what does a workover rig do manufacturer

Drilling calls for complex, carefully engineered equipment — and inevitably this equipment can wear down over time and require replacement. That’s where a workover rig comes in. Workovers are among the most expensive and complicated tasks in the drilling industry, so here are a few things you should understand about them.

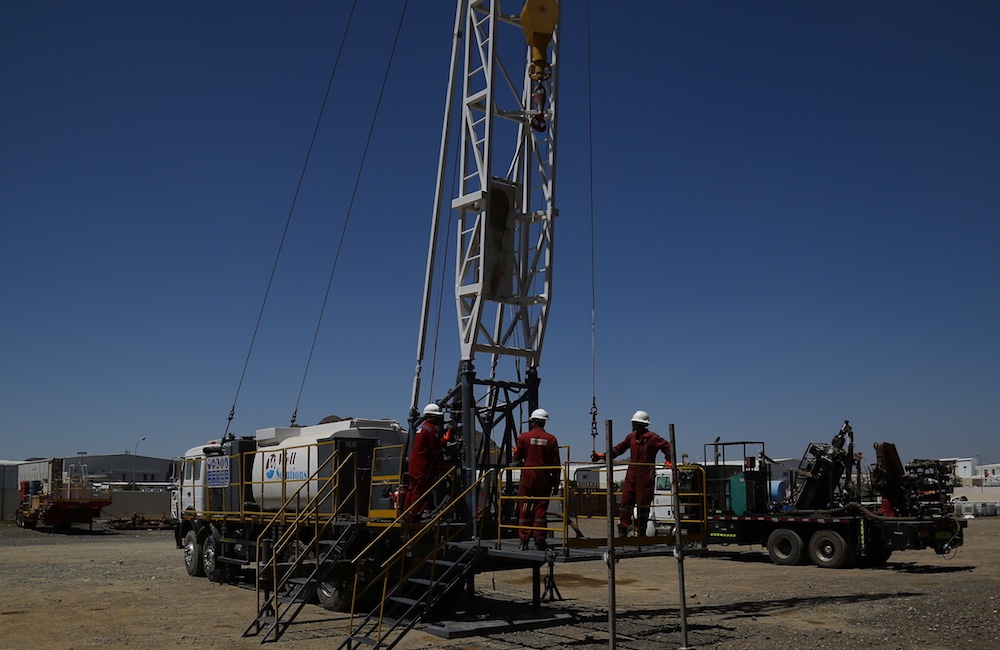

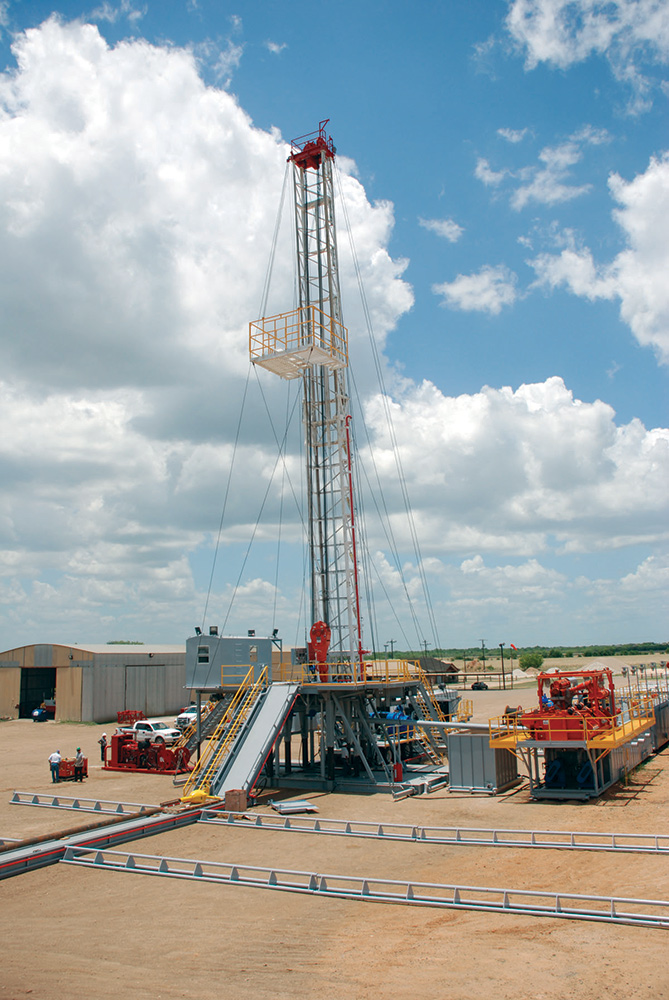

A workover is a complex maintenance task that involves pulling completion hardware out of a well in order to extend the life of the well. A workover rig is a specially designed rig that makes it easier to take out or insert tubing into a well.

