what does a workover rig do free sample

Rig means the vessel described in Recital (A) hereto and includes any share or interest therein and her engines, machinery, boats, tackle, outfit, spare gear, fuel, consumable or other stores, belongings and appurtenances whether on board or ashore and whether now owned or hereafter acquired (but excluding therefrom any leased equipment owned by third parties);

Oil well means any well which produces or appears capable of producing a ratio of less than six thousand (6,000) cubic feet of gas to each one (1) barrel of oil on the basis of the initial gas-oil ratio test.

Horizontal well means a well bore drilled laterally at an angle of at least eighty (80) degrees to the vertical or with a horizontal projection exceeding one hundred (100) feet measured from the initial point of penetration into the productive formation through the terminus of the lateral in the same common source of supply.

Associated Facilities means all associated track structures, over and under track structures, supports (including supports for equipment or items associated with the use of the Network), tunnels, bridges, train control systems, signalling systems, communication systems and associated plant, machinery and equipment from time to time but only to the extent that such assets are related to or connected with the Network but does not include any sidings or yards;

Compression Ignition Engine means an internal combustion engine with operating characteristics significantly similar to the theoretical diesel combustion cycle. The regulation of power by controlling fuel supply in lieu of a throttle is indicative of a compression ignition engine.

service well means a well drilled or completed for the purpose of supporting production in an existing field. Wells in this class are drilled for the following specific purposes: gas injection (natural gas, propane, butane or flue gas), water injection, steam injection, air injection, salt water disposal, water supply for injection, observation or injection for combustion.

Development Well means a well drilled inside the established limits of an oil or gas reservoir, or in close proximity to the edge of the reservoir, to the depth of a stratigraphic horizon known to be productive.

Pilot project means an initial short-term method to test or apply an innovation or concept related to the operation, management or design of a local detention facility pursuant to application to, and approval by, the Board.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

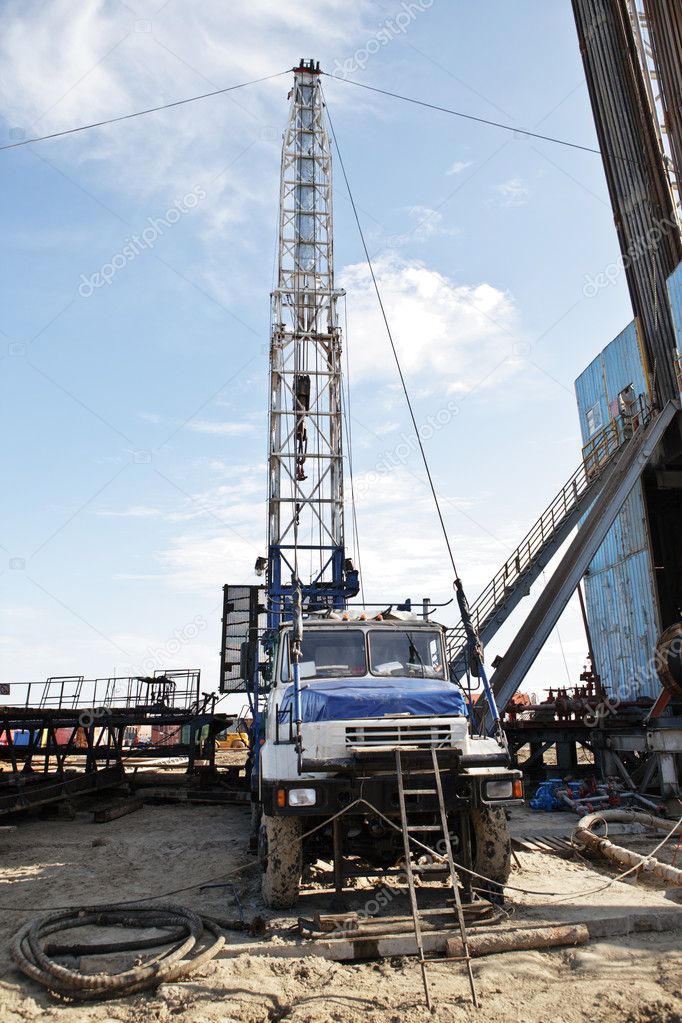

The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically, a workover refers to the expensive process of pulling and replacing completion or production hardware in order to extend the life of the well.

