wire rope failure causes for sale

In 1998, a crane load line broke while lifting the south topside module of the Petronius platform, dropping the module into the Gulf of Mexico. The cost was estimated to be around 116 million US dollars. Since 1999 more than 60 people have been killed as a result of wire ropes breaking and more than 65 associated injuries.

Not many people appreciate that there are literally thousands of wire rope designs, most of which can be put into a specific category. According to BS ISO 4309 2010 there are currently more than 25 categories of crane wire rope, each with differing characteristics and also different discard criteria. Deterioration can be measured, counted or calculated and the wire rope eventually taken out of service based on sophisticated discard criteria published in chosen standards, codes of practice or users handbooks.

Unfortunately there is no simple answer to either of these questions. All wire ropes will eventually break due to corrosion, wear or fatigue even if they are maintained and used properly. Unpredictable wire rope failures will inevitably occur, quite often when you least expect it if the discard criteria is ignored, or those using the equipment are ignorant of it.

James Dawes of Topeka, Illinois, was killed in 2008 after being struck by the boom of a Link-Belt crane; the accident was caused by the boom hoist wire rope breaking. The crane rope had been inspected, but a report said that the inspector failed to reject the rope showing a high number of visible wire breaks. Premature or unexpected wire rope failures can also be attributed to poor manufacture, incorrect handling and storage, poor installation technique, poor selection or fitting of its termination, infrequent or inadequate inspection and poor maintenance. Of course there is always the possibility that mechanical damage can occur and this is usually attributed to human error.

It is necessary, particularly during offshore operations that frequent inspections are carried out over the whole length of the working part of all steel wire ropes. The frequency of inspections should be based on the severity of use and risk assessment and particular attention should be paid to the critical areas of the wire rope; areas that are frequently running over sheaves, compensating sheaves and the rope termination to name a few.

If a wire rope has not been subjected to an abnormal environmental condition such as excessive heat, chemical attack or any corrosive solution and it has not been the victim of any form of mechanical damage, then trained operatives and inspectors can reasonably predict the length of time the steel wire rope is likely to last. That prediction, of course, will be dependent on the knowledge and experience of those making it coupled with known facts about the rope, its current condition and the application it is running on. The Inspector should be aware of the previous rope’s history, capacities of loads and the reeving systems employed together with the frequency of use etc.

Various standards and codes of practice have been written by recognized bodies and institutes based on the experience of experts or representatives of corporate organizations who have a vested interest. These standards do offer guidance on when a wire rope should be removed from service based on wear, abrasion and fatigue amongst others things, but none of these standards have any legal status except when they are called up by contract. Indeed they can all be supported or overturned in a court of law by an expert.

The users handbook, or more importantly the safe use instructions do have legal status. In many parts of the world these days, suppliers of cranes or any machinery for that matter, issue safe use instructions with new equipment. Modern applications employ modern wire rope and, in some cases, sheaves and pulleys that are made with materials other than steel. Original equipment manufacturers of such applications may impose discard criteria for the wire rope that is stricter than those in chosen standards. By law the user must follow manufacturers’ instructions.

Wire ropes will deteriorate much more quickly if they go dry and are allowed to remain in that condition. Tests have proven that a dry rope will lose up to 60 % of its expected life if it is not re-lubricated. There are differing schools of thought as to how wire rope should be lubricated. Some believe that a thin lubricant should be applied using a paintbrush. It is thought that this method allows the lubricant to penetrate. Experience has proven however, that thin penetrative lubricants will easily drain away or fly off in hot climates.

Another school of thought, and the one I stand on, is that grease should be pressure lubricated into the rope. This method, if applied properly, will ensure that the grease penetrates the rope pushing out the old lubricant with it and any possible corrosive agents such as salt water and sand. Any lubricant that is used must be compatible with the type that was applied previously and it is a good idea to consider the environment as well.

In any event, wire ropes usually announce that they are about to break. A series of individual wire breaks can be heard. These are likely to go on over several seconds and continuing for up to ten minutes before ultimate failure. Therefore, if operatives understand the warning signals, expensive incidents could be avoided.

Figure 2 shows two pieces of the same rope, the bottom portion quite clearly shows a progression of wire breaks. The operator was able to put the load down before disaster struck. The root cause of this fault was core deterioration brought about by internal corrosion.

To answer the other question on accountability, the list is extensive. Usually the first suspect is the wire rope manufacturer and that may be where the problem lies, but very often that is not the case. What if you were supplied the wrong rope for the application? Maybe you ordered the wrong rope or your buyer bought it from a cheap unapproved manufacturing source.

Perhaps your supplier is responsible, maybe he provided you with a rope that was produced to the wrong specifications. Would you know the difference? Perhaps you were sold a rope that had been stored in the suppliers or manufactures stock for a number of years and, whilst it was there, it hadn’t been properly maintained. Maybe the rope had been badly handled or installed incorrectly. The list of possibilities is endless.

In 1999 a ropeway in the French Alps snapped causing 21 deaths. In 2003, a ropeway wire rope snapped and 7 people died and a further 42 were injured. In 2007 a crane wire rope snapped at New Delhi’s metro, the entire structure tumbled down crushing workers underneath, six people were killed and 13 more were injured. In 2009 26 people were killed and 5 people were injured when a rope failed in a mine and a further 6 people were injured when a lift rope broke inside London’s Tower Bridge.

If you find yourself in the unfortunate situation after the unthinkable premature failure of a wire rope, then you might like to know that there are independent analytical services capable of determining probable cause. One of these is Doncaster Analytical Services Ltd (DAS), they have an independent metallurgical laboratory providing factual analysis and testing of wire rope for any reason (contact Mr Shui Lee, Technical Director, Tel +44(0)1302 556063, email: shui.lee@doncasteranalyticalservices. com).

You do not need a wire rope to fail in order to learn. Careful analysis of discarded ropes can also give you valuable information about your application, the way it operates, and the rope you have been using.

Based on this information, a trained, skilled and experienced inspector will be able to advise on a better crane or wire rope design, or to an improvement in maintenance procedures and safety.

