wire rope inspection course manufacturer

Wire Rope Rigging Inspection & ReplacementThis micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing.

This micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing. Great for refreshers or toolbox talks/tailgate meetings!

PT Wire Rope Training and Consultancy was established in 2012 and is devoted to developing wire rope and lifting gear specialists, managers and inspectors. The Company is a Lifting Equipment Engineers Association (LEEA) accredited training provider. Our training helps businesses operate safely, efficiently and sustainably, building career opportunities for the people they employ.

This course will provide delegates with an understanding of wire rope inspection requirements for a range of wire ropes. Covering a range of fundamental topics, including legislative requirements and the manufacturing processes the course develops an understanding of inspection requirements of a range of wire ropes and the discard criterion. This course consists of a range of theoretical and practical sessions where delegates will be required to confirm and demonstrate their knowledge of the course through theoretical and practical assessment.

By the end of this training programme the delegate will be:Aware of the relevant legislation applicable to wire ropes, including British Standards and other industry best practice

Personnel who are involved in the inspection, and/or safe use of wire rope. This course is also suitable for those who are involved with, or give advice to, users of wire rope and associated equipment.

Experiential Systems provides annual ropes course inspection services for indoor and outdoor ropes courses, challenge courses, zip lines, canopy tours, adventure parks, obstacle courses, ninja courses, playgrounds, tree-houses, climbing walls and climbing towers.

The annual inspection entails a hands-on inspection of all low and high challenge course elements/components installed. This includes but is not limited to an inspection of the following:

Trees– If trees are used in the construction of your course ESI will note tree size and species, look for damage caused by insects and weather and check for dead fall, and work with certified arborists.

Utility Poles– If utility poles are used in the construction of the course, they will be inspected for appropriate classification, size, age and damage caused by animals and/or weather.

Structures – If building or structures are used in the design of your course, ESI will inspect the connections to the structure, monitor for metal fatigue, inspect for broken or cracked welds, etc.

Wire Rope – All wire rope used for belay lines, zip lines, guy lines and foot lines will be inspected for appropriate terminations, proper drape, tension, defects and rusting.

Lumber– All lumber will be inspected for aging and protruding nails or screws. Additionally all lumber used for structural elements like a platform will be inspected for proper attachment technique.

Programming Equipment – All programming equipment will be inspected for age, wear, and storage and to ensure that proper retirement schedules are kept.

Training Manuals and Policies – ESI will inspect all training and policy manuals as they relate to the maintenance, use, facilitation, training and record keeping of the high and low ropes course.

Upon Completion of the inspection a verbal report will be provided before leaving the site and a written report will be mailed in most cases within 10 days of the inspection. Both the verbal and written report will use one of three findings to respond to each element of your challenge course.

The scope of the inspection service outlined above is limited to a visual and tactile inspection of the challenge course structures, systems and components that are readily accessible to the inspector(s). The inspection will be performed in accordance with ACCT Standards and practices for challenge course inspections (other standards available). The scope of the inspection is limited to the items listed within the inspection report as seen and evaluated on the date of the inspection. The inspection and report are but a snapshot of the course as it was seen during a specific moment in time, and it is beyond the scope of an inspection or the associated report to attest to any future usability or condition of an entire course, system or component(s) that may be subject to environmental damage, normal wear and tear, abnormal or unauthorized use, intentional or accidental modification by others, or are simply inaccessible to the inspector without altering or modifying a component, system or subsystem. The inspector is a challenge course generalist and is not acting as an licensed engineer or expert in any other specific craft or trade. If the inspector recommends that the Client consult with specialized experts (ex. arborist, engineer, etc., or conduct any maintenance, repairs, replacement or testing the Client must do so at the Clients expense

Any area which is not exposed to view, is concealed, or is generally inaccessible because of soil, walls, fixed of immovable barriers, high tensions, general lack of access, or any other activity, system or component that is not included in the inspection report. The inspection does not include any destructive testing or dismantling of components or systems. Client agrees to assume all risks for any and all conditions which are concealed from view at the time of the inspection. The inspection is not a challenge course warranty, guarantee, or insurance policy. Some specific items not included in the scope of inspection services include, but are not limited to: Soil or geological inspection; arboricultural inspection; building code or zoning ordinance violations; engineering analysis of any system; efficiency of any installed components or systems; or mold, fungi, pests, termites, or other wood destroying organisms

In addition to general inspection services ESI is able to provide testing and maintenance services, and schedule any additional consultants to be present at the time of your inspection for an additional fee, and advance notice of these requirements. If your organization is interested in or requires any of these services, please read more about them below.

