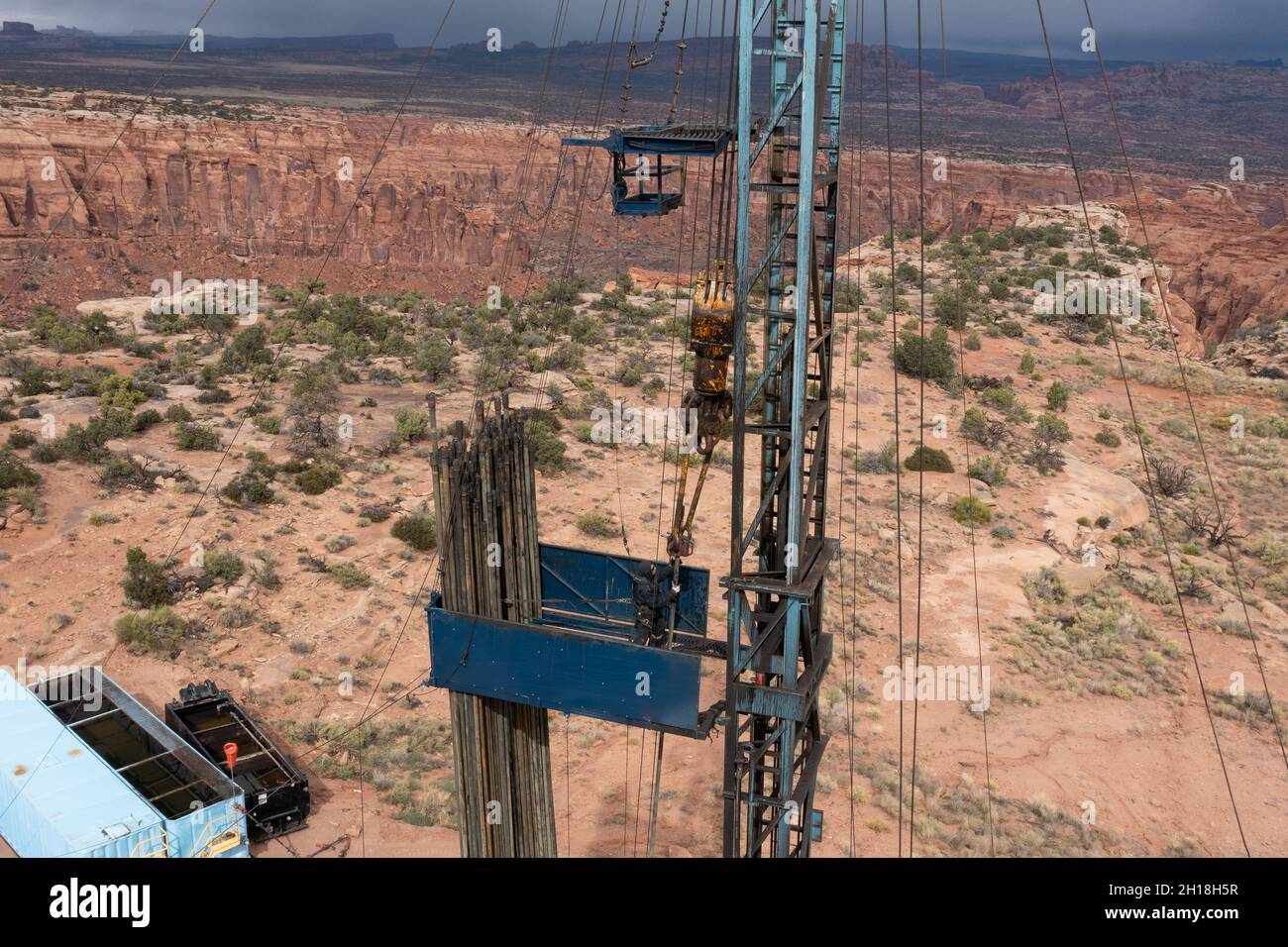

workover rig blocks in stock

Welcome to Pickett Oilfield’s traveling blocks & hooks web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used traveling blocks and traveling equipment to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including traveling blocks & hooks to choose from at competitive prices. Browse our inventory of traveling blocks and traveling equipment for sale at competitive rates.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Cameron provides traveling blocks from 275- to 1,250-tonUS. Precise weighting of our traveling blocks ensures fast free-fall, while their streamlined, compact design eliminates interference with mast or derrick components. Their long service life is enhanced through quality fabrication and the advanced metallurgy of sheaves, beckets, and components. Cameron traveling blocks feature low-inertia sheaves for high performance and reliability.

Product&Reapir: Crown block(TC225 TC250 TC315 TC450 TC585), Travelling block(YC225 YC250 YC315 YC350 YC450 YC450S YC585), Hook(DG225 DG250 DG315 DG350 DG450 DG585 DG675), Rotary table(ZP175 ZP205 ZP275 ZP375 ZP975AS ZP495), Swivel(SL225 SL250 SL450 SL585), Drawworks(JC20 JC30 JC40 JC50 JC70B JC90DB), Mud pump (F-500 F-800 F-1000 F-1300 F-1600 F-1600HL F-2200 F-2200HL 3NB500C,3NB1000C 3NB1300C 3NB1600 SL3NB-1000 SL3NB-1300A SL3NB-1600A),BOP(FH,FZ,Cameron,Shaffer), Control System for Surface Mounted BOP Stacks(FKQ,FKDQ),Disc brake (PS,PSZ, DBS), Bladder accumulator (NXQ), Drilling rig(ZJ40/2250DZ ZJ50/3150DZ ZJ70/4500DZ ZJ90/6750DZ), Workover rig (XJ40,XJ60, XJ80,XJ100,XJ12,ZJ15,ZJ20,ZJ3,XJ350, XJ450, XJ550,XJ650,XJ750), BPM Top