what does a workover rig do in stock

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

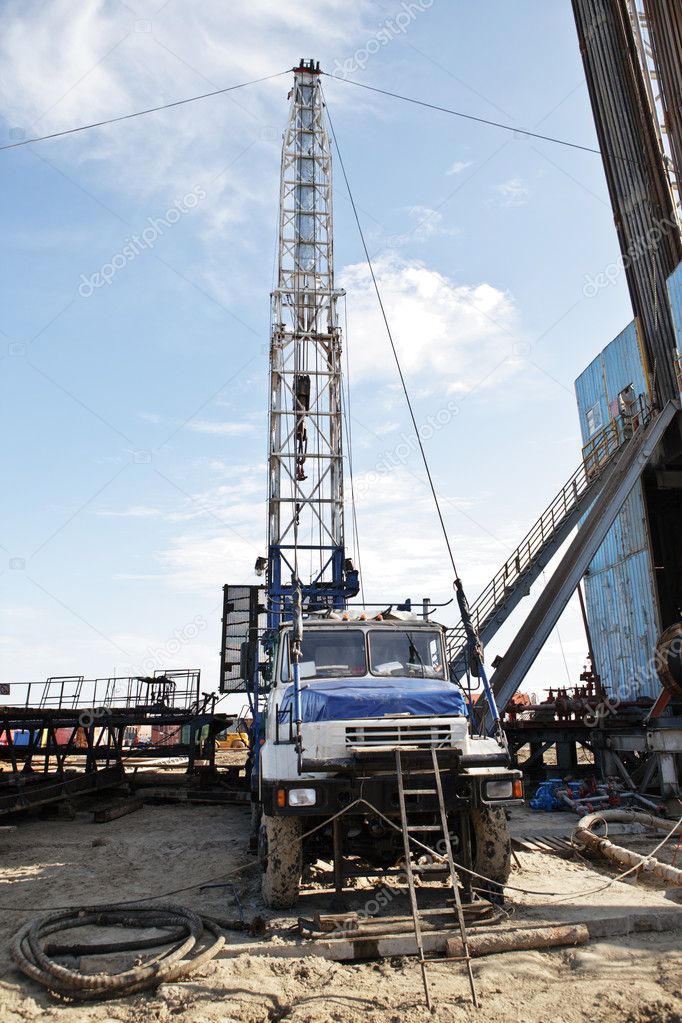

We like to throw around “blog ideas” over here at Croft to help my fellow blog partner, Amy and I have a new fresh blog every week. We try to keep our readers up to date with both the new and the old. Someone threw out the idea of writing about a workover rig. Still being new to the industry, I snatched this topic up because I simply wanted to learn more about it myself! My main focus for this blog is simply discussing what is a workover rig and why it is important.

First off, maybe you know a workover rig by a different name. They can be called completion wells or pulling units. I just want to try to avoid any confusion! I am going to give Wikipedia’s definition first and then break it down to layman’s terms for those of you who don’t quite understand what the Wiki is trying to say (Like me). According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.” Let’s break down some of that Terminology…

Oil Well Intervention: Occurs during or after the life of an oil or gas well. It changes the state of the well, well geometry, manages production or provides well diagnostics.

Coiled Tubing: A long metal pipe used to carry out operations similar to wirelining. However, it has the ability to pump chemicals through the pipe and push it downhole.

Snubbing: This method is used in more demanding situations when wireline and coiled tubing does not offer the strength and durability needed. Snubbing runs the bottom hole assembly on a pipe string using a hydraulic workover rig.

So basically, the purpose of a workover rig is to replace a well with a fresh completion. This may have to happen due to the well deteriorating or the changing of reservoir conditions. This is performed if a well completion is unsuitable for the job at hand. An example of the well deteriorating is the equipment may have become damaged or corroded such as production tubing, safety valves, electrical pumps, etc. An example of the changing of reservoir conditions maybe if the flow of a well has decreased over time. If this happens, when the well was originally drilled, it was fit for tubing that was big enough for a higher flow of oil and gas. As the flow decreased, smaller tubing is now needed.

For a workover to take place, a well must be killed or in other words, stop the flow of oil or gas. This is an intense procedure for a workover to take place, so they are planned long in advance.

The process of performing major maintenance or remedial treatments on an oil or gas well. In many cases, workover implies the removal and replacement of the production tubing string after the well has been killed and a workover rig has been placed on location. Through-tubing workover operations, using coiled tubing, snubbing or slickline equipment, are routinely conducted to complete treatments or well service activities that avoid a full workover where the tubing is removed. This operation saves considerable time and expense.

