workover rig companies in north dakota made in china

GRAND FORKS, N.D. (AP) — A Chinese company has chosen Grand Forks as the site of a manufacturing facility that city officials say could be the largest private sector investment in the community’s history.

Fufeng Group Ltd. picked an approximately 370 acre site in Grand Forks’ agri-business park. The facility is expected to initially require 25 million bushels of corn annually.

YP - The Real Yellow PagesSM - helps you find the right local businesses to meet your specific needs. Search results are sorted by a combination of factors to give you a set of choices in response to your search criteria. These factors are similar to those you might use to determine which business to select from a local Yellow Pages directory, including proximity to where you are searching, expertise in the specific services or products you need, and comprehensive business information to help evaluate a business"s suitability for you. “Preferred” listings, or those with featured website buttons, indicate YP advertisers who directly provide information about their businesses to help consumers make more informed buying decisions. YP advertisers receive higher placement in the default ordering of search results and may appear in sponsored listings on the top, side, or bottom of the search results page.

Sanjack has been committed to the research of automatic workover technology for many years and has a perfect automatic workover technology development, production, and manufacturing system.

In recent years, a whole set of automation technology has been formed in the automation and intelligent development of automatic workover equipment. Through the application of module design, servo drive, integrated control, electro-hydraulic compound drive and other technologies, the supporting products suitable for various types of workover equipment have been developed to meet the needs of oilfield workover equipment upgrading.

Second floor platform automatic pipe arranging manipulator replace the derrick worker on the second-story platform, it is to use fully automatic grabbing/arrange pipe string erection operations, realizing unattended operation on the second-story platform.

Drill floor automatic pipe arranging manipulator can replace workers to complete the placement of the column on the drill floor surface, and connect single joint, thread connection, etc., to achieve unmanned operation of the drill floor for major workover operations.

Two kinds of automatic make-up and break-down equipment with different structural forms and different characteristics replace the manual push-pull operation of hydraulic tong.

The tong body floats and hangs, and the tong mouth automatically aligns the center of the pipe string, which can be clamped reliably without damaging the surface of the pipe body.

The original integrated structure of hydraulic tong and punching tong can meet the thread up and down of tubing/drill pipe at the same time. The tong head has a floating function, which can automatically compensate the center deviation between the pipe string and the jaw and reduce the damage when the tong teeth clamp the pipe body. The torque can be accurately controlled and set, and the make-up torque of pipe string meets the requirements of API. When in standby, it can rotate and give way as a whole to provide more active operation space for the drill floor. The tong head can be deflected to meet the make-up & break-down of the mouse hole string.

Instead of the traditional mechanical elevator, the hydraulic drive valve is opened and closed, and the elevator is deflected and overturned, so there is no need to lift the elevator manually.

Main function: replace the field worker to lift the pipe string and realize the automatic transportation of the pipe string from the ground to the drill floor.

The installation centering and positioning mechanism is designed to realize the accurate positioning of the equipment at one time and shorten the installation time.

The push pulley is designed to realize the traveling sliding between the pulley and the pipe string and effectively protect the screw thread of the pipe string.

It adopts programmable integrated control and industrial network communication to realize centralized control, process management and status monitoring of all automation equipment.

The hydraulic station provides hydraulic power for automatic loading and unloading hydraulic clamps, hydraulic elevators, pipe string conveyors, drill floor manipulators and other equipment.

Even as the Asian nation’s giant energy firms only now begin to see the first glimmers of success in their domestic shale fields, a handful of small manufacturers in China have found a quicker way to join the bonanza: supplying ceramic proppants, a key raw material used in hydraulic fracturing.

Over the past three years, China has emerged as a go-to source for the engineered spherical pebbles that, like sand, are injected deep underground to help “prop” open tight shale rocks as part of the controversial fracking process, allowing oil and gas to flow to the surface.

U.S. imports of the proppants from China have surged 12-fold since 2008, data from the U.S. International Trade Commission shows. At year’s end, Chinese imports will account for 13 percent of the total North American ceramic proppant market, a $3 billion a year business, by analysts’ estimates.

The boom may not last forever. U.S. manufacturers are now gearing up to challenge the Chinese. Prices have surged by 60 percent in two years and eventually experts expect China’s own shale revolution to absorb supply.