drive((DQ120BSC, DQ90BSD, DQ90BSC, DQ80BSC, DQ70BSD, DQ70BSE, DQ70BSC, DQ50BC, DQ40BC, DQ40BSG, DQ40BCQ, DQ40YR, DQ30Y) Make: Bomco, Lanzhou LS,LSPE, SJ Petro, RG Petro, Sichuan Honghua, CPTDC, Beijing BPM, Shanghai Shenkai, Kingdream, CCDC, SJS Serva, DFXK, LS-NOV, Beijing PSK, Gold basin, Renqiu Boke,Guangdong Dongsu.(Guangshi), XBSY.,Tiehu, Rongsheng (HBRS), TSC. Replacements:Mission magnum/Halco centrifugal pump, Cameron FC gate valve,Cameron R check valve, Demco mud valveE( 3K&5K ), Demco butterfly valve,BJ varco handling tools (SDXL, SDML, SDS,DCS,SSC,SSD,YT, HYC, LYT, MP,MYT, MG, RGG, HGG, MGG, TA, SJ), MI SWACO / Mongoose / Derrick / /Brandt / King cobra shale shaker screen (FLC2000,FLC503,Derrick 626), M/D & OTECO Gauge(Type F,Type D,Model 6,Model 7,Model 8), Twin disc,WPT, Eaton clutch & friction disc, National (10-P-130,12-P-160 ,14-P-220 ,8-P-80 ,9-P-100), Gardner denver (PZ-7,PZ-8,PZ-9,PZ-10,PZ-11), EMSCO FB1600.International Brand: Moog, CCS, ATOS, Rexroth, Eaton, Flowrox, Italvibras, Martin, Norgren, Parker, Siemens, Vickers, 3M.Standard:API Spec 4F, API Spec 6A,API Spec 6D,API Spec 600, API Spec 7K, API Spec 8A, API Spec 8C,API Spec 16A, API Spec 16C, API Spec 16D

Inserting and pulling up pipe tubing from oil wells is a precise and challenging job that not every rig is up for. That’s why you need a mobile workover rig from Dragon to get it done right every time. Our workover rigs are state-of-the-art and ready to tackle even the harshest conditions. A workover rig is perfect for site preparation while a standard mobile oil rig can handle a variety of piping tasks. Need workover rig parts, or service on another mobile rig? Dragon has that covered with our parts selection, too. View all of our workover rigs and other drilling rigs today.