A customer recently contacted us to reorder the wire rope component of their Electrolifttwin hook monorail hoist. While the hoist was only a year old, they had replaced the wire rope twice within six months. They sent a picture of the damaged rope and asked for reasons why the wire rope was failing.What’s killing my wire rope?

It’s important to note that the wire rope used for hoists and overhead cranes is specially made of extra flexible Improved Plow Steel (IPS). It’s considered superior in durability and tensile strength (bending) to standard, everyday wire rope.

When properly sized and lubricated, a wire rope should last for years, even with frequent use. Wire rope hoists are recommended for heavy duty applications, high frequency usage and where long lifts are needed.

The Answer:Most likely, there’s a problem with how the hoist is operated. Wire rope failure is almost always due to operator error. By design, hoist hook blocks must be raised and lowered straight up and straight down, and the wire rope cable wraps around the drum, within the grooving, in one layer. In the course of picking up a load, if the operator side pulls the rope by more than about three degrees from vertical, the wire rope will jump the drum’s grooves.

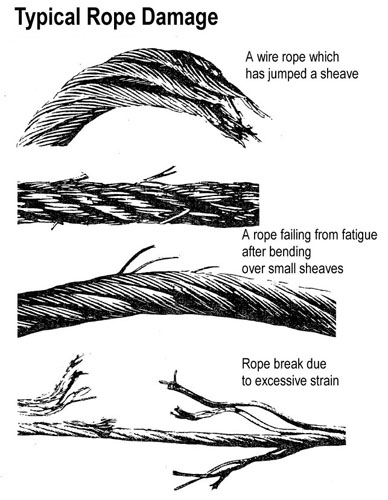

Once the grooves are jumped, the operator must realize the error and stop using the hoist immediately. To correct the issue, the load must be lowered and the wire rope must be allowed to return it to the correct drum grooves. If the operator continues to use the hoist with the wire rope piled up at one end of the drum, the rope gets pinched and the cable can become damaged. Also in the course of usage, if the cable goes slack and the wire rope jumps over the drum guard, it could get caught between the drum and the shaft, and the wire rope could fail.

To prevent this problem, we recommend operator training classesand regular inspection of the unit. Every shift should start with an examination of the rope by lowering the hook all the way down. If the rope is damaged, including even one strand broken, stop the process and get the rope replaced. We recommend keeping spare ropes in stock to avoid downtime and

Hoisting loads with a wire rope is a simple operation. Hook it up; lift it. Turns out, it’s more complicated than it appears. The details of setting up, inspecting, and maintaining lifts with wire ropes are not complicated, but are critical. A lift that goes awry is dangerous. A bad lift puts workers at risk. In this article, we discuss the causes of wire rope failure and how to avoid them.

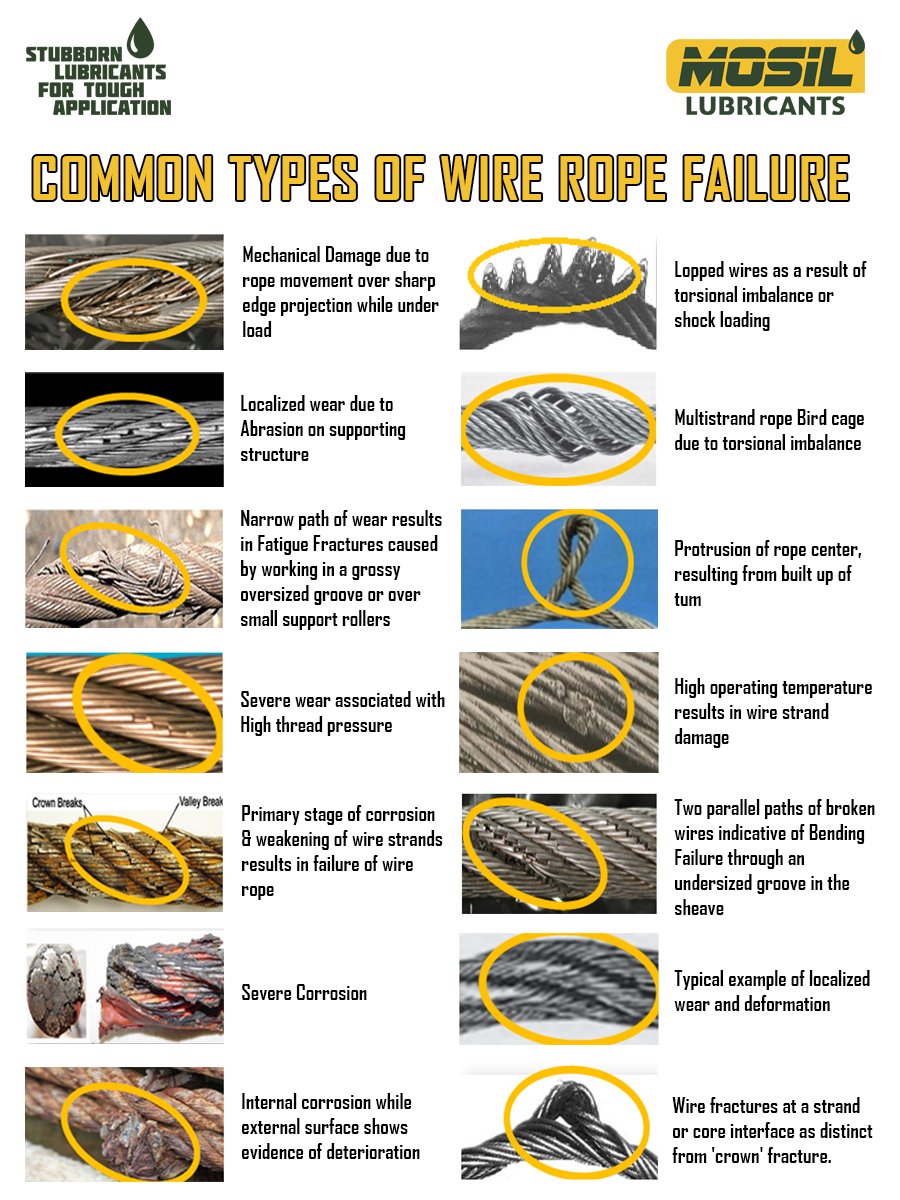

Abrasion breaks are caused by external factors such as coming into contact with improperly grooved sheaves and drums. Or just hitting against some object during operation. Worn, broken wire ends is the result of an abrasion break. Common causes of abrasion breaks include:

Core slippage or protrusion is caused by shock load or improper installation of the wire rope. Excessive torque can cause core slippage that forces the outer strands to shorten. The core will then protrude from the rope. Wire ropes designed to be rotation-resistant should be handled carefully so as not to disturb its lay length.

