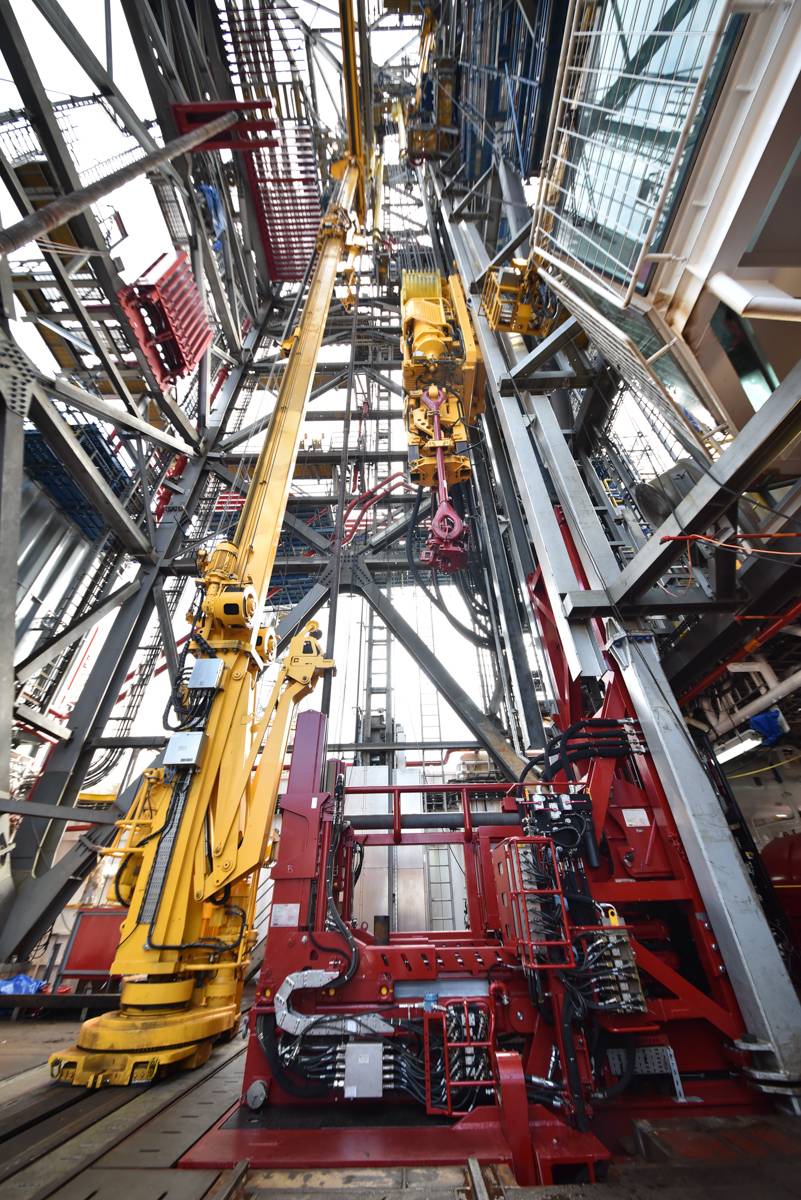

tripping pipe on a workover rig for sale

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

• Draw-work: National 1320-UE Draw-works, 1-1/2” Wireline Sand reel complete with 12000 ft of 9/16in sand line Make up and Brake out cathead complete with 2 GE 752 DC Motors 1 Crown-O- Matic 1 driller console with One Elmago Brake 6032 cooling system with water tank equipped with 1 each of 3x4 Mission Centrifugal Pump driven by electric Motor.