Dragon manufactures a full line of 300 to 1,000 HP Cooper ™ Rigs at our state-of-the-art U.S. facility and our rig team is one of the most seasoned in the industry. Whether you need a used well servicing rig, a workover rig, a drilling rig, mud pumps and systems or parts and service, Dragon has you covered.

Our expansive inventory of parts and accessories includes mud systems, mud hoppers and mud guns, agitators, pipe racks, draw works, API 4F, 4th Edition certified masts, break blocks, McKissick tubing and drilling blocks and refurbished gear boxes for most brands of well servicing units. Our rig masts have a clearance height range of 71-124′ and capacities of 150,000 lbs too 500,000 lbs.

Like all Dragon equipment our used Cooper Workover Rigs are severed duty engineered. We also have hands-on experience building to severe, cold weather specs and in compliance with the state of California’s requirements. When you buy a Cooper™ Rig from Dragon you get a custom, easy to operate, safe rig at a competitive price. Whatever mobile rig solution you need, Dragon will build it, deliver it and back it with the highest level of service and support in the industry.

WILSON WELL SERVICE RIG (Ref#3000Ta) 103’ x 248,000# derrick, Out of service since 2017, lot of rust, will start and run and/or drive down the road POR

Refurbished, 700 hp, Double drum 2042 drawwroks with Parmac 202 brake assist, (2) Caterpillar 3406 Engines, (2) rebuilt Allison 750 6 speed auto transmission with reverse. 112" x 300,000 # hook load capacity on 8 lines, clear height 97 feet, leg spread 7" 6-1/2", racking board, oil bath chain case, elevated rotary drive, all raising lines and guidelines. The Draw-works, hydro-mantic break, and crown assembly have been rebuilt. Heavy duty Draw works drive propeller shaft through right angle gear box, rotary drive propeller shaft, heavy duty reverse gear box and oil bath roller chain, and a self-locking handling winch. Mounted on triple front axle mechanical 6 axle carrier with 134,000# capacity designed to meet highway safety standards with necessary toughness for off road operations. Price: $265,000

Manufactured 2014, 72’ x 180,000# derrick on 4-line (250,000# on 6-line), mounted on 5 axle carrier, Detroit Series 60, Allison transmission, all hydraulic, 8000’ of 5/8” sandline, 100 ton McKissick casing blocks, 1” line 42” x 12” casing drum, 42” x 12” sand drum, disc assist on casing drum, 1500 hours, 3000 miles. Westco power tongs 1-1/2”, 2”, 2-7/8” and 5-1/2”, set of bails/links, tubing elevators 1-1/2” – 2”, rod hook, elevators, wrenches, swab tools, Martin Decker weight indicator, stored inside Price: $645,000

Built 1981, mounted on 5 axle carrier, Detroit 60 Series engine, 104’ x 250,000# mast, 5860 Allison 6 speed transmission, 100-ton McKissick spring loaded blocks, 2 winches, blocks, all lines, drill line, approx. 13,000’ of 9/16” sandline, all guy lines, load lines, belly lines, floor lines and 2 winch lines all with current tags, currently working, excellent condition Price: $320,000

Derrick fell onto rig when being raised, derrick would need to be replaced or repaired. Built 1981, double drum, 42 x 12, 42 x 8, swab drum removed from jack shaft, 5-axle back in carrier, 250,000# derrick with double racking board and triple rod basket, Cat 3408, CLT 5860 transmission, Cooper right angle box, 4 hydraulic leveling jacks, air rod transfer in derrick, hydraulic winch, Kerr 6 cyd 10000 psi Mustang pump powered from jack shaft, Kerr 3-valve release 10,000 psi, tong carrier f/Foster, steel work platform, Parmac 22 SR hydromatic brake. Extra rebuilt 3408 Cat engine. Price as is: $112,500

