tripping pipe on a workover rig free sample

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Wedge-shaped pieces of metal with teeth or other gripping elements that are used to prevent pipe from slipping down into the hole or to hold pipe in place. Rotary slips fit around the drill pipe and wedge against the master bushing to support the pipe. Power slips are pneumatically or hydraulically actuated devices that allow the crew to dispense with the manual handling of slips when making a connection. Packers and other down hole equipment are secured in position by slips that engage the pipe by action directed at the surface.†

The principal component of a rotary, or rotary machine, used to turn the drill stem and support the drilling assembly. It has a beveled gear arrangement to create the rotational motion and an opening into which bushings are fitted to drive and support the drilling assembly.

The heavy square or hexagonal steel member suspended from the swivel through the rotary table. It is connected to the topmost joint of drill pipe to turn the drill stem as the rotary table turns.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

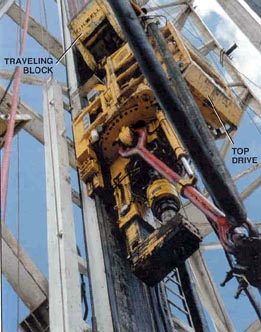

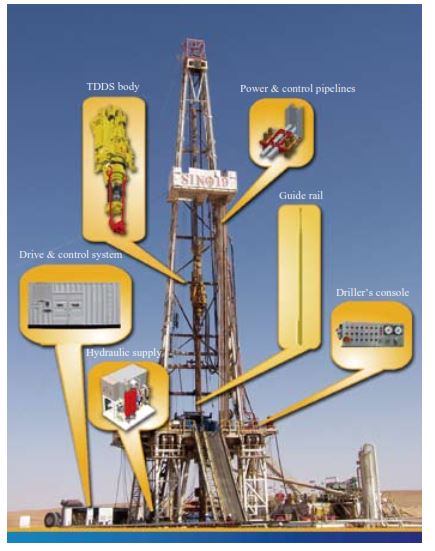

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

The derrickman"s working platform. Double board, tribble board, fourable board; a monkey board located at a height in the derrick or mast equal to two, three, or four lengths of pipe respectively.†

The large wrenches used for turning when making up or breaking out drill pipe, casing, tubing, or other pipe; variously called casing tongs, rotary tongs, and so forth according to the specific use. Power tongs are pneumatically or hydraulically operated tools that spin the pipe up and, in some instances, apply the final makeup torque.†

The cutting or boring element used in drilling oil and gas wells. Most bits used in rotary drilling are roller-cone bits. The bit consists of the cutting elements and the circulating element. The circulating element permits the passage of drilling fluid and uses the hydraulic force of the fluid stream to improve drilling rates.†

The heavy seamless tubing used to rotate the bit and circulate the drilling fluid. Joints of pipe 30 feet long are coupled together with tool joints.†

If you already know that the stuck pipe is caused by wellbore geometry, the following instructions are guidelines on how to free the stuck drill string.

Circulate with low flow rate (300 – 400 psi pumping pressure). It is very important to apply low flow rate because if high flow rate is applied, the stuck situation becomes worse.

If the drill string gets stuck while moving up or with the string in static condition, jar down with maximum trip load and torque can be applied into drill string while jarring down. DO NOT JAR UP. Be cautious while applying torque, do not exceed make up torque.

On the other hand, if the drill string gets stuck while moving down, jar up with maximum trip load. DO NOT apply torque in the drill string while jarring up.

Increase flow rate and circulate to clean wellbore at maximum allowable flow rate. Flow rate must be more than cutting slip velocity in order to transport cuttings effectively.

While tripping out of hole to 6,850’MD, observe over pull 40 Klb over pick up weight. Stop tripping out and attempt to go down no issue. Attempt to rotate, pipe is able to rotate at 30K ft-lb. Attempt to circulate, observe restricted flow.

Note: The adjusted weight is used instead of the plain weight because it represents the whole string better than the plain weight. The plain pipe weight can be used for tubular as casing or tubing which don’t have tool joints.

Note: This stuck pipe formulas is derived from Young’s Modulus equation therefore it does not account for friction in the wellbore. Using this formula will give you rough idea where the stuck pipe is and this is a good location for you to start determine the stuck depth using a wireline free point tool. The precision location must come from the free point tool only.

The Attorneys at Spurgeon Law Firm know what it’s like to spend countless hours tripping pipe on a drilling rig. Stephen and Sam both have experience working on drilling rigs where they have roughnecked on Kelly and rotary drilling rigs.

