what does a workover rig do factory

We like to throw around “blog ideas” over here at Croft to help my fellow blog partner, Amy and I have a new fresh blog every week. We try to keep our readers up to date with both the new and the old. Someone threw out the idea of writing about a workover rig. Still being new to the industry, I snatched this topic up because I simply wanted to learn more about it myself! My main focus for this blog is simply discussing what is a workover rig and why it is important.

First off, maybe you know a workover rig by a different name. They can be called completion wells or pulling units. I just want to try to avoid any confusion! I am going to give Wikipedia’s definition first and then break it down to layman’s terms for those of you who don’t quite understand what the Wiki is trying to say (Like me). According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.” Let’s break down some of that Terminology…

Oil Well Intervention: Occurs during or after the life of an oil or gas well. It changes the state of the well, well geometry, manages production or provides well diagnostics.

Coiled Tubing: A long metal pipe used to carry out operations similar to wirelining. However, it has the ability to pump chemicals through the pipe and push it downhole.

Snubbing: This method is used in more demanding situations when wireline and coiled tubing does not offer the strength and durability needed. Snubbing runs the bottom hole assembly on a pipe string using a hydraulic workover rig.

So basically, the purpose of a workover rig is to replace a well with a fresh completion. This may have to happen due to the well deteriorating or the changing of reservoir conditions. This is performed if a well completion is unsuitable for the job at hand. An example of the well deteriorating is the equipment may have become damaged or corroded such as production tubing, safety valves, electrical pumps, etc. An example of the changing of reservoir conditions maybe if the flow of a well has decreased over time. If this happens, when the well was originally drilled, it was fit for tubing that was big enough for a higher flow of oil and gas. As the flow decreased, smaller tubing is now needed.

For a workover to take place, a well must be killed or in other words, stop the flow of oil or gas. This is an intense procedure for a workover to take place, so they are planned long in advance.

Rig means the vessel described in Recital (A) hereto and includes any share or interest therein and her engines, machinery, boats, tackle, outfit, spare gear, fuel, consumable or other stores, belongings and appurtenances whether on board or ashore and whether now owned or hereafter acquired (but excluding therefrom any leased equipment owned by third parties);

Oil well means any well which produces or appears capable of producing a ratio of less than six thousand (6,000) cubic feet of gas to each one (1) barrel of oil on the basis of the initial gas-oil ratio test.

Horizontal well means a well bore drilled laterally at an angle of at least eighty (80) degrees to the vertical or with a horizontal projection exceeding one hundred (100) feet measured from the initial point of penetration into the productive formation through the terminus of the lateral in the same common source of supply.

Associated Facilities means all associated track structures, over and under track structures, supports (including supports for equipment or items associated with the use of the Network), tunnels, bridges, train control systems, signalling systems, communication systems and associated plant, machinery and equipment from time to time but only to the extent that such assets are related to or connected with the Network but does not include any sidings or yards;

Compression Ignition Engine means an internal combustion engine with operating characteristics significantly similar to the theoretical diesel combustion cycle. The regulation of power by controlling fuel supply in lieu of a throttle is indicative of a compression ignition engine.

service well means a well drilled or completed for the purpose of supporting production in an existing field. Wells in this class are drilled for the following specific purposes: gas injection (natural gas, propane, butane or flue gas), water injection, steam injection, air injection, salt water disposal, water supply for injection, observation or injection for combustion.

Development Well means a well drilled inside the established limits of an oil or gas reservoir, or in close proximity to the edge of the reservoir, to the depth of a stratigraphic horizon known to be productive.

Pilot project means an initial short-term method to test or apply an innovation or concept related to the operation, management or design of a local detention facility pursuant to application to, and approval by, the Board.

Oil plays a central role in the nation"s economy. Without access to crude oil, it would be impossible to create and transport the consumer goods the public relies on.

Drilling companies use wells to extract oil from deep below the Earth"s surface. It is inevitable that a well will experience some performance problems at some point during its lifetime. When a well stops performing as it should, a workover rig is called to the scene.

The easiest way to explain the role of workover rigs in the oil well industry is to liken these pieces of equipment to a car mechanic. Regardless of what is causing a well to experience production issues, a workover rig is called in to address these performance problems and make the well productive once again.

To truly understand the integral role workover rigs play in the oil well industry, you need to be able to determine the types of problems these rigs can address.

Well performance is affected by a variety of factors. Changes in the oil reservoir the well has tapped in to and deteriorating equipment are among the top aggravating factors that negatively affect oil wells.

A workover rig can replace large tubing to accommodate a slower oil reservoir and pull up any deteriorating equipment to make repairs. These vital functions help oil companies avoid financial losses by ensuring all wells continue to produce oil for as long as possible.

During a wireline, measurement devices are lowered into the oil well to determine the extent of the damage. Coiled tubing can also accommodate measurement devices, but its primary purpose is to deliver chemicals to the well.

Snubbing is a last resort when other techniques have failed. The snubbing process requires that a bottom hole assembly be run via a specialized hydraulic workover rig.

Well intervention is necessary to ensure that each oil well that has been drilled continues to meet production goals. Workover rigs are essential to the diagnosis and repair of wells that have started to malfunction. Invest in a workover rig to service your wells in the future.

If you are excited about the prospect of starting an oil drilling company and hitting oil, hold up. There is a lot of money needed to buy umpteen pieces of equipment before you can even start drilling for oil. Even if you think you have all of the equipment you need to drill your first well, you probably do not have any workover rigs. If you are unfamiliar with what a workover rig is or why you would need one before you start drilling for oil, you will find your questions answered below.

