wire rope lubrication machine quotation

Ensure they are properly lubricated and contact us to assist with your next maintenance interval on Syncrolifts, ROV Umbilicals, Cranes, Bridges, Hoists, Dams, ski-lifts...and more.

Centraline Lubro-Tech Engineers Pvt Ltd offers an automatic Wire Rope Lubrication System. This unique system benefits end users and wire rope manufacturers with considerable cost and time savings in lubricating their wire ropes automatically. Manual lubrication of wire ropes via the drip, brush, spatula or rubber glove method has always been a difficult and time consuming maintenance task. Typically messy asphaltic or “blackjack†type products are employed which have coating abilities but very little lubrication or penetration properties. The Centraline wire rope lubricator provides fast and effective one pass lubrication of wire ropes from 5/16†(8 mm) to 2-5/8†(67 mm) in diameter at speeds up to 6670 feet (2,000 meters) per hour, it eliminates the slow and labour-intensive task of manual lubricant application, at the same time achieving more thorough results by forcing quality lubricant under high pressure right through to the core of the wire rope. The wire rope lubrication system package consists of: high strength collar; grease lube pump; air regulator with PG and air control valve; high pressure lube delivery hose and QDC; high pressure lubricant control valve; excess lubricant drain hose; retaining ratchet straps and shackles; carry strap for the collar; robust aluminium storage case; highly durable polyurethane seals (to be selected and ordered separately); aluminium scrapers (to be selected and ordered separately); wire rope cleaner (to be selected and ordered separately). Features and benefits: no more manual greasing; stops corrosion/protects ropes; penetrates to the wire rope core; less waste and mess; fast and efficient – at speeds up to 6670 feet (2,000 metres) per hour; high pressure – high pressure operates up to 6,000 PSI; and lubricates ropes from 5/16†(8 mm) to 2-5/8†(67 mm) in diameter.

The manual lubrication of wire ropes via the drip, brush, spatula or rubber glove method has always been a difficult maintenance task. Typically employed are messy asphaltic or “blackjack” type products, which have coating abilities but very little lubrication or penetration properties.