Corrosion breaks cause pitting on the individual wires that comprise the rope. This type of damage is caused by poor lubrication. However, corrosion breaks are also caused by the wire rope coming into contact with corrosive chemicals, such as acid.

There are many ways the strands of a rope can be crushed or flattened. Improper installation is a common cause. To avoid crushing, you’ll want the first layer of the wire rope to be very tight. You’ll also need to properly break-in a new wire rope. Other causes of crushing include cross winding, using a rope of the wrong diameter, or one that it too long.

Cracks to individual wires are caused by fatigue breaks. Fatigue breaks happen because the wire rope is being bent over the sheave over and over again. In time, the constant rubbing of the wire rope against the sheave or drum causes these breaks. Sheaves that are too small will accelerate fatigue breaks because they require more bending. Worn bearings and misaligned sheaves can also cause fatigue. A certain number of broken wires is acceptable. The worker responsible for equipment inspection prior to use should know the American Society of Mechanical Engineers (ASME) standard for wire ropes. The ASME standard determines whether the wire rope must be replaced. (https://www.asme.org/)

Selecting the right wire rope for the job is critical. There is never a perfect rope. For example, you will need to make a tradeoff between fatigue resistance and abrasion resistance. There are several aspects to wire rope design to consider, including:

In general, the proper wire rope will have a strength rating high enough to handle the load. (Strength is rated in tons.) It can handle the stress of repeated bending as it passes over sheaves or around drums. How you attach the rope in preparation for the lift matters and should only be handled by properly trained workers.

The wire rope (and all the equipment involved in a lift) should be fully inspected prior to the lift. The worker performing the inspection should be well-versed in the types of damage that can cause a wire rope to fail. Using a checklist is highly recommended. This will ensure that the inspection is complete. Worker and supervisor signoff will increase accountability. Of course, the wire rope must be maintained according to the manufacturer’s instructions.

How a wire rope is stored, the weather conditions in which it is used, and how they are cleaned all affect its useful life. The Occupational Safety and Health Administration (OSHA) provides these recommendations: (Source: https://www.osha.gov/dsg/guidance/slings/wire.html)

Preventing wire rope failures starts with selecting the right one for the job. When in doubt, talk with your local equipment dealer. Be prepared to discuss your specific job requirements. A thorough inspection of the wire rope prior to using it is critical. Finally, properly store your wire rope. The selection, inspection, and care of wire rope is key to job safety.

Due to the wide variety of service conditions for wire ropes, they are susceptible to many types of inadequacies and failures. It is important for consumers to frequently inspect wire ropes for signs of wear and fatigue. Wire ropes will inevitably fail if not used according to manufacturing limitations or when routine inspections for fatigue and wear are not properly performed. Eventually, all wire ropes are removed from service when they meet established discard criteria.

Safety should be the top concern of anyone employed in rigging. When working a job where so many lives could be cut short due to carelessness, there is no excuse for laziness or distraction. Rigs should be inspected thoroughly for any potential areas of breakage. It is important for employees to gain a fluency in the causes of wire rope damage and failures so they can spot areas of weakness and fix them before they grow into a dangerous problem.

Corrosion issues in wire ropes are one of the most difficult causes of wire rope damage and failures to identify, which is why it is one of the most dangerous. Wire rope failures due to corrosion are typically the result of poor lubrication. You can measure some amount of the lubrication by looking at the pitted surface of every individual rope, but this tells us little of the damage done to the core. Since it is difficult to identify the full spectrum of corrosion, this break stands apart as mysterious and deadly.

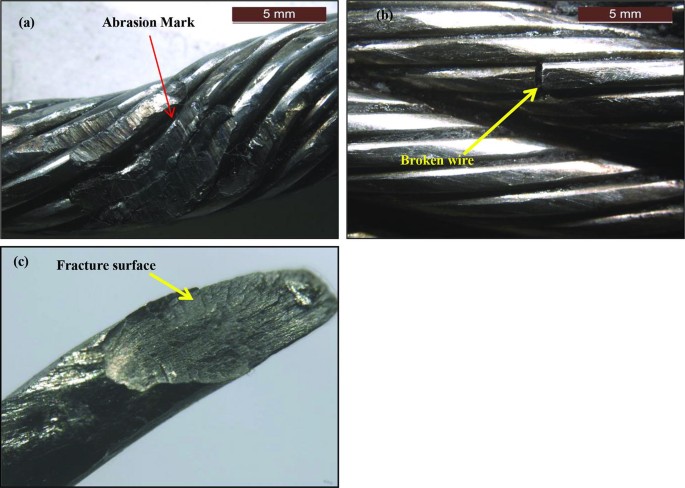

Abrasion-caused failure occurs when the wire rope has been damaged by irregular contact with hoist sheaves and drums or when it awkwardly rubs against an object such as shelving or a crane girder. It is also often caused by poorly grooved drums and sheaves. You know the wire ropes have experienced abrasions when the wire ends are worn thin.

When hoist ropes go through repetitive bending over sheaves, cracks will eventually develop in the individual wires. Sections of the wire that move over the sheaves develop the worst fatigue. The damage can often be seen by the naked eye. Whenever one broken wire appears due to fatigue, more will follow. Since these issues are essentially the result of wear and tear on the rope wire, they are considered a normal part of operating a crane.