Built 2010, Detroit 60 Series engine, 5860 Allison transmission, 103’ x 250,000# mast, double triple, 2 winches, McKissick 100-ton spring loaded blocks, all lines, drill line, approx 13,000’ of 9/16” sandline, all guy lines, load lines, belly lines, floor lines and 2 winch lines all current tags. Excellent condition, currently working. Price: $420,000

Manufactured 2008, 72’ x 150,000# derrick, Detroit Series 60 engine, mounted on 4 axle Crane Carrier, tooled out, Guiberson T60 air slips 100 ton casing blocks, Westco power tongs, currently working Price: $445,000

Double drum, 15,000’ of new 9/16” line, near new 4-line blocks, mounted on 5 axle Crane Carrier, 104’ x 250,000# mast, 750 Allison transmission, Detroit 60 series, currently operating Price: $130,000

Manufactured 1981, mounted on 5 axle carrier, double triple service rig, 96’ x 250,000# derrick, Detroit Series 60 12.7 diesel engine, Allison transmission, 9/16” sandline, 1” drill line, hydraulic jacks, hydraulic catwalk, travelling block, tubing bard, rod basket and all necessary lines. Tooling not included. Price: $115,000

Manufactured 1983, double drum, 96’ x 180,000# derrick, mounted on 5 axle carrier with 92T engine, Allison transmission Price rig only: $300,000 Price with tooling:$340,000

WILSON 42 WELL SERVICE RIG(Ref#7562Ta) Manufactured 1975, 180,000# Pemco double/triple derrick, mounted on Wilson carrier with Detroit 8V71 engine, 4 hydraulic leveling jacks, ready to work Price rig only: $74,500 Price with tooling: $94,500

Manufactured 1983, 70" x 120,000# non telescoping stiff mast, double drum 26 x 8, Detroit 6V71 diesel engine, 740 Allison transmission with Spicer power divider, mounted on 4 axle carrier. Rig runs and truck drives, stacked for several years, good condition Price: $93,500 USD

Manufactured 2009, Detroit 60 Series engine, 96" x 225,000# mast, mounted on 5 axle carrier, blocks, elevators, air slips, one owner Price: $420,000

FRANKS 500 WORKOVER RIG(Ref#7615Tc) Built 1980, refurbished 2018, 102’ derrick, 150 ton blocks, 15,000’ sandline, new engine and transmission, ready to work Price: $430,000

FRANKS 400 WORKOVER RIG(Ref#7615Ta) Built 1979, refurbished 2017, 102’ x 215,000# derrick, 100 ton blocks, 15,000’ sandline, 4 lines Price: $390,000

Built 1981, refurbished in 2018, 102’ derrick, new drilling line, no sand line, 100 ton blocks, 2 winches, has not worked since refurbishment. Price: $390,000

FRANKS 300 SERVICE RIG(Ref#1169Ta) 4-legged derrick, Series 60 Detroit engine, 6850 Allison transmission, blocks, Foster tongs, mounted on 4 axle carrier, working condition Price: $37,500

Manufactured 2004, Cat diesel engine, 96" x 250,000# mast, mounted on 5 axle carrier, blocks, elevators, air slips, needs new air lines Price: $170,000

Manufactured 2007, double drum, 104’ x 250,000# mast, Detroit 60 Series engine, mounted on 5 axle Crane Carrier, McKissick 73 150-ton blocks Price: $470,000

WILSON MOGUEL 42 WELL SERVICE RIG(Ref#3177Tb) Two available, 96" x 280,000# mast, Detroit Series 60 engine, 5860 Allison transmission, mounted on 5 axle Wilson carrier, handling tools Price: $315,000

Double/Triple 96" x 225,000# derrick, 60 Series Detroit engine, mounted on 4 axle carrier, 750 Allison transmission, sandline, blocks Price: $72,500