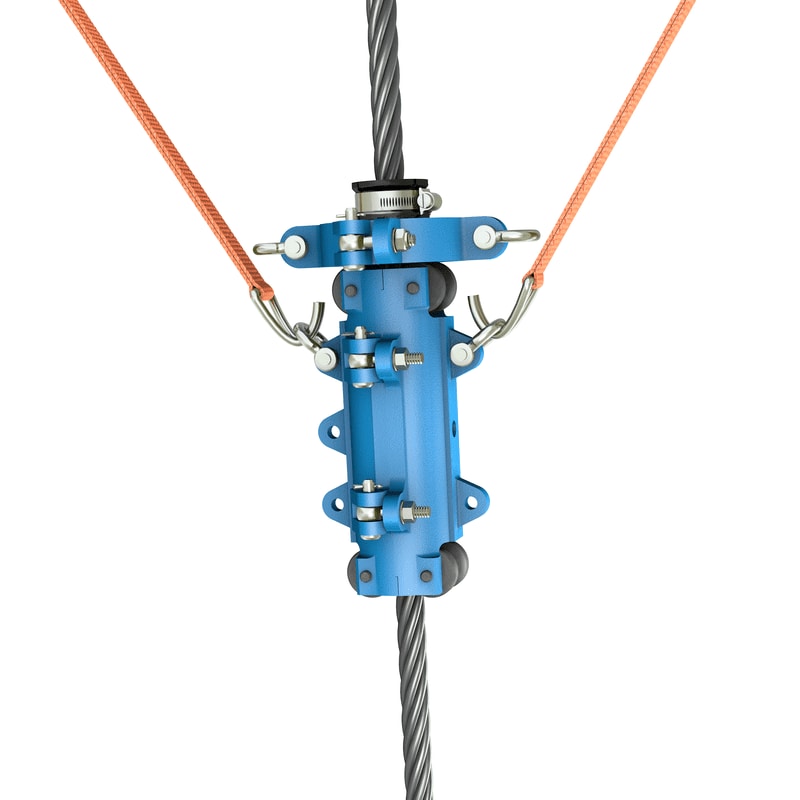

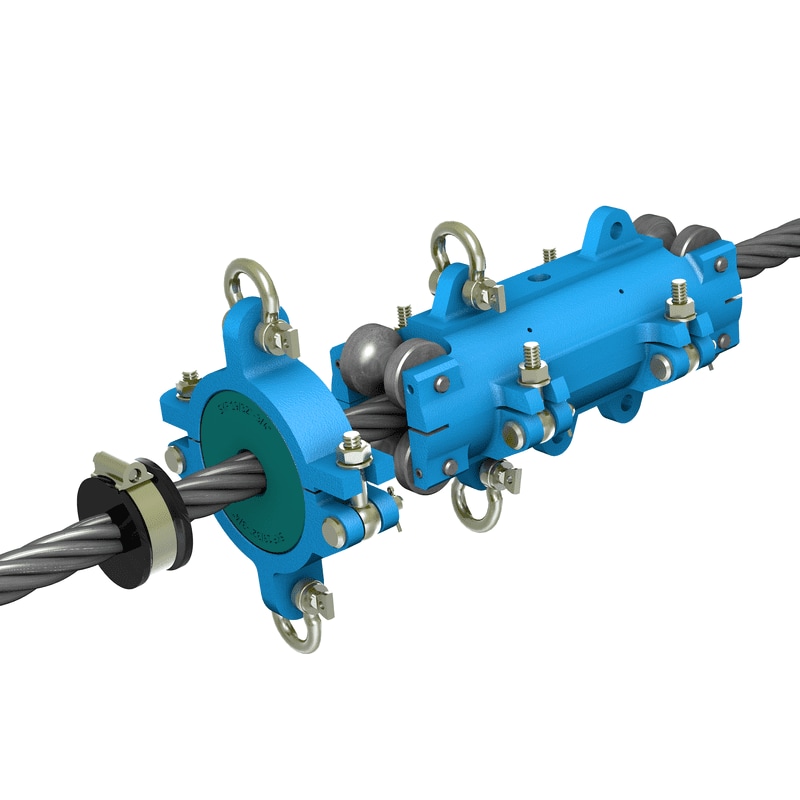

The VIPER Mid MK II Wire Rope Lubricator provides fast and effective lubrication of wire ropes from 5/16 in (8mm) to 2–5/8 in (67mm) in diameter, at speeds up to 6,670 ft (2,000 m) per hour. It eliminates the slow and labor-intensive task of manual lubrication, at the same time achieving more thorough results by forcing quality lubricant under high pressure right through to the core of the wire rope.

The system consists of the lubricator Collar assembly, which houses the polyurethane seals to suit the specific size rope. The assembly is clamped around the rope and anchored to a fixed point. The rope is then pulled through the collar as the lubricant is applied with a high pressure grease pump, forcing lubricant between the strands to the center or the rope. The result is a fully lubricated wire rope with a smooth minimal film of lubricant on the outer strands.

The benefits over conventional drip and brush or spray systems are substantial. The Viper MK II Wire Rope Lubricator operates at a higher pressure than most other lubricator collars on the market; this combined with the robust construction guarantees fast, safe and effective wire rope lubrication.

For lubricating larger rope sizes 2 in (50mm) to 6 1/2 in (165mm), you will need the Viper Maxi MK II. Viper Mini MK II lubricates rope sizes 15/64 in (6mm) to 1 13/32 in (36mm.)Please contact us for more information about these solutions.

Lubricating with the aid of brushes, rags, gloves, or by other means is costly, risky, and ineffective. The lubricant forms a film on the surface which water vapour can penetrate, thus becoming trapped. Temperature changes cause condensation and rust then begins to form from the inside. A wire rope can appear to be in good condition, when in fact corrosion and friction are destroying it from the inside. Its useful life is shortened and it becomes potentially dangerous. Even factory lubricated wire rope requires regular relubrication.

Only the Masto Lubricator penetrates under high pressure all types of wire rope, such as Non-rotating, Dyform, and Locked Coil with heavy grade lubricant. NB. To obtain total penetration through a compact rope the pressure must be minimum 20 bar (285 PSI) in the chamber. Even wire rope subjected to severe surface wear will have a longer life when lubricated with the Masto. Stainless steel, galvanized, and other special types of wire rope require just as much lubrication since friction is the same and corrosion can also occur.

If you start using the MASTO Lubricator, the best results are obtained with the highest quality Wire Rope Grease. If you use SWEPCO 150 Wire Rope Grease your wire ropes will be protected in an optimum way.

An impressive load wear index of greater than 75 and 4-ball weld load of 800 kg demonstrate the superiority of SWEPCO 150’s industry leading extreme pressure and anti-wear protection. The result is significantly longer service life for wire rope and wire rope system components.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

The Masto Lubricator extends the wirerope life. It can use a wide range of lubricants but higher viscosity products are recommended. Oil or liquid will disappear very fast from the rope. Masto saves lubricant and time, and minimises spillage.

