wire rope flemish eye made in china

Qingdao Hitec Hardware Co., Ltd. supplies forged products, specializing in forged couplers, form works, line fittings, hooks, rings and links. All of our products are exported to America and Europe.

We are a professional manufacturer and exporter that is concerned with the design, development and production of Ungalvanized Steel Wire For Further Redrawing, Fishing Steel Wire Rope, pe steel wire rope 6x7+fc 3mm-5mm. All of our products comply with high quality standards and are greatly appreciated in a variety of different markets throughout the world. We are committed to improving employee quality, creating top-rate quality, delivering satisfactory products and services to customers through standardized management. Trust us and you will gain more. We need to develop marketable products to attract customers based on continuous research on industry development and market trends, and understanding the potential needs of customers. Our company adheres to the business philosophy of taking science and technology as the guide, relying on the market and service as the guarantee to promote the vigorous development of enterprises.

Details determine success or failure, professional manufacturing results in excellent quality, we regard quality as life and strive to provide customers with the most excellent Ws73-Tth Flemish Eye Wire Rope Slings and services. We hope that when employees reach a specific goal, they can modify and adjust their own methods and methods according to changes in the outside world, and provide creative suggestions and solutions for the company"s development. We not only provide professional sales services, but also establish a complete after-sales service system to provide guidance and assistance for the problems and difficulties encountered in the development of the enterprise.

We insist on user-centered, adapt to new changes in the demand for equipment and technology, and develop high-tech DIN 766 Stainless Link Chain, seine fishing steel wire rope 6x19w, filled-type compacted strand steel wire rope for hoisting for the market. We take long-term incentives as the starting point, and steadily push forward the internal reform of the enterprise to stimulate the development of vitality. It using the world"s leading system for reliable operation, a low failure rate, it suitable for Argentina customers choice. We pursue a quality policy of meticulous craftsmanship and the pursuit of perfection, and implement the business strategy of continuous improvement and market expansion. We take the industry"s advanced companies as an example, and strive to achieve leading technology, stable products, and develop ourselves in the service of society.

Over the years, with good product performance, perfect quality assurance, and after-sales service, we have won unanimous praise from customers at home and abroad. In the future, we will continue to make progress to become a well-known Ws81-E-E Flemish Eye Wire Rope Slings brand. We have a strong technical force and stable technical professionals, which are professionally trained and certified to work, and have rich practical work experience to achieve 100% customer satisfaction. We are innovating, pioneering and enterprising, to a higher level of management.

Hilifting is the best flemish eye steel swage ferrule manufacturers in China, we supply many different types of wire rope ferrules and swage sleeve which suit a variety of rope and applications.

Wire Rope slings are the most commonly used slings. It widely used used in lifting and hoisting constructions. It is also best solution for heavy loads.

Our company continuously adjusts and optimizes its operating products, strengthens market marketing and expansion, and has a large number of stable customers in the development of the Swaged Wire Rope Sling, Eye Hoist Hook With Latch, Wire Rope Pulling Hoist industry by virtue of advanced management methods, sensitive market information and comprehensive service. All our staffs believe that: Quality builds today and service creates future. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

All of our Ws81-E-E Flemish Eye Wire Rope Slings are independently researched and acquired by our unique technology to make sure that they can be upgraded and updated constantly. Brand can create invisible competitive advantage, good brand can create good market effect and provide huge economic benefits. To create a beautiful future, we would like to cooperate with all friends at home and abroad.

We are the leading manufacturer of Flemish Eye swaging sleeves in China. All our Flemish Eye sleeves have corrosion protection and are made according to the highest quality standard. Surface treatment could be black oxidized or galvanized. Sleeves are stamped for traceability with code, size, and batch number.

All our Flemish Eye swaging sleeves are tested for better swageability. Testing includes hardness test, chemical analysis, microstructure analysis and closed flattening test according to EN 13411-3:2004 standard.

Not suitable for anti-rotation wire rope. According to EN 13411-3, when properly used, the terminal has an efficiency rating of over 90% based on the strength catalogue of the wire rope.

ATTENTION! Before using our Flemish Eye sleeve with any other type of laid, constructed or graded wire rope, it is recommended that the terminals be be destructively tested to demonstrate the adequacy of the assembly.

The Flemish Eye wire rope sling is formed by putting the wire rope on the wire rope at the bottom of the wire rope loop. Swaging glues the ends of the strands in place by forming a streamlined, compact, strong and permanent joint. Flanders wire rope sling eye has all the advantages of manual splicing eye, and is equipped with forged steel sleeve for safety, can complete the termination, and will not cause the wire rope deformation due to rotation, the wire end or the possibility of the wire rope slippingProduct nameflemish eye steel wire rope sling

6. To be the best wire rope slings in ChinaLooking for flemish eye wire rope slings? With wide experience and expertise, STONIMAGE is well-known as one of the largest manufacturers and suppliers in China. We are equipped with a professional factory which can guarantee you the high quality, high precision and reliable performance of our products.