Running in the hole or pulling out of the hole (aka tripping pipe) is one of the most labor intensive job tasks a worker will engage in while on a drilling rig. Long hours of throwing the slips in, breaking or making connections, and racking back stands of pipe in the derrick is mentally and physically exhausting whereby your brain will start to populate abnormal thoughts. Your mind will start to drift due to fatigue and exhaustion and thus cause you to lose focus on the job at hand. Because of this, people are more susceptible of making mistakes, which in turn will cause injury to themselves or someone else. This is why it is imperative that companies have adequate personnel on the job and to allow that personnel to take breaks as needed. Your safety should be priority and always put your health first and the company’s profit second.

All oilfield workers have the right to work in a safe environment. The oilfield is governed by rules, laws, and guidelines to keep workers safe. However, these rules and laws are not always followed and often lead to serious injury. If you have sustained injuries in the oilfield contact our experienced oilfield lawyers at 318-224-2222. Attorneys, Stephen and Sam, have both worked in the oilfield and know the ins and outs. Prior to becoming an attorney, Stephen worked offshore as a Petroleum Engineer gaining valuable experience which he uses to get his clients maximum compensation. Their experience can make the difference when it comes to getting the payment you deserve. Contact Spurgeon Law Firm today for a free consultation.

The rig assist unit was installed on top of the rig’s Bops. A landing joint was lowered into the stack and screwed into the tubing hanger. The snubbing Bops were tested using the rig pump to 35mpa

The stack was equalized using the snubbing unit equalize line to well bore pressure. The hanger hold-down screws were backed out and the tubing hanger staged out using the snubbing units annular and stripping rams

Every tubing connection was staged out of the hole using the stripping rams and annular. The pressure at 21mpa made pulling the connections through the annular with pressure under it unwise. Before the connection was pulled through the annular, the lower stripping rams were closed and the pressure between the rams and annular vented to flare. Once the connection was through the annular element, the chamber between the Bops was re-equalized and the stripping ram opened. This process was repeated for every connection

Once the lift force from the well overcame the weight of the string, the snubbing unit took over pipe movement. The tubing connections were still staged out and the pipe continued to be racked in the derrick

Once the BHA was at surface, the last joint of 73mm tubing with the Fill/Flow sub below it was stopped in the stack. This placed the 3m pup joint below the fill/flow sub across the lower stripping rams

Note that the inside of this last joint was pressurized because of the holes in the fill/flow sub. The plug in the “F” profile on top of the joint was controlling the well pressure from flowing out the tubing

The lower stripping rams were closed and the stack bled off above the rams The pressure inside the joint also vented during this procedure. The firing head of the perforating gun was sealed and now controlled the ID side of the string

The joint was gently snubbed up until the fill/flow sub was above the snubbing unit annular element. The operator continued to raise the tubing until the lower connection of the 3m pup joint engaged the bottom side of the stripping rams. The rams were locked and the chamber between the stripping rams and annular was re-equalized

Make clean housekeeping a habit for all workers to avoid trips and falls. This practice includes picking up tools and small objects from the ground and keeping the floor and footing surfaces as dry as possible.

Equipment is as critical as human behavior when it comes to accidents on drilling rigs. So, tong jaws and elevator should be well lubricated, and tong pins should be in place with nuts and bolts while tong dies are sharp and intact.

Opening and closing of fingerboard latches should be checked systematically, and a mud bucket should be used to collect excess mud and avoid spills on the floor.

The mental and physical state of the workers has a massive impact on their safety performance that can be optimized by adequate sleep, frequent breaks, proper hydration, and a nutritious diet. The crew should always be mentally alert and physically ready to start a new shift.

If you have drilled for any length of time, sooner or later you are going to stick your drill pipe. It’s one of the hazards of the job. Recognizing the different ways drill pipe can get stuck is the first step in prevention — and recovery.

One very common way to stick pipe is differential sticking. This happens when the hydrostatic pressure is significantly higher than the formation pressure. This often occurs when you drill through a low pressure formation that takes light mud, and then drill into a higher pressure formation deeper in the well. In order to control the high pressure formation, you increase the mud weight. This may break down the low pressure formation and force the drill pipe against the formation face in the wellbore. The pipe is then very definitely stuck. It only take 1 or 2 pounds of differential pressure over a short area to stick pipe to the point that it is beyond the strength of the pipe, or the capability of the rig. One clue to this situation is that you can usually circulate freely.