NB! A given seal size only works with one rope diameter, and must fit tightly around the wire rope to achive good results. When ordering seals, please measure the wire rope exactly best by hand (measuregauge) since it may reduce in diameter after a periode in service. New ropes might be larger than the manual says. Seals will ordinarily clean the rope surface satisfactorily. Masto cleans and lubricates wireropes internally and forcing out water, old lubricant and dirt in one operation.

Wire rope forms an important part of many machines and structures. It is comprised of continuous wire strands wound around a central core. There are many kinds of wire rope designed for different applications. Most of them are steel wires made into strands wound with each other. The core can be made of steel, rope or even plastics.

Wire ropes (cables) are identified by several parameters including size, grade of steel used, whether or not it is preformed, by its lay, the number of strands and the number of wires in each strand.

A typical strand and wire designation is 6x19. This denotes a rope made up of six strands with 19 wires in each strand. Different strand sizes and arrangements allow for varying degrees of rope flexibility and resistance to crushing and abrasion. Small wires are better suited to being bent sharply over small sheaves (pulleys). Large outer wires are preferred when the cable will be rubbed or dragged through abrasives.

There are three types of cores. An independent wire rope core (IWRC) is normally a 6x7 wire rope with a 1x7 wire strand core resulting in a 7x7 wire rope. IWRCs have a higher tensile and bending breaking strength than a fiber core rope and a high resistance to crushing and deformation.

A wire strand core (WSC) rope has a single wire strand as its core instead of a multistrand wire rope core. WSC ropes are high strength and are mostly used as static or standing ropes.

Wire ropes also have fiber cores. Fiber core ropes were traditionally made with sisal rope, but may also use plastic materials. The fiber core ropes have less strength than steel core ropes. Fiber core ropes are quite flexible and are used in many overhead crane applications.

The lay of a wire rope is the direction that the wire strands and the strands in the cable twist. There are four common lays: right lay, left lay, regular lay and lang lay. In a right lay rope the strands twist to the right as it winds away from the observer. A left lay twists to the left. A regular lay rope has the wires in the strands twisted in the opposite direction from the strands of the cable. In a lang lay rope, the twist of the strands and the wires in the strands are both twisted the same way. Lang lay ropes are said to have better fatigue resistance due to the flatter exposure of the wires.

Wire ropes are made mostly from high carbon steel for strength, versatility, resilience and availability and for cost consideration. Wire ropes can be uncoated or galvanized. Several grades of steel are used and are described in Table 1.

Steel cable wire is stiff and springy. In nonpreformed rope construction, broken or cut wires will straighten and stick out of the rope as a burr, posing a safety hazard. A preformed cable is made of wires that are shaped so that they lie naturally in their position in the strand, preventing the wires from protruding and potentially causing injury. Preformed wire ropes also have better fatigue resistance than nonpreformed ropes and are ideal for working over small sheaves and around sharp angles.

Lubricating wire ropes is a difficult proposition, regardless of the construction and composition. Ropes with fiber cores are somewhat easier to lubricate than those made exclusively from steel materials. For this reason, it is important to carefully consider the issue of field relubrication when selecting rope for an application.

There are two types of wire rope lubricants, penetrating and coating. Penetrating lubricants contain a petroleum solvent that carries the lubricant into the core of the wire rope then evaporates, leaving behind a heavy lubricating film to protect and lubricate each strand (Figure 2). Coating lubricants penetrate slightly, sealing the outside of the cable from moisture and reducing wear and fretting corrosion from contact with external bodies.

Both types of wire rope lubricants are used. But because most wire ropes fail from the inside, it is important to make sure that the center core receives sufficient lubricant. A combination approach in which a penetrating lubricant is used to saturate the core, followed with a coating to seal and protect the outer surface, is recommended. Wire rope lubricants can be petrolatum, asphaltic, grease, petroleum oils or vegetable oil-based (Figure 3).

Petrolatum compounds, with the proper additives, provide excellent corrosion and water resistance. In addition, petrolatum compounds are translucent, allowing the technician to perform visible inspection. Petrolatum lubricants can drip off at higher temperatures but maintain their consistency well under cold temperature conditions.

Various types of greases are used for wire rope lubrication. These are the coating types that penetrate partially but usually do not saturate the rope core. Common grease thickeners include sodium, lithium, lithium complex and aluminum complex soaps. Greases used for this application generally have a soft semifluid consistency. They coat and achieve partial penetration if applied with pressure lubricators.

Petroleum and vegetable oils penetrate best and are the easiest to apply because proper additive design of these penetrating types gives them excellent wear and corrosion resistance. The fluid property of oil type lubricants helps to wash the rope to remove abrasive external contaminants.