To complete a well servicing, the well is first killed. This halts the flow of fluids in the reservoir. The wellhead and flow line will then be removed and the completion hardware will begin to be pulled out of the well using the workover rig. Replacement parts will then be lowered into the hole accordingly.

Because workovers are involved in time-consuming processes, through-tubing workovers might be initiated, which can occur without forcing teams to kill a well and do a full well servicing. This might be considered first before deciding on a full well servicing.

A workover rig is needed when a well is no longer suitable for the drilling job it was originally built for. Maybe the production tubing has incurred damage over time or downhole tubing has stopped functioning correctly. Or perhaps the contents of the reservoir that the tubing is drawing from has changed and requires adjusted tubular components. In any case, the well is unable to perform efficiently and could even compromise the safety of those working on the well. At that point, its components must be replaced and a workover rig must be constructed.

You always want your well to perform to expectations. Katch Kan can help thanks to our zero-spill installation system, which ensures your well servicing operations will proceed safely and efficiently. We offer a wide array of well servicing solutions, which are designed to prevent fluid spills, keep workers safe, lower clean-up costs and reduce operation time.

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

Workover rigs, also called pulling unit rigs, are specialized oil rigs set up for inserting or pulling pipe tubing in and out of wells. Workover crews are called when an oil well has been drilled, is undergoing repair or is being retired, as indicated by Schlumberger.

These crews are relatively small compared to other rig crews and consist of tool pushers, operators or relief operators, derrick men and floormen or roughnecks. The average workover rig salary overall was $65,039 as reported by Simply Hired in 2022. Available workover rig jobs and descriptions can be found on the Rigzone website.

The acting supervisor on a workover rig is called the tool pusher. The main task of a pusher is to hire, fire and supervise contracting work crews. When contractors have an issue on site, the first person they report concerns to is the tool pusher. Pushers need to have an intimate knowledge of how each and every part of a rig works, both individually and as an overall part of the drilling operation as a whole.

If equipment fails or needs to be reordered, the tool pusher talks with suppliers to get the right parts out on site with a minimum of downtime for the rig. The pusher is responsible for the overall safety of a rig. If the tool pusher has any safety concerns, he has the power to halt production until the concern is resolved.

The operator/relief operator is next in order of responsibility to the tool pusher on a workover rig. The main task of an operator is to control the crane and derrick that hauls pipe in and out of the bored well. In smaller crews, the operator is also the one who drives the rig truck. When laying pipe into a well, the operator directs the truck or derrick to the optimum spot next to the bore opening.

The operator then instructs the derrick hands and roughnecks where to place the bore pipe for easy access by the crane or by hand-loading methods. During a well breakdown or repair, the operator directs the crew hands in storage of extracted pipelines. Because the operators work most closely with derrick hands and roughnecks, they are typically responsible for selection and maintenance of their immediate workover rig crew.

In the pulling unit rig crew hierarchy, the derrick hands come after the operator/relief operators. The main responsibility of a derrick hand is everything that is above ground on the rig. During laying operations, derrick hands assist the operators/relief operators in inserting boring into the well. During repair or breakdown, they assist the operator in pulling pipe out of the well and storing it properly.

In between laying, derrick hands have other responsibilities as well, depending on the size of the crews. In smaller crews, Derrick hands also see to the maintenance of the rig-based electric and diesel generators necessary to power rig equipment.

At the bottom of the pulling unit rig crew in terms of seniority is the floorhand or roughneck. The main task of a roughneck is to perform any kind of tasks asked by either the derrick hand or the operator. These tasks can range from assisting with laying new pipe or removal of old tubing, general construction, to moving new equipment, such as generators. Most crew members on a work-about start their career as a floorhand or roughneck before working their way up to more senior positions.