The solution is to reduce the hydrostatic pressure in the hole until it is equal to the low pressure zone that has you stuck. While circulating, slowly reduce your mud weight by dilution while holding torque on the pipe until it comes free. One problem with this method is that the lower, high pressure formation may start to flow, so be ready to start out of the hole as soon as you’re free to prevent the hole heaving around your drill pipe. You can condition the mud after you’re up in a safe zone. While tripping out under these conditions, don’t shut down for lunch, grease the rig, smoke a cigarette or anything else but keep the pipe moving. If you have to stop, rotate the pipe.

Another common cause of stuck pipe is key-seating. This happens then you drill a deviated hole. It is often caused by formation inclination — doglegging — or too much pulldown. The bit will drill a full gauge hole, but as you get deeper, the pipe will wear a keyseat in the formation. When you come out of the hole, the BHA will ride in the keyseat until the bit gets to it. Then it will stop. Clues to this type of sticky situation: you can still go down and you can circulate freely. If you have a tophead rig, you can often rotate while pulling the pipe and roll past the keyseat. If you have a conventional rotary table rig, you may have to pull into it very gently and rotate the pipe enough to drill your way out of it. This can prove time consuming and frustrating.

Unstable formations can result in a cave in. This will stick pipe tighter than Dick’s hatband. You can’t move the pipe or rotate. The solution is more serious. You will either have to jar it out or wash over it. This can be time consuming and expensive. The prevention is to keep good mud properties, and monitor your gains and losses in the pipe. At the first sign of trouble, pick up, get away from bottom and condition the hole with good mud. Once you have the pipe moving, don’t stop.

Drill pipe can also be stuck mechanically. Dropped slips or a pipe wrench can stick pipe solid. The cures are different according to circumstances. If you can circulate mud, do it. If you can move the pipe, do it. Sometimes a piece of junk will ride the top of the bit until you get up to a soft formation where you can sidewall the junk and proceed.

A few years ago I was on a stuck pipe job in the Northern Rockies. We could circulate freely, but the pipe wouldn’t move or rotate. A classic case of differential sticking or wall-stuck, as we called it. A friend and mentor taught me a trick I’d never seen before. We conditioned the mud until the hole was as perfect as we could get it. Then we put a pretty fair amount of torque in the string and closed the blowout preventer, sealing the top of the well.

We pumped liquid nitrogen into the top of the well, and let the returns come back through the Kelly to the pits. When we had pushed the hydrostatic head of mud as deep as we felt safe, we cleared the floor and opened the preventer. Talk about spectacular! As soon as the pressure was released, the nitrogen came roaring out, lowering the pressure on the formation and freeing the pipe. We immediately started rotating, and conditioned the hole with good mud. I never had to run any tools or anything to free the pipe! I’ve only done that a couple times for various reasons. Usually, because the company man had never heard of it. But it has worked every time I tried it. My point is, every stuck pipe job is a little different, and you are going to have to think “outside the box” to be successful.

Operators working in shallow resource plays, such as shallow oil, unconventional shale gas and coalbed methane (CBM), just can’t get enough of a good thing. At their request, rig manufacturers are expanding the operating and mobility features of the industry’s rigs to a new level of sophistication – the highly or ultra-mobile rig. Highly mobile drilling rigs bring increased agility, automation, safety focus and cost savings, and are being used in deeper oil plays to perform top-hole work. Additionally, highly mobile rigs are carving niches for themselves in workover operations from offshore platforms, as well as geothermal applications.

Mobile and highly mobile rigs are different from their predecessor, the heliportable rig, which is used to access locations where no infrastructure exists, such as Siberia and the Amazon region. Heliportable rigs, which first appeared about 30 years ago, are capable of being broken down into a minimum number of loads, with each load weighing three tons, depending on the type of rig.

“Ironically, the helirig concept has not evolved very much, I suppose due to low-volume demand for these units. However, modular highly portable rigs have taken off, and the demand is very high for the foreseeable future,” Ray Pereira, vice president of North America sales for Drillmec, said.

For the purpose of this article, highly or ultra-mobile rigs are defined as small or medium-size self-driving rigs with wheels, mounted on either a substructure or trailer, and quite often their substructure and mast are self-erecting. How is this different from mobile rigs? According to rig manufacturers, features such as a heightened ability to be broken down and reassembled and still retain full functionality, increased use of automation for added safety and operational ability, and a reduction in crew size all set highly mobile rigs apart from mobile rigs.

“A fully engineered drilling system is even more important in highly mobile rigs given the trend toward more factory-styled well construction and automated drilling,” Eric Quinlan, LOC product manager for Huisman, commented. “The complete integration of third-party equipment into the rig design will further reduce the number of loads required, the rig-up and rig-down times, as well as improve on automation.”