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

Rig means the vessel described in Recital (A) hereto and includes any share or interest therein and her engines, machinery, boats, tackle, outfit, spare gear, fuel, consumable or other stores, belongings and appurtenances whether on board or ashore and whether now owned or hereafter acquired (but excluding therefrom any leased equipment owned by third parties);

Oil well means any well which produces or appears capable of producing a ratio of less than six thousand (6,000) cubic feet of gas to each one (1) barrel of oil on the basis of the initial gas-oil ratio test.

Horizontal well means a well bore drilled laterally at an angle of at least eighty (80) degrees to the vertical or with a horizontal projection exceeding one hundred (100) feet measured from the initial point of penetration into the productive formation through the terminus of the lateral in the same common source of supply.

Associated Facilities means all associated track structures, over and under track structures, supports (including supports for equipment or items associated with the use of the Network), tunnels, bridges, train control systems, signalling systems, communication systems and associated plant, machinery and equipment from time to time but only to the extent that such assets are related to or connected with the Network but does not include any sidings or yards;

Compression Ignition Engine means an internal combustion engine with operating characteristics significantly similar to the theoretical diesel combustion cycle. The regulation of power by controlling fuel supply in lieu of a throttle is indicative of a compression ignition engine.

service well means a well drilled or completed for the purpose of supporting production in an existing field. Wells in this class are drilled for the following specific purposes: gas injection (natural gas, propane, butane or flue gas), water injection, steam injection, air injection, salt water disposal, water supply for injection, observation or injection for combustion.

Development Well means a well drilled inside the established limits of an oil or gas reservoir, or in close proximity to the edge of the reservoir, to the depth of a stratigraphic horizon known to be productive.

Pilot project means an initial short-term method to test or apply an innovation or concept related to the operation, management or design of a local detention facility pursuant to application to, and approval by, the Board.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Take the worry and hassle out of your eyewash stations. Keep your eyewash station ANSI-compliant with Eagle Safety’s workover rig eyewash station inspection. Ensure that your eyewash station is properly cleaned and serviced with the knowledge and expertise of our dedicated service professionals.

Eagle Safety’s workover rig technician will ensure your SCBA’s are cleaned, inspected, and properly charged. SCBA units are inspected to ensure valves, regulators, harnesses, and face masks are all in good operating condition and are clean and ready for use at each workover rig location.

Cylinders are inspected to ensure they are within hydro test date, properly charged, and free from damage and | or corrosion. When necessary, repairs are attended accordingly, as well as cylinder hydro testing and recharge.

A significant advantage of our SCBA inspection and maintenance service is that our equipment is mobile. With our mobile recharging van, we can complete all recharge services on-site which mitigate the need to remove the SCBA’s from the workover rig location. This ensures complete respiratory protection during the inspection process in addition to not having to provide leave behind units. Our preventative maintenance (PM) program can ensure you are compliant and ready for any emergency.

Eagle Safety’s workover rig technician will ensure your portable H2S monitor is bump tested and working properly. The use of portable gas detection devices helps ensure a workplace free from recognized hazards by providing employees working in potentially harmful environments the means to monitor their air quality. Harmful environments may include those with high levels of toxic or combustible gases or oxygen-deficient or enriched air. Many of these conditions cannot be detected by smell or sight and therefore require instrumental monitoring to view their levels.

A bump test, also knows as a functional test should be performed periodically. Most oil & gas operators require them monthly. This procedure tests the alarms and sensors of a gas detector to be sure they are functional. The test exposes the detector to a know concentration of gases that exceed the lowest alarm set-point for the sensor. The bump test verifies the sensor and alarm functionality, but not the accuracy of the instrument. Our bump testing program can ensure you are compliant and ready for any respiratory toxic gas emergency.

Eagle Safety’s workover rig technician will ensure your fixed H2S monitor is calibrated and working properly. Calibration is defined by OSHA bulletin SHIB 09-30-2013 as ‘an instrument’s measuring accuracy relative to a know concentration of gas. Direct reading portable gas monitors compare the sensor’s response to a know concentration of the test gas’. The bulletin stresses that direct-reading portable gas monitors that are properly calibrated can minimize the risk of injury, illness, or death from respiratory hazards such as oxygen deficiency or combustible or toxic gases.

An instrument’s sensors will degrade over time and repeated use. The calibration process allows the instrument the opportunity to self-correct and to reflect the set level of sensor sensitivity. Once a sensor is no longer able to accurately read set values, it has reached the end of its service life and will need to be replaced. Also, any time the detector is dropped or damaged it should be recalibrated. Our monitor calibration and corrective maintenance program can ensure you are compliant and ready for any respiratory toxic gas emergency.

