snubbing unit vs workover rig price

Pumping services tend to get more expensive offshore, because of the degree to which the equipment must be assembled on location. Wire based services still require assembly, but because the parts are smaller can usually be mobilized in larger ‘chunks’ thus requiring less assembly on location. On land, fluid pumping equipment is much more readily portable on trucks or trailers. Workover rigs on land are incredibly cheap in most places as measured on a per diem basis. Part of their advantage is that they arrive to location with most of their key components already assembled in/on one truck. This advantage disappears offshore where the rig must be assembled on site first.

Paying for a drilling rig or intervention vessel is the price of gaining physical access to the well. Everything else must be added to it to get physical access to the general area and then gain access to the well. There is no need for various forms of standalone pumping services because the vessel or rig will already have a cementing unit and/or the mud pumps available for that sort of work.

Performing the same operation over and over again has significant cost savings attached to it. Once the correct housing and supply arrangements are in place, and all the necessary people and equipment have been assembled, continuing to use it altogether ‘as is’ can save an enormous amount of money compared to dispersing it all and starting over again later. For land operations, this is most pronounced in areas where reservoir, surface, and operational practices allow for grouping wells together in relatively small areas, and for clustering well pads. Depending on what work is being done to the wells and how close together they are it may be possible to ‘hop’ from one well to the other without ever moving the equipment on a road or doing a complete rig-down.

Deepwater operations can benefit from this too, but not as much as ‘traditional’ fixed or surface access facilities, because the overall day rate of the rig or intervention vessel is often much higher, and the process of switching between wells is often much lengthier.

On land, you hire the unit and crew, and a small diem fee is added to the cost of employing them so they can stay in a hotel and get food when they are not working. The crews will transport themselves to and from the well and move the equipment to and from the well also.

The costs of conducting business in each of these 3 areas tend to scale very roughly in factors of 10. 100 wells making 50 bbls of oil each on land is a cash cow. Offshore that is a disaster, because the cost of servicing those wells is prohibitive. A more reasonable scenario is 10 wells making 500 bbls of oil each. In deepwater, a well making 500 bbls of oil a day is an abandonment candidate, if indeed it got that far along before abandonment. One well making 5,000 bbls a day is more. The direct cost of hiring (for example) a snubbing unit do not scale by factors of 10, but the overall cost of employing a snubbing unit do. As a result, different types of well servicing make sense in one area which may not make sense in another. On land in areas with ordinary access to infrastructure (not the Sahara or Alaska) operations like slickline are often so cheap that they are a routine procedure, with preventative or predictive maintenance schedules to scrape away paraffin or remove small amounts of scale. By contrast, it is completely cost prohibitive to try and attempt to perform similar work in deepwater – you either design and operate the well in such a way that paraffin and scale do not build up in the wellbore at appreciable rates, or you P&A the well. The cost of routine mitigation is simply too high. The relative cheapness of most workover rigs on land is another major factor. Many types of operations which could in theory be carried out in some other way are done with a workover rig simply because it is the most cost-effective technique, even if other methods might be faster, or involve fewer people. The relatively high cost of a rig for offshore facilities means that in most cases every effort short of getting a rig is tried first. Then a catalogue or list of operations to be conducted by a rig at a given facility will be gradually built up over time until they reach a critical level. At that point, a rig will be sent out to conduct all the operations which only it can perform, moving from one well another to save costs by making the work repeatable.

Snubbing units have evolved into one of the most capable and efficient well servicing tools in the oil & gas industry. In the 1920"s, the need for a rig to work with pressures at surface drove the invention of the snubbing unit. The first snubbing unit was primarily designed to work in well control situations to "snub" drill pipe and or casing into, or out of, a well bore when conventional well killing methods could not be used. The first snubbing unit relied on the draw works of the companion rig to supply its" power. A series of sheaves, cables and counter weights were rigged up so that as the rig"s traveling blocks hoisted up, the snubbing unit would snub in the hole. Conversely, when the traveling blocks on the rig were lowered, the snubbing unit would snub out of the hole. As you can imagine, this required close communication with several different contractors in order to perform the work safely and efficiently.