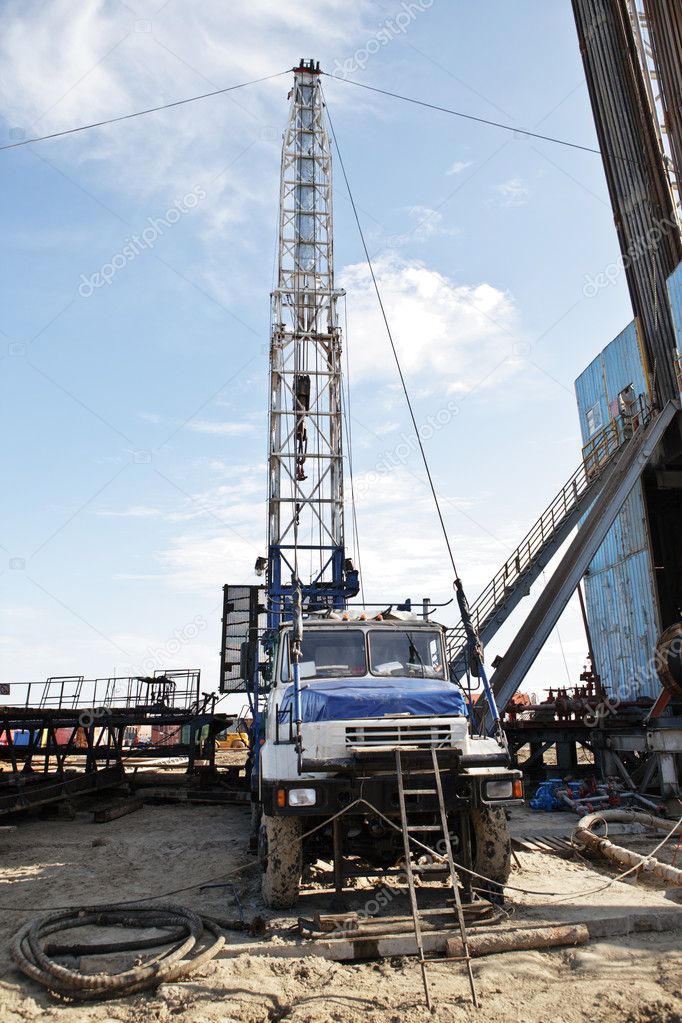

A workover rig is like an abbreviated oil rig. When it is erected, it looks like an oil derrick with its steel tower and smaller base. However, it is called a "workover" rig for three reasons. One, when it is in use, you and your crew will "work over" the oil well with this rig. Two, you and the crew are working over parts of the oil well that are not functioning so well. And three, the work is over on this particular oil well because it is not producing anymore, or not producing enough to be cost-effective if you keep it going. Hence, the work is over, you are working over the rig to fix it or remove it, and you are working over (i.e., working above) the oil well to dismantle it.

Not every well is a deep one, and that is a fact you should accept from the start in the oil business. Sometimes you dig where you think there will be quite the oil collection underground only to find a spot where the oil seems to be passing through but not pooling in the rock. Since you already started the drilling and excavation process, you have to stop. You have to pull up out of the hole, and then you need the workover rig to close the well and prevent flashback from any fires that may start. If you do not have a workover rig for these purposes, a lot of dangerous and potentially lethal events could ensue. Worst of all, you could be sued for anything that happens to anyone if and when you do not remove and close the well securely.

Oil companies that are getting out of the business may sell you one of their workovers. Otherwise, there are plenty of oil company equipment sellers that have new workover rigs for sale, or you could go to sites like workoverrigs.com. Find what fits your budget, and buy that.

Workover rigs, also recognized as pulling units, make up unique petroleum structures for inserting or tearing pipe tubing to and from reservoirs. Workover crews are requested when the oil source has been drilled, is undergoing restoration, or is being retired. Compared with other drilling crews, workover rig teams are relatively tinier.

Workover rigs are used to replace old wells with a new completion. This occurs because of a well deteriorating or any other change in reservoir conditions. For example, tubing, safety valves, pumps, etc. can deteriorate. Worn down parts can be hazardous and unworkable for the current job. Changing reservoir conditions is noted when the flow of the well has decreased over a length of time. This means when it was first drilled, the tubing was suitable for large flows of oil and gas, but now smaller tubing would be necessary.

Tubing can get stuck when crews try to remove them from a well. Workover rigs may be needed to withdraw the stuck pipe. Then flow will be restored and upkeep can continue. Salt bridges are a common cause of stuck pipes. They are made when daily formation cycles keep saltwater in the annulus space. The area retains a saline trace after they wipe the water out. After months of pumping, a heavy layer of residue turns into bridges within the annular space. The salt bridges can slow down or halt production. Sometimes, freshwater is pumped through annular spaces, but it doesn"t entirely prevent salt bridges from forming.

The rigs are controlled within the center with electricity. The workover rigs are sold in single drum form along with double drums. Many use a double telescopic mast and have a wide wheelbase with low, cross-section tires. The double telescopic mast is considered safer than other masts on the market. Manufacturers offer offshore and onshore workover rigs up to 1000 horsepower.

Workover rigs are distinctive petroleum devices for inserting or tearing pipe tubing into and out of reservoirs. Workover teams are sought when the oil supply has been tapped, restored, or decommissioned. Workover rigs are used to change old wells. This typically happens because of well declining. Sometimes when workers attempt to extract them from a well, tubing can get trapped. Then workover rigs are called to remove the stuck pipe. When searching for workover rigs for sale, look for those that fit the criteria set by the American Petroleum Institute. There are many rigs offered at inexpensive rates for both onshore and offshore jobs.

A service rig is a mobile platform loaded with oil industry service equipment that can be driven long distances within the oil fields to service wells.

