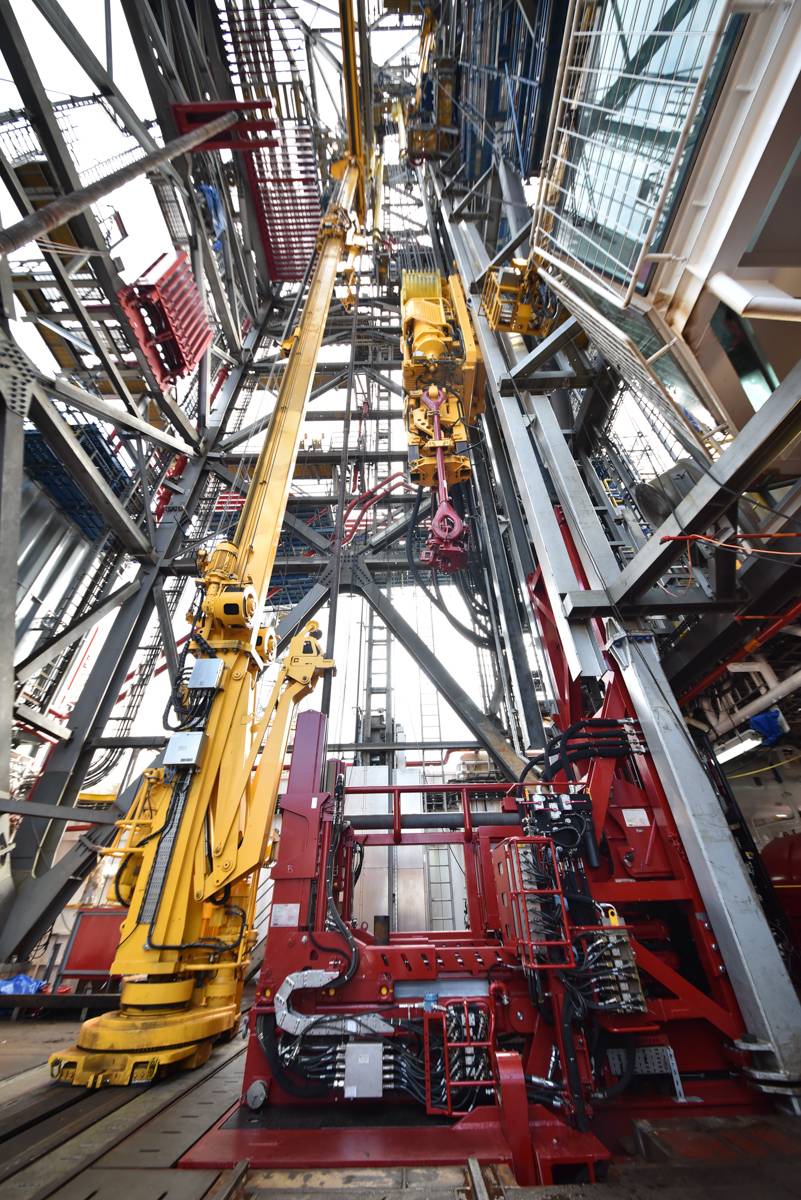

tripping pipe on a workover rig factory

As the hydraracker continued to move, tension caused the pipe to bow and the pipe was released from the lower tailing arm with significant force toward the setback area striking and fatally injuring the employee.

While this incident is still under investigation, drilling rig operators using fingerboards with latches are recommended to:Review and assess applicability of NOV Product Information Bulletin 85766409 and NOV Safety Alert Product Bulletin 95249112

Whilst every effort has been made to ensure the accuracy of the information contained in this publication, neither the IOGP nor any of its members past present or future warrants its accuracy or will, regardless of its or their negligence, assume liability for any foreseeable or unforeseeable use made thereof, which liability is hereby excluded. Consequently, such use is at the recipient’s own risk on the basis that any use by the recipient constitutes agreement to the terms of this disclaimer. The recipient is obliged to inform any subsequent recipient of such terms.

This document may provide guidance supplemental to the requirements of local legislation. Nothing herein, however, is intended to replace, amend, supersede or otherwise depart from such requirements. In the event of any conflict or contradiction between the provisions of this document and local legislation, applicable laws shall prevail.

The automatic operation equipment for minor workover is mainly composed of a wellhead operation device, hydraulic elevator, pipe and rod transmission and arrangement device and electro-hydraulic control system.

Each part of the device has different structural forms and can be selected arbitrarily for personalized configuration according to the needs of users.

The device adopts the structural form of dispersing the functional modules and integrated installation on the workover rig: with the hydraulic tong, manipulator and anti splash snap device set on the derrick of the workover rig, which can expand and rotate, and the safety slip is installed above the BOP.

The device only needs to install safety slips, which realizes rapid installation and migration and shortens the auxiliary working time. The device has the function of moving back and forth, left and right, which is convenient to align the wellhead. The height of the hydraulic tong is adjustable and can adapt to the wellhead with different heights. Hoisting equipment and special transport vehicles are not required for the installation and removal of the device.

In addition to its main function of suspending the pipe string, it also has the functions of automatic tubing mouth match, make-up and break-out, and is also equipped with a guide device bearing reverse torque, which can realize the functions of automatic well washing, sand flushing, drilling, grinding and milling.

Main function: connect to the wellhead flange and clamp the pipe string. Slip teeth are common with other manufacturers for easy replacement. The hydraulic cylinder is clamped and the pipe string is forced to be centered. The clamping is reliable and convenient for automatic operation. Open and close state detection, and realize safety interlock with other equipment.

The main electric control box can be installed on the operation vehicle or integrated into the modular wellhead operation device. The make-up torque of various oil pipes is set on the touch screen to realize automatic make-up and break-down. Equipped with video monitoring, process prompt, safety alarm, etc. The control system has a perfect action interlocking function to ensure the safety and reliability of the workover operation process. All of the electric cabinets, sensors, connectors meet the requirement of Explosion-proof on field.