• Mast & Sub-Structure: Mast Made by Branham, Low Lift Cantilever Height 147 X 30 feet capacity 1,000,000 lbs. Static Hook Load 1,000,000 lbs. at 12 lines. Mast front leg I beam and rear leg angle section; Maximum wind load capacity with pipe racked in mast 75 MPH Racking Platform capacity 5” DP 173 stands, four stand 10” DC, eight stand of 6 ½” DC Complete with 1 each Deadline Anchor 1 each Monkey board 1each Stabbing board. Substructure Swing low lift Cantilever Static Rotary Beam Capacity 750,000 lbs. Set back capacity 700,000 lbs. Height to rotary beams 20" - 6" Drill floor height 25 feet x 37 feet wide. 1 each sub base floor lb 01 1 sub base floor lb 02 1 bottom box driller side 1 bottom box off driller side Complete with 1 Vee door complete 1 Catwalk 1 Doghouse Crown National 6 X 60” Dai meter sheaves. 1 X 60” diameter fast line.

• Top Drive: New/Unused Year Manufacture 2009 Top Drive 500 Ton Complete Assembly Manufacture : NOV Portable Drive Type HPT-06-500 2AC SG TT High Torque.

• Mud Pumps: 3 each National 12P160 Input power : 1600 hp with 2 Traction DC Motors Make by EMD type D79,Blower motors 10HP c) Supercharger pump 1 d) Liner cooling pump 1 Halco 1 x 1.5C Model# N 12 P 160 With 5hp motor e) Lube oil gear pump 1 (belt driven) f) Pulsation Dampner 1 Hydril 16 Gal, 5000 psi g) Pressure relief Valve 1 Retsco Reset relief valve 1500 – 5000 psi.

• BOP Stack: 1 Shaffer 13-5/8” 10,000 psi. Double Ram BOP flange top & bottom with large shear bonnet with tandem booster w/ 2 side outlet 4 1/16 10k. 1 Shaffer 13-5/8” 10,000 psi Single Ram BOP flange Top & bottom dressed with standard bonnet w/ 2 side outlet 4 1/16 10k. 1 Shaffer 21-1/4" 2k Double Bop flange top & bottom dress with large shear bonnet in lower cavity with tandem booster. w/ 2 side outlet 4 1/16 5k. 1 Shaffer 21-1/4" 2k Annular BOP Spherical type studded top and flange bottom. 1 Hydril Annular BOP Type : GK-14- 5000 psi 13-5/8’’ 5000 psi studded top & flange bottom. 1 Drilling Spools 3ft 10,000psi with 2 side outlet 3-1/16" 10k.

• Accumulator Unit: 1 unit BOP control unit Mfg. Koomey complete w/ 8 station accumulator 24 bottle 11 gallon & one electric pump and two air pumps WP 2000psi & 50hp motor c/w 2 ea remote panels c/w 150ft Umbilicals

Well Service | Workover Rigs - 844/80 Double drum draw works. looks to be recently rebuilt. Has new Lebus Grooving on Tubing Drum. Comes w/ 250 HP 2 speed jackshaft/RA BOX. More Info

Well Service | Workover Rigs - CARDWELL KB200B Freestanding Oilfield Workover Rig / Service Rig / Pulling Unit, Service Rigs, Used Cardwell KB200B Freestanding Service Rig, 5 Axle Carrier, Detroit 8V71... More Info

Well Service | Workover Rigs - WELL SERVICE RIG - COOPER 350 Well Service Unit p/b DETROIT 8V-92 Diesel Eng, ALLISON 750 Trans, 42X12-38x8 DRAWWORKS w/dual disc assist, 97â 200,000# Telescoping M... More Info

Well Service | Workover Rigs - CROWN 350 SERIES -- SERVICE KING 104" 205,000# DERRICK, CAT3406, ALLISON 5860,38X10 DOUBLE DRUM DRAWWORKS, CROWN SHEAVES REBUILT 2013 MAIN26âX4,SANDLINE 22â, NE... More Info

Well Service | Workover Rigs - 2008 Crown/Cabot 1058 Service unit mounted on 4 axle carrier w/Detroit 60 Power. New 5860 Drop Transmission. 72" Double rod/single tubing Derrickmast 125000# Rig is in Ex... More Info

Well Service | Workover Rigs - WELL SERVICE RIG - FRANKS 1287-160-DTD-HT D/D Well Service Unit p/b DETROIT 8V-71N Diesel Eng, ALLISON CBT-4460-1 Trans. SERVICE KING 96" 180,000# Hydraulically Raised & ... More Info