Workover rig with 83’ telescoping derrick, 10’ crown extension, 200,000# lift capacity, 100,000# snubbing capacity. Catwalk with 42’ reach, forward and revere motion, hydraulic pipe slide, six portable pipe racks, powered by workover rig. 5000 ft/lb hydraulic rotary, 15k psi working pressure capability kelly hose, 300 ton mast with 5 x 5 heavy wall box tubing and 2 x 2 heavy wall cross sections, (2) mast raising cylinders, 9-1/8 x 25’ telescoping cylinders/crown sheaves with cable guides, (2) winch sheaves/snubbing sheaves, SRS fall protection, retractable flow tube design, non-swivel boom pole on curb side winch, (2) mast supports, 1” lifting cables, mounted on 5 axle Crane Carrier (3rd axle drop), with 375k Volvo Penta engine, 150 gal fuel capacity, hydraulic self-leveling components, 6 speed Allison transmission, 1:1 gear box, (2) 65 gpm pumps, (2) 30 gpm pumps, (1) 28 gpm Commercial shearing pump, 40 gal accumulator storage, single man cab, hydraulic leveling jacks Price on Request

Refurbished, Double/Triple, 96" x 215,000# derrick, Detroit 60 Series, mounted on 4 axle carrier, 750 Allison transmission, sandline, blocks Price: $102,500

Manufactured 1982, Tubing drum 42 x 12, sand drum 38 x 8, Detroit Series 60 diesel engine, 96’ x 200,000# derrick with set of tubing blocks, hydraulic and air hoses gone through, installed all new engine harness and electrical wiring to all lights, transmission. Rebuilt valve bank Price: $200,000

Manufactured 1960’s, double drum, single rig mast, 64’ x 250,000# (tubing and rod racks), 70 ton blocks, 2 lines, Detroit diesel 60 gpm @ 2000 psi, hydraulic system, air clutch. Rig was refurbished 2013/2014 at a cost of $130,000: repairs included used 65’ derrick installed, new 1” main line, repairs to air system, hydraulic system upgrade, leveling jacks, derrick ljghting, tires, 70 ton blocks installed. But the rig has been sitting since 2015 and now needs rebuilding. It doesn’t run. Price as is: $19,500

Manufactured 1980, completely refurbished 2004, 5 axle double drum well service unit, double 15 Parmac brake on main drum, 96" x 180,000# hydraulic raised mast, mast lighting, Detroit 60 Sereis engine, 5860 Allison 6 speed transmission, 4 hydraulic leveling jacks, dual manual outriggers, PD12 Braden utility winch, McKissick 100 ton tubing block 21-31 diving, 1000" of 1" tubing line, 13000" of 9/16" sandline Price: $225,000

CARDWELL KB200B SERVICE RIG(Ref#11674Ta) 72’ x 140,000# stiff mast, 40 x 10 double drum drawworks, 2 aux deck winches, tubing board, rod board, cat walks, railing, stairs, floor BOP controls and accumulator bottles, McKissick 75 ton tubing block and hook, mounted on 5 axle carrier, Detroit 8V71 diesel engine, Alliston CLBT4460 auto transmission PRICE: $127,500

Rig manufacture 1980, mounted on 1980 GMC Brigadier with Cat 3208 engine, includes elevators & misc tools, also includes 1996 1-ton Super Duty tool truck, tandem axle, Cat 3208 diesel, sitting 1-1/2 years Price: $92,500

1980, 475 hp, single drum (new), reworked, 96" x 205,000# hydraulically raised mast, 6 lines, crown block: 3 new sheaves blocks and bearings, racking board, guide wires, (2) hydraulic hoist, weight indicator, block, elevator links, fall safety device, work platform, mounted on 4 axle carrier with Detroit Series 60 diesel engine, Allison transmission, rig in excellent condition and has been well maintained, ready for use PRICE: $115,000