Wire ropes are lubricated during the manufacturing process. If the rope has a fiber core center, the fiber will be lubricated with a mineral oil or petrolatum type lubricant. The core will absorb the lubricant and function as a reservoir for prolonged lubrication while in service.

If the rope has a steel core, the lubricant (both oil and grease type) is pumped in a stream just ahead of the die that twists the wires into a strand. This allows complete coverage of all wires.

After the cable is put into service, relubrication is required due to loss of the original lubricant from loading, bending and stretching of the cable. The fiber core cables dry out over time due to heat from evaporation, and often absorb moisture. Field relubrication is necessary to minimize corrosion, protect and preserve the rope core and wires, and thus extend the service life of the wire rope.

If a cable is dirty or has accumulated layers of hardened lubricant or other contaminants, it must be cleaned with a wire brush and petroleum solvent, compressed air or steam cleaner before relubrication. The wire rope must then be dried and lubricated immediately to prevent rusting. Field lubricants can be applied by spray, brush, dip, drip or pressure boot. Lubricants are best applied at a drum or sheave where the rope strands have a tendency to separate slightly due to bending to facilitate maximum penetration to the core. If a pressure boot application is used, the lubricant is applied to the rope under slight tension in a straight condition. Excessive lubricant application should be avoided to prevent safety hazards.

Some key performance attributes to look for in a wire rope lubricant are wear resistance and corrosion prevention. Some useful performance benchmarks include high four-ball EP test values, such as a weld point (ASTM D2783) of above 350 kg and a load wear index of above 50. For corrosion protection, look for wire rope lubricants with salt spray (ASTM B117) resistance values above 60 hours and humidity cabinet (ASTM D1748) values of more than 60 days. Most manufacturers provide this type of data on product data sheets.

Cable life cycle and performance are influenced by several factors, including type of operation, care and environment. Cables can be damaged by worn sheaves, improper winding and splicing practices, and improper storage. High stress loading, shock loading, jerking heavy loads or rapid acceleration or deceleration (speed of the cable stopping and starting) will accelerate the wear rate.

Corrosion can cause shortened rope life due to metal loss, pitting and stress risers from pitting. If a machine is to be shut down for an extended period, the cables should be removed, cleaned, lubricated and properly stored. In service, corrosion and oxidation are caused by fumes, acids, salt brines, sulfur, gases, salt air, humidity and are accelerated by elevated temperatures. Proper and adequate lubricant application in the field can reduce corrosive attack of the cable.

Abrasive wear occurs on the inside and outside of wire ropes. Individual strands inside the rope move and rub against one another during normal operation, creating internal two-body abrasive wear. The outside of the cable accumulates dirt and contaminants from sheaves and drums. This causes three-body abrasive wear, which erodes the outer wires and strands. Abrasive wear usually reduces rope diameter and can result in core failure and internal wire breakage. Penetrating wire rope lubricants reduce abrasive wear inside the rope and also wash off the external surfaces to remove contaminants and dirt.

Many types of machines and structures use wire ropes, including draglines, cranes, elevators, shovels, drilling rigs, suspension bridges and cable-stayed towers. Each application has specific needs for the type and size of wire rope required. All wire ropes, regardless of the application, will perform at a higher level, last longer and provide greater user benefits when properly maintained.

Lubrication Engineers, Inc. has found through years of field experience, that longer wire rope life can be obtained through the use of penetrating lubricants, either alone or when used in conjunction with a coating lubricant. Practical experience at a South African mine suggests that life cycles may be doubled with this approach. At one mine site, the replacement rate for four 44-mm ropes was extended from an average 18.5 months to 43 months. At another mine, life cycles of four 43-mm x 2073 meter ropes were extended from an average 8 months to 12 months.

In another study involving 5-ton and 10-ton overhead cranes in the United States that used 3/8-inch and 5/8-inch diameter ropes, the average life of the ropes was doubled. The authors attribute this increased performance to the ability of the penetrating lubricant to displace water and contaminants while replacing them with oil, which reduces the wear and corrosion occurring throughout the rope. A good spray with penetrating wire rope lubricant effectively acts as an oil change for wire ropes.

In these examples, the savings in wire rope replacement costs (downtime, labor and capital costs) were substantial and dwarfed the cost of the lubricants. Companies who have realized the importance of proper wire rope lubrication have gained a huge advantage over those who purchase the lowest priced lubricant, or no lubricant at all, while replacing ropes on a much more frequent basis.