Well Service | Workover Rigs - FRANKS 300 D/D 1287 w/hydromatic brake, Well Service Unit p/b DETROIT 8V-71 Diesel Eng, ALLISON 750 Trans, (Reman Dec 2011) FRANKS 96âH 150,000# Tri-Scope Telescopin... More Info

Well Service | Workover Rigs - FRANKS 658 D/D Well Service Unit p/b CAT 3406 Diesel Eng, ALLISON HT-750 Trans, FRANKS 96âH 180,000# 4-Leg Telescoping Mast, Hydraulically Raised & Scoped w/4-Sheave... More Info

Well Service | Workover Rigs - FRANKS 658 D/D Well Service Unit p/b Series 60 Detroit Diesel Eng, ALLISON 5860 Trans, 102âH 225,000# (on 4 line) Telescoping Mast, Hydraulically Raised & Scoped, Db... More Info

Well Service | Workover Rigs - IDECO H35 96̢۪ 210,000 MAST, DETROIT 60 SERIES ENGINE, ALLISON 5860 TRANSMISSION, REFURB 2005, IDECO DERRICK REPLACED WITH NATIONAL DERRICK, TUBING DRUM CON... More Info

Well Service | Workover Rigs - IDECO RAMBLER H-35 Oilfield Workover Rig / Service Rig / Pulling Unit, Service Rigs, Used Ideco Rambler H-35 workover rig / service rig / pulling unit, 4 axle carrier, De... More Info

Well Service | Workover Rigs - 2015 INTERNATIONAL PAYSTAR 5900 Flushby Unit. C/w 2003, Refurbished in 2015, Western Fab Ltd. flushby unit, s/n 03-09-1008, 50 Ft. Mast height, 50,000 lb. pull rating, fr... More Info

Well Service | Workover Rigs - 2005 KENWORTH T800 Flusby Unit. C/w Lash Ent. flushby unit, 47 ft mast, slant compatible, 3x5 Gardner Denver triplex pump, 5000 psi, 2005 Advance 8m3 tank, TC 406 code, P... More Info

Well Service | Workover Rigs - 2003 KENWORTH T800 Flushby Unit. c/w Online flushby unit, 47 ft. mast, slant compatible, Pullmaster HL25 wotking winch, Pullmaster PL5 catline winch, 2002 wabash two comp... More Info

Well Service | Workover Rigs - 2005 KENWORTH T800B Flushby Unit. c/w Online flushby unit model 50-50, s/n 24641, 40 ft. mast,Salnt compatable, Pull master HL25 and PL5 winch, Gardner Denver 3x5 triplex... More Info

Workover rigs are specialized rigs designed for carrying out certain operations in a well. Drillmec is a leader in the production of specialized service rigs, we have rigs that cover a variety of workover operations in the oil and gas industry. Our service rigs have a wide range of applications and provide the best performance in different situations. Drillmec’s mobile drilling rigs are self-propelled, and trailer mounted for easy transportation for a variety of workover well services.

We manufacture a full range of workover rigs with capacities between 60 to 250 metric tons for a variety of well service applications. Our rigs are designed to be electrically or mechanically driven and are built to withstand varying extreme climatic conditions and a variety of terrains. Whether scorching heat of the desert or the bitter cold in the polar region or even the extreme elevation changes of Utica shale, our rigs are ready to deliver optimal performance always.

Drillers seeking versatile water well drill rigs with power and reliability to tackle water well drilling, geothermal drilling, and cathodic protection drilling choose DM450 water well drill rigs for speed and ease combined with reduced downtime. Additional advantages of the water well drill rigs for sale include:

Mud system, top head travel speed, and rotation speed and power combine to quickly conquer clay or cobbles to increase production and profit. Engineered to handle 4-inch to 12-inch wells up to 1,000 feet, tailor the DM450 water well drill rigs to your specific geography and drilling preferences from a wide array of drill rig options. Choosing from an assortment of standardized options minimizes maintenance and makes repairing your water well drill rigs from the field possible with a phone call to our team of expert service technicians. Owners describe their DM450 well digging machines as “stable” and “stout,” praising its simple operation for making it easy to train new operators.