“High mobility allows more wells to be drilled in a year,” he continued. Particularly for pad drilling in the shale plays, rigs must not only be able to skid or walk but also move quickly and safely to the next pad.

“There is a stronger focus on self-erecting components in highly mobile designs, for instance slingshot-type substructure and self-elevating or self-erecting masts,” Thomas Janowski, sales manager for Herrenknecht Vertical, said. The advent of portable top drives, iron roughnecks, as well as casing-running tools, have added to efficiencies of highly mobile rigs, he noted.

The design and construction of these highly mobile rigs have become very sophisticated, as with the case of the Drillmec HH Series rig, where the main rig components, such as the mast and part of the drill floor, are fused to the specially designed trailer. This allows the top drive and iron roughneck to be transported without being removed from the mast. The trailer concept has improved the mobility of mud pumps, mud tanks, variable frequency drive houses and pipe bins for the automatic racking system.

“A key limitation to current rigs is the available resources (people, trucks, etc) that enable the rig move. Location of the wells also plays a role and adds constraints, both geographic and regulatory,” Mr Quinlan said.

Therefore, there is a major push to reduce load weights and dimensions of all modules that are required to erect a highly mobile rig on location while at the same time reducing the number of loads required to fully assemble the rig on site, according to Mr Pereira.

It all comes down to the challenge of how to rethink components, such as a 40-ton mud pump, to make them more easily and economically transportable. “There is no standard solution at all,” Mr Janowski said. “How do you make 40 tons highly mobile? You can put wheels on it, but there are limits as to weight and size of components. It is challenging to design the components on the one hand lighter by using different compound materials like glass-reinforced plastic, and on the other hand, these heavy components like mud pumps, diesel generators and electrical cabinets and steel structures, such as the mast and substructure, have to be able to be broken down into smaller pieces but retain the same operational features.”

Equipment advances have brought challenges to highly mobile rig designs as well. “We are seeing a lot more wires and sensors being installed along with measurement equipment and video cameras,” Mr Quinlan remarked.

According to Atlas Copco, mobile rigs got their start in the energy industry when operators started using water-well rigs to drill for oil and gas. “The industry sort of evolved into using mobile rigs for oil and gas drilling rather than actually beginning at a definitive time. The Atlas Copco RD20 rig was borne out of the need for a mobile rig designed specifically for oil and gas drilling,” Alex Grant, well drilling product line manager for Atlas Copco, recalled. The rig was conceived from the T4 water-well rig and has received several technology upgrades since it was introduced in 1986.

The 120,000-lb hookload RD20 rig now has a sister rig, the highly mobile 200,000-lb hookload Predator, which took five years to develop and is just now finishing field trials. The first production unit is expected to begin work in September this year in a Texas shale play.

“We saw a definite need to get into the bigger fields with the bigger players. That’s where Predator came in. We took a clean sheet of paper and asked the question, ‘What does the oil and gas market need?’ ” Mr Grant said. “Because we desired to have an API 4F rating, we probably spent about two years getting our suppliers lined up…. Structures are designed to three times the loading capacity; that’s something you can’t just evolve from a rig that you already have. In 2010, we built two prototypes and put them in the field in an extensive testing program.”

Recognizing that more operators are performing directional drilling, Atlas Copco also added more pullback capacity to the Predator design. The RD20 rig had a pullback capacity of about 5,500 ft; the Predator has about 8,000 ft to 10,000 ft of pullback capacity.

For Drillmec, the Drillmec HH Series rig saw its evolution from a simple hydraulic rig for water wells upgraded to oil well standards in 1990. The first built-for-purpose HH rig was delivered to Eni in 1994. Since then, each generation of the rig has been improved to include enhanced automatic controls for the pipe handler using programmable logic controllers (PLCs) and advances to the hoisting and hydraulic systems. The latest generations include joystick controls and cyber control touchscreen features. The company offers up to 375-ton HH Series rigs for land applications and up to 600-ton rigs for offshore platforms.

Also on the HH Series rig, the vertical pipe-racking system is assembled in a semi-circular array around the rig floor to contribute to quick rig-up and rig-down. Further, containers can be transported and handled full of drill pipe to save time and to reduce risks associated with pipe handling.

“For us, the challenge in the beginning was to develop a rig that provided very safe working conditions for the crew, a small environmental footprint and a high level of operating efficiency,” Mr Pereira said. “Our extensive knowledge of hydraulics enabled us to effectively use a purpose-made cylinder for the hoisting aspect of the rig, thereby eliminating the need for mechanical drawworks and the operational and transport complexities that it brings. The rigs do not have a conventional mast structure nor drawworks and long wires or traveling equipment as the hydraulic cylinder replaces those items and is the main hoisting element of the rig.”