One of the main components of a snubbing unit is the slip. Stationary and travelling slips are operated in sequence to grip the pipe as it is snubbed into the well. Typically, a minimum of four slip bowls are used in snubbing operations. Two slip bowls are designated for "pipe light" operations. Pipe light is when the well bore forces are greater than the tubular weight in the well bore. The other two slip bowls are designated for "pipe heavy" operations. Pipe heavy occurs when either enough pipe has been snubbed into the well bore and fluid weight inside of the pipe is greater than the snub forces acting against the pipe in the well bore.

While snubbing into the hole, there is a transition point the tubular goes through from being pipe light, to pipe heavy. This transition is an equilibrium typically referred to as the "balance point". The balance point occurs when there is enough pipe weight in the wellbore to equal the snub forces generated against the pipe. In certain instances, thousands of feet of pipe can be moved with minimal effort since the pipe weight is at an equal state with the snub forces. Snubbing contractors calculate this snub force and add in a friction factor from the BOP and wall contact on either a casing or tubing string. If done correctly, the snubbing contractor can predict when this balance point will take place and can properly prepare for it.

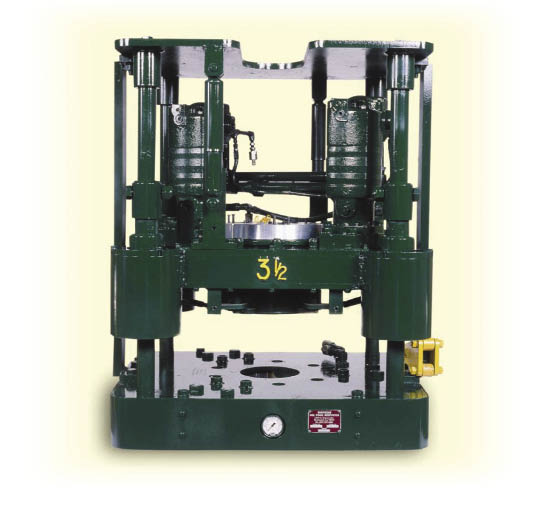

Modern snubbing units are powered by sophisticated hydraulic systems. These hydraulic units typically supply all power required by the components of a snubbing operation. With a better understanding of hydraulics and modern advances, companies have been able to harness this hydraulic energy to develop precision controlled snubbing units. These units move tubulars into and out of a well bore by use of a "multi cylinder jack"; a snubbing jack comes in many sizes depending on the task at hand. They are usually denoted in size by the snubbing unit description (i.e. 460K, 340K, 200K, etc). The 460K snubbing unit has the ability to lift 460,000 LBS and a snubbing capacity of 230,000 LBS. Most snubbing units can typically snub half of their lift rating. Assume you had a well with 10,000 PSI at surface and wished to snub in a string of 2 3/8" tubing. The snubbing contractor can calculate the snub force, add in their respective friction calculations and project the snub force to overcome will be approximately 51,000 LBS. This would put a 120K snubbing unit to close to its maximum capacity of 60,000 LBS snub loading. The safest bet would be a 150K or 235K snubbing unit.

Well control is taken very seriously by snubbing contractors. The BOP is the only barrier between the well bore and personnel. Depending upon well conditions, pressures and work performed, the BOP stack configuration varies greatly; there can be a minimum of three BOP"s and in some cases, up to ten. All of this is determined in the pre-job phase of the operation.

Pipe handling is performed by the snubbing units "gin pole" and "pipe winches". The gin pole is typically telescoped out in excess of 40ft above the snubbing unit. With the use of dual tubing winches, multiple joints of pipe can be handled simultaneously, speeding up the operation.

The snubbing "basket" is the platform where the snubbing personnel work. The basket contains all of the necessary hydraulic controls to operate all the features of the snubbing unit, as well as a large bank of BOP"s and hydraulic valve controls.