Lubricating the traditional way is costly, requiring brushes, gloves and spillages, while the effectiveness is far less. Low-quality lubricants create a superficial layer on the outside, which is still afflicted with rusting at the very core of the core of the wire. This will keep the appearance of a metal wire rope in a healthy shape, while the corrosive moisture is eating away at its core.

Masto Wire Lubricators are the sole brand available to lubricate a wire thoroughly, both on the inside and outside. With the correct supervision and interval lubrication, the wires can last much longer, while avoiding a dangerous situation such as suspended load drop and wire failure. To gain this effect, the lubrication is performed under pressure, which passes through the most compact strand designs in the wire rope industry.

The systematic application of Masto Lubricators creates a minimum of 285 PSI; the lowest amount of pressure required in the lubrication chamber to gain a comprehensive lubricating result. Despite the material of the rope, the mechanical wear and moisture in an environment, the wires are prolonged significantly after Masto wire lubricators reduce friction, increase functionality and prolong the wires’ lifespan.

Masto Lubricators are designed for easy administration, which carry out the lubrication process by using Split Seals. These seals are installable chambers that create a high pressure environment for lubrication. The seals are engineered with two halves that come together and are further secured with two chains. A pump administers the lubricating content while the wire rope roller continues reeling the rope through the chamber.

A world-renowned cable lubrication tool,Masto pressure lubrication is an all-in-one solution. It can be used on land or for underwater lubrication to effectively lubricate wire ropes. It also helps cutting down the overall costs by reducing the intervals of lubrication, increasing the life of wire ropes by eliminating rust, corrosion as well as friction. If you are looking for a perfect wire rope lubrication solution, there is no better choice than Masto Lubricators out there in the market.

Do you still require more information? Unsure about the compatibility of your wire construction with this lubrication method? Or wanting to get a quotation on bulk orders? Contact Us today and we will be eager to answer all your questions.

Kirkpatrick Wire Rope Lubrication Systems are excellent for Wire Rope & Cable Lubrication and Cleaning. In only one application, wire rope can have its surface and groove pattern scraped clean of product build-up and grit, while at the same time new lubricant is uniformly applied to the newly-cleaned surface. Coating product then fills any open spaces within the groove pattern, and internal strands open to receive it. This is accomplished as the wire rope passes through a controlled, 100% pressurized, immersion within the Internal Seal Lubrication Chamber. Surface moisture trapped within the internal strands is displaced and replaced with the newly applied wire rope coating product. Kirkpatrick Systems are functional with both low and high viscosity coatings. They can be incorporated as a Grease Applicator for tough applications where higher viscosity coatings are required to fight friction wear due to strand rubbing, as well as a low viscosity oiling system required for certain Cable Cleaning & Lubrication applications.

I have been inspecting wire rope used for a variety of industrial applications now for over 18 years. The bulk of my work and the most critical is electromagnetic testing of personnel and haulage ropes in the mining industry. A majority of these ropes are in operation 24 hours per day. As such, they are exposed to extreme environmental and chemical wear that greatly detract from their overall service life. Lives and profitability depend on the reliability of these hoist ropes.

Several years ago, one of my clients, Morton Salt in Weeks Island Louisiana began using your wire rope lubrication system and Dynagard™ wire rope lubricants. I inspect Morton’s hoist ropes approximately every 6 months according to Federal guidelines. Prior to Morton’s use of your products, they were replacing their ropes about every 9-12 months. This is not good wire rope life for any application. These ropes were being retired because of excessive corrosion within the internal strands. Salt as well as potash mines have extremely corrosive environments and as a result their rope life is measurably shorter than other types of mining operations. It was discovered that the Dynagard™ Blue wire rope lubricant had significantly restricted internal corrosion over the competitive product previously used for the Morton ropes. In fact, in my opinion it had eliminated the corrosion according to my nondestructive testing of the ropes during the first 12 months it had been tracked. Given these initial test results, I anticipate that the rope life on Morton’s hoist ropes will go from a 9-month life to several years.

I have recommended your wire rope lubrication system to all of my clients. Most are now using your system, and I can categorically say that all but one of those customers have experienced a better life span incorporating your system into their maintenance programs. The one mine that hasn’t, have not used their wire rope lubrication system according to operating instructions supplied with the system or on a regular basis. I have discussed this with them on numerous occasions and have come to the conclusion that they probably never will. Therefore, there is no way to evaluate their program on the same level as the other mines who are successfully increasing their wire rope life in conjunction with Dynagard™ Wire Rope Lubricants and Kirkpatrick Systems.