The hydraulic system includes hydraulic source, wellhead automatic operation device control valve group, hydraulic elevator, hydraulic slip valve group, conveyor control valve group and pipeline, etc.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Annular BOP: A Bop with a full opening elastomer element that has the ability to seal on virtually any shape, as well as seal on itself in and emergency situation.

Balance Point: This term refers to the condition during a trip in or out of the hole where the pipe weight and the lift force exerted by the well acting on the cross-sectional area of the pipe being tripped is at or near equal.

BHA: Bottom hole assembly. Describes the production or workover tools used for completion or workover operations. (i.e. packers, bridge plugs, fishing tools, etc).

BOP stack: A series of blow out preventers stacked together using an equalizing and bleed of spool. Stack normally consists of an annular; equalize spool and a set of stripping rams. In snubbing operations the BOP stack is considered a secondary BOP. When working in conjunction with a workover, service or drilling rig the rig supplies the primary BOP’s.

Counter Balance Winches: A winch that can hydraulically counter balance the weight it is picking up. This gives the winch the ability to automatically feed off should the load placed upon it become greater than the actual weight being held via the hydraulics. Typically the snubbing unit will have two of these winches.

Equalize line: High pressure line pipe, chick sans (swivels) and valves for use during a snubbing operation to equalize or bleed off pressures within different chambers in a snubbing BOP stack.

Equalize spool: A ported spool for use in a snubbing operations allowing the operator the ability to equalize or bleed off certain sections of the BOP stack.

Gas well snubbing: Workover or completion work on a gas well which is either live or underbalanced with a rig assist or self-contained snubbing unit. Many gas well formations are fluid sensitive making a snubbing operation ideal for maximum production of the well. Eliminates the need for expensive kill fluids.

Guide Tube: Any arrangement of support system that prevents columnar buckling of the pipe being snubbed. Typical arrangements can be telescopic or static depending on the design of the snubbing unit structure.

Hydraulic Workover Unit: A unit that competes directly with conventional work over rigs. By utilizing hydraulic cylinders instead of a traditional draw-works arrangement, the unit maintains a small footprint allowing rig up in tight areas such as on offshore platforms.

Live well completions: A well condition where tubulars and tools are pulled or inserted into a well with the use of a rig assist snubbing unit or self-contained snubbing unit. The well has surface pressure from the down hole formations. Wells can be either gas or oil.

Live well workovers: Describes the condition of a gas or oil well is in when tubulars are snubbed in or out of well. There is pressure at surface in these wells making them ideal candidates for snubbing operations.

Lower snubbing basket: The work floor area which allows access to the snubbing crew to the BOP stack components and stationary snubbing and heavy slips.

Passive Rotary: A turn-table integrally mounted in the snubbing unit traveling plate which allows the rotation of the string with the slips closed on the pipe in either the snub mode or pipe heavy mode. This rotary must be driven with an external force be it by hand or with a power swivel rigged above the unit.

Pipe Heavy: In regards to snubbing, this is a pipe condition in which the tubing has sufficient string weight to overcome the forces acting on its cross-sectional area. Once the weight is sufficient, it overcomes the force applied by the pressure in the well and will fall under its own weight into the well.

Pipe Light: In regards to snubbing, this term describes the condition when the well bore forces acting on the cross-sectional area of the pipe being snubbed are greater than string weight; if tubing is not controlled, the snubbing unit will eject itself from the well.

Power-Pack: This is the prime mover that provides the force needed to turn hydraulic pumps which allow the operation of the snubbing jack and BOP systems. Diesel engines are the most common form, although electric drives are also utilized in special circumstances.

Powered Rotary: A turn-table integrally mounted in the snubbing unit traveling plate which allows the rotation of the string with the slips closed on the pipe in either the snub mode or pipe heavy mode. This rotary is driven with hydraulic motors, allowing the unit to perform string rotation without external support equipment.

Rig assist snubbing: A mobile snubbing unit, either truck-mounted or skid-mounted, that works in conjunction with a workover, service or drilling rig for workover or completions work on a live well or underbalanced well. Unit is capable of running or pulling tubulars and tools under pressure.

Scalloped spool: A spacer spool modified for snubbing to allow well bore pressures to equalize or bleed off around the tubing hanger when landing or pulling the hanger.

Self contained snubbing:A snubbing unit which stands alone by itself with no need of a service, workover or drilling rig. A self-contained unit is capable of workover or completion work on a live well or underbalanced well or indirect.

Snubbing: A procedure in which tubing is run or pulled from a well, which is in an underbalanced or live well condition. Snubbing units have specialized pressure control devices which permit them to deliver drilling, completion and workover services while there is pressure in the wellbore. Snubbing units eliminate the need to neutralize well pressure prior to servicing and therefore avoid the formation damage which neutralizing pressure can have on a well’s ability to produce.

Snubbing Assistant: This person’s position is primarily focused on taking direction from the snubbing operator, and entails routine maintenance, pipe handling and power tong operation.

Snubbing jack: The structure of the unit designed to withstand engineered ratings for both the pipe weight and the force applied by the unit’s hydraulic cylinders. The hydraulically operated equipment which enables crews to work on underbalanced or live well.

Snubbing Operator:Equivalent to a driller position, the snubbing operator physically operates the snubbing unit and takes direction from the snubbing supervisor. The operator is responsible for managing the daily activities of the rest of the snubbing crew, and ensuring that the equipment is functioning as designed.

Snubbing slips: A set of hydraulically actuated slips which can be run either inverted or right side up to control the movements of pipe in conjunction with a snubbing jack to insert or extract tubulars under live well or underbalanced conditions.

Snubbing Supervisor:Equivalent to a rig manager or tool push, the snubbing supervisor is responsible for all aspects of the snubbing unit and its operations. He/she is the direct liaison to the oil company representative he/she is working for. All members of the snubbing crew are subordinate to the snubbing supervisor. Typically the supervisor will have in excess of 10 years’ experience in snubbing operations.