In a crucial situation such as COVID-19 exposure, you need professionals who know how to properly sanitize, disinfect, and protect your workover rig location. Eagle Safety understands the delicate nature of managing a decontamination project when a work location is exposed and will work with you to make sure all aspects of your project are handled with the utmost professionalism.

If your workover rig location has a confirmed or suspected case of COVID-19 coronavirus, Eagle Safety has established protocols to provide the most effective sanitation available. In addition, we have a clear project communication plan to keep all stakeholders updated each step of the way. We understand that often the impact of exposure to a virus such as COVID-19 goes beyond the workover rig location itself and affects the morale of personnel, customers, residents, students, and even the general public. Having an effective decontamination plan completed by leading experts in the field of clean up and remediation is critical.

Although many companies thoroughly ‘clean’ the worksites, they rarely effectively disinfect them. Viruses and bacteria are thought to spread mainly from person-to-person. However, what is often overlooked is the possibility of contracting it through contact with a contaminated surface. When someone touches a surface or object contaminated with the pathogen that causes COVID-19 and then touches their own eyes, nose, or mouth, they may expose themselves to it. The virus can be detectable on surfaces like plastic and stainless steel for two to three days, making the spread even more likely. Therefore, virus prevention through disinfection is such a vital part of preparing your business to open its doors back up to the public.

Eagle Safety uses disinfectant foggers in both our sanitation and protection services. There are several reasons this is a better application method over standard pump sprayers other companies typically use. First, foggers are faster than standard pump sprayers. A trained technician can disinfect approximately 15,000 square feet using a fogger. On average, this is 10X faster than a standard pump sprayer. Second, the fogging system reduces the particles to a much smaller size which helps provide better coverage and more even distribution of the chemical disinfectant. Lastly, since the particle size is smaller, there may be less of an impact on materials that are sensitive to moisture such as paper or fabric.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Workover rigs are specialized oil rigs utilized in the process of pulling and replacing production to extend the life of the well. They are also called completion rigs or pulling units. They are used in various operations such as handling rod & tubing work and other associated activities to improve the well output and perform plug & abandonment services. Moreover, oil & gas companies have shifted to workover operations to increase their oil & gas output from mature oilfields. Workover rigs are preferred in onshore and offshore applications. They provide high mobility, which allows companies to move them across oilfields. The stability in oil prices is expected to increase the demand for workover rigs due to increase in production activities across the globe. The rise in demand for oil and natural gas is expected to propel the growth of the workover rigs market over the forecast period.

Oil & gas industries are adversely affected due to the coronavirus outbreak. With decrease in oil prices, many companies are facing financial crisis, which is one of the major factors that reduce the demand for workover rigs over the forecast period. Similarly, the worldwide lockdown has suspended travel privileges, thereby decreasing the fuel consumption across the globe. The lockdown has disrupted the supply chain and forced many companies to shut down their power plants to prevent the spread of the virus. This has further reduced the demand for workover rigs across the globe.

The workover rigs market is expected to grow vigorously due to rise in demand for oil and natural gas. Rise in population and rapid urbanization have increased the demand for these fuels. Increase in demand for oil and natural gas is expected to make companies to enhance oil and gas production to meet the demand. Moreover, increase in oil & gas investments and government support for oil & gas E&P activities are anticipated to increase the requirement for intervention and completion services. Rise in well E&P activities, such as intervention and completion, is expected to boost the growth of the workover rigs market during the forecast period. However, uncertainty and fluctuations in crude oil prices are expected to reduce investments in E&P projects, which, in turn, may impact the workover rigs market over the forecast period.

Digitalization of workover rigs is one of the major trends observed. Automated workover rigs provide better safety and higher precision in operations as they use remotely operated robotic equipment. Integrated software system provides precise data to the operators for future decision making. This technological advancement in the workover rigs market is expected to boost the market growth over the forecast period.

Furthermore, huge investment from government and other private companies to drilling activities is also expected to propel the workover rigs market over the forecast period.

By region, the global workover rigs market is segmented into North America, Latin America, Western Europe & Eastern Europe, Asia-Pacific, and the Middle East & Africa. The Middle East & Africa is expected to become the market leader during the forecast period. High investments and increased current production activities contribute to the market growth in the region. North America is also expected to grow, owing to its increased shale field activities,

Key benefits of the report:This study presents the analytical depiction of the workover rigs market along with the current trends and future estimations to determine the imminent investment pockets.

