tripping pipe on a workover rig in stock

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

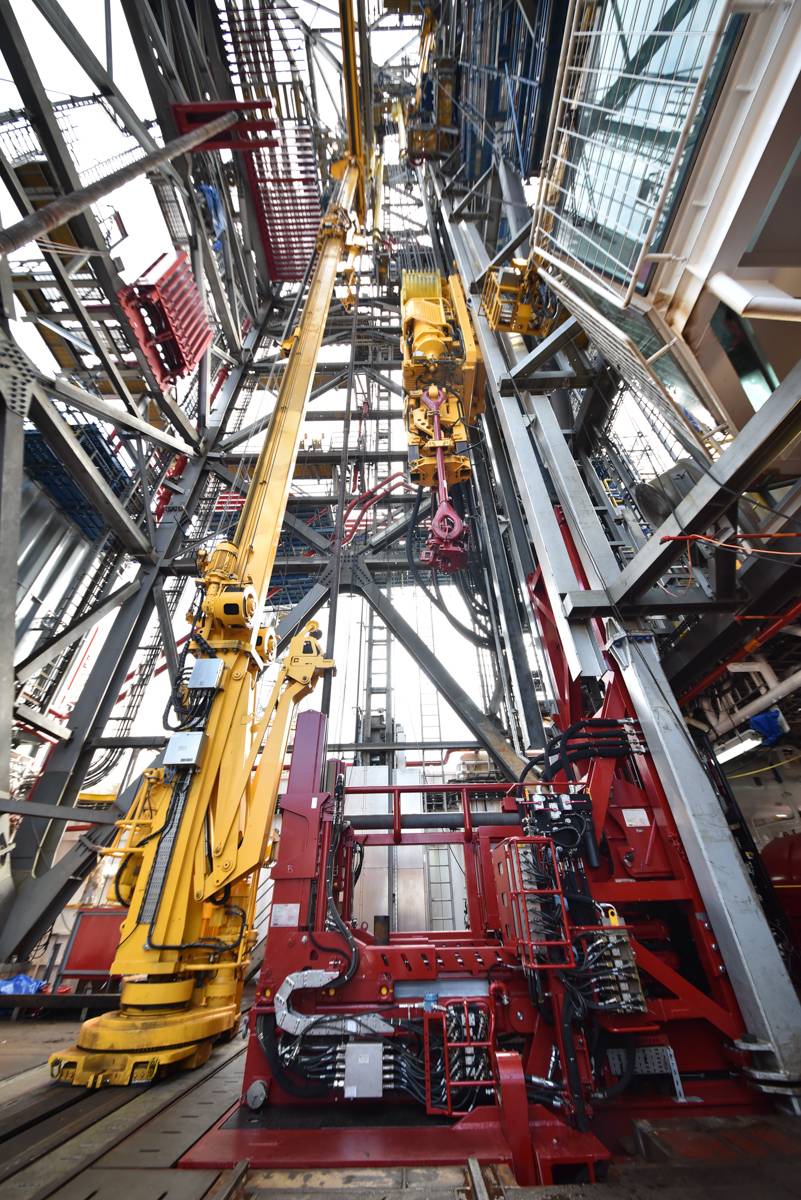

Offshore drilling services provider Ensco has rolled out a new proprietary solution engineered to provide greater pipe tripping safety and efficiency.

When used in concert with other key equipment, sensors and process controls, Ensco’s patented Continuous Tripping Technology (CTT) can fully automate the movement of the drill string into or out of the well at a constant controlled speed.

Ensco president and CEO, Carl Trowell calls the new technology “a step-change efficiency improvement that uses automation and innovative technology to address a repetitive, time-consuming process that is ubiquitous in offshore projects today.”

According to Trowell, “Tripping pipe is on the critical path for all drilling and workover activities and, as a result, meaningful time is spent performing this process over the life cycle of every offshore well.

“Continuous Tripping Technology significantly reduces the amount of time spent tripping pipe, and the faster tripping time that this technology offers is expected to lead to cost savings for customers regardless of water depth or well type,” he said.

Ensco claims CTT enables pipe-accelerated tripping speeds of up to 9,000 feet per hour when deployed during offshore activities. The constant tripping speed minimizes surge and swab pressure on the wellbore by eliminating intermittent stopping and starting as well as excessive peak speeds.