There are several specialized types of service rigs: the carrier, the pumptruck, the doghouse, a 5-ton equipment truck and several crew vehicles. The rigs usually travel in a convoy, because all of the component rigs are needed for proper oil well servicing. The crew use the equipment on the rigs to provide a variety of services, including completions, work-overs, abandonment"s, well maintenance, high-pressure and critical sour-well work and re-entry preparation.

The Rig, or Carrier, is a mobile truck with a derrick and a cab for one driver. The carrier can also be trailer-mounted, enabling it to be towed behind a prime mover. Traditionally, trailer-mounted service rigs are much larger and heavier, with greater capacities.

The Pumptruck has a large tank on the rear, and is used to pump fluid and store fluid from the well during different stages of the maintenance process. It is assembled using a series of pipes and operated with valves and pressure systems.

The Doghouse is a portable building used by the crew members to suit up, eat lunch, and assemble during meetings and breaks. It holds the communications and emergency equipment, a washroom, and has a storage space for inventory and tools. This space is referred to as the Light Plant, and in some occasion"s a tool room, the Light Plant contains a diesel generator to provide electricity for lights and equipment.

The 5 Ton is a large truck which carries tools and other equipment, including the B.O.P."s(blow-out preventer), tongs, a rod table, and extra pipe. It also pulls the doghouse from one location to the next.

Each service rig has a manager called a Toolpush, who orders and monitors supplies, monitors and records the progress of each job and schedules the crew"s time. At times there is also a representative present from the oil company whose wells are being serviced.

Service rig crew"s are often under the supervision of a Consultant who is contracted through said oil company and reviews safety and job tasks with the crew, and organizes the process of moving from each well and ensuring the

Drilling a well is one the most exciting and challenging experiences for anyone involved in the oil industry. But, what happens after you drill and complete a well? You don"t just drill and leave the well alone producing oil until it dries out. Think of it like assembling a car, once someone buys the car they don"t just drive it until it"s broken, instead, every time the owner feels something is wrong with the car he takes it to the dealer to check it out. Thereby, just like a car, an oil well needs Maintenance.

Here"s when workover operations come into play. Every time a well has production problems it needs to be repaired. In this article you"re going to be reading about one particular problem in a well and what we did to solve it. If you"re a young professional in the oil industry and never had the chance to be present in a workover operation, I invite you to go through these lines, hoping they help you knowing a little more about this amazing and unpredictable world.

A few years ago, my rig team received information about the next oil well that we would be repairing. Just by reading the well"s name we immediately inferred that we were going to deal with a really old well. The job program indicated us that this well had a high water cut, this means that most of the production of the well was formation water. We needed to isolate the water producing sandstone in order to leave an upper sandstone open to production.

The well was originally drilled in the 70´s by a split drilling rig, this type of rig was used in the past for operations on shallow waters and it was not like a typical cantilever drilling barge. In this rig, the derrick was separated from the barge and it had to be armed above the foundation of the well. This type of foundation is known as Light Rig Mover foundation and it is formed by four heads with two piles each and a square metal frame 24’ x 24’ approximately. With this particular well, we recall that old saying that states: "Don’t judge a book just by its cover". Let’s move on to the seven steps

The first thing we do before working on any well is an inspection of the location before the rig move, this is very important to determine wheatear the barge can fit in the well location or not. During this well’s inspection we could see that both the well foundation and the wellhead were not in the best condition, but this was fixable and the job could be done, though it would be a real challenge. Finally, the rig was moved and positioned on the well location.

Before removing the christmas tree in order to install the BOPs, we had to secure the tubing by settling a safety valve in the upper landing nipple. In most cases we secure the well by installing a check valve in the tubing hanger, but this well did not have an extended neck hanger, instead it had a wrap around tubing hanger which made the use of slickline tools necessary. We always make a calibration trip before running anything else into a well. In this particular case the tubing string originally installed in the well was 2-7/8”, 6.5 lb/ft from surface to 11413’, and 2-3/8”, 4.7 lb/ft from 11413’ to the entry guide at 11706’. With a Baker Hughes FH Hydraulic packer at 11415’ and an Evolution R3 retrievable packer at 11697’, five gas lift mandrels, a 1.875” landing nipple at 11704’, a 2.313” landing nipple at 214’ and no sliding sleeves. We first ran a 1-27/32” gauge cutter to the bottom of the hole at 12211’ and then a 2-9/32” gauge cutter to 11413’ locating the crossover 2-7/8” x 2-3/8”. Then, before running the valve we ran a slickline tubing scratcher in order to guarantee a good setting of it. So, after a few trips, we installed the valve at 214’ and let the well secured to install de BOP and continue the operations with proper safety.

And then, the surprise began. Usually in a single packer completion we have to pull the string for several hours in order to release it, or in some cases, we must make an internal cut in the tubing with wireline tools, especially in old wells. But every time I have been involved so far in these cases with two packers, it was always necessary to make as many wireline internal cuts, as there are packers in the well completion: One cut above the upper packer and one between packers. Lucky for us, not this time; after only 25 klb of overpull both packers were released and we were able to retrieve the entire well completion joint by joint in a single tubing trip.

This saved us from all the fishing jobs, which in this type of wells is at least two fishing trips (without any complications) and perhaps a few milling trips if the tubing is somehow damaged by the wireline cutters, and this represent lots of saved rig time for the well. In general, the fishing operations take from 40% to 50% of the time needed to finish a workover job. The only thing we had to do was a quick calibration trip to 11945’ with a 4-5/8” tapered mill to guarantee a good operation in our next step.

Once we retrieve an old completion string from a well, we usually run a mechanical packer to make a casing integrity test, in this case we ran an Evolution R3 packer for 5-1/2”, 17-20 lbs/ft casing (not the same one that was retrieve from the original completion, obviously), down to 11645’, 20’ above the first perforated intervals. After successfully testing the casing, the following step was a wireline job.

