wire rope flemish eye brands

Strong & economical, Wire rope cable slings are versatile & long lasting. More durable than nylon slings, wire slings have higher temperature limits. Mechanically spliced eyes offer an efficiency rating of 95% the strength of the cable. Each sling comes tagged with rated capacities.

I&I Sling wire rope slings are mechanically spliced. Compared to loop back or turn back slings, mechanically spliced slings are considered to be the safer option due to the backup redundancy of the splice in the eye. This splice can keep the sling eye together in a situation where the pressed sleeve fails. Flemish Eye slings are fabricated at your local I&I Sling branch location with domestically sourced wire rope. Tight length tolerances are available, wire rope slings can be constructed with +/- the diameter of the rope or in matching sets. Flemish eye slings are compliant with ASME B30.9 and can be proof tested to twice the working load limit.

The Flemish eye without the sleeves has already an efficiency of 75% of the breaking load of the rope; with the sleeve this termination has the same breaking load as the rope, for thick ropes down to 90% of the rope’s breaking load. Superloop with Flemish eye can be used on ropes up to 114 mm in diameter. At our workshop we can make Superloop with a diameter up to 68 mm.

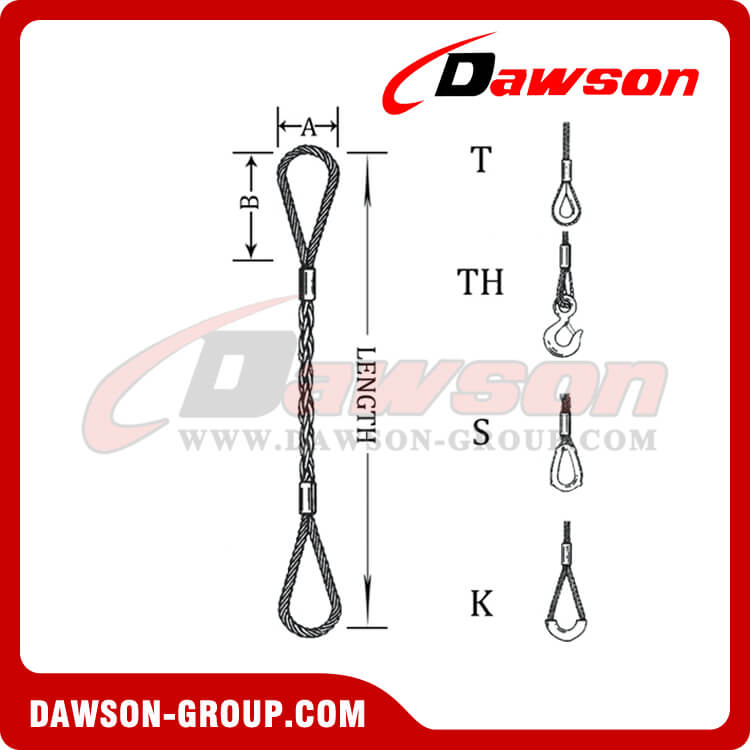

EYE AND THIMBLE - A protective thimble is present to attach the bottom end of the sling to a separate lifting element while the Flemish loop is located atop to allow a choker hitch.

FLEMISH EYE SPLICED SWAGING - The ends of the sling are mechanically formed allowing for larger load capacities than hand-laid wire rope. Loops are secured with a forged metal sleeve and go over the spliced area.

GREATER WEAR RESISTANCE - A 6 x 25 IWRC (Independent Wire Rope Core) classification for wire rope slings offer large outer wires that provide a balance between fatigue and wear resistance.

When looking for strength and durability on that next big rigging job, look no further than our array of LKS Wire Rope Slings. A wide-variety of sizes are available whether working on a small-load lift or preparing to maneuver a massively heavy element. Our slings are there to solve your hoisting, lifting and towing problems.

The wide offering of Single Leg Wire Rope Slings will surely meet your rigging needs on the jobsite. Each eye on these slings is formed using the mechanical Flemish Eye Splice. This process allows for the most efficient use of the rope capacity with top-quality steel as the pull is directly along the centerline of the rope and eye.

or wire rope slings, you may opt for thimble eye (where a thimble if fixed inside the loop to preserve the natural loop shape and prevent direct contact that will damage the cable) or soft eye. Besides, rope ends with machine swaged with ferrules or sockets is a better option than hand spliced slings as it offers more protection.