Increase productiondrilling larger wells with the small water well drill rigs easily maneuvering on job sites. The DM450 drill truck provides ample head feed speed — activated with a fast feed circuit — to flush the cuttings out of holes drilled in sand or clay, providing a clean hole to drop well casing or cathodic protection anodes. The water well drilling rig for sale also features the top head rotation speed needed to handle tricky formations — such as sticky clay.

Expand accesschoosing from multiple mud pump and air compressor options to configure the water well drill rigs for specific geographic areas. Some options, such as sandline winch or pipe spinner systems, can be added to minimize equipment on geothermal drilling job sites.

Ease operationwithengineered design and modern construction, maximizing power to quickly and easily complete jobs while streamlining maintenance and troubleshooting. The control panel with its durable, mechanical controls, simplifies operation. The table assembly — with an opening to handle up to 16-inch casing — is positioned further back from the water well drill rigs, making it easier to handle tooling and set casing.

Armed with the fast head feed speed, many owners of DM450 water well drill rigs successfully complete water well drilling, geothermal drilling, or cathodic protection drilling with the same machine.

With drill rig service shops in Pennsylvania, Florida and Kansas, you’ll have industry-leading drill rig service support nearby for your routine maintenance or more in-depth water well drill rigs remounting and refurbishment work.Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your well digging machine is constructed consistently and tested thoroughly to ensure easier service support.

The durable, mechanical controls neatly laid out on the robust, organized control panel on the DM450 drill rig includes engine monitoring, safety E-stop, hydraulic pressure gauges, friction control levers for mud pump and rotation circuits, and electronic throttle controls. Simple operation makes it easy to train new operators.

Sturdy drillmast on DM450 water well rig provides power needed for tough water well drilling, geothermal drilling, and cathodic protection drilling with jibs to access both sides of the drill rig.

Totally redesigned drillmast on the DM450 drill rig with 25,000-lbs of pullback, 15,000-lbs of crowd force along with 16-inch side shift of the 2-speed rotary drive with 4,600 ft-lb torque. The rigid drill mast design makes drilling straighter holes easier.

The 2-speed main winch motor on the DM450 provides full pull power when tripping out or with flip of a switch provides full speed, making travel time twice as fast. For job sites where support trucks won"t fit on helper side, second jib swings and extends — in the other direction toward the driller"s side —to pick up and place smaller objects.

Using the helper side controls to operate the jib and winch functions controls, the helper loads the drill pipe in the single rod loader. This makes the DM450 drill rig easy to operate with a two-man crew and minimizing top head movement facilitates faster production.

The DM450 drill truck table assembly has clearance for 16-inch PVC casing. Easy access to table opening from control panel simplifies setting variety of casing sizes.

Air-powered holding fork and hydraulically-operated, adjustable breakout wrench make tripping out fast and safe with the DM450 drill rig. The grease fittings on the fork help maintain mobility in freezing conditions.

Available on an automatic truck chassis to further simplify mobilization, the lightweight, compact drill rig is suited for large residential water wells, commercial geothermal, and cathodic protection drilling. Clean layout of the deck, complete with access panels, makes for easier maintenance of securely routed hydraulic hoses from above the rig.

Create opportunity to task helper with other site chores or run a one-man job when you choose rod carousel option capable of backfeeding while running pipe.

Factory-mounted Mudslayer® 250 drilling mud cleaning system uses separate hydraulic circuit eliminating competition among functions, easily connects to pump for quick set up. Addition of the deck-mounted drilling mud cleaning system allows access closer to homes without hauling a mud pan behind the rig, eliminates shoveling out mud pans making job easier on drillers, and creates simpler job site cleanup.

Mud system, top head travel speed, and rotation speed and power combine to quickly conquer clay or cobbles to increase production and profit. Engineered to handle 4-inch to 12-inch wells up to 1,000 feet, tailor the DM450 water well drill rigs to your specific geography and drilling preferences from a wide array of drill rig options. Choosing from an assortment of standardized options minimizes maintenance and makes repairing your water well drill rigs from the field possible with a phone call to our team of expert service technicians. Owners describe their DM450 well digging machines as “stable” and “stout,” praising its simple operation for making it easy to train new operators.