But for now, U.S. demand is quickening as more and more shale wells are drilled from Ohio to Texas, and more service companies prefer the nearly indestructible properties of the ceramic pebbles over traditional sand -- even at 10 times the price. Private equity investors are circling.

“Demand has grown an awful lot and there is only so much production volume in the world,” said David G. Gallagher, vice president of Houston-based CARBO Ceramics, the world’s largest producer of ceramic proppants, which also has a factory in Louyang, China.

“It’s not like you can say ‘tomorrow I want to build a ceramic plant’ and get it next week. We’re talking about a three-year lag,” he told Reuters on Friday. A sand mine, on the other hand, can be set up in only six months, he said.

The quiet emergence of the niche industry is the latest sign of how the rapid development of U.S. gas-and-oil shale deposits is reverberating across the globe, forcing energy companies to grapple with new and unexpected challenges.

It is pitting firms like Carbo Ceramics and France’s Saint Gobain against a dozen mostly smaller, independent Chinese firms who take advantage of cheap local bauxite -- also the raw material to make alumina -- to scale up quickly.

“It’s a profitable business and doesn’t require too much investment,” says an official with a leading Chinese proppant producer, Guizhou Xinyineng Corp, who declined to be named like many in China’s secretive energy sector.

Guizhou is among the producers that are receiving government support to develop new products. The company has also been approached by a U.S. private equity firm that is trying to consolidate U.S. imports, as well as European firms looking for joint-venture partners to develop China’s Bauxite mines. The official declined to name the companies.

All proppants serve a single purpose: They keep fissures in oil and gas wells open after water and chemicals are pumped into the rock in a process commonly known as fracking.

Ceramic proppants, however, are best for drillers looking for uniform size and chemical consistency. They can withstand high temperatures and pressures, and work well either in conjunction with or as replacements for sand, experts say.

“The reason ceramics work better is because it doesn’t crush under the pressure in deep wells and the wells in North Dakota are at 10,000 to 12,000 feet depth,” says Ryan Leininger, regional manager of Rockwater Energy Solutions, a major supplier of sand and ceramics in the Bakken prospect.

Making them is an intense process. In China, producers cook raw bauxite at temperatures ranging from 1,470 to 1,800 degrees Fahrenheit (800 to 1,000 degrees Celsius) and add a ground powder of patented mineral to the mix, which they cook to temperatures above 2,200 degrees Fahrenheit.

They then sell the final product either directly to oil services firms like Halliburton, Baker Hughes and Schlumberger in China or to import and export agencies that ship the proppant in jumbo tote bags to U.S. West Coast ports like Long Beach, California or Seattle, Washington, industry officials in China and the United States say.

There they are shipped by train, typically to North Dakota, where their tough properties are most highly prized. BNSF Railway, the largest rail carrier in North Dakota’s oil fields, expects overall ceramic freight volumes to double next year.

As more and more drilling rigs are moved into North Dakota, demand for the ceramic variety has grown faster than the sector at large. Total North American proppants demand has nearly quadrupled to 70 billion pounds (31.8 million metric tons) since 2009, energy investment boutique Howard Weil says. The share of ceramics has risen from 10 to 15 percent in that period as more companies use a more sophisticated multiple-stage fracking process.

In the Bakken prospect of North Dakota’s prairies, where advances in shale drilling pushed the state’s output to a record 488,000 barrels-per-day in October, a typical well uses about 3 million pounds (1,500 tons) of sand and other proppants, of which ceramic proppants have grown to take a 30 percent share.

More companies are using ceramic proppants in the Bakken shale play because sand usually crushes when pumped into deep wells. Those who do not want to pay $4 a pound - versus just 40 U.S. cents a pound for sand - are turning to resin-coated sand, which is engineered to have better strength than more common silica sands.

Nonetheless, demand for sand is growing too in North Dakota as more wells are drilled. The region currently sources coveted Ottawa sands from Wisconsin and Minnesota mines, although both Halliburton and Baker Hughes have said they are setting up their own mines to control costs.

A few months ago, Chinese imports were about 20 percent cheaper in North Dakota than proppants manufactured in the United States, industry operators said. That margin has narrowed recently and might shrink further because of the multiple intermediate sellers that link the factories in China to operators in U.S. oil-and-gas fields.

Monte Besler, who runs a business that provides consulting services for exploration companies on their well completion jobs in North Dakota’s Bakken oil fields, says Chinese proppants have quality problems.