Sometimes minor repairs are necessary in order to keep a challenge course in passing condition. If Client chooses, Experiential Systems can provide repairs at the time of inspection, if simple repairs are necessary. Scheduling this in advance can save time and effort and could make the difference in an element being usable or not usable for your program between the time that an inspection is done and repairs can be accomplished. Unfortunately, major repairs will not be able to be addressed during inspections typically due to lack of time, labor and materials, unless previously arranged, scheduled and contracted.

Some installations, manufacturers, organizations and Jurisdictions Having Authority (JHA) may also require testing of systems or components periodically. If your organization believes it will require any testing services, please notify us in advance of the inspection so that we can plan for the proper time and resources to complete the requested testing services, and provide your organization a proper quote for those services. All testing services are in addition to standard inspection services and fees.

If desired ESI can provide consultancy with industry experts in conjunction with your inspection. These third-party professional consultations can be coordinated to occur simultaneously to the on-site inspection if required and pre-arranged in advance of the inspection.

The Technical Outdoor Solution, RoSPA assured Wire Rope Inspector Course is highly recommended if you are carrying out operational inspections of your ropes course safety wires and zip lines. It is also one of the courses which would increase relevant knowledge on the career path to become a professional ERCA Inspector.

This course covers all of the aspects required to become a ‘Competent Person’ for the inspection of wire ropes used in ropes courses and zip wires and satisfies the requirement of EN 15567 – Ropes Courses – Operational Inspections.

We will ensure that you have up to date awareness of industry regulations and how they affect you in addition to advice on maintenance, inspections and equipment.

The course will include theory and practical, hands on sessions. The course will be assessed by a theory paper and practical inspection of wire ropes and terminations.

The aim of the course is to provide delegates with a thorough grounding of the legal requirements and safe working practices pertaining to resin socketing of wire ropes and to teach them the practical skills involved.

The course is presented by fully qualified, multi-skilled engineers and technicians all of whom have many years experience of wire rope production and maintenance.

The course focuses on customers’ specific requirements i.e. Type of wire rope to be socketed and experience of trainees attending. Trainers employ the practical methods of instruction, explanation, demonstration, imitation and practice with ongoing assessment leading to certification on successful completion.

Companies/Units who require employee training on the examination and safe use of wire rope carried out at their premises. Specifically those with a working knowledge of wire ropes and involved in the inspection, statutory examination, and/or safe use of wire rope in service. It is also suitable for those who are involved with, or give advice to, users of wire rope and associated equipment/products.

A thorough knowledge of safe use and handling of wire rope in accordance with their operations and the requirements of the Health and Safety at Work Act.

Demonstrate knowledge of wire rope terminology, constructions, characteristics and effect on rope performance, safe use & handling, and applications, through a short written test.

A practical assessment of steel wire rope characteristics including an appreciation of rope strength, flexibility, fatigue, wear, abrasion, rotation and elongation.

Proper operational and safety training is essential for companies working with wire ropes, and we’re excited that we’ll soon be providing a computer-based training solution to you. As always, the completed modules will incorporate 3-D and 2-D animations, sharp and clear writing, audio narration, interactive practice screens, and tests to assess learner retention and comprehension.

Wire Rope Basics will cover: the parts of a wire rope; the different core and strand materials; different finishes; lay length, lay direction, and regular and lang lays; rotation-resistant ropes; rope classifications and rope constructions; nominal diameter; nominal strength; design factor; and maximum working load.

Wire Rope Preparation will cover: selection, transporting, storing, the importance of avoiding kinking, uncoiling, unreeling, drum winding, drum capacity, and drum spooling.

Wire Rope Use, Maintenance, and Inspection will cover: the importance of breaking in a rope, best work practices for wire ropes, lubrication, inspections, valley and crown breaks, common breaking patterns and what they signify, cutting and seizing wire ropes, and tips for extending the service life of wire ropes.

Unlike many other wire rope training courses, TENSOLOGY are able to back up the theory and application of the relevant codes, standards and regulations with experience based know-how to provide the attendee with a more comprehensive understanding of the subject.