Workovers rank among the most complex, difficult and expensive types of wellwork. They are only performed if the completion of a well is terminally unsuitable for the job at hand. The production tubing may have become damaged due to operational factors like corrosion to the point where well integrity is threatened. Downhole components such as tubing, retrievable downhole safety valves, or electrical submersible pumps may have malfunctioned, needing replacement.

In other circumstances, the reason for a workover may not be that the completion itself is in a bad condition, but that changing reservoir conditions make the former completion unsuitable. For example, a high productivity well may have been completed with 5½" tubing to allow high flow rates (a narrower tubing would have unnecessarily choked the flow). Some years on, declining productivity means the reservoir can no longer support stable flow through this wide bore. This may lead to a workover to replace the 5½" tubing with 4½" tubing. The narrower bore makes for a more stable flow.

Before any workover, the well must first be killed. Since workovers are long planned in advance, there would be much time to plan the well kill and so the reverse circulation would be common. The intense nature of this operation often requires no less than the capabilities of a drilling rig.

The workover begins by killing the well then removing the wellhead and possibly the flow line, then installing a B.O.P commonly known as a blowout preventer, then lifting the tubing hanger from the casing head, thus beginning to pull the completion out of the well. The string will almost always be fixed in place by at least one production packer. If the packer is retrievable it can be released easily enough and pulled out with the completion string. If it is permanent, then it is common to cut the tubing just above it and pull out the upper portion of the string. If necessary, the packer and the tubing left in hole can be milled out, though more commonly, the new completion will make use of it by setting a new packer just above it and running new tubing down to the top of the old.

Although less exposed to wellbore fluids, casing strings too have been known to lose integrity. On occasion, it may be deemed economical to pull and replace it. Because casing strings are cemented in place, this is significantly more difficult and expensive than replacing the completion string. If in some instances the casing cannot be removed from the well, it may be necessary to sidetrack the offending area and recomplete, also an expensive process. For all but the most productive well, replacing casing would never be economical.

We like to throw around “blog ideas” over here at Croft to help my fellow blog partner, Amy and I have a new fresh blog every week. We try to keep our readers up to date with both the new and the old. Someone threw out the idea of writing about a workover rig. Still being new to the industry, I snatched this topic up because I simply wanted to learn more about it myself! My main focus for this blog is simply discussing what is a workover rig and why it is important.

First off, maybe you know a workover rig by a different name. They can be called completion wells or pulling units. I just want to try to avoid any confusion! I am going to give Wikipedia’s definition first and then break it down to layman’s terms for those of you who don’t quite understand what the Wiki is trying to say (Like me). According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.” Let’s break down some of that Terminology…

Oil Well Intervention: Occurs during or after the life of an oil or gas well. It changes the state of the well, well geometry, manages production or provides well diagnostics.

Coiled Tubing: A long metal pipe used to carry out operations similar to wirelining. However, it has the ability to pump chemicals through the pipe and push it downhole.

Snubbing: This method is used in more demanding situations when wireline and coiled tubing does not offer the strength and durability needed. Snubbing runs the bottom hole assembly on a pipe string using a hydraulic workover rig.

So basically, the purpose of a workover rig is to replace a well with a fresh completion. This may have to happen due to the well deteriorating or the changing of reservoir conditions. This is performed if a well completion is unsuitable for the job at hand. An example of the well deteriorating is the equipment may have become damaged or corroded such as production tubing, safety valves, electrical pumps, etc. An example of the changing of reservoir conditions maybe if the flow of a well has decreased over time. If this happens, when the well was originally drilled, it was fit for tubing that was big enough for a higher flow of oil and gas. As the flow decreased, smaller tubing is now needed.

For a workover to take place, a well must be killed or in other words, stop the flow of oil or gas. This is an intense procedure for a workover to take place, so they are planned long in advance.