The system, which can be retrofitted to both floaters and jackups, and is particularly well-suited for ultra-deepwater drillships and larger modern jackups, uses automation to eliminate human error and personnel exposure associated with the conventional stand-by-stand method, according to its developer.

“Continuous Tripping Technology is another example of our ongoing investments in innovation that are focused on developing systems, processes and technologies to make the drilling process more efficient and lower offshore project costs for customers,” Trowell said.

“We continue to see better utilization for rigs that deliver the greatest efficiencies for customers’ offshore well programs and, given the proprietary nature of Continuous Tripping Technology, we expect that it will help to further differentiate Ensco’s assets from the competition and position us well for future contracting opportunities.”

Ensco said the CTT system was recently installed and is being commissioned on the 2016-built jack-up ENSCO 123. The rig is expected for delivery in March 2019 following system commissioning and rig acceptance trials.

Two or three single joints of drillpipe or drill collars that remain screwed together during tripping operations. Most modern medium- to deep-capacity drilling rigs handle three-joint stands, called "trebles" or "triples." Some smaller rigs have the capacity for only two-joint stands, called "doubles." In each case, the drillpipe or drill collars are stood back upright in the derrick and placed into fingerboards to keep them orderly. This is a relatively efficient way to remove the drillstring from the well when changing the bit or making adjustments to the bottomhole assembly, rather than unscrewing every threaded connection and laying the pipe down to a horizontal position.

Tripping pipe (or "Making a round trip" or simply "Making a trip") is the physical act of pulling the drill string out of the wellbore and then running it back in. This is done by physically breaking out or disconnecting (when pulling out of the hole) every other 2 or 3 joints of drill pipe at a time (called a stand) and racking them vertically in the derrick. When feasible the driller will start each successive trip on a different "break" so that after several trips fresh pipe dope will have been applied (when running back in the hole) to every segment of the drill string.

The most typical reason for tripping pipe is to replace a worn-out drill bit. Though there are many problems that occur to warrant the tripping of pipe. Downhole tools such as MWD (measurement while drilling), LWD (logging while drilling) or mud motors break down quite often. Another common reason for tripping is to replace damaged drill pipe. It is important to get the pipe out of the wellbore quickly and safely before it can snap.

Drill bits wear and tear like most any other piece of equipment. Once a bit becomes too worn to drill at an adequate rate or make a full-gauge hole, or if the bearings are thought to be near failure, a trip is undertaken to replace the bit. A trip is not considered a bit trip when the purpose of replacing the bit is to change sizes. This is only done when the crew "sets surface, intermediate or longstring" as appropriate.

A fishing trip is when a crew is forced to trip pipe to retrieve loose items in the wellbore. This can result from something being dropped in the hole, i.e. a tool, that would cause damage to the bit if the crew attempted to drill with it on bottom.

Another major cause is known as a "twist off". Twisting off is when the drill string parts by failing catastrophically under the torsional stress. This may happen if the drill string below is pinched in the wellbore, or as the result of a structural weakening of the pipe caused by a washout or a crack in a threaded connection member.

When pipe snaps or a part of the bit breaks off, the crew has to recover all of the separated items from the wellbore. Recovering snapped pipe usually involves placing a specialized tool (an "overshot") with grips set inside of it over the broken pipe in an attempt to capture it. The grip works in a manner similar to Chinese fingercuffs. Sometimes the jagged top of the fish must be milled back to a round outside shape before the overshot can slip over it. The overshot contains a packoff device to make a pressure seal so circulation can be reestablished through the bit to facilitate recovery of the fish. For a broken bit, a magnet is commonly used to remove all of the broken parts.

A cracked pipe can lead to a broken string. Extra care is taken when tripping for one so that too much pull does not cause the cracked pipe to snap. Cracked pipes (i.e., washouts) are usually noticed by a sudden drop in pressure. The crew will usually pump "fastline" (small lengths of manila rope taken from unraveled catline) down the drill string to make a temporary plug and time the pressure to see when it rises back to normal. This enables the crew to know how far down to expect the cracked pipe to be within a few stands; also strands of these rope segments may be seen at the point of washout. Most trips for a cracked pipe are not complete trips like a fishing trip or a bit trip. These can be as simple as only going a few stands down, to pulling the drill collars.

Logging of the open hole may take place at various depths while drilling, and almost always at the end of the drilling operation. The drill string will be removed from the wellbore to allow a logging crew to conduct a survey of the well. After the logging is completed at total depth, the crew will run the drill string back into the well and then proceed to lay it down when coming out of the hole prior to installing the final set of casing (the "production casing").