Today"s snubbing units can be employed to provide a wide range of services. In essence, a snubbing unit is a hydraulic rig that can do everything a rig can do, plus it can perform under pressure in an under balanced live well state. This is especially critical to the operators in the Haynesville Shale, which is known for HPHT wells. With the use of the snubbing units" hydraulic rotary, the unit can be employed for fishing, milling, drilling, side tracking or any task needed to remove bridge plugs, cement or deepen wells.

The industry has become more aware of damages caused by heavy kill weight fluids and mud. This has helped make snubbing units more popular in a completion and workover role, versus its" traditional use as a well control response tool. With the advances in drilling technologies in the unconventional shale market, the benefits of snubbing units have become very apparent. These types of completions often have laterals extending out thousands of feet. With costly stimulations used to help extract the gas more efficiently, operators often times do not wish to turn around and load the well with heavy fluids to complete the well dead.

Coiled tubing has its limitations in reach, due to wall to wall mechanical friction in horizontal wells. Often times the coiled tubing units cannot reach TD or supply the needed weight on bit to mill up composite plugs typically used in completions.

Another clear advantage to using a snubbing unit is its" small footprint, which is critical on the tight locations in the unconventional shale"s. Moreover, the small size and ease of mobilizing is especially useful and cost effective with offshore wells.

In conclusion, with the snubbing unit"s size, ability to handle pressure, rotary capabilities, rigidity of jointed tubing and minimal wall contact, snubbing units have become the chosen resource for these types of completions.

In oil and gas recovery operations, tubular members are usually run or pulled using a workover rig or a snubbing unit. Workover rigs are basically small drilling rigs having a derrick and drawworks, and although they are less expensive to employ than full-sized rigs, their use can still be quite costly.

Snubbing units are smaller, easier to transport and less expensive to operate than workover rigs and are often employed when working a pressurized well that requires tubular members to be forced into the wellbore.

A viable alternative that improves safety and efficiency during snubbing operations consists of a power tong set, with lead and back-up tongs that are mounted on the slip bowl of the traveling jack head of a snubbing unit and rotates with the slip bowl. Service lines for the tong set are not connected during string rotation.

In another version of this type of device, a fluid feed-through swivel is mounted on the tong set, secured to the necessary tong operating and control service fluid lines, such that the tong set can rotate with tong service lines between the tong set and the snubbing unit attached during rotation.

Snubbing is an old technique dating back to the late 1920s in the United States that was primarily used in emergency situations, such as blowouts or uncontrolled wells.

Like coiled tubing techniques, snubbing allows a tubular to be run with a check valve on the end into a live well by means of specialized handling and sealing systems. However, instead of pipe coiled up on a reel, it uses tubing-type pipe lengths run in hole and made up to each other by conventional threaded connections. This means that larger-diameter pipe can be used than in the coiled tubing method.

The snubbing unit therefore offers better flow capacity, breaking load and rotation capacity and is able to put weight on the downhole tool. In contrast, tripping takes longer because the lengths of pipe have to be screwed together and the procedure for running the connections through the safety stack on the wellhead may be slow and represents a high risk for personnel if not done properly.

A snubbing unit consists basically of a pipe-handling system, a wellhead safety system, a hydraulic power unit and the downhole accessories incorporated into the snubbing string.

The pipe-handling system must be able to push the pipe into the well during the snubbing phase (also called light pipe phase), which occurs every time the pipe weight is lower than the wellbore pressure force against it.

With the traveling slips closed and the stationary ones open, the pipe can be tripped over a length corresponding to the stroke of the jacks. Then, all that is required to bring the jack back to its original position is to close the stationary slips and open the traveling slips. After the traveling slips have been closed again and the stationary slips have been opened, the operation can continue.

Operating in this manner requires specialized people, usually consisting of a foreman and three or four people per shift. The space in the snubbing basket is usually very limited and unstable, which magnifies the hazards associated with the manipulation of pipe, elevators and power tongs.

ODS International and Rogers Oil Tools (ROT) have developed a patented power tong built specifically for snubbing and well control applications (Figure 1). It is the only tong designed to ride the jack incorporated with a swinging basket.

ODS-ROT can provide different models, either slip or jack-mounted (Figure 2), providing the choice of eliminating personnel in the snubbing basket by utilizing the remote operation option.

