wire rope inspection course factory

This course will provide delegates with an understanding of wire rope inspection requirements for a range of wire ropes. Covering a range of fundamental topics, including legislative requirements and the manufacturing processes the course develops an understanding of inspection requirements of a range of wire ropes and the discard criterion. This course consists of a range of theoretical and practical sessions where delegates will be required to confirm and demonstrate their knowledge of the course through theoretical and practical assessment.

By the end of this training programme the delegate will be:Aware of the relevant legislation applicable to wire ropes, including British Standards and other industry best practice

Personnel who are involved in the inspection, and/or safe use of wire rope. This course is also suitable for those who are involved with, or give advice to, users of wire rope and associated equipment.

Wire Rope Rigging Inspection & ReplacementThis micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing.

This micro-learning module covers the basics of wire rope inspections and how to know when a wire rope needs replacing. Great for refreshers or toolbox talks/tailgate meetings!

The Rigging, Part 1 course concentrates on the design and characteristics of wire rope. It covers wire rope construction and the different types of rope lay used. This course identifies the classification of wire ropes. It explains how to install wire ropes correctly and reviews the importance of inspection and lubrication.

Proper operational and safety training is essential for companies working with wire ropes, and we’re excited that we’ll soon be providing a computer-based training solution to you. As always, the completed modules will incorporate 3-D and 2-D animations, sharp and clear writing, audio narration, interactive practice screens, and tests to assess learner retention and comprehension.

Wire Rope Basics will cover: the parts of a wire rope; the different core and strand materials; different finishes; lay length, lay direction, and regular and lang lays; rotation-resistant ropes; rope classifications and rope constructions; nominal diameter; nominal strength; design factor; and maximum working load.

Wire Rope Preparation will cover: selection, transporting, storing, the importance of avoiding kinking, uncoiling, unreeling, drum winding, drum capacity, and drum spooling.

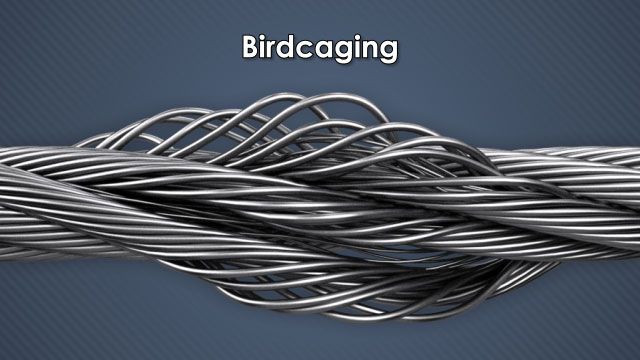

Wire Rope Use, Maintenance, and Inspection will cover: the importance of breaking in a rope, best work practices for wire ropes, lubrication, inspections, valley and crown breaks, common breaking patterns and what they signify, cutting and seizing wire ropes, and tips for extending the service life of wire ropes.

Each course delegate will be expected to complete a short theory test to demonstrate a good understanding of the course contents. If successful, a certificate will be issued. This will help the Employer to address certain legal requirements by being able to demonstrate employee competency. A detailed course handout is also provided for future reference.

The course is generally held at our Head Office at Harworth, however we are also able to utilise other Certex locations, or hold courses at Client premises if adequate facilities are available.

The content of this course and the standard of instruction has been approved by the Lifting Equipment Engineers Association (LEEA). A certificate will be issued by LEEA on successful completion of the course.

Certex UK offers a range of standard training courses as detailed on our web site and bespoke training courses can be tailored to suit your specific needs. Many of our standard courses are LEEA certified.

The aim of the course is to provide delegates with a thorough grounding of the legal requirements and safe working practices pertaining to resin socketing of wire ropes and to teach them the practical skills involved.

The course is presented by fully qualified, multi-skilled engineers and technicians all of whom have many years experience of wire rope production and maintenance.

The course focuses on customers’ specific requirements i.e. Type of wire rope to be socketed and experience of trainees attending. Trainers employ the practical methods of instruction, explanation, demonstration, imitation and practice with ongoing assessment leading to certification on successful completion.

Companies/Units who require employee training on the examination and safe use of wire rope carried out at their premises. Specifically those with a working knowledge of wire ropes and involved in the inspection, statutory examination, and/or safe use of wire rope in service. It is also suitable for those who are involved with, or give advice to, users of wire rope and associated equipment/products.

A thorough knowledge of safe use and handling of wire rope in accordance with their operations and the requirements of the Health and Safety at Work Act.

Demonstrate knowledge of wire rope terminology, constructions, characteristics and effect on rope performance, safe use & handling, and applications, through a short written test.

A practical assessment of steel wire rope characteristics including an appreciation of rope strength, flexibility, fatigue, wear, abrasion, rotation and elongation.

The Rigging Box, Inc. has developed a basic rigging safety and inspection course in order to insure a safe and productive work place for your organization. The purpose of this course is to communicate fundamental skills critical to safe rigging and material handling safety. The course will cover lecture, PowerPoint’s, video, practical applications and can be tailored to cover your rigging techniques relevant to your operation. We have tactfully combined OSHA 1926.251 and EM-385 section 15 in order to keep your employees up to date on current regulations. Please be advised that OSHA 1926.251 and ANSI B.30.9 are now requiring individuals involved with the use of rigging and rigging hardware to be trained in the proper use and inspection criteria.

8613371530291

8613371530291