These trips are routinely expected by the crew. Setting surface occurs after the wellbore is drilled to the predetermined surface depth (e.g., after drilling below fresh water strata). The crew will remove the entire drill string to allow surface casing to be emplaced. The procedure is similar for setting intermediate, only that it typically involves a much longer drill string to be removed. Setting longstring is usually a one time operation combining both surface and intermediate casing. This saves the time of only having to undertake one pipe trip as opposed to two pipe trips.

Tripping refers to the process of removing and/or replacing pipes from the well when it is necessary to change the bit or other piece of the drill string, or when preparing to run certain tests in the well bore.

All across the oilfield, many items are called weird names and “monkey boards” are no exception. In this video, I sat out to show you what monkey boards are as I drove by a local rig. My timing was impeccable and we even get to see more in the video than I imagined. Be sure to watch it, but just in case you can’t, below is a short description.

In short, monkey boards hold vertical stands of drill pipe. The monkey boards are the flat part that sticks out to the side of the rig’s derrick (or mast) close to the top. As drill pipe is “tripped in” or “tripped out” of the well, the monkey boards allow for the excess pipe to be racked back for a close reach to make future connections. Utilizing the monkey boards allow drilling to go faster, as entire “stands” of drill pipe can be racked back in the monkey boards.

To explain what a “stand” of drill pipe is, let’s examine a typical “triple” rig. A “triple” means that the derrick has the room for three entire joints of drill pipe to be above the rig floor. Thus, three joints of drill pipe make up a “stand.” The benefit to a triple rig is that the rig doesn’t have to make connections while drilling, “tripping in,” or “tripping out” except for every three joints (one stand). Thus, rig time is lowered compared to a “double” rig.

Since this sounds confusing, be sure to watch the video to see them in action! We even get to see the “derrickman” which is the person who stands up on the monkey boards to help rack back the stands of drill pipe.

Canadian drilling rigs meet some of the highest regulatory and safety standards in the world. It"s a dynamic and exciting community to build a career in.

Canada’s drilling fleet is always changing to incorporate new technology and meet market demand. Most noticeably, the Canadian drilling fleet is growing in numbers. The fleet has 40% more rigs than it did 15 years ago. Today, the rig fleet offers just over 600 rigs.

For the most part, a rig is a rig is a rig. For example, all rigs have a derrick (the mast-like structure that holds the pipe to be lowered into the well bore) a catwalk that holds the drill pipe, a rig floor where floorhands handle the drill pipe, a drawworks which is the machinery that hoists and lowers pipe and a blowout preventor that enables a driller to control well pressure.

But different size rigs are used depending on the drilling target formation. Oil formations tend to be deeper than gas formations. When investors are most interested in producing oil, large rigs are in high demand. When the market prefers gas production, small rigs are in demand. Western Canada has plenty of both gas and oil, and activity cycles back and forth between preferences of one over the other.

Drilling rigs come in three sizes: singles, doubles and triples. These categories refer to how many lengths of pipe can stand in the rig’s derrick. On a single, the derrick holds one length of pipe. A double holds two, and a triple holds three.

A tall derrick isn’t necessary to drill deeper. If more pipe is needed to drill deeper, a single section of pipe is hoisted to the rig floor and added to the drill string. But sometimes the entire drill string needs to be pulled out of the hole (to change the drill bit, for instance). A derrick that holds multiple lengths of pipe comes in handy and helps the crew to complete this evolution quickly.

A crew working on a triple is able to pull three lengths of pipe out of the hole before unscrewing the pipe. The Derrickman, working from the monkeyboard, sets the ‘stand’ of pipe in the derrick. Then the crew pulls up the next three joints of pipe. This evolution is called ‘tripping’.

The larger derrick is efficient to drill deep wells but isn’t necessary for shallow wells. Single rigs drill wells that are around 1 to 2 kilometres deep. These wells usually access gas basins. Single rigs and their crews change drilling locations often, sometimes every day or every other day.

Doubles and triples are larger rigs with bigger substructures and taller derricks. These rigs drill between 3 and 6 kilometres into the earth and might be at the same location for several months to complete deep drilling operations.