The jack head tong carries the provision of having a three-section cage plate system that can be removed to allow the jack head tong to be open for full wellbore capabilities, matching the BOP’s bore. This is the fastest and safest way to trip pipe with a snubbing unit.

Snubbing is an old technique with relatively little innovation over the past several years. The hazards associated with this type of operations still must be considered when seeking to eliminate risks.

The snubbing power tong introduced in this article is a viable alternative, making operations safer by eliminating movement of the tong on and off the pipe. This eliminates nagging injuries and increases the operational efficiency, which ultimately impacts the overall costs of well servicing programs in benefit of operator and drilling contractors.

A Snubbing System is basically a well servicing system capable of running and retrieving jointed pipe under live wells conditions. A typical Snubbing System is illustrated in Figure 1.

The use of a Snubbing Unit is not only already providing cost effective technology for a wide range of Drilling and Well Servicing applications but also has the potential for providing an alternative way to optimally develop future fields.

Present Snubbing and Hydraulic Workover applications include the undertaking of remedial well work without resorting to the use of kill fluids or lost circulation material and the performing of conventional tubing replacement workovers Snubbing well intervention operations are also now routine where coiled tubing operations are not feasible due to well bore geometry or length and should be considered where platform facilities are unable to handle the weights of larger coiled tubing reels.

Historically, workovers performed through existing tubing ("through-tubing workovers") have been undertaken with wireline or coiled tubing equipment, often supported by the use of a derrick equipment set. Snubbing systems are now performing similar work and are proving to be far more versatile than wireline coiled tubing and conventional workover rigs with the additional ability of being able to run and rotate tubulars while there is pressure on the well. Although certain workover situations will still call for wireline coiled tubing or workover rigs, there are now many situations where a Snubbing Unit is the logical choice. In principle, all of the downhole work that can be carried out by standard rig or through-tubing workover equipment can also be completed by Snubbing Units, with the (current) exception of running large >10 3/4") tubulars.

Future applications for the technology include the horizontal side-tracking of existing wells (which could be performed conventionally or underbalanced). Such operations can either be undertaken through the existing tubing or, where such operations are not deemed feasible, the Snubbing Unit can be used to pull the existing completion prior to the side-track and used for the subsequent running of the liner and completion after drilling.

One of the main advantages of utilising Snubbing equipment is the ability to undertake a whole variety of operations and hence supply the versatility that has, up to now, only been regarded as available from a full derrick equipment set in combination with wireline or coiled tubing equipment.

While hydraulic workover (HWO)/snubbing will never wholly replace traditional workover rigs, particularly in dead well applications requiring multiple trips and fishing jobs, in live and pressured well re-entries the technology offers myriad operational; economic; and health, safety, and environment advantages. From its inception solely as a mechanism for handing tubulars during well control operations, hydraulic snubbing technology has evolved into a mechanism that can perform any operation once considered the sole jurisdiction of conventional drilling and workover rigs.

The ability of modular HWO/snubbing units to pull existing completions, drill open holes, and re-complete a well bore at flowing (near-balanced or underbalanced) conditions has effectively bridged the technological gap between derrick equipment configurations and coiled tubing (CT) units. Consequently, standalone or rig-assisted HWO/snubbing units have been employed successfully in a variety of activities worldwide, from re-completions and completions under pressure to tubing-conveyed perforating to the drilling of sidetracks, slim holes, and well deepening operations, among others.

Together with its capacity to rotate pipe in live well conditions and perform intervention operations without having to shut in production entirely, HWO/snubbing units can often be mobilized and de-mobilized in a fraction of the time and associated costs of a conventional workover rig.

Key to the comparably faster and more cost-effective mobilization and de-mobilization is the modular design that allows HWO/snubbing units with up to 600,000 lb hook load and rotary torque in excess of 14,000 ft/lb to be transported easily by air, sea, or over land. Accordingly, the modular design, in tandem with a comparatively minimal footprint as small as 2,500 sq ft (753 sq m), makes the technology an ideal contender for applications on remote offshore platforms.