Snubbing unit: A hydraulically actuated unit with slips, BOP stack and hydraulic jack for inserting or pulling tubing and BHA’s from underbalanced or live well conditions.

Staging tubing: Is the process of moving tubing into or out of a live or underbalanced well by using different sections of the BOP stack to insert or extract tubing connections or larger diameter tool assemblies. I.e. annular and a set of stripping pipe rams or two sets of stripping rams. The preventers are closed and opened in sequence allowing for tubing connections or larger diameter tools to be staged in with at least one preventer being closed to contain well bore pressures.

Stand alone snubbing (see self contained unit): Use of a snubbing unit by itself without the aid of a service, workover or drilling rig. Unit is capable of workover or completion work on a live well or underbalanced well.

Stationary snubbing slips: A set of snubbing slips that are typically mounted on top of a BOP stack which will hold pipe that is in a pipe light or neutral state.

Stripping: : During snubbing operations this is the procedure where you move pipe through a closed preventer (pipe rams or annular) on a live or underbalanced well containing pressure from the well bore with a closed preventer.

Stripping on: : The procedure in which a snubbing unit is rigged onto a service, workover or drilling rig, which is holding the pipe heavy tubing string with their tubing slips and not with a tubing hanger landed.

Stripping Ram: A hydraulically operated ram style BOP used during snubbing and stripping operations. Typically the ram front insert is a sacrificial material that is easily replaced for extended stripping. Materials for the inserts can be custom ordered for the application at hand.

TEP: A type of tubing plug developed for snubbing to control well bore pressures inside the tubing. Only viable for snubbing in operations. The plug is a machined collar with a removable disc and “o” ring. Once the tubing string has been snubbed in, the disc can be knocked out by equalizing the tubing string and flowing the casing. Once an overbalanced condition has been achieved inside the tubing string, the disc will fall out. Disc may also be removed by sand line or wire line tapping down on the disc once tubing string has been equalized with casing pressures.

Traveling plate: The plate which connects the rods from the hydraulic cylinders together on a snubbing unit where the traveling and heavy slips are attached. There are many cylinder configurations and stroke lengths possible depending on job requirements.

Traveling snubbing slips: A set of slips mounted upside down on a snubbing jacks traveling plate, which controls the movement of tubing in or out of a well. Slips will hold tubing only when tubing is in the pipe light state.

Underbalanced:A term to describe the pressure conditions in a well. Formation pressure is greater than the hydrostatic pressure of fluid, mud, etc… exerted on the formation causing pressure to migrate to surface in a well. A well in an underbalanced state is a prime candidate for snubbing.

Underbalanced completions: The condition of a well when completion services such as snubbing are performed. Formation pressure is greater than the hydrostatic pressure inside the well bore causing pressure to be at surface in the well. Underbalanced completions are prime candidates for snubbing. Typically wells have been perforated before snubbing unit arrives and the unit snubs in a production string to allow the well to be produced.

Underbalanced drilling: This term describes the condition of the well when drilling operations are ongoing. Snubbing units are used to snub out drill strings, i.e. bit changes and then snub in the drill string again or run productions strings.

Underbalanced workovers: The well is live with pressure to surface when workover operations are performed. Rig assist snubbing or self-contained snubbing units are used for the running or pulling of tubulars and BHA’s. Typically the snubbing unit pulls pipe from the well, the original zone is worked over, abandoned, or a new zone perforated and the snubbing unit snubs the production string back into the well.

Well control:In regards to snubbing, well control is the operation of containing well bore pressure with the use of a blowout preventer stack and tubing pressure by the use of a plugging system.

Annular BOP: A Bop with a full opening elastomer element that has the ability to seal on virtually any shape, as well as seal on itself in and emergency situation.

Balance Point: This term refers to the condition during a trip in or out of the hole where the pipe weight and the lift force exerted by the well acting on the cross-sectional area of the pipe being tripped is at or near equal.

BHA: Bottom hole assembly. Describes the production or workover tools used for completion or workover operations. (i.e. packers, bridge plugs, fishing tools, etc).

BOP stack: A series of blow out preventers stacked together using an equalizing and bleed of spool. Stack normally consists of an annular; equalize spool and a set of stripping rams. In snubbing operations the BOP stack is considered a secondary BOP. When working in conjunction with a workover, service or drilling rig the rig supplies the primary BOP’s.

Counter Balance Winches: A winch that can hydraulically counter balance the weight it is picking up. This gives the winch the ability to automatically feed off should the load placed upon it become greater than the actual weight being held via the hydraulics. Typically the snubbing unit will have two of these winches.

Equalize line: High pressure line pipe, chick sans (swivels) and valves for use during a snubbing operation to equalize or bleed off pressures within different chambers in a snubbing BOP stack.

Equalize spool: A ported spool for use in a snubbing operations allowing the operator the ability to equalize or bleed off certain sections of the BOP stack.

Gas well snubbing: Workover or completion work on a gas well which is either live or underbalanced with a rig assist or self-contained snubbing unit. Many gas well formations are fluid sensitive making a snubbing operation ideal for maximum production of the well. Eliminates the need for expensive kill fluids.

Guide Tube: Any arrangement of support system that prevents columnar buckling of the pipe being snubbed. Typical arrangements can be telescopic or static depending on the design of the snubbing unit structure.

Hydraulic Workover Unit: A unit that competes directly with conventional work over rigs. By utilizing hydraulic cylinders instead of a traditional draw-works arrangement, the unit maintains a small footprint allowing rig up in tight areas such as on offshore platforms.

Live well completions: A well condition where tubulars and tools are pulled or inserted into a well with the use of a rig assist snubbing unit or self-contained snubbing unit. The well has surface pressure from the down hole formations. Wells can be either gas or oil.

Live well workovers: Describes the condition of a gas or oil well is in when tubulars are snubbed in or out of well. There is pressure at surface in these wells making them ideal candidates for snubbing operations.