Singles, doubles and triples refer to conventional rig categories. Additional new categories of rigs have introduced different ways of handling pipe. For instance, some companies run coil-tubing rigs that stream tubing from a large reel instead of using drill pipe, or automated drilling rigs that are outfitted with a pipe-handling arm that raises the pipe into the derrick, eliminating the need for a derrickhand to work from the monkeyboard.

Through the 1990s, rig activity focused evenly on the two commodities. Then in 1998, there was a shift: gas wells began to make up the bulk of drilling activity. Through the early 2000s, rig activity increased year over year, but gas wells—which are shallower and can be drilled faster—far outstripped the increase in oil wells. Between 2001 and 2006, oil wells made up about 25% of rig activity, and gas wells 75%.

The drilling industry reacted to this demand by expanding the fleet. In 2007, the rig fleet grew faster than it ever it had before: 49 rigs were added. Most of these new rigs were the smaller ones best suited for gas drilling. Then in 2008, natural gas was on the market in abundance, and the stock market price of natural gas started to fall. Investors pulled back on gas drilling. In 2010, industry was back to an even split between gas wells and oil wells.

And then the turn-around happened: oil drilling overtook gas drilling in western Canada. In 2011, 61% of the wells drilled were seeking an oil formation, versus the 39% seeking gas. Today’s market continues to favour large rigs that can reach deep oil formations. There also is increased interest in accessing these formations at an angle: rig crews drill a well bore that curves toward a drilling target. Drilling rig contractors have been adding equipment in 2013. Unlike 2007"s fleet expansion, these rigs will be the larger, heavier rigs, primed for oil drilling.

As the hydraracker continued to move, tension caused the pipe to bow and the pipe was released from the lower tailing arm with significant force toward the setback area striking and fatally injuring the employee.

While this incident is still under investigation, drilling rig operators using fingerboards with latches are recommended to:Review and assess applicability of NOV Product Information Bulletin 85766409 and NOV Safety Alert Product Bulletin 95249112

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient’s own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.

v: to release pipe that is stuck in the hole by running washover pipe. The washover pipe must have an outside diameter small enough to fit into the borehole but an inside diameter large enough to fit over the outside diameter of the stuck pipe. A rotary shoe, which cuts away the formation, mud, or whatever is sticking the pipe, is made up on the bottom joint of the washover pipe, and the assembly is lowered into the hole. Rotation of the assembly frees the stuck pipe. Several washovers may have to be made if the stuck portion is very long.

n: an accessory used in fishing operations to go over the outside of tubing or drill pipe stuck in the hole because of cuttings, mud, and so forth, that have collected in the annulus. The washover pipe cleans the annular space and permits recovery of the pipe. It is sometimes called washpipe.

n: the assembly of tools run into the hole during fishing to perform a washover. A typical washover string consists of a washover back-off connector, several joints of washover pipe, and a rotary shoe.

n: the reservoir drive mechanism in which oil is produced by the expansion of the underlying water and rock, which forces the oil into the wellbore. In general, there are two types of water drive: bottom-water drive, in which the oil is totally underlain by water; and edgewater drive, in which only a portion of the oil is in contact with the water.

n: on an engine, a device, powered by the engine, that moves coolant (water) through openings in the engine block, through the radiator or heat exchanger, and back into the block.

n: a well drilled to obtain a fresh water supply to support drilling and production operations or to obtain a water supply to be used in connection with an enhanced recovery program.

n: an instrument near the driller’s position on a drilling rig that shows both the weight of the drill stem that is hanging from the hook (hook load) and the weight that is placed on the bottom of the hole (weight on bit).

n: a borehole; the hole drilled by the bit. A wellbore may have casing in it or it may be open (uncased); or part of it may be cased, and part of it may be open. Also called a borehole or hole.

n: an acidizing treatment in which the acid is placed in the wellbore and allowed to react by merely soaking. It is a relatively slow process, because very little of the acid actually comes in contact with the formation. Also called wellbore cleanup. Compare acid fracture.

n: 1. the activities and methods of preparing a well for the production of oil and gas or for other purposes, such as injection; the method by which one or more flow paths for hydrocarbons are established between the reservoir and the surface. 2. the system of tubulars, packers, and other tools installed beneath the wellhead in the production casing; that is, the tool assembly that provides the hydrocarbon flow path or paths.