Depending on the wellhead equipment, one of the foremost drivers for the growing use of HWO/snubbing units is a design engineered specifically to operate under pressures as high as 20,000 psi. Consequently, operators can perform a variety of well intervention operations without having to first kill the well and discontinue production completely.

Compounding the costs associated with lost production is the expense of killing the well and re-initiating production once the re-entry operation is completed. By way of illustration, installing a completion string after a typical fracturing job requires that the operator first employ high-density fluid to kill the well. In addition to the costs of the brine and kill pump are the rig-related expenses associated with running the pipe in the well bore. Afterwards, a CT unit and nitrogen may have to be used to re-start production, magnifying the costs even further.

By comparison, an HWO/snubbing unit normally can perform the same operation in one to two days with production continuing while the operation is under way. All things considered and depending on the specific application, employing an HWO/snubbing unit generally is more cost-effective on new and producing wells than a conventional workover rig and is less than that of the daily rate for a CT unit.

Besides the production revenue lost during the balanced well intervention, there also is the risk of future shortfalls resulting from reservoir damage caused by the introduction of overbalanced kill fluids that are especially harmful to some shales and other highly reactive formations. Hydraulic snubbing not only can use existing pipe and tubing for work string, but it does not rely on kill-weight fluids to bring the well bore to static condition. Consequently, the risk of reservoir damage is minimized dramatically or eliminated altogether.

Moreover, with HWO/snubbing technology, the operator avoids the costs and potential environmental liabilities associated with the onshore/offshore disposal of heavy-weight kill fluid. Also from an environmental perspective, since less equipment is required on location, operators do not have to flow the well to atmosphere to maintain pressure control, thus further reducing the carbon footprint. Since the units do not require any water from nearby streams or underground aquifers, hydraulic snubbing is especially beneficial in areas where water is a premium or scarce resource.

Contemporary hydraulic snubbing technology bears little resemblance to the units introduced in 1929, only 10 years after the development of well cementing. Those first units comprised little more than a series of cables, sheaves, and counterweights and were used strictly for well control operations and snubbing in live completions.

At their conception, snubbing units relied on a rig’s drawworks to hoist pipe in and out of the hole, and the sheaves were rigged up so that as the traveling blocks hoisted upward, the pipe would be snubbed into the well. Conversely, lowering the traveling blocks brought the pipe out of the hole.

Over the years, increased understanding of hydraulics resulted in the development of the “concentric” snubbing unit, which consisted of a hollow hydraulic cylinder. This design also created the first pipe guide that prevented the buckling that plagued earlier units and allowed operators to work on higher-pressure wells with longer strokes, which reduced the time required to complete the job.

Soon afterwards, the first multicylinder snubbing unit was developed, which was a prototype of the system used today. The industry also developed specialized slips and blowout preventers (BOPs) configured for the purpose of snubbing/stripping. As the unit designs progressed, they incorporated stronger gin poles and hydraulic rotary tables. Today, a standard HWO unit can be transformed into an HWO/snubbing unit in an hour with the simple addition of two sets of slips and a tubing guide.

The steady progression of hydraulic snubbing coincided with drilling advancements that have led to the widespread construction of ultraextended-reach drilling, multilaterals, and other unconventional wells that all too often are outside the capability of conventional service tools and technologies. In unconventional plays and well configurations, the advantages of HWO/snubbing to more conventional CT units, for example, are evident. Unlike CT, the ability to rotate the pipe and work string dramatically reduces wall-to-wall frictional drag. In turn, minimizing friction increases depth capability significantly, crucial in laterals that extend past 3,000 ft (915 m).

The benefits of hydraulic snubbing in unconventional applications recently were illustrated in the tight gas North Jonah field in Wyoming’s Pinedale Anticline. Since production from the field was uneconomical using conventional technologies, hydraulic snubbing was employed, allowing the well to be drilled and completed simultaneously. Hydraulic snubbing in concert with an innovative flowback package allowed the well to begin production even as the live completion was still under way.