Increase productiondrilling larger wells with the small water well drill rigs easily maneuvering on job sites. The DM450 drill truck provides ample head feed speed — activated with a fast feed circuit — to flush the cuttings out of holes drilled in sand or clay, providing a clean hole to drop well casing or cathodic protection anodes. The water well drilling rig for sale also features the top head rotation speed needed to handle tricky formations — such as sticky clay.

Expand accesschoosing from multiple mud pump and air compressor options to configure the water well drill rigs for specific geographic areas. Some options, such as sandline winch or pipe spinner systems, can be added to minimize equipment on geothermal drilling job sites.

Ease operationwithengineered design and modern construction, maximizing power to quickly and easily complete jobs while streamlining maintenance and troubleshooting. The control panel with its durable, mechanical controls, simplifies operation. The table assembly — with an opening to handle up to 16-inch casing — is positioned further back from the water well drill rigs, making it easier to handle tooling and set casing.

Armed with the fast head feed speed, many owners of DM450 water well drill rigs successfully complete water well drilling, geothermal drilling, or cathodic protection drilling with the same machine.

With drill rig service shops in Pennsylvania, Florida and Kansas, you’ll have industry-leading drill rig service support nearby for your routine maintenance or more in-depth water well drill rigs remounting and refurbishment work.Our service technicians are backed by our team of engineers to ensure solutions not bandaids to issues. And our production processes mean your well digging machine is constructed consistently and tested thoroughly to ensure easier service support.

The durable, mechanical controls neatly laid out on the robust, organized control panel on the DM450 drill rig includes engine monitoring, safety E-stop, hydraulic pressure gauges, friction control levers for mud pump and rotation circuits, and electronic throttle controls. Simple operation makes it easy to train new operators.

Sturdy drillmast on DM450 water well rig provides power needed for tough water well drilling, geothermal drilling, and cathodic protection drilling with jibs to access both sides of the drill rig.

Totally redesigned drillmast on the DM450 drill rig with 25,000-lbs of pullback, 15,000-lbs of crowd force along with 16-inch side shift of the 2-speed rotary drive with 4,600 ft-lb torque. The rigid drill mast design makes drilling straighter holes easier.

The 2-speed main winch motor on the DM450 provides full pull power when tripping out or with flip of a switch provides full speed, making travel time twice as fast. For job sites where support trucks won"t fit on helper side, second jib swings and extends — in the other direction toward the driller"s side —to pick up and place smaller objects.

Using the helper side controls to operate the jib and winch functions controls, the helper loads the drill pipe in the single rod loader. This makes the DM450 drill rig easy to operate with a two-man crew and minimizing top head movement facilitates faster production.

The DM450 drill truck table assembly has clearance for 16-inch PVC casing. Easy access to table opening from control panel simplifies setting variety of casing sizes.

Air-powered holding fork and hydraulically-operated, adjustable breakout wrench make tripping out fast and safe with the DM450 drill rig. The grease fittings on the fork help maintain mobility in freezing conditions.

Available on an automatic truck chassis to further simplify mobilization, the lightweight, compact drill rig is suited for large residential water wells, commercial geothermal, and cathodic protection drilling. Clean layout of the deck, complete with access panels, makes for easier maintenance of securely routed hydraulic hoses from above the rig.

Create opportunity to task helper with other site chores or run a one-man job when you choose rod carousel option capable of backfeeding while running pipe.

Factory-mounted Mudslayer® 250 drilling mud cleaning system uses separate hydraulic circuit eliminating competition among functions, easily connects to pump for quick set up. Addition of the deck-mounted drilling mud cleaning system allows access closer to homes without hauling a mud pan behind the rig, eliminates shoveling out mud pans making job easier on drillers, and creates simpler job site cleanup.

With business ranging from residential to agricultural water well drilling, from 4-inch to 12-inch wells, customer praised the DM450 drill rig for completing the small wells just as easily as the big wells with less downtime than his previous rig.