Considering the number of Workover Rigs off contract and stacked it is now highly important that contractors have their equipment in ready to go on contract condition. Major oil companies and operating companies will require a history of good Rig Maintenance.

This Workover Rig Maintenance program consist of a complete maintenance schedule for all the equipment listed below. Any item listed on any of the check list worksheets can be changed and edited to suite any Workover Rig and any piece of equipment. It also covers Diesel Haulers and Water Haulers if you own your own trucks. Any item can be removed or changed to suite your Workover Rig and equipment.

Here"s how cdl is used on rig hand resumes:Learned more of forklift operation as well as extensive CDL Driving experience.Skills UsedOperation of various equipment and tools.

Here"s how h2s is used on rig hand resumes:Worked & certified around H2S Accomplishments I was acknowledged multiple times in big safety meetings for showing my awareness of safety.

Heavy equipment, also known as heavy machinery, refers to heavy-duty trucks that are specifically built to complete building works, most often earthwork activities or other major construction projects. Heavy machinery works by multiplying the amount of input force added to force exerted, allowing jobs that would otherwise take hundreds of workers and weeks of labor to be completed in a fraction of the time.

Here"s how heavy equipment is used on rig hand resumes:Remove and replace well heads, able to work safely around heavy equipment and flammables, operate machine shop tools safely.

Job safety analysis is the process of analysing the occupational safety at a workplace. It measures factors like safety wellbeing and health of employees. It also aims to solve conflicts that may further lead to the assault of an individual either by a colleague or the employer.

Here"s how job safety analysis is used on rig hand resumes:Experience with safety meetings and Job Safety Analysis as per company standard and policies.

Weather conditions refer to atmospheric conditions in terms of temperature, wind, precipitation, clouds, and humidity. It describes the degree to which the atmosphere is hot or cold, wet or dry, calm or stormy, clear or cloudy.

Meetings that are held among the officials of a company or an organization to discuss ways to provide a safer and risk-free environment for the staff and customers of the company are called safety meetings. These meetings are commonly conducted in companies that deal in risky business involving the use of dangerous machinery and harmful chemicals.

Here"s how safety meetings is used on rig hand resumes:Help co-workers repair rig, Participate in daily safety meetings to help avoid incidents, Help rig stay clean and keep drilling

Zippia allows you to choose from different easy-to-use Rig Hand templates, and provides you with expert advice. Using the templates, you can rest assured that the structure and format of your Rig Hand resume is top notch. Choose a template with the colors, fonts & text sizes that are appropriate for your industry.

Cardiopulmonary resuscitation or CPR is a medical procedure that involves chest compression to help a patient breathe. This artificial ventilation helps in keeping the brain function in place and regulates blood throughout the body. CPR is a lifesaving procedure that is used in emergencies.

Here"s how flow lines is used on rig hand resumes:Monitored issues with the well such as closed valves along the flow lines in order to prevent pressure buildup.

General maintenance is the regular check-up and repairs of machinery, buildings, and other mechanical equipment. General maintenance is performed by repair workers who are skilled to handle the day-to-day defects produced in the machinery. General maintenance aims to make sure the items remain in the best operational conditions. Usually, a set of planned activities are performed regularly by an expert to monitor the maintenance.

Here"s how general maintenance is used on rig hand resumes:Perform general maintenance of draw works, load and off-load pipe and assists in rig movement.

Here"s how swab is used on rig hand resumes:Help on Swab Rig/Fix Leaks/Hook up Wells/Roustabout/Read Meters/Keep Records of Wells/Walk Pipelines/Soap & Flow Wells/Maintain the Running of Four Compressors

The following is a list of seasonal work gear worn by drilling rig workers. Savanna supplies rig employees with coveralls, hard hat, safety glasses & impact gloves (1 pair).

Drilling rig crews are generally made up of six (6) people: Rig Manager, Driller, Derrickhand, Motorhand, Floorhand, and Leasehand. Each crew works 12 hours shifts as the rig operates 24 hours per day, and each position is vital to the operation of the rig.

