wire rope inspection course supplier

Wire Rope Rigging Inspection & ReplacementThis micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing.

This micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing. Great for refreshers or toolbox talks/tailgate meetings!

PT Wire Rope Training and Consultancy was established in 2012 and is devoted to developing wire rope and lifting gear specialists, managers and inspectors. The Company is a Lifting Equipment Engineers Association (LEEA) accredited training provider. Our training helps businesses operate safely, efficiently and sustainably, building career opportunities for the people they employ.

This course will provide delegates with an understanding of wire rope inspection requirements for a range of wire ropes. Covering a range of fundamental topics, including legislative requirements and the manufacturing processes the course develops an understanding of inspection requirements of a range of wire ropes and the discard criterion. This course consists of a range of theoretical and practical sessions where delegates will be required to confirm and demonstrate their knowledge of the course through theoretical and practical assessment.

By the end of this training programme the delegate will be:Aware of the relevant legislation applicable to wire ropes, including British Standards and other industry best practice

Personnel who are involved in the inspection, and/or safe use of wire rope. This course is also suitable for those who are involved with, or give advice to, users of wire rope and associated equipment.

Objective: This training is aimed at persons who directly or indirectly come into contact with wire ropes and should always be available to them. They should ease the proper handling of wire ropes and convey the necessary expertise. Compliance with the instructions in the training should ensure the safe handling of wire ropes and help to prevent dangers and minimize repair costs and downtimes.

EN10264-2: 2012-3 Steel wire and wire products - Steel wire for ropes - Part 2: Cold-drawn non-alloy steel wire for ropes for general applications. Changes to the machine as well as non-observance of the regulations from

As a major supplier of rigging equipment to companies in various industries, we offer a wide variety of wire rope products, including cable laid grommets and steel wire rope. Our inventory also includes a wide selection of wire rope slings, chain slings, synthetic slings, full body safety harness and accessories, cargo lashing, mooring ropes, chain hoists and manual lifting equipment and much more.

We also offers a wide portfolio of services including crane and lifting equipment inspection, load testing, crane and lifting equipment operator certification, rigger certification, training, NDT services, rental of spoolers, load cells and test weight, high pressure lubrication of wire rope etc.

Each course delegate will be expected to complete a short theory test to demonstrate a good understanding of the course contents. If successful, a certificate will be issued. This will help the Employer to address certain legal requirements by being able to demonstrate employee competency. A detailed course handout is also provided for future reference.

The course is generally held at our Head Office at Harworth, however we are also able to utilise other Certex locations, or hold courses at Client premises if adequate facilities are available.

The content of this course and the standard of instruction has been approved by the Lifting Equipment Engineers Association (LEEA). A certificate will be issued by LEEA on successful completion of the course.

Certex UK offers a range of standard training courses as detailed on our web site and bespoke training courses can be tailored to suit your specific needs. Many of our standard courses are LEEA certified.

Unlike many other wire rope training courses, TENSOLOGY are able to back up the theory and application of the relevant codes, standards and regulations with experience based know-how to provide the attendee with a more comprehensive understanding of the subject.

Cleveland, OH – Mazzella Companies recently launched a new online sling inspection course to complement the Lifting U™ brand of classroom and online training programs. Sling Inspections is the second addition to the library of online courses available at LiftingU.com.

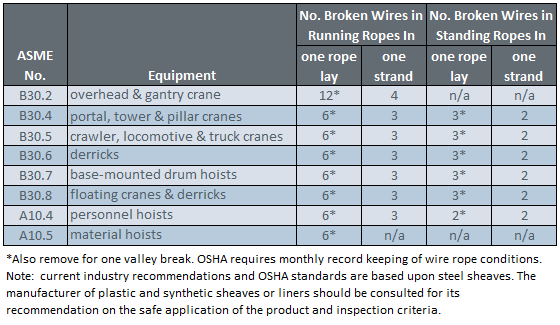

Mazzella’s Sling Inspections course consists of eight lessons and focuses on OSHA 1910.184 Slings and ASME B30.9 Slings standards. Each lesson features hands-on video inspections, performed by certified Mazzella Inspectors, to demonstrate proper inspection technique and identify ASME’s removal from service criteria.

“All of the tagging, inspection, and removal from service criteria is from applicable OSHA and ASME standards. We had all of this information already available on our website, but we realized that we could package this into an online course that was engaging and easy to share with others,” says Tom Horner, Corporate Rigging Inspection Manager of Mazzella Companies.

Other topics covered in each lesson, include: inspection frequencies, sling tag requirements, inspection criteria, disposal of damaged/failed slings, and best practices for sling use and maintenance.

“Not only did we rely on information from industry standards, but also on the expertise and experience of our inspectors and trainers. The video demonstrations and real-world examples of damaged slings set this course apart from others we’ve seen,” says Mike Minissale, Director of Marketing of Mazzella Companies.

Mazzella Companies will continue to offer more online lifting and rigging courses in the future. To enroll in Lifting U™ and learn more about their classroom and job site training programs, please visit LiftingU.com.

Objective: The training is intended to provide personnel with good theoretical and practical basic training in the use and maintenance of steel ropes.

The course provides a thorough introduction to knowledge about steel ropes, the correct use / choice of steel ropes and what requirements are set for those who use and control steel ropes.

Anyone who is to use work equipment as mentioned in §10-1 and §10-3, must have practical and theoretical training that provides knowledge of construction, operation, use properties and area of use, as well as maintenance and control.

8613371530291

8613371530291