Being fluent in safety measures is just as valuable to an employer as competency with cable rigging hardware. People who know how to spot areas for potential failures can keep themselves and their coworkers secure, which saves time, money, and even lives.

Severe rusting leads to premature fatigue failure of single wires. When the rope shows more than one wire failure near a fitting, it should be removed immediately. To prevent abnormal corrosion, the rope should be kept well lubricated. In situations where abnormal corrosive action can occur, it may be necessary to use galvanized or stainless steel wire rope.

But on one particular day in early May of 2009, it wasn’t a boom reaching toward the big Texas sky that was causing people to stop and stare; it was one that was lying in a heap just beside the water, lattice sections bent and lacings twisted into mess of mangled steel and frayed wire rope. “I got the call to investigate the cause of loss on a Manitowoc 888 that was being used to drive underwater pilings at a dock in Port Isabel,” says JR Bristow, of Bristow Truck and Equipment Specialists, an organization based in Ridgewood, NJ that provides failure analysis and appraisals, among other things, for heavy equipment. “The operator was hoisting the boom when it just sort of gave out and crashed to the ground. No one was hurt, but the boom was in bad shape. The initial reserve was set at $500,000.”

Though a half million dollars wasn’t a total loss – the crane was valued at $1.5 million – it was a pretty hefty price to pay for something that, as it turned out, could have been avoided. On lattice-type cranes, booms are raised and lowered using boom hoist wire rope, and when that wire rope shows surface wear or corrosion, or worse, has broken wires within the rope strand, it can fail. It’s usually just a matter of time.

The subsequent investigation that followed revealed that the wire rope used to hoist the boom of the Model 888 had been in an out-of-service condition for quite some time, due to lack of proper lubrication.

“An examination of the failed boom hoist wire rope revealed that the wire rope had gone without the proper lubrication, which was the responsibility of the insured per the attached lease agreement,” Bristow remembers. “I also noted significant broken wires within the rope strands at an average of six to 12 per strand lay. Clearly, if the insured had performed a daily inspection of the boom hoist wire rope as required, that incident would not have happened.”

The broken strand condition that Bristow observed was caused by load cycles that occurred during boom up and boom down functions that were part of the daily operation of the crane. Simultaneous compression and expansion of the wire rope usually occurs as it travels over the hoist sheaves, and that causes the gradual deterioration of the strand wires.

Like many other segments of the crane and rigging industry, the nuances of wire rope are complicated and varied. Considerable time, money and resources have been invested in new technology, new inspection suggestions and new manufacturers. And rightly so. As was the case in Bristow’s example earlier, there’s quite a bit at stake in terms of both human capital and equipment cost.

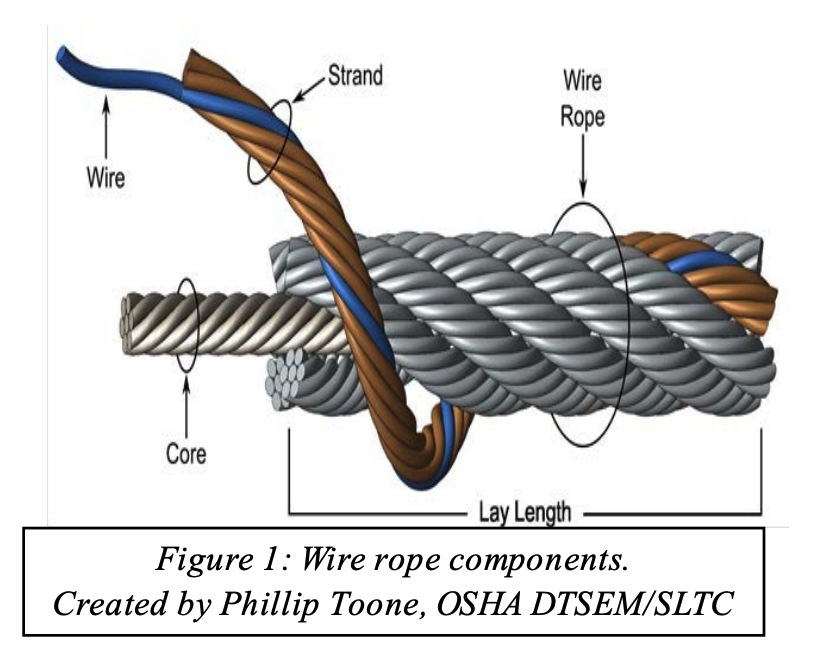

Python High Performance wire rope, a wire rope manufacturer that has produced a number of resources to assist people in understanding and ultimately purchasing wire rope, clarifies the structure of wire rope on its website www.pythonrope.com.

Python’s site explains that a typical wire rope can contain hundreds of individual wires. These wires are fabricated and formed to operate at close bearing tolerances to one another. When a wire rope bends, each of its many wires slides and adjusts in the bend to accommodate the difference in length between the inside and the outside bend. The sharper the bend, the greater the movement, and the greater capacity for stress on the wire rope.

While manufacturers of wire rope are many and varied, each of the wire ropes they produce have three basic components:The wires, which form the strands and collectively provide the rope strength

According to Python’s site, the greatest differences in wire ropes are found in the number of strands, the construction of strands, the size of the core and the lay direction of the strand versus the core. But what does that mean for the layperson? What should he or she look for when purchasing wire rope?

Tony Fastuca, vice president Python America & High Performance Products, says that most people buy rope based on four ideal standards. “Abrasion resistance, fatigue resistance, flexibility and strength. Those four typical standards often weigh into a purchase decision: he says. “A buyer sometimes has to give a little in one area to get a bit more in another, but a lot of buyers are looking for a good balance of those four standards.”

Whereas other products usually come with an expected lifespan, wire ropes don’t really have an average operational life. “There are records that exist of wire ropes getting two to three years of use, sometimes longer,” says Fastuca. ”But it’s about the level of wear on the rope, not the length of time it’s been in service.”

Just as the crane itself needs to undergo frequent and period inspections, the wire rope does, too. Fastuca talks of the so called “A,B,Cs” of wire rope abuse – abrasion, bending, crushing.