“We’ve had issues with contaminants in the proppants. I found balls and razor blades, some pretty crazy things,” he said, adding operators worry about failures on high-pressure pumps because of materials that sneak into proppant shipments as they go through multiple sellers to reach U.S. oil fields.

The price advantage that the imports have enjoyed will dwindle further when China, the world’s largest energy consumer, develops its own shale resources more extensively.

Last week, for example, PetroChina confirmed it is producing shale gas in southwestern Sichuan province, in a joint development with Royal Dutch Shell. It could be the country’s first commercial shale gas production, although PetroChina said it is struggling to attain stable rates of output.

What is more, rising costs of production in the emerging economy are pushing prices higher. Over the last two years, the price of higher-grade ceramic proppants in China has gone up by 60 percent to $800 a ton, industry sources say.

“The inflation things that are happening in China, most Americans don’t understand, but it is large,” Gary Kolstad, CEO of Carbo Ceramics said in late October.

Carbo Ceramics is turning instead to the U.S. market. In August, it applied for a permit to build a proppant plant in Millen, Georgia, in addition to the two factories it already operates in that state. Four other firms have filed for permits to set up or expand six ceramic proppant plants in Georgia, Arkansas, South Carolina and Missouri, states rich with minerals like bauxite.

Despite these concerns and the addition of new American plants, the increasing demand for ceramic proppants in North America will ensure a wide enough playing field for everyone.

“So long as the price of oil and gas is high, there will be demand for our products,” said Ningfang Liang, chief financial officer of China GengSheng Minerals, a Chinese proppant producer listed in New York.

BISMARCK, N.D. (KFYR) - After a China-based manufacturer made moves to develop a corn milling plant in Grand Forks near the US Air Force base, some North Dakota residents are pushing back.

More than 300 acres of farmland in the state was owned by three local farmers and was not for sale when Chinese company Fufeng offered to buy it. They bought the land at more than $26,000 and acre. The city says the corn milling plant would add jobs and tax revenue, but many people have voiced concerns.

A group of residents collected signatures to bring the deal to a city-wide vote. Area property owners have also brought concerns to the city, worrying about higher taxes and costs related to property annexation, traffic increases, and noise and odor.

Assists the Rig Operator in performing job activities associated with the rig-up and rig-down of the workover rig, picking up/laying down and standing back rods…

Manages tools on the workover rig floor and assists in daily maintenance. Must have a minimum of 1 year of experience as a workover rig floorhand to be…

Spot in, rig up, and rig down well service unit (rig). Minimum of 1 year operating rig. Workover rig experience (minimum 6 months verified experience).

Installs / disassembles (rig up/rig down) of wireline and pressure control equipment in accordance with original equipment manufacturer’s standards including…

Operate the rig safely during rig up/down and pulling operations. Perform all required equipment inspections-workover rig, fall arrest system, derrick, hoisting…

The successful candidate will have an outstanding track record of success in workover rig experience in operating heavy equipment while ensuring communication…

Ensures all crew members are at the rig and prepared to work at the scheduled time. Determines how a service job will be performed based on specific conditions…

Inspects the setting up, taking down and transportation of the assigned workover rig. The Rig Operator, reporting to the assigned Tool Pusher/Field Supervisor,…

Operate the rig safely during rig up/down and pulling operations. Perform all required equipment inspections-workover rig, fall arrest system, derrick, hoisting…

Communicates with customer and/or the delegated well site representative, rig crew and field support staff. Plans, directs, supervises, and evaluates the work…

3+ years workover rig / wellsite supervisory experience. Ensures efficient maintenance of assigned rig and equipment. High school diploma, equivalent or higher.

The Floor Hand position is part of a 4-5 person workover rig crew on a well service rig, who are responsible for performing services on oil and gas wells…

Operate the rig safely during rig up/down and pulling operations. Perform all required equipment inspections-workover rig, fall arrest system, derrick, hoisting…

Perform services on oil and gas wells as part of a 3-5 person workover rig crew. Lifts, removes, installs and operates well head pump, jacks and performs other…

We are immediately hiring full snubbing crews for 170k stand alone rig assist and 150k rig assist snubbing units! High school diploma, GED or equivalent.

The Williston City Commission has awarded up to $167,000 in STAR Fund incentives for four business expansions at its meeting on Tuesday, January 26, 2021. The projects included Baja Auto Sales, Circle T Transport and Construction, Prizm Company and Pronghorn Well Service, LLC.