The process of performing major maintenance or remedial treatments on an oil or gas well. In many cases, workover implies the removal and replacement of the production tubing string after the well has been killed and a workover rig has been placed on location. Through-tubing workover operations, using coiled tubing, snubbing or slickline equipment, are routinely conducted to complete treatments or well service activities that avoid a full workover where the tubing is removed. This operation saves considerable time and expense.

If you are excited about the prospect of starting an oil drilling company and hitting oil, hold up. There is a lot of money needed to buy umpteen pieces of equipment before you can even start drilling for oil. Even if you think you have all of the equipment you need to drill your first well, you probably do not have any workover rigs. If you are unfamiliar with what a workover rig is or why you would need one before you start drilling for oil, you will find your questions answered below.

A workover rig is like an abbreviated oil rig. When it is erected, it looks like an oil derrick with its steel tower and smaller base. However, it is called a "workover" rig for three reasons. One, when it is in use, you and your crew will "work over" the oil well with this rig. Two, you and the crew are working over parts of the oil well that are not functioning so well. And three, the work is over on this particular oil well because it is not producing anymore, or not producing enough to be cost-effective if you keep it going. Hence, the work is over, you are working over the rig to fix it or remove it, and you are working over (i.e., working above) the oil well to dismantle it.

Not every well is a deep one, and that is a fact you should accept from the start in the oil business. Sometimes you dig where you think there will be quite the oil collection underground only to find a spot where the oil seems to be passing through but not pooling in the rock. Since you already started the drilling and excavation process, you have to stop. You have to pull up out of the hole, and then you need the workover rig to close the well and prevent flashback from any fires that may start. If you do not have a workover rig for these purposes, a lot of dangerous and potentially lethal events could ensue. Worst of all, you could be sued for anything that happens to anyone if and when you do not remove and close the well securely.

Oil companies that are getting out of the business may sell you one of their workovers. Otherwise, there are plenty of oil company equipment sellers that have new workover rigs for sale, or you could go to sites like workoverrigs.com. Find what fits your budget, and buy that.

Rig means the vessel described in Recital (A) hereto and includes any share or interest therein and her engines, machinery, boats, tackle, outfit, spare gear, fuel, consumable or other stores, belongings and appurtenances whether on board or ashore and whether now owned or hereafter acquired (but excluding therefrom any leased equipment owned by third parties);

Oil well means any well which produces or appears capable of producing a ratio of less than six thousand (6,000) cubic feet of gas to each one (1) barrel of oil on the basis of the initial gas-oil ratio test.

Horizontal well means a well bore drilled laterally at an angle of at least eighty (80) degrees to the vertical or with a horizontal projection exceeding one hundred (100) feet measured from the initial point of penetration into the productive formation through the terminus of the lateral in the same common source of supply.

Associated Facilities means all associated track structures, over and under track structures, supports (including supports for equipment or items associated with the use of the Network), tunnels, bridges, train control systems, signalling systems, communication systems and associated plant, machinery and equipment from time to time but only to the extent that such assets are related to or connected with the Network but does not include any sidings or yards;

Compression Ignition Engine means an internal combustion engine with operating characteristics significantly similar to the theoretical diesel combustion cycle. The regulation of power by controlling fuel supply in lieu of a throttle is indicative of a compression ignition engine.

service well means a well drilled or completed for the purpose of supporting production in an existing field. Wells in this class are drilled for the following specific purposes: gas injection (natural gas, propane, butane or flue gas), water injection, steam injection, air injection, salt water disposal, water supply for injection, observation or injection for combustion.

Development Well means a well drilled inside the established limits of an oil or gas reservoir, or in close proximity to the edge of the reservoir, to the depth of a stratigraphic horizon known to be productive.

Pilot project means an initial short-term method to test or apply an innovation or concept related to the operation, management or design of a local detention facility pursuant to application to, and approval by, the Board.

Manufacturer of standard & mobile rigs & carriers for oilfield applications. Includes well servicing from 14,000 ft. to 22,000 ft., workovers from 10,000 ft. to 16,000 ft. & drilling from 6000 ft. to 10,000 ft. Specifications include brakes range from 28 in. dia. x 8 in. wide to 42 in. dia. x 12 in. wide, barrels from 12 3/4 in. x 38 in. to 18 in. x 43 in., chains from 1 1/4 in. to 1 3/4 in., clutches of 24 in. with single & 2 plate air friction outboards, shafts of 5 in. dia. to 6 1/2 in. dia. & gross weights from 63,200 lbs. to 115,000 lbs. Also includes forged steel, demountable options, mufflers with spark arrestors, dry type air cleaners, transmissions with torque converters, water splash brake cooling & up to 6 axles.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

In order to solve low degree of work over automation, labor-intensive job dangerous, poor working environment issues, Shengji has developed a series of mechanical work over system, including workover automatic system, minor workover automatic system and snubbing operation equipment.

Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity. Shengji, in cooperation with the Shengli Drilling Corporation, have designed an oilfield workover rig automation system.

The system includes double monkey board pipes ranging robot, bolted beam system, machine hand, power catwalk, power elevator, hydraulic chuck, power control and monitoring system. The system uses one-button automated operation. The operation only needs one driller, one wellhead operator and one patrol personnel.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

We like to throw around “blog ideas” over here at Croft to help my fellow blog partner, Amy and I have a new fresh blog every week. We try to keep our readers up to date with both the new and the old. Someone threw out the idea of writing about a workover rig. Still being new to the industry, I snatched this topic up because I simply wanted to learn more about it myself! My main focus for this blog is simply discussing what is a workover rig and why it is important.

First off, maybe you know a workover rig by a different name. They can be called completion wells or pulling units. I just want to try to avoid any confusion! I am going to give Wikipedia’s definition first and then break it down to layman’s terms for those of you who don’t quite understand what the Wiki is trying to say (Like me). According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.” Let’s break down some of that Terminology…

Oil Well Intervention: Occurs during or after the life of an oil or gas well. It changes the state of the well, well geometry, manages production or provides well diagnostics.

Coiled Tubing: A long metal pipe used to carry out operations similar to wirelining. However, it has the ability to pump chemicals through the pipe and push it downhole.

Snubbing: This method is used in more demanding situations when wireline and coiled tubing does not offer the strength and durability needed. Snubbing runs the bottom hole assembly on a pipe string using a hydraulic workover rig.

So basically, the purpose of a workover rig is to replace a well with a fresh completion. This may have to happen due to the well deteriorating or the changing of reservoir conditions. This is performed if a well completion is unsuitable for the job at hand. An example of the well deteriorating is the equipment may have become damaged or corroded such as production tubing, safety valves, electrical pumps, etc. An example of the changing of reservoir conditions maybe if the flow of a well has decreased over time. If this happens, when the well was originally drilled, it was fit for tubing that was big enough for a higher flow of oil and gas. As the flow decreased, smaller tubing is now needed.

For a workover to take place, a well must be killed or in other words, stop the flow of oil or gas. This is an intense procedure for a workover to take place, so they are planned long in advance.

High quality cost-effective diesel drilling onshore large load workover rig,The rig structure is compact and well designed, highly integrated, and optimized to save working space. The power system is a hydraulic+ mechanical type with high comprehensive efficiency. A class II or self-propelled type chassis can be adopted to meet the various requirements of the end-users.

The mast is front-open type, with a single section or double-section structure, hydraulic raising and hydraulic telescoping, or mechanical telescoping.

Band brake or hydraulic disc brake can be applied as the main brake of the drawworks. The water cooling thrust plate pneumatic brake or water brake can be used as an auxiliary brake.

The drill floor is a twin-body telescopic type or a parallelogram structure, both of which are convenient for installation and transportation. The dimension and height of the drill floor can be designed according to the end-user’s requirements.

By connecting with the best workover rigs manufacturers and suppliers you can grow your business and satisfy your clients with top-notch products and services. At ExportHub you’ll find global workover rigs suppliers and manufacturers ready to serve your demands. Regardless of where you are located, you can get your products manufactured easily without setting foot out of your national border. As a leading B2B platform, we highlight the following attributes of the listed manufacturers and suppliers.

Still wondering where to start? Allow us to help you out! Call us at +1-214-306-7737 or fill out a short form on our Contact us page and a representative will get back to you in no time.

Inserting and pulling up pipe tubing from oil wells is a precise and challenging job that not every rig is up for. That’s why you need a mobile workover rig from Dragon to get it done right every time. Our workover rigs are state-of-the-art and ready to tackle even the harshest conditions. A workover rig is perfect for site preparation while a standard mobile oil rig can handle a variety of piping tasks. Need workover rig parts, or service on another mobile rig? Dragon has that covered with our parts selection, too. View all of our workover rigs and other drilling rigs today.

8613371530291

8613371530291