Key Market Players Mesa Southern Well Servicing, Sun Well Service, Inc., Nordic Gulf, Drillmec Drilling Technologies, Automated Rig Technologies Ltd, Moncla Companies, San Antonio International, Eastern Well Services, MBI Energy Services, Superior Energy Services

The Workover Rigs market will remain attractive over the forecast period owing to rising consumption of petroleum products. As a result, the Exploration and Production (E&P) located globally will increase their investment due to increasing demand and positive outlook of the oil and gas market.

The ongoing rise in oil prices can be regarded as new phase for the companies operating in the sector. Adding to this, the participants are looking to attain growth through domestic and international expansion as well as adding new production related services. As Workover Rigs providers play important role in the production operation making them key segment in the reviving upstream sector and hold massive share in the overall spending of the companies.

Moreover, the investment from government as well as private sector in the drilling activities is also expected to rise and surge in shale gas production is expected to fuel the growth of the Workover Rigs market in the coming years. The oversupply of Workover Rigs in the cyclical oil & gas market is one of the major restraint to the market.

However, the industry has recovered successfully from the recent oil price crisis and industry outlook will remain positive in the coming years. One of the major trend in the market will use of environment friendly Workover Rigs. The government authorities are directing energy companies to decrease carbon footprint that will shift the focus of the companies towards use of components that run renewable energy in the coming years.

There are a number of problems that can develop in a producing well that can negatively affect operations, production and ultimately revenue generated, such as failure of mechanical equipment, changes in production characteristics, plugging and increases in injection pressure. After a well goes into production, these events may occur, requiring modification of the well in order to achieve optimal production; this is called well intervention.

Many times, at the slightest hint that there may be a problem with a producing well, well intervention solutions are sought. Should these problems be overlooked, the well may reach zero production over time. The problem within the well and the economics of the proposed solution are weighed in deciding how to solve the production problem.

Many times, remedial work constitutes employing a workover rig to repair the well. Similar to a drilling rig, a workover rig is smaller and requires no mud pumping or pressure-control systems. A workover rig is used to retrieve the sucker rod string, pump or production tubing from the well or run wireline cleaning and repair equipment into the well. It is important to note that with workover activities, production must be stopped and the pressure in the reservoir contained, a process known as �killing� the well.

A cost- and time-effective solution for well intervention operations employs coiled tubing. Instead of removing the tubing from the well, which is how workover rigs fix the problem, coiled tubing is inserted into the tubing against the pressure of the well and during production.

The coiled tubing is a continuous length of steel or composite tubing that is flexible enough to be wound on a large reel for transportation. The coiled tubing unit is composed of a reel with the coiled tubing, an injector, control console, power supply and well-control stack. The coiled tubing is injected into the existing production string, unwound from the reel and inserted into the well.

Coiled tubing is chosen over conventional straight tubing because conventional tubing has to be screwed together. Additionally, coiled tubing does not require a workover rig. Because coiled tubing is inserted into the well while production is ongoing, it is also a cost-effective choice and can be used on high-pressure wells.

All performed on a live well, there are a number of well intervention operations that can be achieved via coiled tubing. These include cleanout and perforating the wellbore, as well as retrieving and replacing damaged equipment.

Additionally, some advances in coiled tubing allow for real-time downhole measurements that can be used in logging operations and wellbore treatments. Enhanced Oil Recovery (EOR) processes, such as hydraulic and acid fracturing, can also be performed using coiled tubing. Furthermore, sand control and cementing operations can be performed via coiled tubing.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Their exceptional mobility, stability, and ease of operation are the outcome of our extensive experience in the design and production of mobile drilling rigs.

Belonging to the same family, Sovonex™ service rigs comprise many of the technological advantages that result in smooth operation and make the life of our customers’ easier:

Wide selection: At our production facility in China we design and develop workover rigs for service depths ranging from 1,600 m to 8,500 m (5,250 ft-27,900 ft), and workover depths from 2,000 m to 9,000 m (6,600 ft-30,000 ft) for 2 7/8” DP.

Full API coverage: The different components of our well-servicing rigs are manufactured to the following API standards:Steel structures, such as the mast: API Spec 4F

Highly maneuverable : Sovonex™ mobile drilling rigs and self-propelled workover rigs possess excellent driving properties in the desert, mountain, and other impassable terrains.

Powerful CAT engines and a custom-made chassis that can be equipped with single wheel full suspension enable well service operations in even the most remote areas.

Suited for corrosive environments: All steel parts are specially protected against corrosion through the application of multiple layers of ship paint. The same coating process is used in marine shipbuilding.

Reduced NPT: The mast is erected hydraulically to reduce time for rig up and increase safety. Likewise, all rig components have been designed to allow for fast assembly and disassembly.