I shall continue to recommend your products to any clients that I encounter. My job has been made much easier if the mine ropes are properly lubricated and maintained. Once again, thanks. Keep up the fine work. You have my permission to use this letter as a testimonial of a fine product and caring company who takes pride in customer support.

Originally got 7 or 8 months out of his ropes. The last rope he took out of service: 26 Months. He says this is because of the impoved program they developed around the use of our Dynagard™ Blue and the Jumbo Model JU400 Wire Rope Lubricator.

The Kirkpatrick Model SU35B Wire Rope Lubricator evaluated during the project appears to have significant potential for reducing material usage and waste disposal costs. Significant labor savings are possible due to the reduced labor required to perform cable cleaning and lubricating events. Of equal importance, the wire rope lubrication system is a safer alternative than the previous method used because it does not require personnel to place grease on their gloves and wipe the crane cable. The cost analysis showed a 10-year ROI of approximately $ 135,900.60 and a breakeven point of .41 years.

USS Hancock: The Kirkpatrick Wire Rope Lubricator / Cable Cleaner: The Wire Rope Lubricator / Cable Cleaner has eliminated the need for two people and 3 hours to complete this Preventative Maintenance Schedule (PMS). Now one maintenance man can clean and lubricate a cable in less than 30 minutes.

The automated wire rope lubrication system extends the life span of wire rope, reducing the costs of removing and disposing of worn out wire rope and the purchase and installation of replacement rope. Operating costs are also reduced, because cranes are less frequently taken out of service to be refitted with new wire rope. The automated system cleans and lubricates wire rope at a rate of 100 feet per minute as compared to the manual rate of approximately one foot per minute. Cleaning and lubricating wire ropes on cranes using the old manual method took approximately five eight-hour workdays per crane. Using the automated system, wire rope on a crane can now be cleaned and lubricated in one eight-hour day. This represents significant savings in labor costs.

The automated wire rope lubricator has reduced PWC San Diego’s annual cost of cleaning cables from about $320,000.00 a year to approximately $34,000.00, a yearly generating savings of approximately $286,000.00.

Navy Public Works Department, San Diego prevents WMSD’s, Increases Productivity, and Reduces Costs with Automated Cleaning and Wire Rope Lubrication System (Kirkpatrick Model SU35B Wire Rope Lubricator)

Kirkpatrick Model SU35B Wire Rope Lubricator USS Wasp (LHD-1): 400′ of 1 1/8″ load line lubricated. 75% of 35-pound pail of QPL Approved Dynagard™ Blue™ wire rope lubricant used. 21 pounds of previously applied MIL-G-18458B lubricant removed.

Mr. Raymond Beaudreau, a civilian consultant for Military Sealift Command, requested that the vessels 2-1/4” rusty and kinked Tow Wire be used for the operation. The wire was respooled at approx. 150’ per minute through the Jumbo Lubrication Collar (Wire Rope Lubricator).

Results: “Examined 2-1/4” Tow Wire and found it to be scraped clean of rust and old lubricant. New lubricant had penetrated every visible part of the wire.” “The system worked well and performed well and achieved good results on substantially degraded rope (2-1/4” Tow Wire).”

Letter from Commander, Naval Sea Systems Command to Commander in Chief, U.S. Atlantic and U.S. Pacific Fleets after completion of Navy tests of The Kirkpatrick Wire Rope Lubrication System. Subject: Wire Rope Lubrication System Evaluation. (1988)

“The results of the evaluation and demonstrations were highly successful. The wire ropes were opened, exposing the inner surfaces of the wire strands, which were found to be as well lubricated as the external surface of the wire rope. The use of wire rope lubricators will contribute to a longer service life of wire rope and reduce the man-hours required to accomplish PMS.”

Letter from Commander, Naval Sea Systems Command to Commander In Chief, U.S. Atlantic and U.S. Pacific Fleets after completion of Navy tests of The Kirkpatrick Wire Rope Lubrication System. Subject: Wire Rope Lubrication System Evaluation. (1988)

U.S. Navy Supervisor of Salvage Evaluation of Kirkpatrick Jumbo Wire Rope Lubricator (1983): Evaluations performed on T-ATF Powhaten (New York) and the ATF Papago (Virginia Beach)

Manual Wire Rope Preventative Maintenance of all of the ship’s wires was taking a week to complete. Now, since receiving the Model SU35B Wire Rope Lubricator, the time to complete the project has been reduced to 1 day with fewer shipboard personnel involved.

Using the Kirkpatrick Model SU35B Wire Rope Lubricator and Dynagard™ Environmental Wire Rope Lubricants has increased rope their rope life from 2 – 3 years to 8 or 9 years. The job is now performed in one day over the 2 or 3 days it took previously.