SKYTOP BREWSTER RR400(Ref#13190T) Mounted on 4 axle carrier, single drum drawworks, 8x7 disc assisted brakes, tubing board, Cat3406B engine, Allison 860DB transmission, 100 ton McKissick block, Foster 58-92R tongs, misc hand tools, approx 36" base beam for rig, ready to work Price: $110,000

Manufactured 1976, 50 Series Detroit engine, 4460 Allison auto transmission, 96" x 180,000# Skytop derrick, 100 ton McKissick blocks, 7000" of 9/16" sandline, BJ tubing tongs, Guiberson air slips, 2-3/8 and 2-7/8 elevators, rod wrench, rod elevators, weight indicator, lubricator pump, misc tools Price: $320,000

500 hp, manufactured 2007, Pemco 104" x 225,000# derrick, double triple, 100 ton McKissick blocks, BJ style tubing tongs, rod tongs, rod basket, 8"3" bales, 16,993 miles on truck, 4016 hours, all handling tools

Built 1966, Double drum 1058 drawworks, 8500’ sandline, blocks, 96’ x 150,000# derrick, mounted on 4 axle carrier, Detroit 6V92T replaced August 2019, PTO, power steering and alternator/generator needs modifications to work with new Turbo diesel engine

Refurbished 2017, 4 lines, 96’ x 205,000# mast, 8V71 Detroit engine, mounted on CCC, 75 ton McKissick blocks, tubing board, rod basket, work platform, rigged up and working in field Price: $295,000

Manufactured 1977, 72’ x 125,000# derrick, 8V71 Detroit engine (rebuilt), Allison 750 transmission, 6500’ of new 5/8” sand line, tubing line new, drum brakes new, new style McKissick blocks, working daily Price rig only: $157,500

Double drum drawworks with hydromatic brake, 10" brakes, 96" x 180,000# derrick, mounted on 4-axle PEMCO carrier with hydraulic support legs, 8V71 Detroit, 4460 Allison transmission, Spicer 784 split shaft gearbox, 250 hp right angle drive, 650" of 7/8" tubing line, 8000" of 9/16" swab line, 100 ton Sowa block, hydraulic winch, hydraulic weight indicator, 84" links, 2-3/8" and 2-7/8" tubing elevators, BJ tubing slips, Foster 5893R power tongs with lift in derrick, rod hook, rod stripper, rod elevators, wrenches, transfers, rod fishing tools, misc hand tools and connections Price: $140,000

Manufactured 1974, double drum drawworks, double triple 96" x 180,000# derrick with a hydromatic. The rig has working line with heavy traveling block and approx. 12,000" 9/16 sand line. Mounted on Skytop carrier with tandem steering and rear ends 4 axles W/ tag axle, 4 leveling jacks, powered by an 8V-71 with a Allison 4460 transmission, (note transmission was overhauled in early 2000"s) and the engine has a new head on right bank. The rig has two leveling jacks on the rear and two leveling jacks on the front which are located right behind the steering axels. Tooled out with hydraulic rod and hydraulic tubing tongs, air slips, rod and tubing elevators, hand tools and misc over items. PRICE REDUCED: $115,000

10 x 13 pole, double Drum, Franks 33” air over grease, brakes in good shape, 7/8” tubing line, tubing blocks, tong pressure adjustment, hi/low on tubing, air slips control, master kill on drawworks, Foster 36 with 8’ lift ram, air backup, swing around tong rack, mounted on 2001 Freightliner F80 truck, Cat C12 Series 3125, Fuller 9-speed transmission, PTO, winch for pole scope Tulsa 48, blocks raise pole, dual fuel tank, dual battery, 50 gal hyd tank, toolboxes, hydraulic outriggers, BJ rod tongs, ¾” and 7/8” heads, tools, swabs, extra tongs, orbits, drilling head Price: $242,500

Built 1966, Double drum 1058 drawworks, sandline has 5/8” line, 75 ton blocks on tubing drum, 10 x 13 single pole, 6V471 Detroit engine, standard transmission, 3 axle carrier, good tires, misc parts and accessories including chains, seals, old style oiler, sitting since 2016, running when parked, includes spare parts. Price: $47,500