The principle goal of a wire rope inspection is to find potential problems before they manifest into incidents or serious accidents. Inspections should be performed slowly and methodically, with a keen eye for corrosion or broken wires or sections of rope that look questionable. Because the reality of wire rope is that it will fail if it becomes worn out, overloaded, damaged, misused or improperly maintained. It can lead to huge headaches for companies that try to take shortcuts or don’t properly maintain it – a risk that just isn’t worth taking.

Wire Rope is an item often found on Wire Rope Cranes. Unfortunately, though these wires are not unbreakable and can/will succumb to the pressure of constant use and may potentially snap when in use. Which is why it is important to know what to look out for in an unsafe wire rope, the Government of Canada recommends a visual inspection of the wire before each use, but full inspections should be undertaken by a trained professional periodically. This article will cover what causes wire ropes to break, what your professional inspector will do to ensure your rope is safe and what you can look out for when completing your frequent inspection to ensure the rope is safe to work with.

When you hear the term wire rope you may picture in your mind a metal and seemingly unbreakable rope, and through wire ropes, can and will stand up better than many other rope types it is unfortunately not unbreakable. Some things that can cause a wire rope to break include:

Kinks caused by improper installation of a rope, sudden release of a load or knots that were made to shorten a rope can cause the rope to become compromised

Many of these causes can be minimized by the use of proper crane design and rope maintenance procedures, most of these causes though are unavoidable and are considered to be part of a normal rope life. The two main causes that are considered unavoidable are crushing and internal and external fatigue.

Many wire ropes are subject to a lot of repetitive bending over a sheave, which causes the wire to develop cracks in its individual wires. These broken wires often develop in the sections that move over sheaves. This process will become escalated if a rope travels on and off of a grooved single layer drum, which causes this to go through a bending cycle. Tests in the past have shown that winding on a single layer drum is equal to bending over a sheave because it causes similar damage.

Fatigue breaks often develop in segments as stated before these segments are usually the part of the rope surface that comes into direct contact with a sheave or drum. Because this is caused by external elements rubbing, oftentimes these breakages are external and visible for the eye to see. Once broken wires start to appear, it creates a domino effect and quickly much more will appear. Square ends of wires are common for fatigue breaks. These breaks are considered a long-term condition and are to be considered part of the normal to the operating process.

Internal Breaks,these breaks can develop over time-based upon the loading of the hoist. Many ropes are made of a torque-balanced multi-strand design, which comprises of two or more layers of strands. A torque balance is created in multi-strand ropes, by layering the outside and inside ropes in opposite directions. Multi-strand ropes offer much more flexibility and have a more wear-resistant profile. Though the wires in these ropes touch locally and at an angle, which causes them to be subject to both the effect of radial load, relative motion between wires and bending stresses when bent on sheaves or drums.

Nicking and fatigue patterns such as the ones discussed before occur in Independent Wire Rope Cores or IWRC ropes. IWRC ropes have outer wires of the outer strands, which have a larger diameter than the outer core strands. This helps to minimize inner strand nicking between the outer strands of the IWRC. The outer strands and the IWRC strands are approximately parallel. Often their neighbouring strands support these outer strands while the outer IWRC wires are relatively unsupported.

With these geometrical features it allows for the wire to fluctuate under tensile loads, the outer IWRC wires are continuously forced into valleys in between the outer strand wires and then released. This system results in secondary bending stresses which leads to a large number of core wires with fatigue breaks. These breaks are often close together and form in groups. This eventually leads to the IWRC breaking or completely disintegrating into short pieces of wire that lay, half a length long. This condition is often called complete rope core failure.

It is as the IWRC fails, and the outer strands lose their radial support then valley breaksform. Valley breaks occur when the outer strand wires bear against each other tangentially. This results in interstrand nicking, which restricts the movement of strands within the rope; without the freedom to move, secondary fatigue breaks occur in the outer strands, which will develop a stand tangent points. These breaks occur in the valleys between the outer strands hence why they are called valley breaks.

So to go over what we just learned, internal broken wires occur often in ropes that are operated with large diameter sheaves and high factors of safety. These breakages can occur when a reeving system incorporates sheaves lined with plastic or all plastic sheaves; these sheave units offer more elastic support than their steel counterparts. Which causes the pressure between outer wires and sheave grooves to be reduced to the point where the first wire breaks will occur internally.

If a section of a rope travels on and off of a grooved multi-layer drum, then it goes through what is called a bending cycle. The bending cycle occurs by a section of rope spooling in the first layer and is bent around the smooth drum surface, but when the second layer rolls around the rope section in the first layer will be spooled over. This causes the first layer to become compressed and damaged on the upper side by the second rope layer. With continued spooling the rope layers in the second and higher layers will, in turn, be damaged on both sides during contact with their neighbouring rope layers. This damage is caused both by the compression of the rope and by the rope laying on a rough surface.

Accelerated wear occurs where the point of the rope is squeezed between the drum flange and the previous layer. Often times the slap of rope at the crossover points causes peening, martensitic embrittlement and/or wire plucking, further associated rope damage is caused when the rope crosses over from layer to layer on a drum.

Also, if the lower wire rope areas where not spooled under sufficiently high tension the lower wraps can become displaced by the additional rope sections which would allow for these new rope sections to slide down in between them, which will lead to severe rope damage.

Many regulators have decided that the Statutory Life Policy be overly wasteful and they tend to use the Retirement for Clause Policy. A wire rope deteriorates slowly over its entire service, but to be aware of the state of deterioration, a wire rope must be periodically inspected. Moderate deterioration is normally present, and low levels of deterioration do not justify retirement. Which is why you have wire rope inspections to monitor the normal process of deterioration. This ensures that the rope can be retired before it can become dangerous. Besides, these inspections can detect unexpected damage or corrosion on the wire rope which will allow you to take corrective actions to ensure the longevity of the wire rope.