Elsewhere, in an oil producer offshore Dubai, the technology was used in a live re-completion encompassing tubing-conveyed perforating (TCP) guns and acid stimulation at a well depth of 9,500 ft (2,898 m). After pulling the completion, the operator was able to run a cast-iron bridge plug and TCP guns before perforating. After successfully performing the acid stimulation, the hydraulic snubbing unit was used to run the re-completion assembly. From rigup to rigdown, the operation required 15 twelve-hour days.

The technology also was applied in a dry and pressurized re-completion of an onshore 16,000-ft (4,880-m) deep gas well in Sharjah. After the tree was frozen and removed, the BOP stack was installed and the 5-in. production string pulled from the hole. Afterwards, a tapered 27?8-in. to 31?2-in. production string was run in the hole to 8,500 ft (2,593 m), at which time a retrievable bridge plug was used to isolate the reservoir from surface to change out the hanger spool. The remaining completion installation was completed with 31?2-in. production tubing. The entire operation, including rigup and rigdown, was completed in 11 days.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Jereh truck/trailer mounted workover rig is mechanically and hydraulically driven. The power system, drawworks, mast, travelling system and transmission mechanism of the workover rig are mounted on the self-propelled chassis, which improves the moving efficiency greatly. Now, Jereh truck mounted workover rig series cover the workover depth from 2500m to 7000m and drawworks power from 250HP to 1000HP, featuring high operation load, reliable performance, excellent off-road performance, convenient movement and low operation/moving cost. Besides, workover rigs for arctic, desert and highland applications are available.

Cost effective: It has wide applications and can achieve operations such as running tube string, milling and drilling plugs under pressure, and cooperating with fracturing units for stimulation operations in high pressure oil/gas wells;

Snubbing is a process that controls the pressure of oil or gas in order to run or pull tubing, drill pipe, or casing. These applications use the standard snubbing unit to complete or re-complete wells in a “live well” condition. Any type of workover application can be performed utilizing quick jacks.

Snubbing units are often used in place of workover units for offshore applications. Snubbing can offer the same services at a greatly reduced cost to the customer. Snubbing can be performed on live and dean wells. Milling operations can be faster and more precise with snubbing units due to infinite control of torque and speed of the rotary mounted on the snubbing jack. Snubbing is versatile alternative that can overcome the limitations of other workover systems - wireline, coiled tubing and conventional workover rigs. It eliminates the use of kill fluids that can damage the producing formation and require costly disposal. Snubbing is also a faster solution. Snubbing units can often have the task completed before a conventional workover operation is even rigged up.

Snubbing is your best choice when conventional draw works are absent. The self-contained equipment requires little space and can finish the job quickly. The hydraulic system"s precise control over force protects against overload and allows responsive tool manipulation.

The rig assist unit was installed on top of the rig’s Bops. A landing joint was lowered into the stack and screwed into the tubing hanger. The snubbing Bops were tested using the rig pump to 35mpa

The stack was equalized using the snubbing unit equalize line to well bore pressure. The hanger hold-down screws were backed out and the tubing hanger staged out using the snubbing units annular and stripping rams

Once the lift force from the well overcame the weight of the string, the snubbing unit took over pipe movement. The tubing connections were still staged out and the pipe continued to be racked in the derrick

The joint was gently snubbed up until the fill/flow sub was above the snubbing unit annular element. The operator continued to raise the tubing until the lower connection of the 3m pup joint engaged the bottom side of the stripping rams. The rams were locked and the chamber between the stripping rams and annular was re-equalized

BHA: Bottom hole assembly. Describes the production or workover tools used for completion or workover operations. (i.e. packers, bridge plugs, fishing tools, etc).

BOP stack: A series of blow out preventers stacked together using an equalizing and bleed of spool. Stack normally consists of an annular; equalize spool and a set of stripping rams. In snubbing operations the BOP stack is considered a secondary BOP. When working in conjunction with a workover, service or drilling rig the rig supplies the primary BOP’s.

Counter Balance Winches: A winch that can hydraulically counter balance the weight it is picking up. This gives the winch the ability to automatically feed off should the load placed upon it become greater than the actual weight being held via the hydraulics. Typically the snubbing unit will have two of these winches.