n: the methods used to control a kick and prevent a well from blowing out. Such techniques include, but are not limited to, keeping the borehole completely filled with drilling mud of the proper weight or density during operations, exercising reasonable care when tripping pipe out of the hole to prevent swabbing, and keeping careful track of the amount of mud put into the hole to replace the volume of pipe removed from the hole during a trip.

n: the equipment installed at the surface of the wellbore. A wellhead includes such equipment as the casinghead and tubing head. adj: pertaining to the wellhead.

n: the recording of information about subsurface geologic formations, including records kept by the driller and records of mud and cutting analyses, core analysis, drill stem tests, and electric, acoustic, and radioactivity procedures.

n: the maintenance work performed on an oil or gas well to improve or maintain the production from a formation already producing. It usually involves repairs to the pump, rods, gas-lift valves, tubing, packers, and so forth.

n: a portable rig, truck-mounted, trailer-mounted, or a carrier rig, consisting of a hoist and engine with a self-erecting mast. See carrier rig. Compare workover rig.

n: a slender, rodlike or threadlike piece of metal usually small in diameter, that is used for lowering special tools (such as logging sondes, perforating guns, and so forth) into the well. Also called slick line.

n: a formation fluid sampling device, actually run on conductor line rather than wireline, that also logs flow and shut-in pressure in rock near the borehole. A spring mechanism holds a pad firmly against the sidewall while a piston creates a vacuum in a test chamber. Formation fluids enter the test chamber through a valve in the pad. A recorder logs the rate at which the test chamber is filled. Fluids may also be drawn to fill a sampling chamber. Wireline formation tests may be done any number of times during one trip in the hole, so they are very useful in formation testing.

n pl: the lowering of mechanical tools, such as valves and fishing tools, into the well for various purposes. Electric wireline operations, such as electric well logging and perforating, involve the use of conductor line.

n pl: special tools or equipment made to be lowered into and retrieved from the well on a wireline, for example, packers, swabs, gas-lift valves, measuring devices.

n: a cable composed of steel wires twisted around a central core of fiber or steel wire to create a rope of great strength and considerable flexibility.

n: the performance of one or more of a variety of remedial operations on a producing well to try to increase production. Examples of workover jobs are deepening, plugging back, pulling and resetting liners, and squeeze cementing. See recompletion.

n: a special drilling mud used to keep a well under control while it is being worked over. A workover fluid is compounded carefully so that it will not cause formation damage.

n: 1. in drilling, the string of drill pipe or tubing suspended in a well to which is attached a special tool or device that is used to carry out a certain task, such as squeeze cementing or fishing. 2. in pipeline construction, the string of washpipe that replaces the pilot string in a directionally drilled river crossing. The work string remains in place under the river until the actual pipeline is made up and is ready to be pulled back across the river.

Figure 8.06 shows a schematic diagram of a typical top-drive rig. In a top-drive drilling rig, the top-drive (Item 6 in Figure 8.06) is suspended from the traveling block (Item 5 in Figure 8.06) and attached to a guide system (gear train and rail system) on the derrick. The top-drive is an electrical motor that has the ability to travel vertically up and down and to impart torque to the drill pipe. These drilling rigs began to appear in the late 1990s. Although the top-drive supplies the torque for the system, a rotary table is still used to supply stability to the drill string and as a redundant (back-up) rotary system.

The advantages of a top-drive rig are that longer sections of drill pipe can be (1) connected to the drill string when the rig crew is drilling ahead, (2) connected to the drill string when tripping into the hole, or (3) unconnected from the drill string when tripping out of the hole.

As we saw in our discussion of a Conventional Rotary Table Rigs, the next 30-foot joint of drill pipe to be added to the drill string is temporarily stored in the mousehole on the rig floor. This joint of drill pipe is added to the drill string when drilling ahead or tripping into the wellbore. Tripping is the process of running drill pipe into or out of the hole for purposes other than drilling ahead. For example, if a drill bit needs to be changed due to wear, then the entire drill string needs to be pulled from the wellbore (tripping out of the hole), the drill bit needs to be replaced, and the drill string needs to be run back into the wellbore (tripping into the hole) to resume normal drilling operations. You can imagine how much ineffective rig time (in terms of not drilling ahead) is used tripping into or out of the wellbore and making or breaking connections in the drill string–particularly if the well"s TD (Total Depth) is 10,000–15,000 feet (or a shallower well has a 10,000-foot horizontal section).

Note: On the website linked above, you can select a name from the list or a number on the graphic to see a definition and a more detailed photo of the object.