Lower snubbing basket: The work floor area which allows access to the snubbing crew to the BOP stack components and stationary snubbing and heavy slips.

Passive Rotary: A turn-table integrally mounted in the snubbing unit traveling plate which allows the rotation of the string with the slips closed on the pipe in either the snub mode or pipe heavy mode. This rotary must be driven with an external force be it by hand or with a power swivel rigged above the unit.

Pipe Heavy: In regards to snubbing, this is a pipe condition in which the tubing has sufficient string weight to overcome the forces acting on its cross-sectional area. Once the weight is sufficient, it overcomes the force applied by the pressure in the well and will fall under its own weight into the well.

Pipe Light: In regards to snubbing, this term describes the condition when the well bore forces acting on the cross-sectional area of the pipe being snubbed are greater than string weight; if tubing is not controlled, the snubbing unit will eject itself from the well.

Power-Pack: This is the prime mover that provides the force needed to turn hydraulic pumps which allow the operation of the snubbing jack and BOP systems. Diesel engines are the most common form, although electric drives are also utilized in special circumstances.

Powered Rotary: A turn-table integrally mounted in the snubbing unit traveling plate which allows the rotation of the string with the slips closed on the pipe in either the snub mode or pipe heavy mode. This rotary is driven with hydraulic motors, allowing the unit to perform string rotation without external support equipment.

Rig assist snubbing: A mobile snubbing unit, either truck-mounted or skid-mounted, that works in conjunction with a workover, service or drilling rig for workover or completions work on a live well or underbalanced well. Unit is capable of running or pulling tubulars and tools under pressure.

Scalloped spool: A spacer spool modified for snubbing to allow well bore pressures to equalize or bleed off around the tubing hanger when landing or pulling the hanger.

Self contained snubbing:A snubbing unit which stands alone by itself with no need of a service, workover or drilling rig. A self-contained unit is capable of workover or completion work on a live well or underbalanced well or indirect.

Snubbing: A procedure in which tubing is run or pulled from a well, which is in an underbalanced or live well condition. Snubbing units have specialized pressure control devices which permit them to deliver drilling, completion and workover services while there is pressure in the wellbore. Snubbing units eliminate the need to neutralize well pressure prior to servicing and therefore avoid the formation damage which neutralizing pressure can have on a well’s ability to produce.

Snubbing Assistant: This person’s position is primarily focused on taking direction from the snubbing operator, and entails routine maintenance, pipe handling and power tong operation.

Snubbing jack: The structure of the unit designed to withstand engineered ratings for both the pipe weight and the force applied by the unit’s hydraulic cylinders. The hydraulically operated equipment which enables crews to work on underbalanced or live well.

Snubbing Operator:Equivalent to a driller position, the snubbing operator physically operates the snubbing unit and takes direction from the snubbing supervisor. The operator is responsible for managing the daily activities of the rest of the snubbing crew, and ensuring that the equipment is functioning as designed.

Snubbing slips: A set of hydraulically actuated slips which can be run either inverted or right side up to control the movements of pipe in conjunction with a snubbing jack to insert or extract tubulars under live well or underbalanced conditions.

Snubbing Supervisor:Equivalent to a rig manager or tool push, the snubbing supervisor is responsible for all aspects of the snubbing unit and its operations. He/she is the direct liaison to the oil company representative he/she is working for. All members of the snubbing crew are subordinate to the snubbing supervisor. Typically the supervisor will have in excess of 10 years’ experience in snubbing operations.

Snubbing unit: A hydraulically actuated unit with slips, BOP stack and hydraulic jack for inserting or pulling tubing and BHA’s from underbalanced or live well conditions.

Staging tubing: Is the process of moving tubing into or out of a live or underbalanced well by using different sections of the BOP stack to insert or extract tubing connections or larger diameter tool assemblies. I.e. annular and a set of stripping pipe rams or two sets of stripping rams. The preventers are closed and opened in sequence allowing for tubing connections or larger diameter tools to be staged in with at least one preventer being closed to contain well bore pressures.

Stand alone snubbing (see self contained unit): Use of a snubbing unit by itself without the aid of a service, workover or drilling rig. Unit is capable of workover or completion work on a live well or underbalanced well.

Stationary snubbing slips: A set of snubbing slips that are typically mounted on top of a BOP stack which will hold pipe that is in a pipe light or neutral state.

Stripping: : During snubbing operations this is the procedure where you move pipe through a closed preventer (pipe rams or annular) on a live or underbalanced well containing pressure from the well bore with a closed preventer.

Stripping on: : The procedure in which a snubbing unit is rigged onto a service, workover or drilling rig, which is holding the pipe heavy tubing string with their tubing slips and not with a tubing hanger landed.

Stripping Ram: A hydraulically operated ram style BOP used during snubbing and stripping operations. Typically the ram front insert is a sacrificial material that is easily replaced for extended stripping. Materials for the inserts can be custom ordered for the application at hand.

TEP: A type of tubing plug developed for snubbing to control well bore pressures inside the tubing. Only viable for snubbing in operations. The plug is a machined collar with a removable disc and “o” ring. Once the tubing string has been snubbed in, the disc can be knocked out by equalizing the tubing string and flowing the casing. Once an overbalanced condition has been achieved inside the tubing string, the disc will fall out. Disc may also be removed by sand line or wire line tapping down on the disc once tubing string has been equalized with casing pressures.

Traveling plate: The plate which connects the rods from the hydraulic cylinders together on a snubbing unit where the traveling and heavy slips are attached. There are many cylinder configurations and stroke lengths possible depending on job requirements.

Traveling snubbing slips: A set of slips mounted upside down on a snubbing jacks traveling plate, which controls the movement of tubing in or out of a well. Slips will hold tubing only when tubing is in the pipe light state.

Underbalanced:A term to describe the pressure conditions in a well. Formation pressure is greater than the hydrostatic pressure of fluid, mud, etc… exerted on the formation causing pressure to migrate to surface in a well. A well in an underbalanced state is a prime candidate for snubbing.