Safety has become a paramount driver alongside economics for highly mobile rigs. “Try to remove personnel from unsafe areas is what we’ve done,” Atlas Copco’s Mr Grant said.

“From a mechanical standpoint to achieve safety, we’re getting into more computer-controlled systems, such as a wireless pipe-handling system where the operator can stand away from the whole operation, observe from a distance and still control the unit. We’re bringing computers more into it. It’s the same with the driller; with the use of electronics, we’re able to stand away from the drill table, stand back in the doghouse even and operate the rig from back there, out of the area where injuries typically occur,” Mr Grant said.

“Drillmec uses single 45-ft joints of range 3 drill pipe that is transported in pipe bins and ready to be used,” Mr Pereira said. “There are no delays waiting to make up stands and set them in fingerboards. Stand-building operations can take days. With the HH Series rig, there is no need to touch the pipe, thereby increasing safety parameters.”

The LOC 250, Huisman’s first highly mobile rig, is a containerized rig, meaning that all elements of the rig fit into standard ISO containers, and has casing-while-drilling capabilities. Since introducing the LOC 250 in 2005, the company has upgraded its design to include AC drive, a higher hookload and an expanded mud system, and the LOC 400 was introduced in 2009. The next generation of the LOC 400, to be introduced in late 2012 or early 2013, will feature a higher level of automation, even quicker rig moves and enhanced skidding capabilities.

“We’re conducting a study on rig moves, finding the weak links and engineering the process to improve it, and preparing recommendations for field personnel to accomplish rig moves quicker,” Mr Quinlan said.

Increased rig safety features desired by operators have brought about another benefit – a reduction in the number of crews needed to run the rig. “The more features you have, such as self-erecting masts, self-erecting substructures and highly mobile components, the less the risk of accidents related to these activities. In Herrenknecht Vertical’s case, a high level of automation, together with the concept of mobility, eliminates almost all of the dangerous jobs on the rig,” Mr Janowski explained. “The number of people involved in tripping pipe in and out is limited to two persons.”

The Drillmec HH Series rig advanced automation concept requires few crew members as well. The concept “allows it to perform most of the routine drilling operations, including tripping in and out the drill string, with an almost unmanned drill floor where worker presence is basically limited to thread doping and handling the bottomhole assembly,” Mr Pereira said. “No one is exposed to direct contact with rotating tubulars, tongs and wrenches or to falling objects.”

“With the latest Atlas Copco rig, the Predator, we’ve got it down to the minimum amount where we can have three people operating a rig as opposed to the six or seven people that would be on a conventional rig,” Mr Grant said.

With Herrenknecht Vertical’s Terra Invader rig, only two people are involved in tripping pipe in and out. The rig came onto the work scene in a geothermal application in Germany in 2006, just one year after the company was established. This rig, which has a box-on-box substructure, is tailored to the Western European market, where cranes are readily available.

“The design criteria are different in that the situation regarding cranes and heavy trucks in Europe is slightly different from the rest of the world,” Mr Janowski noted. “It’s cheaper to install a crane because it’s available and you can rig-up in two days with a crane.”

“There has always been a demand for high mobility in this industry, but the higher the costs are for drilling and transportation, the higher the demand to make the equipment more mobile than before,” Mr Janowski noted. According to him, exploration drilling in remote places, on artificial islands, in the Brazilian Amazonas region and in Siberia has prompted the increased demand for highly mobile units. Crane and truck load capacities are limited. Cost levels are quite high, and the need to reduce crew cost is an issue.

An economic boost has been a huge plus for operators choosing highly mobile rigs. In addition to the shale plays in North America, key markets are North Africa and the Middle East. “In the Middle East, you have only to drill 700 to 900 meters (2,297 to 2,953 ft) to access resources. Drilling takes only five or six days,” Mr Janowski commented. “There must be a relation between the drilling time and the moving time. When you drill five days, no one would accept a rig move time of five days.”

“It is not just the rig design that enables high portability,” Mr Quinlan remarked. “The contractor must also have the right procedures and systems in place and have a dedicated rig-moving team that knows the rig and how to move it. It’s no use having a rig that can move in two days and be waiting for trucks for three days before it can move.”

“With the Huisman LOC rigs, we wanted a rig that could be moved anywhere on the planet with the same ease as moving a few miles on the road. In this regard, we have been very successful. To move the LOC rigs overseas is very cost effective and can be cheaper than rig moves over land.”