Equalize line: High pressure line pipe, chick sans (swivels) and valves for use during a snubbing operation to equalize or bleed off pressures within different chambers in a snubbing BOP stack.

Equalize spool: A ported spool for use in a snubbing operations allowing the operator the ability to equalize or bleed off certain sections of the BOP stack.

Gas well snubbing: Workover or completion work on a gas well which is either live or underbalanced with a rig assist or self-contained snubbing unit. Many gas well formations are fluid sensitive making a snubbing operation ideal for maximum production of the well. Eliminates the need for expensive kill fluids.

Guide Tube: Any arrangement of support system that prevents columnar buckling of the pipe being snubbed. Typical arrangements can be telescopic or static depending on the design of the snubbing unit structure.

Hydraulic Workover Unit: A unit that competes directly with conventional work over rigs. By utilizing hydraulic cylinders instead of a traditional draw-works arrangement, the unit maintains a small footprint allowing rig up in tight areas such as on offshore platforms.

Live well completions: A well condition where tubulars and tools are pulled or inserted into a well with the use of a rig assist snubbing unit or self-contained snubbing unit. The well has surface pressure from the down hole formations. Wells can be either gas or oil.

Live well workovers: Describes the condition of a gas or oil well is in when tubulars are snubbed in or out of well. There is pressure at surface in these wells making them ideal candidates for snubbing operations.

Lower snubbing basket: The work floor area which allows access to the snubbing crew to the BOP stack components and stationary snubbing and heavy slips.

Passive Rotary: A turn-table integrally mounted in the snubbing unit traveling plate which allows the rotation of the string with the slips closed on the pipe in either the snub mode or pipe heavy mode. This rotary must be driven with an external force be it by hand or with a power swivel rigged above the unit.

Pipe Heavy: In regards to snubbing, this is a pipe condition in which the tubing has sufficient string weight to overcome the forces acting on its cross-sectional area. Once the weight is sufficient, it overcomes the force applied by the pressure in the well and will fall under its own weight into the well.

Pipe Light: In regards to snubbing, this term describes the condition when the well bore forces acting on the cross-sectional area of the pipe being snubbed are greater than string weight; if tubing is not controlled, the snubbing unit will eject itself from the well.

Power-Pack: This is the prime mover that provides the force needed to turn hydraulic pumps which allow the operation of the snubbing jack and BOP systems. Diesel engines are the most common form, although electric drives are also utilized in special circumstances.

Powered Rotary: A turn-table integrally mounted in the snubbing unit traveling plate which allows the rotation of the string with the slips closed on the pipe in either the snub mode or pipe heavy mode. This rotary is driven with hydraulic motors, allowing the unit to perform string rotation without external support equipment.

Rig assist snubbing: A mobile snubbing unit, either truck-mounted or skid-mounted, that works in conjunction with a workover, service or drilling rig for workover or completions work on a live well or underbalanced well. Unit is capable of running or pulling tubulars and tools under pressure.

Scalloped spool: A spacer spool modified for snubbing to allow well bore pressures to equalize or bleed off around the tubing hanger when landing or pulling the hanger.

Self contained snubbing:A snubbing unit which stands alone by itself with no need of a service, workover or drilling rig. A self-contained unit is capable of workover or completion work on a live well or underbalanced well or indirect.

Snubbing: A procedure in which tubing is run or pulled from a well, which is in an underbalanced or live well condition. Snubbing units have specialized pressure control devices which permit them to deliver drilling, completion and workover services while there is pressure in the wellbore. Snubbing units eliminate the need to neutralize well pressure prior to servicing and therefore avoid the formation damage which neutralizing pressure can have on a well’s ability to produce.

Snubbing Assistant: This person’s position is primarily focused on taking direction from the snubbing operator, and entails routine maintenance, pipe handling and power tong operation.

Snubbing jack: The structure of the unit designed to withstand engineered ratings for both the pipe weight and the force applied by the unit’s hydraulic cylinders. The hydraulically operated equipment which enables crews to work on underbalanced or live well.