Underbalanced completions: The condition of a well when completion services such as snubbing are performed. Formation pressure is greater than the hydrostatic pressure inside the well bore causing pressure to be at surface in the well. Underbalanced completions are prime candidates for snubbing. Typically wells have been perforated before snubbing unit arrives and the unit snubs in a production string to allow the well to be produced.

Underbalanced drilling: This term describes the condition of the well when drilling operations are ongoing. Snubbing units are used to snub out drill strings, i.e. bit changes and then snub in the drill string again or run productions strings.

Underbalanced workovers: The well is live with pressure to surface when workover operations are performed. Rig assist snubbing or self-contained snubbing units are used for the running or pulling of tubulars and BHA’s. Typically the snubbing unit pulls pipe from the well, the original zone is worked over, abandoned, or a new zone perforated and the snubbing unit snubs the production string back into the well.

Well control:In regards to snubbing, well control is the operation of containing well bore pressure with the use of a blowout preventer stack and tubing pressure by the use of a plugging system.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 406b4f95116c28dca247da206ca234ea 63.210.148.230 10/25/2022 04:41 PM UTC

Drilling and completion technologies have helped US shale plays to gain more attention than even a few years ago. Vertical wells used to be the name of the game in some oil-rich areas such as the Niobrara shale in the Denver-Julesberg basin in parts of Colorado, Wyoming, Kansas and Nebraska. Very few horizontal wells had been drilled in the Niobrara until a few years ago.

Drilling contractors have helped the boom by building fit-for-purpose rigs with enhanced drilling capabilities that reduce operational cycle times and costs. Rigs built for the Bakken are winterized, and most also have skidding capabilities for pad drilling. Better fracturing and completion techniques allow operators to drill longer horizontal laterals to optimally drain the formation without having to drill additional wells.

Unit Drilling Corp owns and operates 122 rigs and is active in virtually all US shale plays, from Haynesville, Barnett and Eagle Ford in Texas to the Woodford, Cana Woodford, and the Mississippi and the Marmaton plays in Oklahoma.

“The interesting thing about the Mississippi and Marmaton plays is that both are targeting shallow formations between 5,000 and 7,000 ft before going horizontal,” saidJohn Cromling, executive vice president for Unit Drilling. “That opens up a new area for another class of rigs, 1,000-hp rigs that are equipped for horizontal drilling.”

“Shale plays have progressed from vertical wells to highly deviated wells to horizontals, and horizontals with long laterals,” Mr Cromling said. “Drilling rigs evolved accordingly.”

He listed five key technologies that helped rigs to successfully drill the various shale plays, and each has helped to reduce operational cycle time and/or improve safety.

First is top drives. Second is larger and higher horsepower mud pumps, “because hydraulics are the key to drilling horizontal wells,” he explained. “The pre-eminent factor for drilling horizontal wells, much more so than the hookload of the derrick or drawworks horsepower, is hydraulic horsepower.”

The third technology is the mud system. “During horizontal drilling with high rates of penetration and with a large volume of solids being removed during the process, a good mud system is necessary to remove the solids,” Mr Cromling explained.

Another key area is the drillstring. “We are doing things with drillstrings now that we had been taught for 50 years not to do,” Mr Cromling said. “Pipe in compression, for example, and running heavy-weight pipe instead of drill collars and running it above the drill pipe.”

The fifth technology is skidding systems. “All of the shale plays are in the development process to some extent,” he said. “Most of the rigs in the Barnett shale can skid, and a lot of wells in the Bakken are at the development stage and they are drilled with rigs that can skid over multiple well pads.”

“It could take as little as three hours to prepare for the skidding operation and another three hours to restore the unit for drilling operations, while the actual move is usually less than one hour,” Mr Cromling said.

Other equipment that helps reduce operational cycle time includes a BOP handling system, which is critical for rigs that skid from wellhead to wellhead. The system picks up the BOP in a single unit from one wellhead, suspends it in the rig’s substructure while moving and then lowers it to the next well via hydraulic winches. “All of our skidding rigs have BOP handling systems, and it is a key factor in saving a lot of time in the preparation and restoration of the rig when skidding,” Mr Cromling explained.

Some operators also prefer the hydraulically operated catwalk, not necessarily because it saves time but because it eliminates third-party service and improves safety.

It’s interesting to note that most of Unit Drilling’s rigs do not incorporate cyber chairs with joystick controls. “We have some rigs with joysticks and a lot of rigs that do not,” Mr Cromling said. “Most of our newbuild rigs do not use joystick controls. Some people are convinced that if you don’t have a joystick your rig doesn’t have all of the new technology that is available,” he continued.

When asked if using a rig without a joystick is more of an operator preference, Mr Cromling said, “That is more my preference. I think our rigs drill just as fast and efficient” as rigs with joysticks and automatic drilling systems.”

Anadarko Petroleum’s total 2011 capital expenditures are expected to be between $6.2 and $6.6 billion, with about 10% allocated to US shale plays. In the Eagle Ford, the company increased its average estimated ultimate recoveries to more than 450,000 barrels of oil equivalent per existing well. Its 200-plus planned wells for 2011 also signify a doubling of drilling activities from 2010 levels.

In the Marcellus, Anadarko plans to operate 10 rigs and participate in more than 250 wells this year. “The Marcellus will continue to be the only domestic dry natural gas field where the company will be actively drilling due to the play’s proximity to premium natural gas markets that enhance already robust economics,” the company said in a news release.

“Anadarko had nine rigs operating in the Marcellus play as of late March,” said Steve Bosworth, vice president of worldwide drilling for Anadarko, “including one rig that spuds and air-drills the vertical section of the wells from a multi-well pad to the kick-off depth to begin drilling the horizontal lateral portion.”