Keeping up the “geo-pace” required drilling multiple borings per day in the Colorado mountains, installing geothermal loops. Customer claimed their DM450 drill rig outproduced the combined footage of three other rigs on the geothermal drilling job.

A southern California customer drills cathodic protection holes for power utility companies. Local drillers in the area were completing one, 500-foot hole per week. Upon purchasing a DRILLMAX® drill rig and completing training they were able to complete one, 500-foot hole in an eight to 10-hour day, increasing cathodic protection drilling production for the utility companies.

DRILLMAX® DM450 provides remarkable power for its compact configuration. NEW rod carousel options accommodate drill pipe preference while it permits performing one-man operation.

Demand for geothermal energy has generated drilling industry growth. For many companies, geothermal drilling business is booming, while others weather fluctuations by diversifying their service lines with a single rig.

In business for more than 40 years, DRILLMAX® focuses on making the driller’s job easier. We"re continually enhancing our line of compact, powerful tophead drive drill rigs for the water well drilling, geothermal drilling, and cathodic protection drilling industries. The latest DRILLMAX® drill rig line includes:

Sturdy drillmast on DM450 water well rig provides power needed for tough water well drilling, geothermal drilling, and cathodic protection drilling with jibs to access both sides of the drill rig.

Bell nipple (#22) is a section of large diameter pipe fitted to the top of the blowout preventers that the flow line attaches to via a side outlet, to allow the drilling mud to flow back to the mud tanks.

Blowout preventers (BOPs) (#23 and #24) are devices installed at the wellhead to prevent fluids and gases from unintentionally escaping from the wellbore. #23 is the annular (often referred to as Hydril named after a manufacturer), and #24 is the pipe rams and blind rams.

Casing head (#27) is a large metal flange welded or screwed onto the top of the conductor pipe (also known as drive-pipe) or the casing and is used to bolt the surface equipment such as the blowout preventers (for well drilling) or the Christmas tree (oil well) (for well production).

Centrifuge (not pictured) is an industrial version of the device that separates fine silt and sand from the drilling fluid. It is typically mounted on top or just off of the mud tanks.

Derrick (#14) is the support structure for the equipment used to lower and raise the drill string into and out of the wellbore. This consists of the sub-structure (structure below the drill floor level) and the mast.

Desander / desilter (not pictured) contains a set of hydrocyclones that separate sand and silt from the drilling fluid. Typically mounted on top of the mud tanks.

Drawworks (#7) is the mechanical section that contains the spool, whose main function is to reel in/out the drill line to raise/lower the traveling block.

Drill bit (#26) is a device attached to the end of the drill string that breaks apart the rock being drilled. It contains jets through which the drilling fluid exits.

Drill floor (#21) is the area on the rig where the tools are located to make the connections of the drill pipe, bottom hole assembly, tools and bit. It is considered the main area where work is performed.

Drill pipe (#16) is a joint of hollow tubing used to connect the surface equipment to the bottom hole assembly (BHA) and acts as a conduit for the drilling fluid. In the diagram, these are stood in the derrick vertically, usually to save time while tripping pipe.

Drill string (#25) is an assembled collection of drill pipe, heavy weight drill pipe, drill collars and any of a whole assortment of tools, connected and run into the wellbore to facilitate the drilling of a well. The collection is referred to singularly as the drill string.

Elevators (not pictured) are hinged devices that is used to latch to the drill pipe or casing to facilitate the lowering or lifting (of pipe or casing) into or out of the wellbore.

Flow line (#28) is large diameter pipe that is attached to the bell nipple and extends to the shale shakers to facilitate the flow of drilling fluid back to the mud tanks.

Goose-neck (#10) is a thick metal elbow connected to the swivel and standpipe that supports the weight of and provides a downward angle for the kelly hose to hang from.

Kelly drive (#19) is a square, hexagonal or octagonal shaped tubing that is inserted through and is an integral part of the rotary table that moves freely vertically while the rotary table turns it.