Hello Bob, I tried your wire rope lubricator today for the first time and I can only say wonders about it. It has cut by 90% the time we have to spend on lubricating our skip hoist and it does a much better job than our old method of using rags. I am attaching some photos. Please feel free to use them as you wish.

Brad used to be with the United States Coast Guard in Key West, Florida and used the Kirkpatrick SU35B Wire Rope Lubricator there. He said his crew used to laugh at other sources on the base who continued with hand maintenance for their wire ropes. They would take 10 hours to complete what he and his crew could do in 2 or 3 using the Kirkpatrick System.

I have just witnessed the best Kirkpatrick crew lubricate well over a kilometer of wire rope in 6 hours. Our personnel are really getting the program down. The guys are getting used to adjusting the air pressure and wire rope travel speed. The SU35B Wire Rope Lubricator and Dynagard™ Blue look pretty good. My Maintenance Division Head said he ordered more Dynagard™ Blue.

We really like the Dynagard™ “E” as used on our Dam Gate Hoist Ropes. It Holds Up Really well. Applied to some old cable by hand. After a couple of months, it had worked its way in.

Purchased their system in 1982 for use on over 23 miles of 1 1/2″ conveyor cable. This wire rope’s replacement cost is in the one-million-dollar range. Subsequent to incorporating their wire rope lubrication system, their replacement schedule was every 5 to 6 years. They have now gone eight years without replacement.

We were rewarded by a system that not only lubricated the wire rope uniformly; it cleaned the surface and removed the moisture. An additional benefit was the tension it sets up on the wire rope while lubricating.

If each district purchased a system for its individual sizes of wire rope, we could all have safer, easier, and most important, quality maintenance of wire rope.

I am writing this letter to tell you how impressed we are with the longevity and durability of your seal and scraper plates. We used a 3/4″ set on 60,000 ft. of 3/4″ 6 x 19 class IWRC that made up the topping, purchase and vang wires of deck mounted cargo booms on the Naval Reserve Ship USS Comet. We fully expected to replace this 3/4″ seal and scraper plate kit after this job. This has not been the case. These seals and scraper plates have given us years and approximately I00,000 ft. of extra service.

The use of the Kirkpatrick System has shown that tower guy wire maintenance jobs, which normally take a week to complete, can now be accomplished in three days or less. As we travel up the guy wire during the lubrication/coating process, we can see water being forced out of the wire 3 to 4 feet in front of our basket due to the pressure being exerted internally by the lubricant/coating our system is forcing into the internal strands.

Wire rope life has increased by at least 30% due to the use of the Kirkpatrick System. This is based on Magma’s findings that wire rope expectancy was only about 600 to 700 hundred thousand tons prior to incorporating the Kirkpatrick System into their maintenance program. The goal was 1,000,000 tons after purchase. They are now getting 1,300,000 tons before wire rope replacement according to my personnel.

Wire rope tensile strength loss has gone from 10% to 2% using their Kirkpatrick System. A reduction of 60% in lubricant consumption was also reported. Braniff Inspection Systems, Bill Braniff

Installation and use of the Kirkpatrick Model JU120 System has cut wire rope cleaning and lubrication time by 5O%, freeing up vital man hours to be used in other areas of necessity. Periodic maintenance requirements call for a specified section of wire rope to be cut back for external and internal inspection. The latest inspections have shown complete lubrication to the wire rope’s core.

Over the last few years, at my recommendation, numerous systems have been purchased by our mining customers to be used in conjunction with our lubricants. Kirkpatrick Systems thoroughly coat and lubricate. I have always been impressed with the amount of trapped water seen pouring from the rope as it exits the lubrication collar due to pressure being exerted in the Internal strands as the lubricant is being applied. One of our customers in particular has saved several hundred thousand dollars in wire rope replacement.

Wire Rope used in up shaft ventilation was being lubricated at 50 ft. to 60 ft. per minute using a grease funnel installation. Since purchasing their Kirkpatrick System, lubrication speed has been increased by 100%. Mine personnel estimates the life of their wire rope has been increased by 50% to 90%.

Beneits of wire rope lubrication Groove cleaner advantages The use of lubricant on a steel wire rope considerably reduces friction and, as a result, it minimizes the following two related factors: Regular lubrication helps to increase the lifetime of a steel wire rope signiicantly compared to a wire rope that has not been lubricated. Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general. The...