The company said it will continue to invest in other emerging onshore oil plays, including Bone Spring, Avalon shale and Wolfcamp in the Permian Basin, and the horizontal Niobrara play. Anadarko was operating two rigs in the Niobrara in late March and expected to increase that to three rigs by early April. “We are drilling Niobrara wells on a limited basis at the moment,” Mr Bosworth said. “It’s still early in the evaluation, but we hope to be running six operated rigs there by the end of this year.”

Mr Bosworth is convinced that, even if some line items are higher in cost than other methods resulting in the same end, operators will always save money by reducing the operational cycle times. Anadarko looks for higher-quality, higher-technology rigs for its horizontal shale drilling programs.

“The reason we feel we do as well as we have on the operational end is by utilizing these higher-quality rigs,” Mr Bosworth explained. “We look for a rig that will not compromise safety, and in fact improve safety, while improving our operational cycle time.”

He said the automatic catwalk is a safety improvement and eliminates additional third-party service personnel on location. He has similar feelings about separate crews to run casing. “Basically we are connecting two pieces of pipe,” he said. “It should not be dramatically different for a rig crew to run casing versus having a third-party casing crew and timing the logistics of that crew to the rig.”

Anadarko has been able to eliminate having a third-party casing crew about 20% of the time, but Mr Bosworth believes that will increase not only for Anadarko but across the industry. In time, a rig crew running casing will become more proficient at it, he added.

Pad drilling has also brought operational and economic benefits by allowing the company to batch together certain operations and “make it more like a manufacturing process,” Mr Bosworth said. “We are trending toward operating rigs with skidding capabilities because they are becoming more important to us from an operational efficiency standpoint by moving from wellhead to wellhead in a matter of hours rather than days.”

Mr Bosworth is not convinced that all technology is necessary from an economic standpoint. For example, while some operators often use rotary steerable systems in horizontal shale plays, “we think we do well with conventional tools depending on the particular area,” he said.

On the other hand, Anadarko’s success with rotary steering is resulting in increased use, depending on the area. “We are very encouraged by the rotary steerable wells we drilled in the Eagle Ford,” he said. “About 10% of those wells are drilled with rotary steerables, and I think we will be at about 50% during the next month or two. If you really want to get the consistent, repeatable good results, you are going to have to do that with technology.”

Helmerich & Payne has been building FlexRigs since the late 1990s and the A/C drive FlexRig3 since 2002. Today, the company boasts a 100% utilization rate of more than 200 FlexRigs in its US fleet. Most of them are working in shales.

“From our perspective, for the shale and unconventional plays, the more complex directional and horizontal wells, you need to begin with a platform that is A/C variable-frequency drive,” said John Lindsay, H&P executive vice president and COO. “We believe those rigs are the most efficient in the industry from a drilling performance viewpoint.”

The company has about 50 FlexRigs in the Eagle Ford, 21 in the Bakken, 20 in the Cana Woodford in Oklahoma, 16 in Haynesville (down from 29 last year due to low natural gas prices), and 11 rigs in the Barnett (down from about 25 rigs at the peak, also due to lower gas prices).

The FlexRig design concept is better safety and efficiency. “There are significant time savings to be gained in addition to the drilling process that benefits from lean manufacturing concepts,” Mr Lindsay said. “Only about 30% to 40% of the total well cycle is drilling; other areas for improvement include running casing, BOP nipple up and down, tripping pipe and moving the rig.”

The industry is also working on systems that will use real-time downhole data, for example, to deliver better performance based on the well that is being drilled, Mr Lindsay said. “With unconventional plays, there is a much more focused approach on factory delivery. The industry is set up much better today to look at a factory approach to exploiting reserves, which is a continuous focus on high-performance drilling.

“There also are a lot of lean techniques that go along with that – fit-for-purpose lean technology that continues to drive down drilling times by driving waste out of the process,” he continued. “After all, that’s what we are doing – we are manufacturing a hole.”

About 450 of the approximately 1,700 rigs working onshore US are A/C drive rigs, Mr Lindsay noted, and H&P owns just over 40% of those 450 units. There are also more than 700 mechanical rigs working in the US today, and it is estimated that over 200 of those are drilling in unconventional shale plays. But he added, “It’s not a function of the (mechanical) rigs not being able to drill the well. It is a function of the rigs not being able to drill the well as efficiently and economically as an A/C drive rig.

“Drilling has become more complex,” he continued. “Several years ago only 30% of the rigs working in the US were drilling horizontal and directional wells. Today, it is a direct inverse of that, with over 70% of the rigs drilling horizontal and directional wells. And the horizontal laterals have increased in length an average of 30% to 50% over the past two years.”

Those factors are why A/C variable frequency drive (VFD) technology will continue to gain market share, Mr Lindsay believes. “A/C VFD technology has enabled the deployment of the first generation of true high-efficiency multi-parameter electronic drillers,” he said.

H&P is able to drill concurrently using multiple parameters such as weight-on-bit, torque, Delta P and rate of penetration compared with a traditional auto driller that controlled only weight-on-bit. “We are just scratching the surface of what these systems will be able to do in the future.”

Many of the company’s rigs can skid over multi-well pads, and it manufactures its own skid system rather than buying from a third party. The skid system for its onshore rigs was adapted from its bidirectional skidding system used for offshore platform rigs, and in 2006 the first FlexRig4S unit was introduced in the Piceance Basin in Colorado that was capable of drilling 22 wells on a single pad. Shale development programs typically use drilling pads with between three to 10 wellheads, and this same system is being used today in the Marcellus, Bakken, Barnett and Eagle Ford.

Brigham Exploration said it will increase its operated fleet to 12 rigs this year in the Williston Basin’s Bakken and Three Forks plays by adding a rig every month beginning after May, when an eighth rig joins the fleet of rigs Brigham operates. “Accelerating from eight to 12 operated rigs is anticipated to increase Brigham’s drilling pace by approximately 44 gross wells per year” when the 12-rig level is met, which is anticipated to occur by September 2012.

“We are going to drill about 11 gross wells per rig per year,” said Erik Hoover, operations manager for Brigham. That translates into about 100 wells during 2011 and increasing to about 130 wells in 2012.