The plan for this particular well was to isolate a sand formation with a high water cut, in order to start draining another sands from the same formation. This had to be accomplished by setting a bridge plug at 11930’ and also, placing 12’ of cement slurry above the plug with a dump bailer. As in the slickline jobs, we run a calibration trip before doing any wireline job, even though we had run a tapered mill before. After running a 4-9/32” gauge ring and a 3-1/8” junk basket, we ran the bridge plug with the wireline and activated the setting tool, letting the plug installed at 11930’. A final wireline trip was made in order to place the cement slurry above the plug with a Dump Bailer, this is a tool consisting of one or several cylindrical metal containers that are run in a wellbore to place small volumes of cement slurry or similar material. At the top of tool there is a hole through which the containers are filled with the material, the bottom of the tool is covered with a cap that will be removed with a small explosive charge once the tool is in position. In this well we coupled four containers into the well, placing the charge at the bottom and leaving the upper hole just above the rotary table. Then, we proceed to mix the cement slurry and filled the dump bailer, running it into the wellbore and detonating the charge at 11915’ leaving a volume of slurry enough to cover 12’ of a 5-1/2”, 20 lbs/ft casing.

As I stated before, this was a really old well, and the wellhead was pretty damaged and rusty. Hence, the next step for us was to replace the tubing head. This step required to remove the BOP, so it was necessary to run a mechanical packer along with an inside blowout preventer, setting the packer at 90’ to prevent the well from flowing uncontrollably while we worked on the wellhead. The tubing head size was 11” (bottom) x 7-1/16” (top), 5000 psi, and it was replaced with a new one with the same size and working pressure. However, this was not just removing one piece of wellhead and installing the new one, because once we started disassembling the bottom flange (11”, 5000 psi) we found that many of the bolts and nuts were highly corroded and it was impossible to remove them with the wrenches. Only 6 out of 12 bolts were removed with the wrenches, for the rest of them, we had to use a blowtorch equipment to cut and retrieve them. Finally, the new tubing head was in place, the BOP were reinstalled and we were ready for the final step of the job.

The last step of this workover job, after solving the bottom hole problem and replacing the wellhead, was to run the well completion. The equipment was ran down to 11402’ and it was composed by 368 joints of 2-7/8” 6.5 lbs/ft tubing, five gas lift mandrels, two 2.313” landing nipples, and a Weatherford Stratobar hydraulic packer, the completion was hanged in the new tubing head installed and then we performed the final slickline jobs to test the tubing string and set the hydraulic packer without any major complications.

This sums up our entire work on this well, leaving it ready for production. Yes, after more than 40 years of being originally drilled, this well is still capable of producing a very significant amount of crude oil. That’s how important workover operations are, if a well has the proper maintenance, its commercial life is longer and more productive. Besides, a workover operation is not as expensive as the drilling of a new well.

I think is only fair to say that each one of the steps I described include several activities that might need a little more detailed explanation to be completely understood, but it would be extending my writing too much. I also think it’s important to let readers know the reason why I decided to write about this particular well; if you look back in step 3, I said that the fishing activities take 40-50 % of the rig time needed to finish a workover job, the special thing about this well is that we didn’t required fishing activities since the original well completion was entirely retrieved just by pulling it out of the well. So, this is one of those cases when you get very, very lucky, and after a not quite good first impression we ended up successfully completing a job estimated to be done in 20 days in only 12.5 days, congrats for us!

If you"re used to hauling lots of materials regularly when you are digging a well or doing industrial work, it"s important that you get the help of contractors that can assist you. There are a lot of contractors that can sell or rent workover rigs when you need to use them. It"s crucial that you research these rigs and how they can help you out so that you are able to secure the right model and use it effectively.

Since workover rigs are some of the most commonly rented and sold pieces of heavy equipment, you should learn all the details about how they can help you. These rigs are useful at drilling work, such as digging wells, extracting oil, and installing foundations. When you have a rig that facilitates this work, you will be better able to manage your workflow in a way that is helpful to you.

These rigs are helpful for stopping and starting the flow of fluids and gases when necessary and can make your operation a lot safer. You should use the best rig for your needs, from the brand of the rig to the size of the rig. The more you know about your project up front, the easier it"ll be to find the best rig.

In order to get your hands on a workover rig, consider purchasing or renting one from a company near you. When speaking to these companies, always have them provide their license. You will also need to do your own independent research and find some references from others who have used their rigs.

Choose between renting or buying your workover rig. This decision will depend on how often you need to use it and what sort of equity and assets your company holds. Be sure that you also know who will be operating it. If you"re putting your staff in charge of operation or hiring independent contractors, always make sure that OSHA standards are kept every time that the rig is used.

Drawworks – The drawworks consist of a revolving drum around which the drilling line or work line is spooled or wrapped. It also includes a shaft on which the catheads are mounted

• Hydraulic workover equipment is more portable than conventional equipment and can be set up and torn down easily. This aspect is important in offshore or other remote locations where transportation of heavy equipment is difficult.

• Hydraulic workover equipment is flexible. Lifting capacities can be made high and currently range to 340,000 pounds. It is possible to handle, pull, and run large OD downhole tools of moderate length under pressure. Rotary capabilities have been

Figure 15 shows a typical hydraulic workover rig on a land location. BOP rams are visible below the vertical hydraulic cylinders. Above the cylinders is a work platform on which is

located the operating control console. The hydraulic oil supply tank, pumps, and engine driver are at ground level. Numerous hydraulic hoses connect the assemblage.