Work in the oil and gas services industry is seasonal. Because of the weight of rigs and their equipment, and the remote location of wells, these locations are often only accessible when the ground conditions can tolerate heavy loads. Therefore, wells are typically drilled and serviced in the winter when the ground is frozen solid, or in the summer, when the ground has thawed and dried sufficiently. During the spring and fall, when the ground is in a transitional state, it is too soft to move equipment on and easily damaged. For this reason, provincial governments implement “road bans” prohibiting heavy loads from operating in certain areas. During this time, rig work is slower, and many rigs are shut down and their crews sent home. Be prepared to be off for anywhere from 6 to 12 weeks without pay during this time. However, rigs that are shut down are usually in need of maintenance, and there may be opportunities for employees who would like to help in this regard. Employees may be eligible for Employment Insurance benefits during seasonal shutdowns.

To work on a drilling rig, you must be able to get to and from all of your work locations. As drilling often occurs in remote areas, having reliable transportation is considered mandatory for non-camp locations. Drilling rigs commonly operate 24 hours per day, 7 days per week with either three crews working 8 hour shifts or two crews working 12-hour shifts. Most often day crews and night crews will alternate weekly, so each crew has a chance to work during both the day and night. Most crews will work 14 days straight with 7 days off in-between. The typical living situation while working falls into three categories: Non-Camp, Full Camp and Texas Camp.

Non-Camp: When the rig site is near a town, non-camp conditions normally apply. Crews will stay in hotel rooms and receive a per day living allowance for food and accommodation. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and accommodation out of your own pocket.

Full-Camp: When a rig site is in a remote location, crews may stay in a full camp. In a full-camp all food and full accommodation is provided. Once at the camp, the crew travels to and from the rig in the crew truck. Almost all camp work is available in the winter only.

Texas Camp: These camps are typically located nearby the rig location. Crews are responsible for supplying their own bedding, cooking supplies, groceries and toiletries. While staying at a texas camp, a daily allowance is provided for food and toiletries. The living allowance is paid out on your pay cheque based on days worked, therefore you will need to be able to pay for your food and toiletries out of your own pocket.

Savanna employees are paid every two weeks via direct bank deposit. Savanna’s compensation package includes company group health, dental and disability coverage including paramedical coverage (acupuncturist, chiropractor, massage therapist, naturopath physiotherapist and much more). Savanna also offers a competitive and rewarding retirement savings plan.

Once you have completed your orientation, you will immediately receive any other necessary training. This involves Workplace Hazardous Materials Information System (WHMIS) and Transportation of Dangerous Goods (TDG), along with an in-depth General Safety Orientation. This training is mandatory and provided by Savanna at no cost to the employee. Job-related, hands on training is conducted in the field through Savanna’s Rig Mentoring Program.

Some well locations have sour gas (Hydrogen Sulfide or H2S) present which is extremely dangerous. All employees are required to possess a valid H2S Alive certificate regardless of whether they are working on a sour gas well. This can be obtained by signing up for and completing a one-day (8 hour) course.

Courses are available at various locations across the province. For more information, contact Energy Safety (formerly Enform) at (780) 955-7770 or visit www.enform.ca or Leduc Safety Service at (780) 955 3300 or visit www.leducsafety.com. The cost of the course is usually between $130 and $150 plus tax, and the certification is valid for three years.

While it is not mandatory to have this certification, each service rig crew is required to have two members who are certified in Standard First Aid with CPR level C. Therefore, obtaining a certification beforehand is a great way to improve your chances of being hired.

Savanna is committed to providing a safe, productive and respectful work environment. As such, Savanna has Policies in place to ensure the protection of our employees, contractors, the pubic and the environment. All Savanna employees are required to acknowledge and follow the policies at all times.

Download Workover & Drilling Rig Inspection Checklist As we mentioned in the Rig Audit Article, rig inspection is an important process that shall be done from time to time. Especially, after the rig moving to a new drilling location.

The Workover Rigs market will remain attractive over the forecast period owing to rising consumption of petroleum products. As a result, the Exploration and Production (E&P) located globally will increase their investment due to increasing demand and positive outlook of the oil and gas market.