This system is useful for detecting external rope deterioration. To use this approach, the inspector will lightly grab the rope with a rag. The inspector then glides the cloth over the rope. Often times external broken wires will porcupine (stick up). When the rope moves along the wire it will be snagged on the broken wire. The inspectorwill then stops dragging the cloth along the wire and visually inspects the condition of the wire.

Frequently broken wires often do no porcupine, which is why a different test procedure must be utilized. This test involves moving along the rope two or three feet at a time and visually examining the rope. This method though can become tiresome because oftentimes the rope is covered in grease and many internal and external defects will avoid detection through this method.

Another method involves measuring the wire ropes diameter. This involves comparing the diameter of the current rope to the original rope’s diameter. Changes in the diameter of the rope indicate external and/or internal rope damage. This method is not perfect because many different wire breakages damages do not change the diameter of the rope.

You can also check for several visible signs of distributed losses of the metallic cross-sectional area. This is often caused by corrosion, abrasion and wear. To internally check for damage, you can insert a marlinspike under two strands and rotate it to lift the strands and open the rope.

Visual inspections are often not well suited for the detection of internal rope damage. This means that they have limited value as the only means of wire rope inspection. Though visual inspections do not require special machines. When completed by a knowledgeable and experienced rope examiner through visual inspections can be valuable tools for evaluating rope degeneration.

Electromagnetic Inspections or EM gives a detailed insight into the exact condition of a rope. EM is a very reliable inspection method and is a universally accepted method for inspecting wire ropes for mining, ski lifts and other similar industries. There are two distinct EM inspection methods, which have been developed to classify defects called Localized-Flaw (LF Inspection) and Loss-of-Metallic-Area Inspection (LMA Inspection type)

LF Inspection is similar to the rag-and-visual method. This inspection method is suited primarily for finding localized flaws, such as broken wires. Which is why small hand-held LF instruments are called electronic rags.

Electromagnetic and visual wire rope inspection methods are like peanut butter and jelly or cookies and milk they are the perfect combination, and both are essential for safe rope operation. Which is why both methods are often used to ensure maximum safety.

A program that involves periodic inspections is extremely effective. To establish baseline data for future inspections, a wire rope inspection program should begin with an initial inspection after a break-in period. Then the inspections should follow at scheduled intervals, with documentation of the ropes deterioration over its entire service life.

For multi-strand ropes often times visual inspections are ineffective which is why statutory life policy for a ropes retirement is often adopted. This means that these ropes are often discarded long before they should be meaning millions of dollars’ worth of perfectly good wire ropes are being thrown away annually.

Some people have suggested that non-rotating ropes should not be used if cranes use a single layer winding on a drum. Following this line of thought, this would mean multi-strand ropes should be used only when winding on multi-layer drums. This would cause wires to break the surface faster than internal wire damage can occur, these non-rotating wire ropes will be replaced long before internal fatigue can set in.

When internal broken wires are the problem electromagnetic rope testing can be the solution. Though there are some factors one needs to take into account such as certain regulations require rope retirement when a certain number of broken wires per unit of rope length exceed a set limit. This discard number that is specified in retirement standards refers solely to external wire breaks. This means the condition of a wire rope with internal breaks is therefore left up to the inspector.

Though you also need to take into account detailed detection and quantitative characterization of internal broken wires in ropes with many breaks and cluster breaks could be a problem. These difficulties are caused by the fact that electromagnetic wire rope can be influenced by several parameters such as:

Clusters of broken wires can cause an additional problem because the relative position of broken wires concerning each other within the rope is not known

Broken wires with zero or tight gap widths are not detectable by electromagnetic inspection because they do not have a sufficient magnetic leakage flux.

When you consider all of this you can quickly realize that you can only estimate the number of broken wires that have formed on a wire rope. You can use the LF trace for the detection of broken wires, though unfortunately it is not quantitative so it cannot be used to estimate the number of broken wires. Though it is good to note that if any internal broken wires are present an LMA trace will show rapid relatively small variations of a cross-section.

An electromagnetic inspection will help to enhance the accuracy and reliability of the inspection, by combining visual and EM methods they will be able to detect deterioration at the earliest stages. The inspections can be then used as an effective preventive maintenance tool. For example, the inspector early on detects corrosion, and you immediately apply the corrective action of improving the lubrication of the wire rope.

Wire ropes should be inspected by a certified inspector when installing it, and periodically throughout its life cycle. A wire rope should go through a quick, but thorough inspection every day that you use it at the beginning and end of each shift and you should keep records of all inspections. Ensure that your certified wire rope inspector uses a combination of visual inspection methods and electromagnetic inspection methods because this will ensure the optimum safety and longevity of the rope. This is especially true for ropes that are more likely to develop internal broken wires, and inspections completed by a certified inspector is the best way of having a preventive maintenance program and extending the life of your wire rope.

Queensland Division of Workplace Health and Safety, “Non-rotating hoist wire ropes, multi fall configurations, Health and Safety Alert,” http://www.whs.qld.gov.au/alerts/97-i-5.pdf

Verreet, R. “Wire rope damage due to bending fatigue and drum crushing,” O.I.P.E.E.C.(International Organization for the Study of the Endurance of Wire Rope) Bulletin 85, June 2003, Reading (UK), ODN 0738, pp. 27-46.

Wire ropes are designed to be extremely strong and durable to safely lift and secure heavy items. Wire ropes are commonly used with overhead lifting and rigging equipment to hoist loads – so when things go wrong, it can be extremely dangerous.

Wire rope hazards have caused hundreds of injuries and even fatalities on construction sites. According toone report, more than 60 people were killed over 15 years due to a wire rope breaking.

When wire rope is handled or stored incorrectly, it can tremendously increase the likelihood of a safety hazard. Some of the most common safety issues with this piece of industrial equipment include broken strands, corrosion, crushed wires, or fatigue that causes the rope to slip, stretch, or snap.

At Elite Sales, we have fulfilled lots of orders forwire ropesto replace broken or damaged equipment. So, take our advice with these tips to reduce wire rope hazards through proper handling.

OSHA requires that all overhead lifting and rigging equipment be carefully inspected before use. Certified crane operators are typically responsible for this task – but all workers interacting with wire ropes should know how to conduct an inspection.