Also regarding improved economics, Mr Grant pointed out that “in addition to the rig’s ability to be broken down into manageable pieces that can be rolled down the road to the next site, the pieces are smaller and the capital outlay is a lot less to achieve the same result as that achieved by drilling with a conventional rig. We run less crew; staff overhead is a lot less. Ultimately, if you’re going for the shallower stuff, the overall cost of ownership is a lot less … roughly two-thirds of the cost of a big conventional rig.”

Rig manufacturers believe there is savings to be realized from use of a highly mobile rig to drill the top-hole section when an operator is targeting deeper reserves. The conventional rig doesn’t need to stay on-site as long. There’s also savings to be realized from reducing nonproductive time.

“It’s about decreasing nonproductive time and increasing safety,” Mr Pereira remarked. “The correct application of a fast-moving or portable rig can save the operator days in mobilization and demobilization between wells. Depending on the distance to the next well location, the Drillmec HH Series rig can be ready for drilling within 72 hours. A well-trained crew can do it in less than 48 hours.”

According to Drillmec, one of its expanded rig capabilities as a result of the design was for the rig to become an integral part of the substructure. “We figured, wouldn’t it be great if you could run the hydraulics of the substructure from the rig itself and offer connections on the substructure to quickly connect an air or mud pump system and reduce the downtime for setup,” Mr Grant said. “The other part was to have the pipe-handling on the back of that.” The Drillmec rigs have the main rig components fused to the specially designed trailer.

With Atlas Copco, Mr Grant said they’re expanding the operational ability of their highly mobile rigs by taking manual labor out of the scenario where possible. For example, “with the Predator rig, the driller has the more accurate ability to dial-in to a computer what he is trying to accomplish; for instance, establish weight on bit by dialing it in,” Mr Grant said. “Before, the driller had to watch the pressure gauge and dial-in weight-on-bit information as the formation changed.”

Highly mobile rigs are meeting diverse global drilling requirements as well. Drillmec’s HH Series rigs are currently operating in shale plays in North America, in the deserts of Egypt and the Middle East, in remote locations in Peru, Colombia, Venezuela and Australia, as well as in geothermal projects in Iceland and Chile. Further, the company recently announced the sale of 25 hydraulic rigs, with an option for an additional 125 rigs, to Chinese drilling company Greka Drilling. The units will work in CBM and shale-gas applications in China’s Shanxi Province.

Huisman’s LOC rigs have drilled oil, gas and geothermal wells in the US and Europe. Although the LOC rigs were designed for onshore drilling, the company has developed a concept and performed basic engineering on a LOC rig for offshore application.

“We have worked on a very interesting concept for using our LOC rig as a modular platform rig with a unique installation procedure onto the platform. This solution would see platform installation in a few days as compared with the several weeks required for similar modular rigs,” Mr Quinlan said.

In addition to shallow-resource development, Atlas Copco has found success using its highly mobile units to do top-hole drilling and set the casing so that conventional double or triple rigs can go in later to drill the deeper sections.

“We can use a top head drive to push the head down onto the drill bit to create weight on bit,” Mr Grant said. “The conventional rigs are not top head drive; they’re relying on collars and sticks of steel to give them weight on bit, making it harder there at the top of the hole.”

As operators expand their search for resources across the globe, rig manufacturers are keeping pace, delivering innovations in operation and transportability.

With more advances already on the drawing board, rig manufacturers are confident that the next generation of highly mobile rigs will continue to meet operator expectations.

Here"s how flow lines is used on derrick hand resumes:Worked in the derrick latching pipe and pulled rods in the rod basket Serviced well heads and flow lines

Meetings that are held among the officials of a company or an organization to discuss ways to provide a safer and risk-free environment for the staff and customers of the company are called safety meetings. These meetings are commonly conducted in companies that deal in risky business involving the use of dangerous machinery and harmful chemicals.

Rules and regulation set by a company that reflect the company"s code of conduct are called company policies. These rules apply to people anywhere in the company. The policies may apply inside and outside of the workplace. Company policies are mentioned in an organization"s handbook.

Here"s how company policies is used on derrick hand resumes:Maintained and carried out all company policies and procedures to stay in accordance with all safety regulations and compliance.

Job safety analysis is the process of analysing the occupational safety at a workplace. It measures factors like safety wellbeing and health of employees. It also aims to solve conflicts that may further lead to the assault of an individual either by a colleague or the employer.