The eye or loop end preparation is formed using the Flemish Eye Splice. This splice is then secured by swaging a metal sleeve over the strang ends, at the junction of the splice. There are no exposed wires and serving is not required.

The swage metal sleeve flows around the wires and prevents the strands from unlaying. Depending on the application, the sleeve can be steel, aluminum, or stainless steel.

The Flemish Eye is spliced by unlaying one half of the strands from the other half at the core. The two halves are joined at the bearing point of the eye and laid back in the opposite direction. The final step is to secure the strands with a metal sleeve.

1. Vertical- The Vertical, or straight, attachment is simply using a sling to connect a lifting hook or other device to a load. Full rated load of the sling may be used, but never exceeded. A tagline should be used on such a lift to prevent rotation, which can damage the sling. A wire rope sling with a hand-tucked splice can unlay and fail if the sling is allowed to rotate.

Triple leg slings have 50% more capacity than double leg only if the center of gravity is in center of connection points and the legs are adjusted properly(equal share of the load)

When lifting vertically, the load will be shared equally if the center of gravity is spaced equally between the pick points, as in the first illustration at right. If the weight of the load is 10,000 lbs., then each sling will have a load of 5,000 lbs. and each shackle and eyebolt will also have a load of 5,000 lbs.

FLEMISH LOOP AND EYE HOOK WITH SAFETY LATCH - This attachment style offers versatility and an additional level of safety with the latch positioned on the Eye Hoist Hook for a more secure connection.

FLEMISH EYE SPLICED SWAGING - The ends of the sling are mechanically formed allowing for larger load capacities than hand-laid wire rope. Loops are secured with a forged metal sleeve and go over the spliced area.

GREATER WEAR RESISTANCE - A 6 x 25 IWRC (Independent Wire Rope Core) classification for wire rope slings offer large outer wires that provide a balance between fatigue and wear resistance.

When looking for strength and durability on that next big rigging job, look no further than our array of HSI Wire Rope Slings. Awide-varietyof sizes are available whether working on a small-load lift or preparing to maneuver a massively heavy element. Our slings are there to solve yourhoisting, lifting and towing problems.

The wide offering of Single Leg Wire Rope Slings will surely meet your rigging needs on thejobsite. Each eye on these slings is formed using the mechanical Flemish Eye Splice. This process allows for the most efficient use of the rope capacity with top-quality steel as the pull is directly along the centerline of the rope and eye.

The wire rope sling is not quite as durable. The wire rope sling is not as flexible as chain but its greater stiffness can be an advantage if it has to be inserted through a small opening or beneath a load. However, when wrapped around a load, the wire rope sling often tends to deform permanently to the shape of the load. Wire rope suitable for slings comes in a variety of grades and constructions. In most cases looping back and securing the loop with ametalsleeve terminates the rope. This forms a loop or soft eye, the simplest form of sling end. Thimbles are used to support and protect the eye from abrasion. Wire rope is generally cheaper and lighter than chain which can be a plus, particularly for applications that require long sling lengths.

Wire rope slings adopt precast concrete construction and the main parts include wire rope, inner core, strand, center, steel wire, steel stocks and others.

We can customize various kinds of rigging according to customers’ requirement. Usually, the minimum circumference S of the sling is 50 times the wire rope diameter and the bending radius must be not less than 4 times of the wire rope diameter. The zone between the clamps can’t be bent under lifting force and the length is intended to be the dimension measured between the bearing points of the slings and the measured length of a ferrule-secured sling shall not differ from the nominal length by more than two rope diameters or 1% of the nominal length.