“With oil prices the way they are, liquid-rich fields are king,” Mr Hoover said. “Some plays are liquid rich, but the Bakken is probably the only true oil resource shale play.”

All of Brigham’s rigs in the Bakken are Nabors rigs, and the operator recently contracted two newbuild Nabors B Series PACE rigs. “I think many of the future Williston Basin rigs will be newbuilds because we’re now in more of a manufacturing mode, and newer rigs will likely be able to ‘walk’ from location to location and therefore reduce drilling costs,” Mr Hoover said.

Nabors Drilling Rig 266 drilled Brigham Exploration’s Abelmann 23-14 #1H well in the Bakken Shale, which underlies Montana, North Dakota and parts of Canada. Initial production from this well was 4,169 bbl/day of oil equivalent with 33 frac stages. Nabors believes it holds the largest market share in the Bakken. Nabors photo courtesy of Jim Blecha Photography

Brigham’s wells average 17-23 days to TD, including a 10,000-ft vertical section and a 10,000-ft horizontal lateral. Three years ago, these wells took 30-35 days to drill.

Better drilling techniques account for some of the time reduction. For example, some operators who use oil-base mud in the lateral section are drilling 30-day wells. “We use oil-base mud in the intermediate section of our wells and brine water in the lateral,” Mr Hoover explained. “We typically set the bar at 20 days, but our record well was drilled in 14 days.

“With brine water we can drill up to 2,500 ft per day, but with oil-base mud we are lucky to get 1,000 to 1,200 ft per day,” he added. Most of the time, it would make sense that oil-base mud would result in a slicker downhole environment, reducing drilling time. However, when viscosity is added to the Bakken formation, it changes the drilling dynamics, Mr Hoover said. In some areas, oil-base mud is required where higher mud weights are necessary, but most of Brigham’s acreage is in normally pressured areas.

The rig and experienced drilling crews account for the faster drilling times as well. “Rigs are customized for the Williston Basin, and there are a few differentiators,” Mr Hoover noted. “One is an AC electric top drive drilling system, which is installed on virtually every Williston Basin newbuild rig.”

“New technologies and equipment on the rigs include BOP handling systems and automatic catwalks, which make these rigs more efficient,” Mr Hoover said. “There also are new drill bit technologies and directional drilling tool improvements.

“We’ve learned how to drill better, and that knowledge is combined with improved rig quality to contribute to fewer days drilling the well,” he added. “There also is a big push for safety, and some of the new technologies and equipment also increase safety on the rig.”

Nabors Drilling is active in numerous shale plays around the US and says it holds the largest market share in the Bakken shale, for which the company’s B Series PACE rig is designed. The B Series is essentially a winterized iteration of its 1,500-hp rigs for shales and conventional fields in warmer climates.

Nabors Drilling’s Rig 981, an SCR unit, drilled for Shell in the Marcellus, which underlies Ohio, West Virginia, Pennsylvania and New York. Nabors photo at right courtesy of Jim Blecha Photography

“The B series rigs with walking capability are well-suited for simultaneous operations when development drilling begins,” said Ronnie Witherspoon, senior vice president and general manager, Nabors Drilling Northern Division. “The rig can clear existing wellheads, and its skidding capability is conducive to pad layouts.”

Most new B Series units are delivered with Columbia substructure moving systems. Additionally, the rigs can be fitted with a moving system later if they are not delivered so equipped. The rigs are also equipped with technologies from CanRig, a Nabors company, including an automated catwalk, Torq-Matic floor wrench, a top drive drilling system with Soft Torque software to mitigate stick-slip and downhole vibration, and Rockit, a surface rotary steerable system that rotates the drillstring in horizontal wells to reduce downhole friction.

Nabors Rig 981, an SCR unit, is drilling a well for Shell in the Marcellus Shale. Ronnie Witherspoon, SVP and general manager for Nabors Drilling Northern Division, says the company is continuing efforts to enhance rigs, equipment and software for shale drilling. In plays such as the Marcellus, wells are often drilled in a manufacturing mode. Minimizing the number of days on a well and reducing costs are key considerations for operators, he said.

“All of our technology enhancements are geared toward optimizing drilling efficiencies while addressing the operator’s ultimate goal of minimizing the number of days on a well and shaving costs,” Mr Witherspoon said.

“When shale plays are in development, they will be in a manufacturing mode, so to speak, where well after well will be drilled from a multi-well pad,” he explained. “What we are trying to do with our rigs, equipment and software is to optimize the process and continue to drive down the number of days on a well.”

Breakouts enable hands-free breakout and makeup of rod string tool joints. The jaw design enables gripping anywhere between the size range without modification. Units and installation kits are available for new and existing mast structures. An installation kit or specially designed extension is available

Hydraulically operated from the main control panel, the power breakout (hydraulic roughneck) arm mounts on the RH side of the mast opposite the operator. The arm swings beneath the top head by a hydraulically powered geared actuator. The lower jaws grab and hold the lower joint while the upper jaws grab and rotate the upper joint to make or break the connection.

The unit’s height is adjustable by 40″ to allow for variances in the landed height of the drill string. Two sets of jaw dies are required to cover the full diameter range of this unit. 8 x 3528-0011 dies are required for clamping diameters under 5″. Torque is adjustable in both the make and break directions and is monitored via a hydraulic pressure gauge.

Diaspan spanners completely surround the Drill rod, interlocking and self-tightening when operated. 4” diaspans are cast 4140 high tensile alloy hardened and tempered steel. 5” spanners upwards are CNC machined from Bisalloy 80 wear plate.

The jaw inserts are machined from 4140 high tensile alloy, hardened and tempered with high quality tungsten carbide serrated inserts. The jaws are fitted into the spanner body and secured by countersunk head screws. All inserts are replaceable when worn.

Schramm’s Drillers Monitoring system allows the operator to view all drilling parameters live including, hole depth, WOB, engine information and feed and rotation speeds. All data points are recorded 4 times per second and stored on the PLC for download and analysis.