The pipe-handling assembly consists of travelling slips, stationary slips, and hydraulic cylinders . The hydraulically-powered slips are used to grip the workstring as it

is pushed into or pulled out of the well. In a snubbing operation where pipe is pushed into the well under pressure, the travelling slips grasp a joint of pipe, and are driven downward

At that point, the stationary slips are closed, holding the pipe in place. The travelling slips are released and lifted to their original position, then closed. When the travelling slips have

This snubbing action is powered by a set of four hydraulic cylinders. These cylinders utilize pressure supplied by hydraulic pumps to drive the pistons housed within each of the

ranging up to 340,000 capacity. The capability for handling larger sizes of pipe makes feasible the retrieval or insertion of well tubing under pressure in addition to concentric

tubing work. This capability is the most recent extension of the hydraulic workover technique. As such, the scope of potential applicability is significantly broadened in both initial completion and workover activities.

The circulating system (pumps, tanks, lines, etc.) is the same as for other workovers with the exception of a one-way check valve installed in the bottom of the workstring or tubing.

Two basic devices are used for sealing the outside diameter of the tubing during work under pressure. These are ram-type blowout preventers and solid rubber element tubing strippers.

Stripper elements are generally considered adequate for control of pressure up to 2,500 – 3,000 psi. These elements are constructed of solid synthetic rubber compounds.

They can stretch as couplings pass so that some downhole tolls can be stripped through them. The useful life of the stripper element depends largely on the external condition of

With three BOP elements in a stack, and with piping to create an equalizing chamber, higher pressure operations are feasible. shows the sequence of operations when entering the hole using the ram BOP stack. The stack operation is summarized below

• After the connection passes the lower rams, the lower rams are closed and pressure is then released for the equalizing chamber between the rams through a vent line.

• The third set of pipe rams is located below the two working sets and is for basic well control. They serve as safety devices by not being subjected to wear in the snubbing process.

One can easily see that many maneuvers are required of an operator in stripping tubing with the use of working-ram-type preventers. In contrast, the simple stripper requires no action

A stripper is also more economical to use than working rams. Working rams arenevertheless useful in many circumstances, and should be included in the BOP stack to

Clearly, the well pressure acting on the cross-sectional area of the plugged pipe will be lifting it upward while gravitational pull on the pipe mass will be acting downward.

In some case, power tongs are used to make up or break out pipe, and are powered by air or hydraulic pressure. When circulating through the workstring or rotating the pipe, power

swivels or power subs are normally made up onto the top joint of pipe. In some cases, a hydraulically powered rotary table is mounted on top of the travelling slip assembly. The

Almost every fishing job presents special problems requiring proper analysis, creative thinking, and the exercise of good judgment to successfully accomplish the objective.

Tools and equipment are lost in the hole for variety of reasons. A very common example is seen during drilling operations, when part of the drill string may get stuck in the hole. In

screens and slotted liners used in gravel-packed completions which need to be retrieved, stuck packers, parted workstring, and tools which inadvertently fall into the wellbore

The costs and inherent risks when fishing make it imperative that the operations and engineering personnel involved communicate freely. Predicted additional cost and risk in

For relatively simple, straight forward fishing jobs such as the recovery of pipe inadvertently dropped or left in the hole, an overshot can be used for fast, inexpensive recovery. For a more complicated job-such as recovery of stuck, cemented, or plasticized pipe, ore recovery of several wireline tools with wireline on top of them – special fishing tools and skills will be required. When cases such as these arise, an experienced fishingtool operator should be used.

The final part of this section deals with workover rig selection criteria. Typical workover operations are listed as keywords in the left-hand margin, and the different factors affecting

conventional rigs are preferred for a number of reasons. For drilling it is often necessary to use a high weight-on-bit in order to achieve reasonable penetration rates. This requires a

larger workstring. High torque requirements are another reason for using larger tubular goods. In many cases where drilling is required, a new downhole completion configuration

Concentric rigs are suitable for some light milling operations, however. In particular, they can be used to mill up very hard sand bridges that cannot be washed through. They are also

used for removing deposits such as paraffin or plastic consolidation materials from inside the tubing string. Of course, they offer the only means for milling and drilling inside

All three categories of rigs (conventional, concentric, and coiled tubing) can be used for squeeze cementing operations, although the first two types perform the vast majority of jobs

Concentric rigs can and do perform a large percentage of routine squeeze cementing operations, especially when an entire set of perforations are to be squeezed. For these applications a balanced-plug technique is used to spot the cement across the interval, then the workstring is pulled above the cement top and squeeze pressure is applied. An example of this procedure, covered in detail i “Remedial Cementing”, is shown in

A fairly recent technique that has proved successful in some areas is the use of a concentric workstring and inflatable packer to squeeze channels in the cement sheath behind the

casing. The workstring and packer are run through the tubing into the casing where the packer is inflated between the two sets of perforations that connect the channel. Then,

cement is pumped down the workstring, through the channel, and back out above the packer. The cost savings over using a conventional rig can be significant.

of where a conventional rig would be used is where holes that can be sealed with cement develop in the production casing above the packer. There may be other times when

concentric techniques are not applicable, such as when a squeeze packer is required to keep pressure off the casing or when cement needs to be milled out of large-diameter casing

The kind of rig used for the recompletion depends on wellbore specifics. If the intended interval after the workover is above an existing retrievable packer then a

If the new completion interval is below the existing perforations, however, the option theoretically exists to recomplete using concentric techniques or a conventional rig.

The decision then is based on such factors as depth, hole angle, casing and tubing size, etc., and their effect on the ability to mill out cement a cement plug to perforate the lower zone.

If the new completion interval is higher than the old interval, yet still below the packer then concentric work usually becomes very attractive. In this case the old perforations can be squeezed and a cement plug left in the casing.