Kelly hose (#9) is a flexible, high pressure hose that connects the standpipe to the kelly (or more specifically to the gooseneck on the swivel above the kelly) and allows free vertical movement of the kelly, while facilitating the flow of the drilling fluid through the system and down the drill string.

Racking board (#15) is the catwalk along the side of the derrick (usually about 35 or 40 feet above the "floor"). The monkey board is where the derrick man works while "tripping" pipe.

Mud motor (not pictured) is a hydraulically powered device positioned just above the drill bit used to spin the bit independently from the rest of the drill string.

Setback (#17) is a part of the drill floor (#21) where the stands of drill pipe are stood upright. It is typically made of a metal frame structure with large wooden beams situated within it. The wood helps to protect the end of the drill pipe.

Stand (#16) is a section of 2 or 3 joints of drill pipe connected and stood upright in the derrick. When they are pulled out of the hole, instead of laying down each joint of drill pipe, 2 or 3 joints are left connected and stood in the derrick to save time.

Standpipe (#8) is a thick metal tubing, situated vertically along the derrick, that facilitates the flow of drilling fluid and has attached to it and supports one end of the kelly hose.

Vibrating hose (#6) is a flexible, high pressure hose (similar to the kelly hose) that connects the mud pump to the stand pipe. It is called the vibrating hose because it tends to vibrate and shake (sometimes violently) due to its close proximity to the mud pumps.

Substructure type ZT90 with max capacity 202,000 lbs, 101 US ton (900KN) consisting of 6 x telescopic legs, box type, with rotary table base and setback base independent of each other

Draw works: JC18/11 350hp with 1” (26mm) drill line size, complete with band brake and hydromantic brake. equipped with sand line drum for 4000m of 5/8” cable

1 x generator Model: VOLVO 300KW, Voltage 130/400V, Frequency: 50HZ, Generator and MCC are housed in a single house. Lighting fixtures are rated for service in classified areas as per API RP 505 for rig system

Driller’s console panel is furnished with other interface devices such as instrumentation system, hydraulic weight indicator and stand pipe pressure gauges

Mud Pumps: Qty 1 x F-500hp triplex pump c/w liner wash and charge pump, Suction strainer, dampener and pulsation dampener, reset relief valves with integrated bleed and relief valve line. Pump is powered by CAT C-15 540 HP engine and Allison 5610HR Torque Converter/Transmission

11” 3K Annular BOP, 11” 3K Double Ram (2 sets of rams provided), Drilling Spool, BOP Test Pump, (air powered) with hoses and chart recorder. BOP Test Base. BOP Stack Lifting device. Transport Skid. BOP Control Unit. Choke and Kill Manifold 3-1/16” X 3K. 3-1/16” X 3K Manual valves. Non-return Valve on kill line. All high pressure fire proof hydraulic hoses, hand wheels etc.

Elevators, Bails, Manual tongs, Pipe spinner, Casing power tong, Hydraulic unit, Kelly with drive bushings, rotary table bushings, pipe racks, TBG power tong XQ89/3C

Air compressor is driven by the carrier engine; air receiver is mounted in the carrier chassis. All air hard and flexible air lines as well as control valves and quick connect fittings are supplied

MR-8000 mobile drilling rig manufactured in accordance with API 4F standards by Drillmec in 2008 (re-certified & refurbished in December 2019) and it was designed and manufactured for drilling oil, natural gas, underground gas storage and geothermal wells.

Total Mud Tank Capacity: 1344bbl, Trip Tank: 40bbl, Shale Shaker: 2ea x MI-Swaco Mangoose PT, Mud Cleaner: MI-Swaco Mangoose PT, MI-Swaco D-Sander / D-Silter, D-Gasser: Swaco Vaccum D-Gasser Horizontal

Other Auxiliary Equipment: Dog House, Dog House, High Pressure Ground Line, Monkey Board, Mud Tanks & Carrier Walkways, Handrails, Rotary & Mud Pump Discharge Hose, Cable Protectors, Stairs, BOP Skid & Trolley, Driller Panel, Drilling Recorder 8 Pens, Rig & Mud Tanks Lightening System

8613371530291

8613371530291