The ongoing rise in oil prices can be regarded as new phase for the companies operating in the sector. Adding to this, the participants are looking to attain growth through domestic and international expansion as well as adding new production related services. As Workover Rigs providers play important role in the production operation making them key segment in the reviving upstream sector and hold massive share in the overall spending of the companies.

Moreover, the investment from government as well as private sector in the drilling activities is also expected to rise and surge in shale gas production is expected to fuel the growth of the Workover Rigs market in the coming years. The oversupply of Workover Rigs in the cyclical oil & gas market is one of the major restraint to the market.

However, the industry has recovered successfully from the recent oil price crisis and industry outlook will remain positive in the coming years. One of the major trend in the market will use of environment friendly Workover Rigs. The government authorities are directing energy companies to decrease carbon footprint that will shift the focus of the companies towards use of components that run renewable energy in the coming years.

The grey steel girders of Platform Holly rise 235ft (72m) above the waters of the Pacific Ocean, just a couple of miles off the Santa Barbara coast. Above the water, this decommissioned oil rig is dull and lifeless, but the view below the surface is very different. Beneath the waves, colourful fish, crabs, starfish and mussels congregate on the huge steel pylons, which stretch for more than 400ft (120m) to the ocean floor.

There are more than 12,000 offshore oil and gas platforms worldwide. As they drain their reservoirs of fossil fuels below the sea, they eventually become defunct when they produce too little fuel for extraction to be profitable to their operators.

The big question is what to do with these enormous structures when the fossil fuels stop flowing. With curbing climate change rising up the international agenda, and with some questioning whether we have already passed peak oil, hastened by the coronavirus pandemic, the number of defunct rigs in the ocean is set to get bigger. Removing them from the water is incredibly expensive and labour-intensive. Allowing them to rust and fall into disrepair is an environmental risk that could seriously damage marine ecosystems.

For some species, offshore rigs are even better nurseries than natural reefs. The towering pylons are the perfect spawning grounds for tiny fish larvae

But there is one way in which these old rigs can be remarkably useful: the subsurface rig provides the ideal skeleton for coral reefs. Teeming with fish and other wildlife, offshore rigs like Platform Holly are in fact the most bountiful human-made marine habitats in the world.

The practice of transforming rigs into reefs in the United States dates back almost 40 years. In 1984, the US Congress signed the National Fishing Enhancement Act which recognised the benefits artificial reefs provided and encouraged states to draw up plans to turn defunct rigs into reefs. The five coastal states on the Gulf of Mexico – Alabama, Florida, Louisiana, Mississippi and Texas – all have rigs-to-reefs programmes and have converted more than 500 oil and gas platforms into artificial reefs.

When oil companies cease drilling in these states, they decommission their platform by sealing the oil well. Then they can either choose to remove the entire platform or convert it into a reef by removing just the upper section of the structure.

Reefing a platform is an attractive proposition for oil and gas companies as it is significantly less expensive than total removal and is estimated to save the industry millions of dollars each year. Campaigners say it is a win-win situation as companies spend half of their decommissioning savings on the state"s artificial reef programme. This money goes towards maintaining the platforms, marine conservation and education. Due to the abundant marine species living there, the platforms in the Gulf of Mexico have become hotspots for diving, snorkelling and recreational fishing.

Marine scientists Emily Hazelwood and Amber Sparks are on a mission to replicate this conservation success in other parts of the world. They founded the California-based organisation Blue Latitudes in 2014 to raise awareness about the benefits of rigs and persuade oil companies and governments to designate them as permanent reefs.

"We"re trying to help the general public understand that conservation isn"t always just about saving the whales," says Sparks. "There are other ways we can look at complex ideas in our oceans, such as repurposing manmade structures like artificial reefs."

Offshore rigs are among the most productive fish habitats in the world, according to marine biologist Milton Love who has spent 20 years studying fish populations around oil and gas platforms in California. They provide marine wildlife with food, shelter from predators and a safe breeding ground.

For some species, the rigs are even better nurseries than natural reefs, says Love. The towering pylons are the perfect spawning grounds for tiny fish larvae. "A lot of them are just drifting," says Love. "They want to settle." The 500ft (150m) high underwater structures provide an opportunity for just that.