It is a very common practice when completing a wellbore that intersects a number of distinctly different zones to complete from the bottom up. The lowermost zone is produced

The type of workover rig that is required for repair or replacement of downhole equipment depends on what downhole equipment is involved. If the equipment is suspended in the

For other repair/replacement operations, however, a conventional rig usually be required since retrieval of the entire completion string becomes necessary. Examples in this

often with the drilling rig. If performed at some later time in the well’s history, it is necessary to use a conventional workover rig to pull the tubing, run the screen and gravelpack packer, and re-run the completion.

The exception to this is the rare occasion when a gravel-pack is designed for a tubingless completion. In this case a concentric rig can be used to run the small diameter screen.

However, gravel-packing with 1-in. screens is seldom advisable because of operational problems during the pack and also due to poor performance thereafter.

Chemical consolidation treatments have been pumped both through a concentric workstring and bullheaded down the existing completion string. The advantage of using the small 1-in. or 1-1/4-in. workstring for placement is that fluid mixing and contamination problems are minimal due to the small capacity of the workstring. The disadvantages of the concentric

string approach are the cost of the rig and the chance of sticking the pipe in the hole if a leak develops while pumping the consolidation chemicals. In general, however, placement

Stimulation treatments are so varied that each of the general workover categories, bullhead, concentric, and conventional, can be the optimum solution. Each one of these is discussed

• Bullhead – Bullhead methods are often used for injection of small volumes of chemicals such as solvents, surfactants, and small acid jobs. They work best if the treating interval is fairly short, but special fluid diversion techniques can be used to

improve coverage of longer intervals. Large hydraulic and acid fracturing treatments can also be bullheaded if the tubing is fairly large (for low friction pressure) and if the

workstrings and coiled tubing because reciprocation of the workstring through the treating interval improves coverage of the zones by the acid. Coiled tubing is especially useful because it can be reciprocated over long lengths while maintaining

• Conventional – A conventional workover rig is primarily required when a well is to be fractured and the existing completion must first be pulled either because the tubing is

too small to permit high injection rates or because the packer mechanism was not designed to withstand the tensile forces generated during fracture treatments.

The choice depends to a large extent on the size of the casing, the material to be washedout, and the fluids available. In general, reverse circulation is preferred because of the

higher velocities through the tubing which improve solids transport. This in general rulees out the use of coiled tubing because it has no collapse resistance. Concentric strings can

· Increase a declining production or injection rate caused by low reservoir pressure, low reservoir permeability, formation damage, wellbore restrictions, high viscosity oil,

In the life of a well, the producing rate will decline as reservoir pressure declines. To maintain a constant producing rate as reservoir pressure declines, the flowing bottom-hole

For example, with a reservoir pressure of 2000 psi, withdrawal of 400 barrels of fluid per day from a well with a PI of 2 will require a flowing bottom-hole pressure of 1800 psi. If the

reservoir pressure falls to 1000 psi, however, the flowing bottom-hole pressure must now be drawn down to 800 psi to produce 400 barrels per day. This pressure may be too low to

The reservoir drive mechanism has a direct bearing on how long reservoir pressure can provide a high flowing bottom-hole pressure. As shown in Figure 1, water, gas-cap, and

dissolved-gas-drive producing mechanisms each exhibit distinct pressure behavior as the oil in place is produced. Reservoir pressure in dissolved-gas-drive reservoirs drops rapidly and

From a workover standpoint, low reservoir pressure presents a difficult situation. Stimulation is less effective than in a high-pressure reservoir because there is less pressure differential

to capitalize on the increased permeability. Perforating an additional interval is a temporary measure, at best, and may complicate future workovers. Installation of artificial lift

Once the fluids near the wellbore are produced, productivity in a reservoir of low natural permeability declines rapidly. Wells completed in very low permeability formations are

Unless formation damage is also present, matrix acidizing is not applicable in this type of stimulation. A large-volume hydraulic fracturing treatment, designed to yield high conductivity and maximum drainage area, is usually the most effective approach.

In a reservoir which contains low-gravity crude, productivity may decrease as reservoir pressure declines and liberates the gas dissolved in the oil. To facilitate production, oil mobility near the wellbore and in the drainage area should be maximized.

Oil mobility can be increased by heating the reservoir with steam injection or other thermal processes. Heat reduces oil viscosity and thus stimulates production

Water production problems can originate from the reservoir itself or from other sources such as casing leaks and primary cement failures. Water production is costly from both lifting and disposal standpoints. However, recovery from water-drive reservoirs requires a large influx of water into the reservoir, which may eventually necessitate producing considerable quantities of water from the reservoir before the economic limit for oil recovery is reached.

water-oil contact as a reservoir is depleted. Water encroachment is a normal occurrence in water-drive reservoirs as the aquifer moves into the oil zone to replace withdrawals. Excessive water production in this instance can usually be controlled by

create abnormally low-pressure areas around the wells. If such wells are located low on the structure and near the water level, water will tend to be drawn up across the bedding planes and into the well as a “water cone” or be drawn up along the

Gas production form an oil well result from a gas originally dissolved in the reservoir oil or from free gas that has segregated and become trapped above the oil as a gas cap. Free gas

In the dissolved-gas-drive reservoir, gas originally in the oil is liberated from solution as oil production begins and reservoir pressure declines. Further liberation and expansion of solution gas is requirement for primary oil recovery from a reservoir

of this type. As oil withdrawals continue, the increase in gas saturation permits gas to be produced along with the oil. As production proceeds, the relative permeability of the

gas production in this instance is usually not a well problem but a problem of the reservoir as a whole. Workovers are not generally successful at reducing the gas-oilratio for these wells.