First, the wire rope should be visually inspected to note any of the most common signs of wear and tear. This includes crown or valley breaks in the exterior strands or any kinks in the wire rope.

Any visible rusting, loose wires, kinking, or damaged fitting should be noted immediately. The wire rope should be replaced or repaired before it is used, as even a few broken wires could compromise its strength and durability.

Dryness or dust forming on the wire rope is an indication that hasn’t been recently lubricated. This can cause the wire rope to break far more easily, so this must be taken into consideration during the inspection as well.

Wire ropes are commonly damaged when they are being moved as the strands can get caught, broken, or bent. Correctwire rope installation and handlingare crucial for extending the life and use of this equipment. So, all employees who handle wire ropes should receive adequate training for proper handling.

Special care should be taken when the wire rope is unreeled or uncoiled. The strands can easily get kinked or crushed during this process. The best practice is to pull the wire rope in a straight line off of the reel or mount it on a revolving stand to ensure that the rope does not look or kink.

All wire ropes should be routinely re-lubricated as well. This helps to reduce wear from friction and movement and also protects the wires from corrosion.

Additionally, all handlers should be aware of practices that can damage wire ropes and avoid them at all costs. For instance, battening down the wire rope sling to secure it can crush and break the strands. This is unfortunately a fairly common practice on construction sites – so supervisors should strictly enforce correct handling.

Wire rope can get damaged during storage, too. All wire ropes must be completely dried and stored in a cool, temperature-controlled space. It is also best to avoid stacked coiled wire rope directly on the ground and instead stack it on cement or metal.

As an industrial hardware supplier, we understand that it is not just the way that these materials are handled – but also the quality of the equipment that lowers safety risk. Cheap wire rope will rust or wear down quickly, which increases the likelihood of it breaking.

First, be sure that you only purchase wire rope made with improved plow steel (IPS), extra improved plow steel (EIPS), or even extra-extra improved plow steel (EEIPS). This means that the wire rope is made of stronger steel than mild plow steel (MPS).

You should always double-check that you are using the correct wire rope for your application. There are many different styles, constructions, and patterns available which are optimized for certain uses.

For example, some are designed to berotation resistantwhich is best for overhead lifting. The central core of the wire rope is also an important factor to consider. A fiber core is best for applications where elasticity and stretch are needed – but it is not ideal for high heat or heavy loads. Wire strand cores on the other hand are best when additional stability is needed for securement.

Working with a trusted and experienced industrial wire rope supplier can be extremely beneficial here. Not only will this give you access to a wide range of wire rope options, but you can receive advice and guidance from professionals.

Here at Elite Sales, we’ve worked with construction companies and industrial manufacturers for years to provide top-rated equipment. We carry a great selection of wire rope in many styles, lengths, diameters, and constructions to meet nearly all applications. Plus, our team of experts is just a phone call away.

Reducing the risk of wire rope hazards on the job site needs to be a top priority. Any mistakes with wire rope installation, transportation, or storage can lead to major safety issues. One of the easiest ways to do this is enforcing proper handling of top-quality wire rope equipment throughout the organization.

If you are looking to purchase high-quality wire rope for your business, be sure to check out our selection. Elite Sales is proud to carry top-rated industrial hardware. Our team is available to answer any questions and direct you to the exact types you need for any application.

Wire rope can go through a lot of abuse. These ropes are used for numerous types of applications, from overhead rigging to tie-downs, and they are constantly under a lot of friction and pressure.

Ask any wire rope distributor, and they’ll tell you that if a wire rope is even slightly damaged, it could lead to disaster. Every year, more than 10% of fatal occupational injuries are caused by accidents related to wire ropes snapping and dropping heavy materials.

To reduce this risk of lost and damaged materials, injury, or even death, it is important to take exceptional care of wire ropes. Ensuring that these critical pieces of industrial hardware equipment are in tip-top shape can also help to lower material costs. Additionally, it can save your team a lot of time spent repairing and replacing broken wire ropes.

Our team at Elite Sales has been working in the industrial hardware supply industry for many years. We know a thing or two about how to care for wire rope.

It is not only the heavy workloads and movement that wear down a wire rope – it is also the way that it is handled and stored. Wire ropes can be damaged by exposure to extreme temperatures and even small amounts of water or humidity.

You should always wipe down wire ropes before putting them away to make sure that they are completely dried. It is best to keep them in a temperature-controlled space, especially during the winter. Extreme cold temperatures can make the metal more brittle and prone to breaking.

If you will be leaving wire ropes outside or if they will be exposed to any water, it is highly recommended that you use either stainless-steel or galvanized wire ropes. Electro or hot dip galvanized and stainless-steel wire ropes are naturally rust-resistant. However, most wire rope distributors still recommended that you keep wire ropes as dry as possible to prevent any issues.

Finally, do not store wire ropes on the ground, as this can cause scratches and snags on the wires. If you are using galvanized wire ropes, the ground could chip away at the zinc coating, leaving the alloy steel exposed. It is best to keep wire ropes on cement or metal surfaces to prevent termite damage, dust, or other damaging conditions.

There are some things you can do before, during, and after wire rope transport that will help to prevent wear and damage. Be sure to ask your wire rope distributor questions about the designs and options before you buy wire rope wholesale, such as:

These factors can make a difference in when and how you will use the ropes for specific purposes. For instance, it may be best to opt for a rotation-resistant wire rope for overhead lifting to reduce twisting – which can wear the wire strands down.

Wire rope distributors suggest that wire ropes should be cleaned and lubricated regularly, especially after extreme weight loads or dry, hot temperatures. The strands can be cleaned with steam or compressed air that removes debris. Then, a layer of mineral oil or petrolatum-based lubricant should be applied. This will help to reduce friction and create a protective layer over the wire rope strands.

Purchasing wire ropes wholesale can get expensive. You want your investment to last as long as possible. Fortunately, you can extend the life of a wire rope dramatically by carefully inspecting it regularly to catch signs of wear that can be fixed. Inspections should only be conducted by trained workers who know what to look for. Special attention should also be given to specific spots on the rope, such as points of attachment.