Double drum (second drum is removed, rig is running as single drum), hyd pole and down riggers, mounted on 1990 Crane Carrier, 9 sp Eaton Fuller transmission, 100,000 miles, 8 x 10 telescoping poles, 3/4” cable, no tooling Price: $52,500

10 x 13” pole, single drum, mounted on 1980 Brigadier 9500 Series truck with 671 inline Detroit, drop box, travelling blocks, tubing lines, hyd jacks, no tooling, sitting since 2000 PRICE: $49,500

Cable Tool Drilling and Completion Rig, 60" double poles rated to 150,000#, 5000" drill capacity, 10,000" pull capacity, propane Waukesha 145 engine, 500 gal propane tank, trailer moutned with International 4300 truck, last drilled 2012, 2300" drill line on drum, 3500" on spool casing drum, heavy block sandline drum, cat heads each side, tooling, spare engine Price: $72,500

400’ of 7/8” block line, 9/16” sandline drum (no cable), 2000’ of ¾” drilling drum, 3 McKissick sheaves, air clutches and controls, mounted on 1961 Mack truck with 250 hp Cummins engine, older rig but runs good. Includes elevators, oil saver pump, no BJ tongs, currently working. Price: $87,500 - Pennsylvania

Triple drum, friction clutch, cathead (sandline holds 2400’ of 5/8” line), mounted on tandem axle Chevy truck with 427 gasoline engine, 8-5/8” x 45’ single pole, new tires, power steering, wireline unit, good usable rig for shallow oil/gas lease, drills, workover, swab capabilities, no tools Price: $112,500 - Oklahoma

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This is a family owned company operated by people with over 40 years in the oilfield equipment industry. We have over 100,000 square foot of warehouse and offer a wide selection of well service, work over, and drilling rig tools and parts to accommodate the industry"s many varied needs.

We can create complete rig tool packages, as well as provide equipment locating. We provide our customers with additional expertise to aid in choosing the best products for their application. Our team has skill, experience and knowledge in everything from operating the brake handle to operating oil and gas wells. We understand The tool and supply needs of the petroleum industry.

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

Snubbing units have evolved into one of the most capable and efficient well servicing tools in the oil & gas industry. In the 1920"s, the need for a rig to work with pressures at surface drove the invention of the snubbing unit. The first snubbing unit was primarily designed to work in well control situations to "snub" drill pipe and or casing into, or out of, a well bore when conventional well killing methods could not be used. The first snubbing unit relied on the draw works of the companion rig to supply its" power. A series of sheaves, cables and counter weights were rigged up so that as the rig"s traveling blocks hoisted up, the snubbing unit would snub in the hole. Conversely, when the traveling blocks on the rig were lowered, the snubbing unit would snub out of the hole. As you can imagine, this required close communication with several different contractors in order to perform the work safely and efficiently.

Today"s snubbing units can be employed to provide a wide range of services. In essence, a snubbing unit is a hydraulic rig that can do everything a rig can do, plus it can perform under pressure in an under balanced live well state. This is especially critical to the operators in the Haynesville Shale, which is known for HPHT wells. With the use of the snubbing units" hydraulic rotary, the unit can be employed for fishing, milling, drilling, side tracking or any task needed to remove bridge plugs, cement or deepen wells.

The industry has become more aware of damages caused by heavy kill weight fluids and mud. This has helped make snubbing units more popular in a completion and workover role, versus its" traditional use as a well control response tool. With the advances in drilling technologies in the unconventional shale market, the benefits of snubbing units have become very apparent. These types of completions often have laterals extending out thousands of feet. With costly stimulations used to help extract the gas more efficiently, operators often times do not wish to turn around and load the well with heavy fluids to complete the well dead.

In conclusion, with the snubbing unit"s size, ability to handle pressure, rotary capabilities, rigidity of jointed tubing and minimal wall contact, snubbing units have become the chosen resource for these types of completions.

8613371530291

8613371530291