Casing leaks result in both influx of undesirable gas or water into the wellbore and the uncontrolled loss of reservoir fluids to other zones. Since casing leaks are usually associated with corrosion, the permeability of their development increases

When performing a workover to repair a mechanical failure, the engineer should study the well files to determine if other problems exist, which can be repaired at the same time.

· Collapsed casing during operations in which high pressures are applied through theperforations below a packer (squeeze cementing, hydraulic fracturing).

A detailed cost survey will usually reveal that auxiliary rig tools and equipment cost approximately as much as the rental rate of the basic workover rig. Thus, as much attention should be given to the choice of auxiliary equipment as is given to the choice of workover technique and rig rate.

Contractors vary widely with respect to the tools and equipment furnished with the rig. An inventory of the equipment provided with a rig will make comparisons of hourly rig rates more meaningful. In addition, use of an inventory will ensure that all necessary equipment is on-hand and extra equipment is not ordered.

However, the equipment provided may not be rate to handle a potential problem on the well to be reworked. In addition, the age and testing history of these preventers should

Some rigs include a swab line, which can reduce the cost of completion operations, if the rig is intentionally kept in place until the zone is evaluated. However, using a rig-provided swab line can be a disadvantage if using it means that the rig is

kept in place at workover-rig rates when it could be replaced by a lower-cost swabbing unit. In addition, keep in mind that swabbing is a specialized operation. The workover

cost of units rented from service companies. However, in some cases, the rig pumps may not have sufficient capacity and pressure rating to perform the necessaryoperations.

Workover rigs sometimes include tankage. The amount of tankage needed depends on the quantity of circulating and treating fluids needed for workover operations. The quantity of fluid which must be premixed and on-hand for well control

crews to operate for longer periods of time without fatigue. Proper utilization of this equipment can double the speed of tripping operations and thus save rig time.

In any operation, safety of the personnel is the most important factor. Every employee has the responsibility to properly use equipment, to maintain it in good condition, to observe the established working rules at all times, and to practice the

In addition, company personnel at the rig site should be sure that the rig and service company personnel are aware of and observe the established safety rules. This can be facilitated by holding pre-job meetings to inform all on-site personnel of safety hazards, safety equipment location and use, and established safety rules.

Rigs are often chosen on the strength and capability of the equipment. In practice, personnel and supervision on a particular rig are often of equal importance to the equipment brought to the rig site. The number of men in the rig crew often dictates

The relief schedule of a contractor is also important. Contractors who work men for longer periods of time without providing relief penalize the operator with lower efficiency during the latter part of the tour of duty.

Associated with this concept are the employment practices of a contractor during slack periods. Some contractors maintain key supervisors on a full-time basis but pay rig crews only when work is available. This can result in rig crews with low experience levels.

additional cost to the workover operation, enough back-up equipment should be on hand to plan for contingencies. When planning the workover, consider what could go wrong

After assessing the problem and reviewing alternative techniques, the engineer should evaluate the best alternative techniques with respect to economics, limitations and

present completion interval or in possible new completion intervals? If well stimulation is contemplated, would successful stimulation increase recovery?

What is the direct payout, i.e., the length of time required for the total cash outlay to be recovered through the new cash inflow generated by the project?

– If the workover is postponed, what would the cost be? Would impending additional recovery programs render workover of this well more attractive in the future?

What is the risk factor? The degree of risk should be weighed against anticipated gain from a successful job. The degree of risk should be assessed through past experiences in areas with similar type of work or in the same or comparable

As discussed earlier in this Chapter (Subject 19.4), the choice of workover technique is sometimes limited by the capabilities and limitations of the workover rig units. For example, treatment operations, such as remedial cementing, matrix acidizing, and corrosion treatments, sometimes require that the treatment fluid selectively placed into a single zone or portion of a zone. While wireline and concentric techniques have some flexibility in this respect, use of a conventional workover rig allows use of the full casing ID and thus a wider range of downhole tools and packers can be used. On offshore locations, the compactness of wireline and concentric units is a premium. In addition, wireline units are the quickest and most efficient, thus reducing rig time, a major

Conventional rigs are slow and cumbersome; however, they are not as limited by factors such as operating depth, high bottom-hole temperatures and pressures, and severe I d restrictions. All of these factors must be considered before selecting a particular workover technique to perform the desired workover operation

If you"re used to hauling lots of materials regularly when you are digging a well or doing industrial work, it"s important that you get the help of contractors that can assist you. There are a lot of contractors that can sell or rent workover rigs when you need to use them. It"s crucial that you research these rigs and how they can help you out so that you are able to secure the right model and use it effectively.

Since workover rigs are some of the most commonly rented and sold pieces of heavy equipment, you should learn all the details about how they can help you. These rigs are useful at drilling work, such as digging wells, extracting oil, and installing foundations. When you have a rig that facilitates this work, you will be better able to manage your workflow in a way that is helpful to you.

These rigs are helpful for stopping and starting the flow of fluids and gases when necessary and can make your operation a lot safer. You should use the best rig for your needs, from the brand of the rig to the size of the rig. The more you know about your project up front, the easier it"ll be to find the best rig.

In order to get your hands on a workover rig, consider purchasing or renting one from a company near you. When speaking to these companies, always have them provide their license. You will also need to do your own independent research and find some references from others who have used their rigs.

Choose between renting or buying your workover rig. This decision will depend on how often you need to use it and what sort of equity and assets your company holds. Be sure that you also know who will be operating it. If you"re putting your staff in charge of operation or hiring independent contractors, always make sure that OSHA standards are kept every time that the rig is used.

When you are interested in getting the absolute best from your industrial and manufacturing work, it"s only right that you also invest in the ideal equipment for the jobs you conduct. For example, if you invest in busy plants or oil fields, you owe it to yourself to invest in workover rigs. In this regard, you will want to do business with professionals that can assist you in not only finding the right equipment but also using it in a way that is productive for every process that you carry out.