Do you experience a short lifespan for your steel wire ropes? Deal with a supplier who is slow in responding & customer service? Or did you pay high prices for average quality products that fails you all the time? 83%of our clients claim that these made them search for a better option and subsequently worked with us since.

© 2003-2021 PROlift. All materials – including but not limited to text, images, graphics, multimedia are the copyright-protected property of Forum Industry or, as applicable, its commercial partners.

Steel wire rope slings as a basic material handling tool are most frequently used in marine line. Also they offer a strong, dependable and economical option for most lifting applications. Their popularity is enhanced by the numerous sling configurations available to support a broad range of applications. These configurations include single and multi-part slings (such as round braids, flat braids, Tri-Flex and cable laid slings), grommets, single leg slings, multiple leg bridles, and a wide variety of fittings and attachments.

Relative to other types of slings, wire rope slings are average in strength/weight ratio, average in abrasion and cut resistance, poorest in elongation and flexibility, and average for high temperatures (IWRC only).

A mechanical (or flemish) splice sling is most frequently used and is fabricated by unlaying the rope body into two parts, one having three strands, the other having the remaining three strands and core. The rope is unlayed far enough back to allow the eye to be formed by looping one part in one direction and the other part in the opposite direction and laying the rope back together.

The strands are rolled back around the rope body and a metal sleeve is slipped over the ends and pressed (or swaged) to secure the ends to the sling body. A hydraulic swaging press with special dies is used to bond the sleeve in place. Extreme pressure forces the steel sleeve to flow into the voids between the wires and strands, creating an assembly that maintains most of the wire rope"s nominal breaking strength.

As a professional manufacturer for wire rope slings and heavy lift assemblies, SOLAR has been the No.1 wire rope and sling supplier in SH area. Our customers are mostly Shipbuilding, Shipping, Offshore construction, and ship service providers. With swaging machine up to size 120mm and experienced splicing workers, we provide strongest and safest wire rope slings. Also our sales staffs are professional with lifting equipment, and could provide with customer correct wire rope and slings for their equipment or lifting requirements.

Slings are constructed of high strength 6 x 19, EIP, IWRC class wire rope (6 strands of 19 wires each, Extra-Improved Plow steel, surrounding an Independent Wire Rope Core) that resists abrasion for longer life. Wire rope sling is manufactured using a mechanically swaged, flemish splice technique to form the eyes, so that the eye strength is not solely dependent on the sleeve for greater reserve strength. Slings are supplied with a Tuff-Tag that shows rated capacities, providing easy to read capacity information to promote safety. Slings comply with OSHA and ASME B30.9 standards.

The eye or loop end preparation is formed using the Flemish Eye Splice. This splice is then secured by swaging a metal sleeve over the strang ends, at the junction of the splice. There are no exposed wires and serving is not required.

The swage metal sleeve flows around the wires and prevents the strands from unlaying. Depending on the application, the sleeve can be steel, aluminum, or stainless steel.

The Flemish Eye is spliced by unlaying one half of the strands from the other half at the core. The two halves are joined at the bearing point of the eye and laid back in the opposite direction. The final step is to secure the strands with a metal sleeve.

1. Vertical- The Vertical, or straight, attachment is simply using a sling to connect a lifting hook or other device to a load. Full rated load of the sling may be used, but never exceeded. A tagline should be used on such a lift to prevent rotation, which can damage the sling. A wire rope sling with a hand-tucked splice can unlay and fail if the sling is allowed to rotate.

Triple leg slings have 50% more capacity than double leg only if the center of gravity is in center of connection points and the legs are adjusted properly(equal share of the load)

When lifting vertically, the load will be shared equally if the center of gravity is spaced equally between the pick points, as in the first illustration at right. If the weight of the load is 10,000 lbs., then each sling will have a load of 5,000 lbs. and each shackle and eyebolt will also have a load of 5,000 lbs.

High quality wire rope steel lifting slings fabricated with flemish eye splice and swaged sleeve. High resistance to fatigue, abrasion-resistance and heat resistance make them ideal in a variety of environments.

Wire Rope is made out of multiple steel wires that form individual strands and are wrapped around a core. They provide durability, flexibility, and the ability to handle bending stresses. There are many

Our Wire rope slings are made with 6x25 EIPS IWRC rope. Fabricated from extra improved plow steel (EIPS) and independent wire rope core (IWRC) which provides support for the outer

8613371530291

8613371530291