The Lincoln wire rope lubrication system eliminates manual lubrication and, in turn, yields improved results. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation for longer service life. The wire rope lubrication system applies the right amount of lubricant, distributes it evenly and eliminates over-lubrication waste. Advantages: • Fast and eficient – reduces lubrication time by up to 90% vs. manual lubrication • Increases operator safety • Easy to use with any wire rope up to 2 in (52 mm) • Helps to prevent corrosion • Protects the wire ropes...

Typical wire rope lubrication system components Ordering wire rope lubrication (WRL) systems: 1 Select seal and roll kit to it the wire rope diameter. Interchangeable kits include seals and rolls to it wire rope diameters in their respective size ranges. Seal and roll kits Seal and roller kit model 3 Select pump and accessory package to it the required grease container size. Pump and accessory packages Nominal wire rope diameter 1) minimum maximum Pump and accessory package includes the Lincoln series 20 50:1 grease pump, air ilter, regulator, gauge, low control, WRL sling with ratchet,...

Groove cleaner helps extend wire rope service life Groove cleaner Separating bushing Designed to complement the Lincoln wire rope lubricator, the groove cleaner removes dirt and used grease from the rope before it passes through the lubricator. Utilizing the cleaner improves the penetration of new grease and enhances corrosion protection to extend wire rope service life. Each groove cleaner is produced individually based on rope speciications to make sure that the device proile matches accurately with the strands. The groove cleaner unit consists of a groove cleaner device, as well as...

Groove cleaner and separating bushing identiication codes For the correct selection of a groove cleaner and separating bushing, the user must determine the accurate dimensions and type of wire. We recommend the following steps: A Measure the real diameter (A) of the wire rope with a caliper. Identify the number of outer strands. Determine the lay (right or left) of the wire rope strands. 4 Choose the separating bushing that its with the nominal diameter of the wire rope. Separating bushing Order no. Nominal wire rope diameter minimum maximum in For wire rope diameters 19/32" - 3/4" For wire...

6 The groove cleaner is designed and manufactured in accordance with the exact size of the wire rope. In order to request the product, the client must provide the rope speciication, or send a sample. To ensure an effective cleaning, the groove cleaner must be tightened with a breeze T-bolt (included). Groove cleaner element with breeze T-bolt clamp For rope strands with right lay Groove cleaner element with breeze T-bolt clamp For rope strands with left lay Order no. Wire rope diameter in Wire rope diameter in

skf.com/WRL | skf.com/lubrication | lincolnindustrial.com ® SKF and Lincoln are registered trademarks of the SKF Group. © SKF Group 2019 The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein. PUB LS/P2 17901 EN · August 2019 Certain image(s)...

Manual lubrication of wire ropes via the drip, brush, spatula or rubber glove method has always been a difficult and time-consuming maintenance task. Typically messy asphaltic or ‘blackjack’ type products are employed which have coating abilities but very little lubrication or penetration properties.

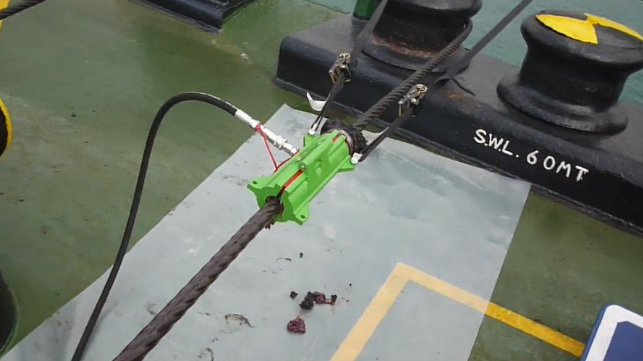

The Centraline Wire Rope Lubricator provides fast and effective one pass lubrication of wire ropes from 8mm to 67 mm in diameter at speeds up to 2,000 metres per hour. It eliminates the slow and labor-intensive task of manual lubricant application, at the same time achieving more thorough results by forcing quality lubricant under high pressure right through to the core of the wire rope.

The Wire Rope Lubrication System Package comprises: High Strength Collar, Grease Lube Pump, Air regulator with PG & Air control valve, High pressure Lube delivery hose & QDC, High pressure lubricant control valve, Excess lubricant drain hose, Retaining ratchet straps & shackles, Carry strap for the collar, Robust aluminum storage case, etc.

Centraline WRL can be used with advantage in a plethora of industrial applications. Wharf Cranes, Ship Cranes, ROV Cables, Mine Winders, Mobile Cranes, Oil Well Platforms, Anchor Ropes, Deck Winches, Overhead Cranes and Ship Loaders. Centraline has more than 30 years experience in providing Industrial Lubrication Equipment & Solutions both in India and abroad.

8613371530291

8613371530291