All of the projects utilized the Williston STAR Fund/Bank of North Dakota Flex PACE Program to purchase property for their developments. The Flex PACE may be used to purchase real property and equipment or cover selected capital needs. The Flex PACE combines funds from the PACE Fund and Williston STAR Fund at a 2:1 ratio to buy down the interest rate on businesses’ loan.

Tricia Anderson, Pronghorn Well Service co-owner, said the funds will help them purchase a building and land for equipment storage and maintenance. Pronghorn provides workover rig and oilfield services.

“Having a shop will provide our company a central location to hire new employees, hold safety meetings and training and repair equipment,” said Anderson. “Our hands-on work is out in the oilfield, but we are super excited for the growth potential this grants us.

Keith Olson, Director of the Small Business Development Center in Williston, worked with the owners of all four projects. He said it’s nice to see the Flex PACE program help the local business base grow and expand.

“Most have been working on finding the right space and we have worked with them over the past few years waiting for the right opportunity to buy,” explained Olson. “Flex really helps make it happen when they finally find the purchase that works for them. It is great to see such diverse projects early in the year and from a wide variety of industries.”

“Survival during the pandemic has been challenging,” Anderson admitted. “With a lot of prayer, we have made it through. We are thankful every day for our continued opportunities.”

Baja Auto Sales -up to $32,000 from the Flex PACE Interest Buydown program to purchase the lot at 1014 2nd Street West. Baja is going to relocate its used car lot and detail business to the new, larger location.

Circle T Transport and Construction–up to $42,000 from the Flex PACE Interest Buydown program to purchase a larger shop at 5825 Hamilton Lane. Circle T is a family-owned business that offers a variety of hauling services plus snow removal and mowing.

Prizm Company – The dance school is purchasing property to diversify and grow its business. Prizm received up to $41,000 from the Flex PACE Interest Buydown program to purchase property at 5003 2nd Avenue West. The new location will house a daycare in the residence and a dance studio in the pole barn.

Pronghorn Well Service, LLC – the company has workover rigs and winch trucks to haul oilfield equipment. Pronghorn is purchasing a shop and property at 4914 21st Avenue Northwest for equipment storage and maintenance. They will receive up to $52,000 from the Flex PACE Interest Buydown program to purchase the building.

Baker Hughes is an Equal Opportunity Employer. Employment decisions are made without regard to race, color, religion, national or ethnic origin, sex, sexual orientation, gender identity or expression, age, disability, protected veteran status or other characteristics protected by law.