The improved efficiencies coming from a top-drive is that an entire 90-foot stand (or triple) of drill pipe can be connected to the drill string rather than a single 30-foot joint. This is because the top-drive can go to the full height of the derrick using the traveling block to connect to the entire stand of drill pipe. Note, however, that not all top-drives use a triple when connecting drill pipe; some use a Double (two joints), while others use a single joint from a mousehole.

The Drill Training - Run drill pipe through rotary table YouTube clip (1:07) is an animation of how drill pipe connections are made on a conventional rotary rig. As I mentioned, on a conventional rotary table rig, only one joint (30 feet) of drill pipe can be added to the drill string at one time.

Figure 8.07: Rig Components - showing Kelly, Kelly Bushing, Rotary Table, Mousehole, and Rat Hole (screen capture at 9 seconds of the Drilling Training video)

In the screen capture shown in Figure 8.07, we see many of the components discussed in this lesson: the kelly, kelly bushing, rotary table, mousehole, and rat hole. Throughout the video, you can see these components of the rig used in action.

In the screen capture shown in Figure 8.08, we see the slips (yellow). As shown in the video, the slips are used to suspend the drill string when it is disconnected from the rig’s hoisting system.

In the screen capture shown in Figure 8.09, we see the mechanical tongs (red). As shown in the video, the mechanical tongs are used to grip the kelly and drill string to aid in uncoupling (unscrewing) the two.

The A Drill Pipe Connection YouTube clip (5:42) below is of several Roughnecks (discussed earlier in this lesson) on an actual rig crew performing the same operations that you saw in the animation. Again, these tasks are being performed on a conventional rotary table drilling rig.

At several points in the video you can see a roughneck Throw Chain around the drill pipe. The Winding Chain is used to apply the torque that is used to screw or unscrew the threads in the drill pipe to couple or uncouple the joints.

What I like about this clip, and the reason that I selected it, was because of the “non-standard operating procedure” that seems to be occurring in the video. Did you spot it?

At around 2:52 into the video, it appears that while two of the roughnecks were trying to remove the slips from the master bushing, the hoist system on the derrick was attempting to assist them by lifting the kelly and drill pipe to release pressure from the slips. Instead of freeing the slips, the hoist appears to have lifted the entire section of the rig floor covering the rotary table, along with the two roughnecks. You can hear someone laughing in the video.

At around 3:31 into the video, one of the roughnecks and the hoist appear to use a piece of drill pipe to tamp the section of rig floor back into place. This piece of drill pipe is then placed into the mousehole as the next piece of drill pipe to be connected to the drill string. This is not a standard operating procedure on the rig floor. After this incident, you can see the rotary table and kelly bushing rotating in the manner discussed in these lesson notes.

In this video, you can see two roughnecks connecting Doubles (two joints) of drill pipe to the drill string as they trip into the wellbore. You can tell that they are connecting doubles by counting the joints as they go into the wellbore. You can also tell that they are tripping into the hole because as they add the new drill pipe, they just run it into the hole and do not drill.

The Making a connection on a top drive triple from the derrick YouTube clip (3:26) is of a Derrickman (discussed earlier in this lesson) making connections on a top-drive rig from the perspective of the monkey board (Item 4 in Figure 8.06).

In this video, the derrickman appears to be connecting Triples (I think that I count three joints of drill pipe looking downward to the rig floor). As I mentioned, this video is taken from the monkey board on the top of the derrick.

The improved efficiency of the top-drive rigs comes from its ability to connect longer sections of drill pipe during tripping and drilling operations. This is done in less rig time and with less cost than a conventional rig. The two major advantages of a top-drive drilling rig are:

Extended Reach Drilling enables wells with long horizontal or near-horizontal lengths to be drilled through the reservoir in a more efficient manner than in the past. These long horizontal wells are one of the technology enhancements that has resulted in the “shale boom” in the U.S. domestic oil and gas industry in formations such as the low permeability Marcellus Shale in western Pennsylvania, Ohio, and West Virginia. The other technological advancement required for the shale boom was the ability to stimulate these extended reach wells with multiple hydraulic fractures (as we discussed in Lesson 7).

Stock images of drillers, motorman, roughnecks, tower hands, worms, and stock photography of oil field workers climbing the tower, making connections on drilling rig floors, and tripping pipe on drilling rigs.

8613371530291

8613371530291