Heavy equipment, also known as heavy machinery, refers to heavy-duty trucks that are specifically built to complete building works, most often earthwork activities or other major construction projects. Heavy machinery works by multiplying the amount of input force added to force exerted, allowing jobs that would otherwise take hundreds of workers and weeks of labor to be completed in a fraction of the time.

Here"s how heavy equipment is used on derrick hand resumes:Worked on the Rig Floor with heavy equipment in a four man crew working using tongs to connect drill pipe.

Here"s how drill pipe is used on derrick hand resumes:Mixed sack chemicals, ran casting, tagged casing through V-door and unhooked cables from casing, tubing and drill pipes.

Zippia allows you to choose from different easy-to-use Derrick Hand templates, and provides you with expert advice. Using the templates, you can rest assured that the structure and format of your Derrick Hand resume is top notch. Choose a template with the colors, fonts & text sizes that are appropriate for your industry.

Here"s how h2s is used on derrick hand resumes:Attended a H2S Safety Course and a safety course through West Texas Safety Training Center for Chevron petroleum.

Here"s how mud pumps is used on derrick hand resumes:Maintained all safety policies and procedures-Worked in the derricks-Assisted driller as needed-Relief drilling-Maintained mud pumps and equipment-Maintained drilling fluids per mud program

Pulleys are primarily designed to lift heavy items easier through a shaft, cable, and belt. It is also used to support the movement of different systems, facilitating the transport of people and things.

Safety procedures are a set of standardized procedures, that ensures minimal to no risk to people, resources, and the work environment. A company follows the step-by-step safety procedures as it they not only keep the customers and the employees safe, but also help in avoiding legal claims.

Cardiopulmonary resuscitation or CPR is a medical procedure that involves chest compression to help a patient breathe. This artificial ventilation helps in keeping the brain function in place and regulates blood throughout the body. CPR is a lifesaving procedure that is used in emergencies.

An air compressor is a power tool used to convert power into potential energy, which is generally stored in the form of compressed air. Air compressors have several methods of pushing more air into a cylinder, thereby increasing the pressure. The compressor stops when the pressure reaches its upper limit and remains in the tank until demand occurs.

Roughneck is a term for a person whose occupation is hard manual labor. The term applies across a number of industries, but is most commonly associated with the workers on a drilling rig. The ideal of the hard-working, tough roughneck has been adopted by several sports teams who use the phrase as part of their name or logo.

Originally the term was used in the traveling carnivals of 19th-century United States, almost interchangeably with roustabout. By the 1930s the terms had transferred to the oil drilling industry. In the United Kingdom"s oil industry starting in the 1970s, roughneck specifically meant those who worked on the drill floor of a drilling rig handling specialised drilling equipment for drilling and pressure controls. In practice, these workers ranged from unskilled to highly skilled, depending subjectively on the individual worker"s aptitude and experience. By contrast, a roustabout would perform general labor, such as loading and unloading cargo from crane baskets and assisting welders, mechanics, electricians and other skilled workers. The word roughneck was in use in the U.S. oil drilling industry even earlier and had a similar meaning.

In oil fields, a roughneck"s duties can include anything involved with connecting pipe down the well bore, as well as general work around a rig. The crew of a land-based oil rig can be further divided into several positions:

Toolpusher: The highest position at the drilling location, responsible for every crew. A toolpusher may stay on location for a few days or weeks at a time during operations, whereas individual drilling crews work only eight- or 12-hour shifts or "tours" (pronounced as "towers").

Derrickhand (derrick-man): Responsible for the drilling mud, the mud pits where drilling fluids are circulated around the system, and the mud pumps, as well as being the hand up in the derrick manipulating stands into and out of the fingers during tripping operations. Acting as a lead for the driller who is mostly restricted to the rig floor. In many cases the derrickman is exclusively responsible for work in the derrick during "tripping" pipe in and out of the hole.

Pit Watcher: Responsible for the drilling mud, the mud pits, and associated pumping/circulating of mud and various fluids through the pits, downhole and returning through the pits.

Motorman (motorhand): Responsible for maintenance of various engines, water pumps, water lines, steam lines, boilers and various other machinery incorporated into the rig on a daily basis. Also responsible for movement of equipment on site. On a four-man drilling crew the motorman is also the chainhand.

Boilerman: Though this position is now obsolete, before the mid-20th century, when most rigs were steam-powered, the boilerman was responsible for the boilers. The boilerman also functioned as the laundryman, steam-cleaning the last crew"s greasy work clothes in the "blow barrel" and then hanging them up to dry in the warm air near the boilers.