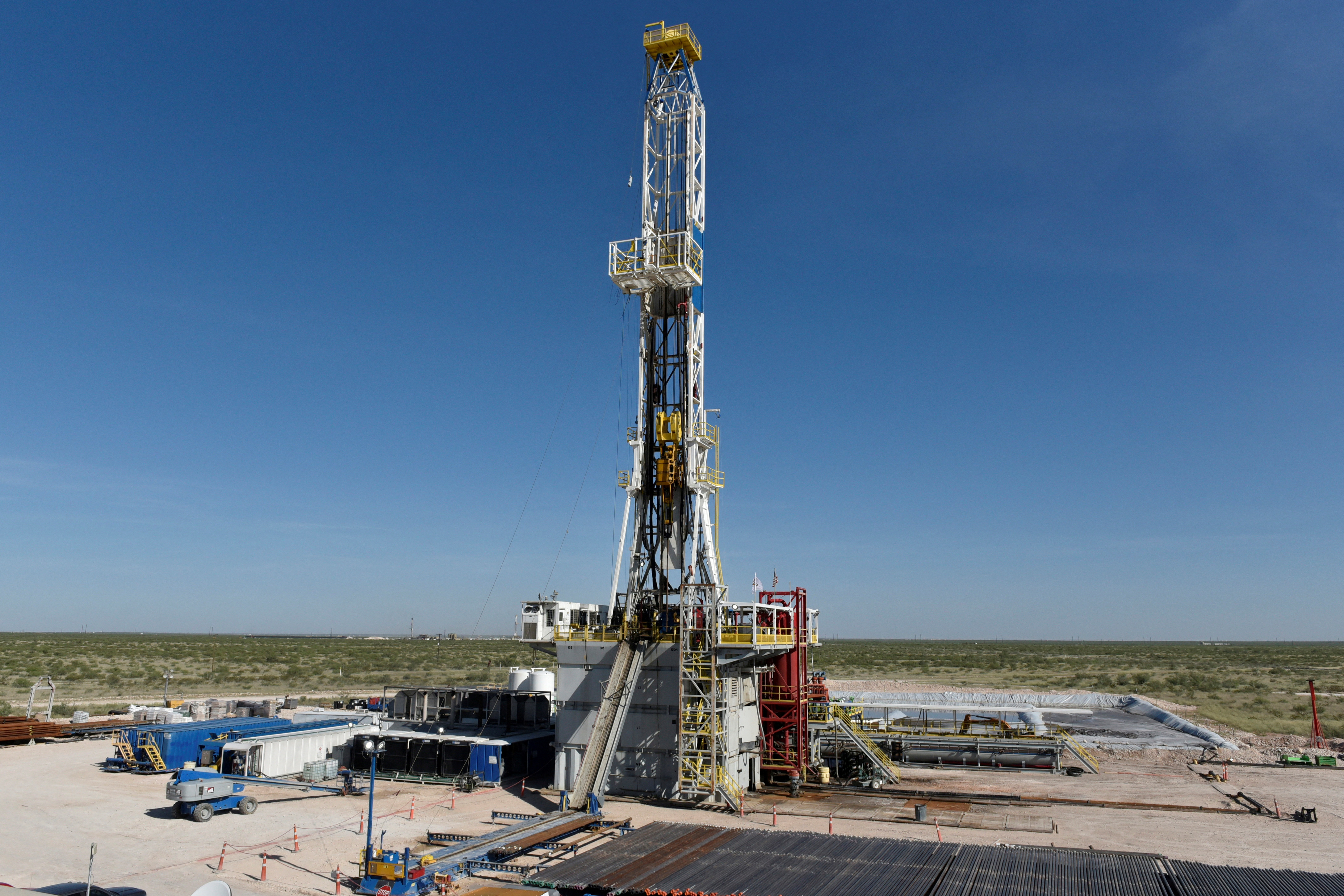

Every workover rig available is going right now in the Bakken, North Dakota’s top oil and gas regulator Lynn Helms said on Friday, during his monthly oil production report, as companies try to get wells online as quickly as possible after back-to-back blizzards idled a substantial number of four and five-well pads in Williams, Divide, and McKenzie counties.

March was a good month for production, Helms said, with a 2.8 percent increase in crude oil production from 1.089 million barrels per day to 1.12 million barrels per day. That figure is 2 percent above revenue forecast. Gas production, meanwhile, rose 4.5 percent to 3.01 billion cubic feet per day from 2.87 billion cubic feet per day in February.

Gas capture percentages were 95 percent, and this time Fort Berthold was a bright spot, with 97 percent capture. Helms said he expects continued improvement in the Fort Berthold area, with new solutions for gas capture in the works for the Twin Buttes area, which has been a problem spot.

But production is not going to look as rosy in April, Helms said, and may not look great in May either, given the time it will take to repair electrical distribution infrastructure. Load limits remain in place because of wet conditions, and that is a condition that might go on for a while, given the recent flooding issues caused by rain.

“We saw production in the first blizzard dropped from about 1.1 million barrels a day to 750,000 a day,” Helms said. “We recovered not quite back to a million barrels a day. And then the second blizzard came in. It was heavily impactful on electrical power and infrastructure in the Bakken oil fields.”

“It took a week, or I guess within a little bit less than a week, we recovered to 700,000 and it’s taken another week, we think we’re back at about a million barrels a day.”

One of the biggest of problems was that so many natural gas processing plants were knocked out of service, some for nine hours and others for well over a week.

“Just this past week, our largest gas plant came on and that’s really enabled a lot of production to come back on,” Helms said. “So we’re back to a million barrels a day, maybe a little more. You know all of the large operators reported enormous production losses. And of course that has led to the deployment of every workover rig available being out there trying to get wells back on production.”

Last weekend in Williams County, a dozen four and five-well pads along Highway 2, headed toward Ray, remained idle. They appeared to be without electricity, with some poles still clearly broken and lines laying down on the ground.

In his discussions with drilling contractors, Helms has learned that most drilling rigs went south to Texas and New Mexico, both of which escape winter sooner than the Bakken. Those areas hired the available workforce, too, which has added to the Bakken’s difficulty in attracting workforce.