One of the big beneficiaries is rockfish, stocks of which have been heavily depleted due to overfishing along the US West Coast. These fish are found in abundance around oil platforms. For instance, the platforms have helped revive the critically endangered bocaccio rockfish. "We"ve found a very high density of young bocaccio at platforms, around 400,000 at six platforms. We didn"t see that at natural reefs," says Love, adding that the number of juvenile bocaccio found at rigs was enough to boost the adult stock of the Pacific Coast population by around 3%.

The abundant fish populations found at Californian platforms can partly be attributed to the fact that oil rigs serve as de facto marine protected areas, says Love. In California, fishing around oil and gas platforms is prohibited.

Chris Lowe, a marine biologist at California State University who has been tracking fish populations in southern California since 2008, says there is clear evidence that fish are drawn to the platforms.

For one study, Lowe attached sensors to fish living by three oil platforms, before moving them to a natural reef located up to 18km (11 miles) away and monitoring their movements over two years. A quarter of the fish, across all species, quickly returned to their home oil platform, while others would migrate back during non-breeding seasons. "They had a higher likelihood of going back to their original platform than somewhere else. They really like their home platform. This showed us a lot about how the fish treat the platform as a habitat," says Lowe.

One reason for this affinity is that the rigs offer a property rarely found in featureless open water: their considerable height. The platform acts as a pinnacle and allows fish to move into deeper water as they mature, without having to leave their habitat, according to Lowe. Typically, fish living in shallow reefs will leave their habitat when they are fully grown and venture out to open sea. The fish found on oil rigs simply have to move down the platform, without ever venturing far from their refuge.

Many scientists are calling for Californian platforms to be preserved as artificial reefs, given the bountiful ecosystems they harbour. The state introduced a law in 2010 allowing for rigs to be converted in reefs, but to date no platforms have been reefed. That could change in the next decade; eight of the state"s 27 rigs are no longer operating and several will be decommissioned in the next few years.

Blue Latitudes" Sparks says it is a challenge convincing Californians, "the greenest folks you"ll meet", of the merits of keeping rigs in the ocean. California is the US state with the most ambitious climate goals. By 2030 the state aims to slash emissions by 40% compared with 1990 levels and has passed a law that all electricity must come from carbon-free sources by 2045.

"Californians are very opposed to offshore oil and gas and many of them want their coastline and view free of those structures," says Kristen Hislop, a marine conservationist at the Environmental Defense Center, an advocacy group based in the Santa Barbara region, where there are 20 platforms.

While marine life might benefit from the subsurface structures, there are concerns about the rigs-to-reefs programmes also supporting extractive industries (Credit: Alamy)

It"s not hard to see why some are reluctant. The extraction and burning of fossil fuels including oil and gas are major drivers of climate change. Overall, in 2019, gas made up 21% and oil 34% of the world’s CO2 emissions from fuel, with a significant proportion coming from offshore rigs like these and thousands of others.

But the objections are not just symbolic. There are concerns that the cost savings offered to oil companies under the rigs-to-reefs programme could encourage them to expand, Hislop notes. She adds that research and discussions about what to do with the rigs once they have been decommissioned are ongoing.

But Blue Latitudes says the aim of rigs to reefs is not to reward polluters and boost the oil industry, but to protect valuable marine habitats by offering an alternative to complete platform removal.

If California"s platforms are toppled, it would result in the loss of 27 huge marine ecosystems. Some of these rigs are taller than the Eiffel Tower – the Harmony platform in the Santa Barbara Channel, for example, reaches depths of 1198ft (365m). "California platforms are some of the largest and deepest in the world," says Hazelwood. "You don"t even see the beams, they are so encrusted with marine wildlife."

The emissions from travel it took to report this story were 0kg CO2. The digital emissions from this story are an estimated 1.2g to 3.6g CO2 per page view.Find out more about how we calculated this figure here.

If you liked this story,sign up for the weekly bbc.com features newsletter, called "The Essential List". A handpicked selection of stories fromBBC Future,Culture,Worklife, andTravel, delivered to your inbox every Friday.

8613371530291

8613371530291