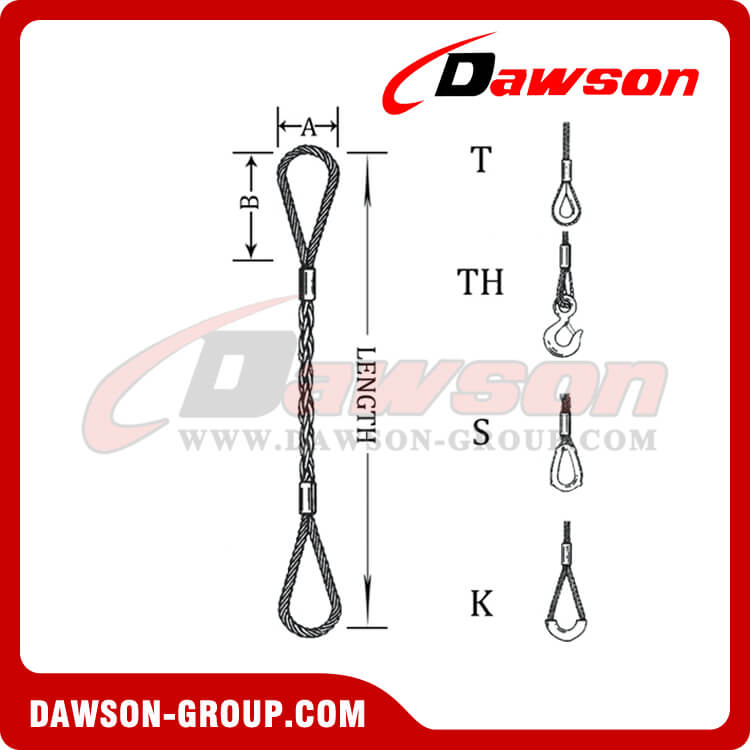

There are various sockets available such as open socket, closed socket and others. Also, the eye type include Flemish eye, pressed soft eye, spliced eye, thimble eye, standard eye, hard eye at both end.

②Choker hitches reduce lifting capability of a sling, since this method of rigging affects the ability of the wire rope components to adjust during the lift, places angular loading on the body of the sling, and creates a small diameter bend in the body at the choke point.

Wire rope slings are always packaged in plywood reel/plastic reel/wooden reel/coil in container, and then they will be palletized or put into a crate or a box.

There are various types of wire rope slings including slings with soft eye, hoist slings, slings with soft eye and two legs, steel ferrule secured slings, slings with Flemish eyes, ferrule secured endless slings, slings with steel-ferrule secured end stops, slings with swaged steel tie rod, slings with single hook, slings for crane, slings with sockets, slings with master link and two legs, slings with cuneiform connector, flat wire rope mesh slings, slings with master link and four legs, endless wire rope slings, container lifting slings for sea oil platform, large diameter cable laid slings, slings for lifting reinforcing steel bars, cable laid grommet slings, cable stocking, slings with spliced eye termination and others, and the main products are as following.

2-Leg bridle slings constructed of two wire rope assemblies that are attached to an oblong ring are designed for general lifting when the attachment can be made directly to the load. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. The advantage of wire rope slings is that they are resistant to corrosion, heat, sunlight and most chemicals and they are custom built to meet your specific needs for any application.

3-Leg bridle wire rope slings constructed of three wire rope assemblies that are attached to an oblong ring are designed to handle unbalanced loads. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object. We carry a range of wire rope slings in our hire fleet with soft eye configurations at each end, available in various capacities and effective working lengths.

4-Leg bridle wire rope lifting slings constructed of four wire rope assemblies that are attached to an oblong ring are designed for balanced or unbalanced loads and for heavy lifts when the weight can easily be distributed over four points. The lifting ends of the wire rope legs can be fitted with a variety of hooks, eyes, or rings to allow attachment to nearly any object.

The endless wire rope slings are orbicular, economical and adaptable slings with no fixed wear points, using special technology and the most advanced equipment and known for its softness, high tension and increased suspension points. They are suitable to lift and move tubes, pipes and long metal parts which suited in small and limited spaces and for high/large lifting loads, they are also adaptable for special bulk hoisting requirements of different conditions, such as transformers, shipbuilding and special machinery (where the warning mark locates cannot be used as lifting point)

Slings can be realized with galvanized or ungalvanized wire rope, special rope protected by strong PVC sleeve to resist against sharp edges without damaging the goods surface is also available as per your request.

7. According to the strength, wire rope slings can be divided into vertical breaking strength, chocker breaking strength, basket breaking strength, and except for standard eye size, thimble eye size, there are others of different eye hook capacity.

④Evidence of heat damage or if a wire rope sling having a fiber core is exposed to temperatures in excess of 200° F or if a wire rope sling having a steel core is used at temperatures above 400° F or below minus 60° F.

⑤Corrosion of the rope or end attachments or not laying and opening up of a tucked splice. Also, when end attachments that are cracked, deformed, or worn.

⑦Avoid twists, kinks and knots before lifting, store wire rope slings where they will not be subjected to dirt, moisture, extreme heat, corrosion or mechanical damage.

⑧Protect the sling body against sharp edges and corners of loads, protrusions or abrasive surfaces. Sharp bends can distort wire rope and reduce its strength.

⑨Never "shock load" wire rope slings, the actual force caused by a sudden application of load can easily exceed rated capacities and damage slings and abruptly releasing a load can also damage the slings.

8613371530291

8613371530291