“It’s taking around two months to train and deploy a drilling rig and crew, and very similar timeframes for frack crews,” Helms said. “So it’s just very, very slowly coming back.”

“There have not been any new frack fleets constructed since before the pandemic,” Helms said. “So the iron that’s out there is starting to show some wear and tear, some age, and, at some point, we’re going to have to see capital deployed to bring that iron back on.”

“I was reading an article today, and some of the large operators were saying, ‘Well you know we could bid up the price to hire frack crews, but all we would be doing is hiring them away from smaller companies that can’t afford to pay as much.’ So there wouldn’t be a gain in the number operating, in the number of wells completed, or really a more rapid rise in production. So it’s very much workforce limited.”

North Dakota rig counts are at 40 right now and Montana rigs are at 2, according to figures from North Dakota Pipeline Authority Justin Kringstad. Helms said the Bakken hasn’t seen those numbers since March of 2020. There are about 15 frack crews running now, a number last seen in April 2020.

Prices, however, have been well ahead of revenue forecasts, pushed in part by sanctions against Russia, which attempt to choke a major source of financial capital for the invasion of Ukraine, as well as continued supply chain issues and lower than expected production from OPEC.

“Today’s price is almost $102 a barrel for North Dakota light sweet and $106 West Texas,” Helms said. “So we’re estimating about $104 a barrel for North Dakota crude prices. That’s more than double revenue forecast. Revenue forecast was based on $50 oil, so that’s 108 percent above that.”

“And of course the market did not like the signal that it got this week or late last week of the cancellation of the offshore lease sales in the Alaskan lease sales,” Helms said.

“For example, the RMPs, or the resource management programs, and the records of decision from Corps of Engineers and Forest Service weren’t filed along with information about why various quarterly lease sales were canceled,” Helms said. “And why some of the tracts were chosen that were chosen to be in this latest lease sale.”

North Dakota is a few days away from a May 18 deadline for protests in the projected June sale, which has 15 parcels listed. If there’s a protest against one or more of the tracts, they could be pulled from the sale for further consideration.

For the latest global offshore drilling market report, oil drilling market forecast, and top offshore drilling companies profiles, please see Global Offshore Drilling Market Report 2018-2022, or request your

Schlumberger is currently topping the list of the world’s top offshore drilling companies. It is the biggest offshore drilling contractor (in terms of revenue) not just in the US but across the world has a history of science and technology innovation, backed by strategic mergers and acquisitions. From conventional to application-specific systems for geothermal wells, rigs, jack-ups, unconventional plays and more, Schlumberger’s drilling services are designed to trim down the installation time and enhance safety.

Schlumberger supplies the industry’s most comprehensive range of products and services, from exploration through production and integrated pore-to-pipeline solutions for hydrocarbon recovery that optimize reservoir performance.

As part of Newsweek’s ‘Green Rankings’, Schlumberger was ranked 118th out of 500 large eco-conscious companies. In its own speciality, the company is the 3rd ranked offshore driller out of 31 entries.

Halliburton serves the upstream oil and gas sector throughout the lifecycle of the reservoir, from locating reserves and managing geological data, to drilling evaluation, well construction, completion and production optimization through the life of the field. Offshore drilling services offered by Halliburton include horizontal and directional drilling, measurement-while-drilling, logging-while-drilling, multilateral systems, underbalanced applications and rig site information systems.

Fluor Corporation is a MNC engineering and construction firm, the largest such entity in the ‘Fortune 500’ rankings, with a listing of 149. The company specializes in engineering, procurement, and construction management services for drilling and production resources at offshore fields and other energy assets. Fluor was involved in the development of some major offshore areas such as the Enfield oil field in Australia, Nasr/Al-Nasr field development in Abu Dhabi, UAE, the Ku-Maloob-Zaap field in Mexico, and the Bohai Bay field in China.

Baker Hughes specializes in drilling, production, and completion services for oil, gas and other energy industries. Offshore drilling systems offered by Baker Hughes include directional drilling services, measurement-while-drilling, coiled tubing and re-entry, logging-while-drilling, casing/liner drilling systems, drilling optimization, and remote drilling. Who Dat field in the Gulf of Mexico and the Skuld offshore field in the Norwegian Sea are some of the major offshore oil fields wherein the company offers its deep-water drilling services.