Snubbing Operator:Equivalent to a driller position, the snubbing operator physically operates the snubbing unit and takes direction from the snubbing supervisor. The operator is responsible for managing the daily activities of the rest of the snubbing crew, and ensuring that the equipment is functioning as designed.

Snubbing slips: A set of hydraulically actuated slips which can be run either inverted or right side up to control the movements of pipe in conjunction with a snubbing jack to insert or extract tubulars under live well or underbalanced conditions.

Snubbing Supervisor:Equivalent to a rig manager or tool push, the snubbing supervisor is responsible for all aspects of the snubbing unit and its operations. He/she is the direct liaison to the oil company representative he/she is working for. All members of the snubbing crew are subordinate to the snubbing supervisor. Typically the supervisor will have in excess of 10 years’ experience in snubbing operations.

Snubbing unit: A hydraulically actuated unit with slips, BOP stack and hydraulic jack for inserting or pulling tubing and BHA’s from underbalanced or live well conditions.

Stand alone snubbing (see self contained unit): Use of a snubbing unit by itself without the aid of a service, workover or drilling rig. Unit is capable of workover or completion work on a live well or underbalanced well.

Stationary snubbing slips: A set of snubbing slips that are typically mounted on top of a BOP stack which will hold pipe that is in a pipe light or neutral state.

Stripping: : During snubbing operations this is the procedure where you move pipe through a closed preventer (pipe rams or annular) on a live or underbalanced well containing pressure from the well bore with a closed preventer.

Stripping on: : The procedure in which a snubbing unit is rigged onto a service, workover or drilling rig, which is holding the pipe heavy tubing string with their tubing slips and not with a tubing hanger landed.

Stripping Ram: A hydraulically operated ram style BOP used during snubbing and stripping operations. Typically the ram front insert is a sacrificial material that is easily replaced for extended stripping. Materials for the inserts can be custom ordered for the application at hand.

TEP: A type of tubing plug developed for snubbing to control well bore pressures inside the tubing. Only viable for snubbing in operations. The plug is a machined collar with a removable disc and “o” ring. Once the tubing string has been snubbed in, the disc can be knocked out by equalizing the tubing string and flowing the casing. Once an overbalanced condition has been achieved inside the tubing string, the disc will fall out. Disc may also be removed by sand line or wire line tapping down on the disc once tubing string has been equalized with casing pressures.

Traveling plate: The plate which connects the rods from the hydraulic cylinders together on a snubbing unit where the traveling and heavy slips are attached. There are many cylinder configurations and stroke lengths possible depending on job requirements.

Traveling snubbing slips: A set of slips mounted upside down on a snubbing jacks traveling plate, which controls the movement of tubing in or out of a well. Slips will hold tubing only when tubing is in the pipe light state.

Underbalanced:A term to describe the pressure conditions in a well. Formation pressure is greater than the hydrostatic pressure of fluid, mud, etc… exerted on the formation causing pressure to migrate to surface in a well. A well in an underbalanced state is a prime candidate for snubbing.

Underbalanced completions: The condition of a well when completion services such as snubbing are performed. Formation pressure is greater than the hydrostatic pressure inside the well bore causing pressure to be at surface in the well. Underbalanced completions are prime candidates for snubbing. Typically wells have been perforated before snubbing unit arrives and the unit snubs in a production string to allow the well to be produced.

Underbalanced drilling: This term describes the condition of the well when drilling operations are ongoing. Snubbing units are used to snub out drill strings, i.e. bit changes and then snub in the drill string again or run productions strings.

Underbalanced workovers: The well is live with pressure to surface when workover operations are performed. Rig assist snubbing or self-contained snubbing units are used for the running or pulling of tubulars and BHA’s. Typically the snubbing unit pulls pipe from the well, the original zone is worked over, abandoned, or a new zone perforated and the snubbing unit snubs the production string back into the well.

Well control:In regards to snubbing, well control is the operation of containing well bore pressure with the use of a blowout preventer stack and tubing pressure by the use of a plugging system.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291