen.760181207

J. S. Petronyuk, O. V. Priadilova, V. M. Levin, O. A. Ledneva and A. A. Popov, “Structure and Elastic Properties of Immiscible LDPE-PP Blends: Dependence on Composition,” Proceedings of Materials Research Society on Nanomaterials for Structural Applications, Vol. 740, Boston, 2-6 December 2002, pp. 261-266.

All wire ropes should be thorougly inspected at regular intervals. The longer it has been in service or the more severe the service, the more thoroughly and frequently it should be inspected. Be sure to maintain records of each inspection.

Inspections should be carried out by a person who has learned through special training or practical experience what to look for and who knows how to judge the importance of any abnormal conditions they may discover. It is the inspector’s responsibility to obtain and follow the proper inspection criteria for each application inspected.

Sheaves facilitate the smooth and safe operation of overhead crane hoists. Damaged sheaves can wear ropes prematurely and cause other dangerous hazards, such as binding wire rope. Konecranes technicians are trained to identify and correct problems with sheaves and other parts of hoisting equipment.

Sheaves carrying ropes which can be momentarily unloaded shall be provided with close-fitting guards or other suitable devices to guide the rope back into the groove when the load is applied again.

The sheaves in the bottom block shall be equipped with close-fitting guards that will prevent ropes from becoming fouled when the block is lying on the ground with ropes loose.

In using hoisting ropes, the crane manufacturer"s recommendation shall be followed. The rated load divided by the number of parts of rope shall not exceed 20 percent of the nominal breaking strength of the rope.

Rope clips attached with U-bolts shall have the U-bolts on the dead or short end of the rope. Spacing and number of all types of clips shall be in accordance with the clip manufacturer"s recommendation. Clips shall be drop-forged steel in all sizes manufactured commercially. When a newly installed rope has been in operation for an hour, all nuts on the clip bolts shall be retightened.

Wherever exposed to temperatures, at which fiber cores would be damaged, rope having an independent wirerope or wire-strand core, or other temperature-damage resistant core shall be used.

Replacement rope shall be the same size, grade, and construction as the original rope furnished by the crane manufacturer, unless otherwise recommended by a wire rope manufacturer due to actual working condition requirements.

Konecranes wire rope inspections can help crane users extend the life of hoist ropes. Ropes, sheaves and other reeving system components are inspected for compliance with crane standards, and to determine if they have flaws that could hinder safe operation. Contact us today to schedule an assessment.

8613371530291

8613371530291