If there are only small issues, such as a broken strand or frayed end, they may be fixable if they are caught early enough. The worn-down portion can be wrapped in a new wire to create a seized end. This wrap should then be fused to create a strong seal and prevent future damage to that point of the rope. Also, always work with a reputable wire rope distributor to receive quality products.

Although wire ropes are not the most technical piece of equipment on construction sites, it still requires specialized training to handle and maintain. All employees must be taught how to unload, store, and transport wire ropes properly to prevent excess wear and tear.

For instance, all handlers should know the proper procedure for coiling or winding the ropes. Wire ropes can easily snag or bend, so this task must be done carefully and correctly. Additionally, if a rope is wound too tightly, it can cause friction between each wrapped layer or even crush in the innermost coils.

Supervisors must be careful to enforce proper handling. Failing to properly inspect or use wire ropes could lead to damaged equipment and OSHA violations, as well as an extremely dangerous work environment. There is no excuse for shortcuts when it comes to handling these ropes! Hence, before you buy wire ropes wholesale, be sure to read up on how to care for wire rope.

Extending the life of your wire rope is not difficult, but it does require a bit of extra attention and maintenance. Ultimately, the best way to ensure that they do not wear down quickly is by purchasing highly-rated, top-quality wire ropes in the first place.

At Elite Sales, we offer the highest quality industrial hardware equipment available. If you are looking for a wire rope distributor you can trust, reach out to our team. We carry a wide variety of wire rope styles, sizes, and grades so you can find the exact type you need for the job at hand.

A thorough inspection of suspension wire ropes in service shall be made once a month. Suspension wire ropes that have been inactive for 30 days or longer shall have a thorough inspection before they are placed into service. These thorough inspections of suspension wire ropes shall be performed by a competent person.

The need for replacement of a suspension wire rope shall be determined by inspection and shall be based on the condition of the wire rope. Any of the following conditions or combination of conditions will be cause for removal of the wire rope:

The building owner shall keep a certification record of each monthly inspection of a suspension wire rope as required in paragraph (g)(5)(iii) of this section. The record shall include the date of the inspection, the signature of the person who performed the inspection, and a number, or other identifier, of the wire rope which was inspected. This record of inspection shall be made available for review by the Assistant Secretary of Labor or the Assistant Secretary"s representative and by the employer.

Suspension wire rope shall be inspected by a competent person for visible defects and gross damage to the rope before every use and after each occurrence which might affect the wire rope"s integrity.

Wire ropes are complex machines with a great many moving parts. They require attention, skilled operators, careful maintenance, inspection and lubrication.

In spite of their vital importance, wire ropes are frequently treated as and considered low-tech commodities. Failures are frequently accepted as “inevitable.”

With the appropriate inspections, wire rope failures can be predicted, and expenses and losses reduced. Consider that the price tag of rope failures can easily be in the seven or even eight digit range, and the cost of an inspection is marginal.

Much more dependable than visual inspections, magnetic rope testing (MRT) is a reliable non-destructive evaluation/examination (NDE) procedure used for the in-service inspection of wire ropes. NDE methods allow the detection and evaluation of external as well as internal rope deterioration. This allows the inspection of a rope’s entire cross-section to the core. MRT drastically increases wire rope safety. At the same time, it promises significant annual savings.

Ropes usually degrade internally with no visible indications. Internal deterioration modes include inter-strand nicking that will eventually develop into clusters of internal broken wires and corrosion including corrosion pitting.

External deterioration includes winding-on-drum damage. Urgently needed, suitable inspection equipment and procedures are now available – especially for the quantitative characterization of internal rope deterioration.

In this blog, we will cover three common forms of wear and tear that wire can experience out in the field. Though wear does occur naturally, regular inspection, maintenance, and equipment repair can help ensure appropriate cycle life for your cable products while also minimizing risks and failures. Be on the lookout for signs of abrasion, bird caging, and kinking as you inspect and operate your equipment.

Abrasion, peening, and corrosion typically impact the outer surfaces of wire rope. Abrasion is a form of metal loss or erosion, and peening describes metal deformation. Both of these phenomena occur when a wire rope contacts other metallic surfaces, or when it passes over a drum or sheave. Sheaves that are heavily worn or badly corrugated can expedite wear and friction, causing the individual cable wires to break down and press together. Additionally, when sheaves are poorly lubricated, they cause pitting in the cable surface that leaves them vulnerable to corrosion and rust. Even a brand new cable is susceptible to premature wear if they are not maintained correctly, and paired with appropriate pulleys.

Bird caging is a severe form of wire rope distortion that causes the individual outer strands of a cable to unravel and expand, creating a bird cage shape at the damage site. Bird caging is usually caused by sheaves that impart unintentional rotation. When a non-rotation resistant cable experiences torsion caused by excessively tight, or incorrectly positioned sheaves, it triggers the outer cable strands to lift away from their normal position. Bird caging poses a severe hazard. To prevent future issues, the damaged cable should be immediately removed from operation, and the sheaves remedied.

A kink is the permanent deformation of strands in a wire rope caused by unintended bending and twisting. This usually occurs when the rope is twisted into a tight loop and then snapped back to a straight direction, leaving a permanent curve at the bend site. Though kinks often result from improperly handling or installing wire rope, they can also appear during service if a heavy load is released suddenly, or if a wire rope bends around too small of a sheave. While most kinks show obvious signs of catastrophic failure, others may appear insignificant or repairable through re-straightening. However, it is important to note that kinks always result in permanent strand damage, no matter how severe they may seem on the surface. If not addressed in a timely manner, kinks pose a severe safety hazard.

Though cable damage may happen unexpectedly, you can set yourself up for success by employing high quality wire rope from the start. Luckily, Strand Core manufactures high quality domestic aircraft cable and wire rope for military and commercial applications. Start a quote today, or contact us with any questions at https://strandcore.com/contact/.

8613371530291

8613371530291