A competent person must begin a visual inspection prior to each shift the equipment is used, which must be completed before or during that shift. The inspection must consist of observation of wire ropes (running and standing) that are likely to be in use during the shift for apparent deficiencies, including those listed in paragraph (a)(2) of this section. Untwisting (opening) of wire rope or booming down is not required as part of this inspection.

Significant distortion of the wire rope structure such as kinking, crushing, unstranding, birdcaging, signs of core failure or steel core protrusion between the outer strands.

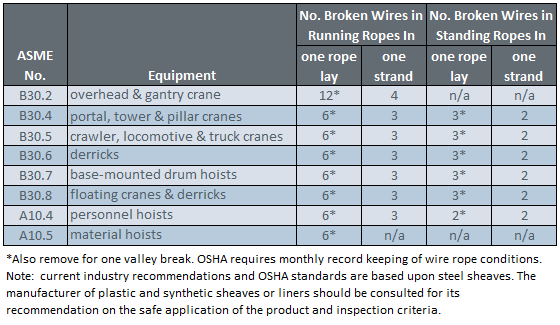

In running wire ropes: Six randomly distributed broken wires in one rope lay or three broken wires in one strand in one rope lay, where a rope lay is the length along the rope in which one strand makes a complete revolution around the rope.

In rotation resistant ropes: Two randomly distributed broken wires in six rope diameters or four randomly distributed broken wires in 30 rope diameters.

In pendants or standing wire ropes: More than two broken wires in one rope lay located in rope beyond end connections and/or more than one broken wire in a rope lay located at an end connection.

If a deficiency in Category I (see paragraph (a)(2)(i) of this section) is identified, an immediate determination must be made by the competent person as to whether the deficiency constitutes a safety hazard. If the deficiency is determined to constitute a safety hazard, operations involving use of the wire rope in question must be prohibited until:

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If a deficiency in Category II (see paragraph (a)(2)(ii) of this section) is identified, operations involving use of the wire rope in question must be prohibited until:

The employer complies with the wire rope manufacturer"s established criterion for removal from service or a different criterion that the wire rope manufacturer has approved in writing for that specific wire rope (see § 1926.1417),

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the deficiency (other than power line contact) is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. Repair of wire rope that contacted an energized power line is also prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

Where a wire rope is required to be removed from service under this section, either the equipment (as a whole) or the hoist with that wire rope must be tagged-out, in accordance with § 1926.1417(f)(1), until the wire rope is repaired or replaced.

The inspection must include any deficiencies that the qualified person who conducts the annual inspection determines under paragraph (c)(3)(ii) of this section must be monitored.

Wire ropes on equipment must not be used until an inspection under this paragraph demonstrates that no corrective action under paragraph (a)(4) of this section is required.

At least every 12 months, wire ropes in use on equipment must be inspected by a qualified person in accordance with paragraph (a) of this section (shift inspection).

The inspection must be complete and thorough, covering the surface of the entire length of the wire ropes, with particular attention given to all of the following:

Exception: In the event an inspection under paragraph (c)(2) of this section is not feasible due to existing set-up and configuration of the equipment (such as where an assist crane is needed) or due to site conditions (such as a dense urban setting), such inspections must be conducted as soon as it becomes feasible, but no longer than an additional 6 months for running ropes and, for standing ropes, at the time of disassembly.

If the deficiency is localized, the problem is corrected by severing the wire rope in two; the undamaged portion may continue to be used. Joining lengths of wire rope by splicing is prohibited. If a rope is shortened under this paragraph, the employer must ensure that the drum will still have two wraps of wire when the load and/or boom is in its lowest position.

If the qualified person determines that, though not presently a safety hazard, the deficiency needs to be monitored, the employer must ensure that the deficiency is checked in the monthly inspections.

All documents produced under this section must be available, during the applicable document retention period, to all persons who conduct inspections under this section.

Each course delegate will be expected to complete a short theory test to demonstrate a good understanding of the course contents. If successful, a certificate will be issued. This will help the Employer to address certain legal requirements by being able to demonstrate employee competency. A detailed course handout is also provided for future reference.

The course is generally held at our Head Office at Harworth, however we are also able to utilise other Certex locations, or hold courses at Client premises if adequate facilities are available.

The content of this course and the standard of instruction has been approved by the Lifting Equipment Engineers Association (LEEA). A certificate will be issued by LEEA on successful completion of the course.

Certex UK offers a range of standard training courses as detailed on our web site and bespoke training courses can be tailored to suit your specific needs. Many of our standard courses are LEEA certified.

8613371530291

8613371530291