Schramm’s rod retention system provides an unparalleled level of safety and prevents the possibility of a rod being dropped during the loading and unloading into the mast. The units are designed for use on the Schramm 685, however can be fitted to other masts on the market with some modification. The intrinsically safe clamps retain the rod whilst unloading or loading. Proximity switches activate the clamping mechanism, with a dead man switch to release.

Schramm’s disengage clutch is designed to have no sliding contacting parts to eliminate the ability for the clutch to ‘slip’ during operation. The clutch can be decoupled when the compressor is not required, resulting in considerable fuel savings and reduced wear. The clutch incorporates a cushioned drive element to isolate the driven component from the engine’s harmonic vibrations.

The inline oiler has been designed to provide automatic lubrication to down hole equipment. The venturi and adjustable needle valve ensures that a steady controlled supply of oil is entrained in the air system only when needed. With its small size it can be mounted easily to the deck of the rig or on a support carrier.

The pneumatic injection models are designed to inject into high pressure air streams. The oil flow volume is infinitely variable by both needle valve oil flow adjustment and pneumatic flow adjustments. Available in a compact 80L design to fit almost anywhere on the rig to a full 200L system suitable for drill and blast sized operations.

Schramm’s fabricated rotary head has been tried and tested in some of the harshest drilling conditions the world has to offer. The design incorporates straight cut gears, ensuring a high torque capacity is maintained. Three different size dual input motor configurations are available. A standard 76mm bore through the main spindle with a 104mm option available. Multiple output thread options in either box or pin configuration.

Suitable for reverse circulation, grade control, blast hole and water well drilling applications. Head travel guides are fitted with nylon wear pads and can be configured to suit most drill rig designs.

The Radio Remote Upgrade systems replace the existing direct or pilot hydraulic controls that are mounted on the machine and allow the operator to control either the rod loader or tramming functions from a safe distance. The system allows the operator to move around the machine ensuring they have a clear view of the surroundings, this is critical when tramming in confined areas or loading onto rig transporters.

Schramm’s sequenced rod spin cage was designed alongside the increased requirement for operational exclusion zones on a drill site. The cage is designed to conform to Australian standards for machine guarding and to operate seamlessly with the rod loader. The cage is fitted with status lights allowing the operator to see when it is in the open and closed position.

Multiple walkway configurations are available for both sides of the drill rig, allowing for safe access to the rig deck and rod bin for pre-start checks and maintenance. The rod bin walkway design allows for the loading of Rods via forklift without the need to remove the walkway.

Exploration jib booms are available with 500kg and 750kg ratings. The boom assembly mounts to the top of the mast and rotates through a worm drive slew ring. Stops are added to ensure the boom stops at 90 or 135 degrees from storage position.

The DA554 rod loader is designed for improved safety, reliability and productivity with extreme versatility. The tram lockout safety function is standard and prevents the jaws from moving when the tilt arm is raised over 15 degrees.

The EDM Diamond Rod Feeder has been designed to greatly reduce manual handling and risk of related injury when running in/tripping out diamond pipe. It can work with any rig, top drive or chuck drive, with a main winch can be operated by one person via pilot or remote control. Works on mast angles of 45° to 90° and the platform has a capacity of 200m N pipe.

Schramm’s tilt head assembly has been developed to fit all new and existing water well rigs. The tilt head pivot points are fitted with bronze bushes, including grease points located on a service bulkhead. The complete assembly maintains the full original pullback capacity of the rig. Proximity sensors are located on both locking cylinders and ensure the arms are locked in the drilling position.

Schramm’s electric over hydraulic hardware and software upgrades are available across the range of both new and used Schramm drilling rigs. Incorporating electric over hydraulic valves, controlled by a Programmable Logic Controller (PLC), the rig operator can view and change drilling and operating parameters and view rig diagnostics via a Human to Machine Interface (HMI).

Schramm’s rig mounted surveillance system provides a fully integrated solution to monitor worksites remotely. It also assists with avoidance of costly Lost Time Injuries (LTI’s) through accident prevention and health and safety training support. Primarily used in the Exploration Drilling and Mining industries, it is suitable for use on all drilling rigs or vehicles where monitoring safety systems and procedures can assist prevent injuries to employees.

With an ever-changing market, Schramm recognizes how important adaptability is. This is why we have developed Lazy Susan Field Installation Kits for rig model T300M, T450 series and the T685 series drills. Our Lazy Susan Field Installation kit can be across multiple applications, such as Water Well, Geothermal, Exploration and Grade Control.

Nobody knows your rigs like the people who built them. That’s why Schramm offers the most cost-effective solutions available to maximize the life and performance of your Schramm rig.

From factory rig updates with the latest technologies, to complete refurbishments from the ground up, Schramm certified professionals are standing by to ensure your rigs are always running at full capacity to maximize profitability.

The revolutionary Air Control system manages the compressor and variable speed fan controls to maintain a constant pressure and temperature on the system with a simple interface. This automated Compressor control system matches the volume of air created to the volume being consumed by modulating the positioning of the inlet control valve. The valve position is controlled by an attached cylinder.

The compressor sump pressure indicates whether the compressor needs to make more or less air to match the consumption. The control system is capable of artificially lowering the pressure below system demand, or lowering the volume below potential with operator overrides.

The Program logic controller (PLC) is the brain of the entire automated Air Control System. The controls on the control panel send commands to the PLC. The PLC then translates those

at a constant speed dictated by the opening of the inlet control valve. The maximum amount of air can be limited to the compressor system by turning the Volumetric Limit rotary knob on the control panel. This is just a limit of the maximum volume; the actual volume is determined by the compressor pressure set point and loading conditions.

The compressor control system monitors engine load and reduces the compressor volume as necessary to prevent the engine from shutting down due to being overloaded. The Air Control system is available for all new rigs with a compressor and can be retrofitted onto older rig models.

8613371530291

8613371530291