When you work with oil rigs or any other kinds of fluid wells, few types of equipment can offer you the level of service that a workover rig can. For instance, workover rigs are helpful because they are versatile in doing whatever kind of well work you need. These rigs are helpful because they can be used for snubbing, tubing and any other kind of work. Gas and oil work is invasive, and workover rigs extract fluids from the ground in a way that is accurate and useful. Whether you are looking to restore a well perform a simple assessment, having access to this equipment can be just what you need.

Next, you will need to do your best to shop for a workover rig that will help you with any kind of process you are conducting. Whether you are looking to purchase or rent one of these machines, research the manufacturer first and ensure that they produce nothing but the best machinery for your rig maintenance. Look into the service that will give you flexibility and longevity, whether you decide to purchase a workover rig or if you would rather spring for a rental.

Look into purchasing or renting a rig that has OEM parts included so that you can get the most useful service out of it. What"s more, you also owe it to yourself to maintain your workover rigs and use them properly, in order to keep your facility at its best and to extract the most value from the machinery as a whole.

Take the time to consider the points presented and find a company that can help you out. You can learn more by visiting a website like workoverrigs.com.

High quality cost-effective diesel drilling onshore large load workover rig,The rig structure is compact and well designed, highly integrated, and optimized to save working space. The power system is a hydraulic+ mechanical type with high comprehensive efficiency. A class II or self-propelled type chassis can be adopted to meet the various requirements of the end-users.

The mast is front-open type, with a single section or double-section structure, hydraulic raising and hydraulic telescoping, or mechanical telescoping.

Band brake or hydraulic disc brake can be applied as the main brake of the drawworks. The water cooling thrust plate pneumatic brake or water brake can be used as an auxiliary brake.

The drill floor is a twin-body telescopic type or a parallelogram structure, both of which are convenient for installation and transportation. The dimension and height of the drill floor can be designed according to the end-user’s requirements.

Workover rigs, also called pulling unit rigs, are specialized oil rigs set up for inserting or pulling pipe tubing in and out of wells. Workover crews are called when an oil well has been drilled, is undergoing repair or is being retired, as indicated by Schlumberger.

These crews are relatively small compared to other rig crews and consist of tool pushers, operators or relief operators, derrick men and floormen or roughnecks. The average workover rig salary overall was $65,039 as reported by Simply Hired in 2022. Available workover rig jobs and descriptions can be found on the Rigzone website.

The acting supervisor on a workover rig is called the tool pusher. The main task of a pusher is to hire, fire and supervise contracting work crews. When contractors have an issue on site, the first person they report concerns to is the tool pusher. Pushers need to have an intimate knowledge of how each and every part of a rig works, both individually and as an overall part of the drilling operation as a whole.

If equipment fails or needs to be reordered, the tool pusher talks with suppliers to get the right parts out on site with a minimum of downtime for the rig. The pusher is responsible for the overall safety of a rig. If the tool pusher has any safety concerns, he has the power to halt production until the concern is resolved.

The operator/relief operator is next in order of responsibility to the tool pusher on a workover rig. The main task of an operator is to control the crane and derrick that hauls pipe in and out of the bored well. In smaller crews, the operator is also the one who drives the rig truck. When laying pipe into a well, the operator directs the truck or derrick to the optimum spot next to the bore opening.

The operator then instructs the derrick hands and roughnecks where to place the bore pipe for easy access by the crane or by hand-loading methods. During a well breakdown or repair, the operator directs the crew hands in storage of extracted pipelines. Because the operators work most closely with derrick hands and roughnecks, they are typically responsible for selection and maintenance of their immediate workover rig crew.

In the pulling unit rig crew hierarchy, the derrick hands come after the operator/relief operators. The main responsibility of a derrick hand is everything that is above ground on the rig. During laying operations, derrick hands assist the operators/relief operators in inserting boring into the well. During repair or breakdown, they assist the operator in pulling pipe out of the well and storing it properly.

In between laying, derrick hands have other responsibilities as well, depending on the size of the crews. In smaller crews, Derrick hands also see to the maintenance of the rig-based electric and diesel generators necessary to power rig equipment.

At the bottom of the pulling unit rig crew in terms of seniority is the floorhand or roughneck. The main task of a roughneck is to perform any kind of tasks asked by either the derrick hand or the operator. These tasks can range from assisting with laying new pipe or removal of old tubing, general construction, to moving new equipment, such as generators. Most crew members on a work-about start their career as a floorhand or roughneck before working their way up to more senior positions.

In order to solve low degree of work over automation, labor-intensive job dangerous, poor working environment issues, Shengji has developed a series of mechanical work over system, including workover automatic system, minor workover automatic system and snubbing operation equipment.

Oil well workover is a high-tech, high-risk work. The conventional oilfield workover rig has problems such complicated operating procedures and high labor intensity. Shengji, in cooperation with the Shengli Drilling Corporation, have designed an oilfield workover rig automation system.

The system includes double monkey board pipes ranging robot, bolted beam system, machine hand, power catwalk, power elevator, hydraulic chuck, power control and monitoring system. The system uses one-button automated operation. The operation only needs one driller, one wellhead operator and one patrol personnel.

The oilfield automatic workover rig has a high degree of automation adopting modular integration and advanced robot closed-loop control technology. It functions as self-diagnosis, leakage and short circuit protection and fault alarming, etc. It has remote monitoring capability.

The automatic workover rig greatly increases the automation of workover operations, reduces the number of operators, decreases workers’ labor intensity. The technology is advanced, safe and reliable.

8613371530291

8613371530291