Chainhand (Floorhand): This position is given to a floorhand that can also throw the chain that helps spin up the connections, but as of 2013automated on the drilling rigs is pretty much just another floorhand that watches out for the worm and does not get as filthy.

Leadhand/Floorhand ("worm"): Usually the lowest member of the drilling crew, those in this position are often nicknamed "worm", because this hand has the dirtiest and most physically demanding position. The floorhand works primarily on the rig floor where he is the one actually operating the tongs, iron roughneck, tugger, and catwalk, and doing pretty much any other job which is asked of him.

Roustabout (leasehand): On bigger rigs and offshore rigs, a roustabout does most of the painting and cleaning so roughnecks can take care of other work.

The Edmonton Oilers of the National Hockey League used to use an oil rigging roughneck with an ice hockey stick as one of their secondary logos. The roughneck, as a symbol of hard work and fortitude, was the inspiration for the Calgary Roughnecks lacrosse team, as well as the Tulsa Roughnecks of the North American Soccer League, the Tulsa Roughnecks of the United Soccer Leagues, and the Tulsa Roughnecks FC of the USL. The West Texas Roughnecks of the Indoor Football League also use this nickname. In the BAFA National Leagues, the Aberdeen Roughnecks have also adopted the nickname. In the AUDL (American Ultimate Disc League) the Dallas team is also the Roughnecks. One of the inaugural teams of the revamped XFL was the Houston Roughnecks

In Chapter 3 of Nick Carraway describes him as looking like "an elegant young rough-neck, a year or two over thirty, whose elaborate formality of speech just missed being absurd."

Stan Rogers"s song "Free in the Harbour", about the migration of Atlantic fisherman to the oil industry for work, describes these migrants as "Calgary Roughnecks from Hermitage Bay."

Inglis, Tom (January 31, 1988). Directional Drilling. Petroleum Engineering and Development Studies (2nd ed.). Springer. p. 236. ISBN 978-0860107163. Retrieved 2 January 2015.

Objective :To obtain a challenging position with a progressive company, which allows to utilize educational and job skills, where will be a productive team member, contributing quality ideas and work ethics.

Objective :To obtain a position in the drilling industry that will best utilize experience and abilities, with a company that provides opportunities for career advancement.

Summary :Extensive experience in automotive and manufacturing industries. Expertise in tooling and equipment includes trouble shooting, quality methods and Kaizen techniques.

Objective :Oil & Gas Drilling Professional with progressive experience in field drilling operations. Knowledge of rig equipment, rig safety, down-hole drilling operations, work-over and completion activities.

Objective :Obtain a position as an entry level engineer to support pipeline integrity that combines leadership experience, specialized knowledge and achievement in areas of safety, managing employees.

Summary :An accomplished Roughneck promoted from Floor Hand to Driller in four years. Responsible and supervised a four man crew for daily maintenance, drilling operation and OSHA safety requirements.

Objective :Production Coordinator Specialist with over nine years of fabrication, management, and production coordination experience. Experienced in production for projects of all levels of complexity.

Headline :Objectives Applying for this position hope to achieved, in doing a good job. Through the development of these skills hope to expand the company"s ability to target high profile.

Summary :Roughneck is responsible for delivering the product in a timely and efficient manner. This includes organizing, leading, and managing the team of construction workers.

Description :Adjusted machine feed and speed if the machine malfunctioned. Started machine operations by inserting control instructions into control units.

Headline :Survey equipment to set grades Would like a job on a Ca off shore drilling rig. Assembly, tuning, and plan development as well as modifying antenna prototypes.

Headline :Operator with positive attitude and a commitment to safety, quality, customer service and lean manufacturing. Flexible and dependable with ten years in an industrial environment.

Responsible for overseeing and maintaining the rig equipment and personnel. In charge of all installing, maintaining and troubleshooting all rig related equipment.

Drilling operations, in general, are hazardous in nature and whatever can be done to alleviate this situation is important from a point of view of personnel safety and overall efficiency. Some of the most important drilling operations are pipe handling, tripping, and connection make up. These operations can be inconsistent, causing delays and potentially cause pipe or thread damage to the drill string. Further, these operations are some of the most hazardous on the drilling rig and can be exacerbated by personnel error, fatigue, environmental factors and inclement weather.

To address this, an automated racking board pipe handling system has been developed for land and bottom founded offshore rigs, which has the capability to address the following:Remove personnel from the mast/derrick and the "red zone" areas of the rig floor

This paper will describe in detail the features of this automated system, which is compatible with land rigs (double and triple), jack-up, platform, and barge rigs. Additional case studies will show how this step change has been implemented on rigs to date.

8613371530291

8613371530291