With every service rig, we send technical staff to our customer to provide first-hand technical support. The engineer responsible for the rig design is always part of the service crew.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The escalation in geo-political tensions has significantly altered the outlook for the energy sector. Oil and gas stocks have surged higher with visibility for EBITDA margin expansion and cash flow upside. There are other attractive investment themes beyond the exploration companies. It’s also a good time to remain invested in drilling stocks.

With higher oil price, oil and gas companies will look at expanding exploration and drilling activities. This will translate into incremental demand for onshore and offshore drilling. In general, offshore assets have a higher break-even as compared to onshore oil and gas assets. Therefore, offshore drilling activity is likely to accelerate significantly in the coming quarters.

Drilling companies have gone through a rough phase after the pandemic. The current oil price scenario implies higher rig utilization as well as an upside in day-rates. It’s expected that between 2021 and 2025, onshore drilling expenditure is likely to be $34 billion.

Rystad Energy also believes that offshore drilling activity will continue to improve in 2022. However, these estimates are prior to the current surge in oil price. I would not be surprised if the capital allocation for onshore and offshore drilling activity increases meaningfully in 2022 and beyond.

In addition to higher rig utilization, day-rates for onshore and offshore drilling are also likely to increase. This will boost key margins and free cash flow outlook for drilling companies.

It’s worth noting that as of February 2022, Transocean reported an order backlog of $6.5 billion. Since the backlog is front-end loaded, there is clear revenue visibility for 2022 and 2023.

Another point from a growth perspective is that Transocean has a fleet of 39 rigs. However, the operating fleet as of February 2022 was 25. With the markets gaining traction, the cold stacked rigs are likely to be operational in the coming quarters. This will boost the revenue visibility.

At the same time, the idle rigs are likely to be contracted at a higher day-rate. This also hold true for any rig that’s going off-contract in the next few quarters. This will translate into EBITDA margin expansion.

From a financial perspective, Transocean has a robust liquidity backlog of $2.7 billion. The company seems to be fully financed for the next 18 months-24 months. The cash flow from operations will further help in improving the credit profile of the company.

From a fleet perspective, Borr Drilling reported 18 operating rigs as of February 2022. Additionally, the company has five warm stacked rigs and another five rigs under construction.

While the new rigs will be delivered in 2025, the warm stacked rigs provide revenue upside visibility in the foreseeable future. Borr Drilling is expecting to have all rigs in operation by the end of 2022.

It’s worth noting that in 2021, Borr Drilling was awarded 34 new contracts with a backlog potential of $717 million. With higher oil price, it’s likely that order intake will accelerate through 2022. This will boost the company’s revenue visibility for 2023 and help in EBITDA margin expansion.

On the flip-side, further equity dilution might be a concern. However, if oil remains firm and day-rates continue to improve, any dilution factor will be more than offset by improvement in cash flows.

For 2022, Borr Drilling has guided for revenue of $375 million to $400 million. Further, the company has guided for adjusted EBITDA of $115 million to $140 million. At the market capitalization of around $500 million, these metrics indicate that the stock is attractive.

A big reason to like Helmerich is the company’s balance sheet. Even with an extended period of downturn, the company has maintained an investment grade balance sheet. As of December 2021, Helmerich reported $1.2 billion in liquidity and a debt-to-capitalization of 17%. As onshore drilling activity accelerates, the company is positioned for aggressive growth. Helmerich also has rig presence in Argentina, Bahrain and Columbia. International expansion is another potential growth catalyst for the company.

It’s also worth noting that the company has a fleet of 271 rigs. Of this, only 174 were contracted as of January 2022. The recent surge in oil price would imply that contracting activity accelerates in the next few quarters. This provides ample growth visibility. If industry recovery sustains, there is also visibility for dividend growth.

I am bullish on rig contracting activity for 2022 considering the company’s modern fleet. Since August 2020, Helmerich’s skidding FlexRig design has increased market share. Super specification rigs give the company a competitive advantage as compared to peers.

Overall, HP stock is among the quality drilling stocks to consider for the portfolio. The company is well positioned to benefit from a high oil price environment.

On the date of publication, Faisal Humayun did not hold (either directly or indirectly) any positions in the securities mentioned in this article. The opinions expressed in this article are those of the writer, subject to the InvestorPlace.com Publishing Guidelines.

Faisal Humayun is a senior research analyst with 12 years of industry experience in the field of credit research, equity research and financial modeling. Faisal has authored over 1,500 stock specific articles with focus on the technology, energy and commodities sector.

8613371530291

8613371530291