Transocean Ltd. is the world’s largest provider of offshore contract drilling services across the globe. With 140 mobile offshore drilling units, four ultra-deepwater new build units, and five high-specification jack-ups, the company’s fleet is considered one of the most versatile and modern in the world owing to its significant emphasis on technically demanding sections of the offshore drilling business.

The company’s operations are geographically dispersed in terms of oil and gas exploration. As its drilling rigs are mobile assets that can be moved according to prevailing market conditions, the company operates comfortably in a single market scenario as well as internationally. More recently, Transocean has shown great resolve in dealing with the oil crash and the industry’s general lethargy and is poised to have a dominant 2018.

For more than 25 years, UK-based Ensco Plc has been bringing energy to the world as an international provider of offshore drilling services in the oil and petroleum industry. Ensco has a significant presence in the most strategic offshore basins across six continents. On Oct 6, 2017, Ensco acquired the Houston-based offshore driller Atwood Oceanics in an all-stock deal. The company has made timely acquisitions to grow into a dominating offshore drilling company, and the acquisition of Atwood has incremented the organization’s brand value.

In 2017, things were a bit uncertain for the Bermuda-based offshore drilling company Seadrill. The company used a Chapter 11 bankruptcy filing to get its balance sheet in order. Bankruptcy risk for Seadrill grew considering a crushing industry downturn and billions of dollars in debt that had to be serviced. However, the company has the most capable, newest fleets of drilling vessels in operation and a strong track record of efficient and safe procedures that make it an ideal partner for several oil producers.

Post declaration of bankruptcy, Seadrill sports a strong balance sheet. The investors are thinking smartly and keeping Seadrill on their radar, to engage once again after the company emerges from bankruptcy completely sometime in 2018. If things go right for Seadrill, 2018 is poised to be an excellent year.

Noble Corporation, one of the leading offshore drilling companies for the oil and gas sector, has had an incredibly difficult time along with its competitors since the start of the oil crash, but has made many noticeable improvements in recent times. The company owns and operates one of the most versatile, modern, and technically advanced fleets in the offshore drilling industry.

Noble’s offshore fleet spells versatility. This affords the company the best vantage point, of all the other big drillers, to fight for and win contracts. This is strategy one for Noble in 2018.

The US based public limited company operates a fleet of 28 offshore drilling units, comprising of 14 drillships and six semisubmersibles along with 14 jack-ups. These machinery are focused squarely on ultra-deepwater and high-specification jack-up drilling jobs, applicable across both emerging and established regions worldwide.

Diamond Offshore Drilling incorporated on April 12, 1989 and traces its foundation to the earliest days of the offshore drilling sector. Today, the company operates in the waters of six continents, supplying comprehensive drilling services to the global energy industry. Configured to attain the optimum balance of performance and flexibility, Diamond Offshore’s fleet has amassed its reputation on more than four decades of real-world drilling experience. The company’s diverse fleet includes 14 jack-ups, 30 semisubmersibles, and one dynamically positioned drillship.

Rowan is one of the best-positioned companies in the offshore drilling industry in terms of both tackling weather weaknesses and taking advantage of the improved industry conditions. The company has the only UDW fleet in the industry composed of all seventh-generation rigs, which delivers extra performance and safety features as requested by customers. The company is financially powerful and has adequate cash to handle its commitments until 2023.

Rowan’s fleet comprises of 23 offshore drilling jackup rigs and 4 UDW drillships. An additional 5 jackup rigs are also listed as part of its JV with Saudi Aramco.

The majority of the company’s 2017 revenue was generated from the following partnerships: 29% : Saudi Aramco, 17% : Anadarko Petroleum, 14% : Cobalt International Energy, 7% : Repsol and ConocoPhillips.

For detailed information about the global offshore drilling market size, offshore oil and gas industry statistics, and top offshore drilling companies, take a look at Technavio’s FREE!

The company operates both in deep waters and shallow, using hi-tech drilling fleet including the ultra-deepwater DP drillships Saipem 12000 and Saipem 10000 and the fifth-generation semi-submersible drilling units Scarabeo 7 and Scarabeo 5.

Weatherford International, domiciled in Switzerland and operationally based in Houston is one of the leading offshore drilling companies and suppliers of a wide range of equipment and services for the oil and gas drilling industry, operating in nearly 100 countries. Their drilling business is on its way to becoming a standalone independent drilling contractor. Today, the company operates with a fleet of 115 rigs and 6000+ people. By and large, it is a new breed service company that provides the industry more efficient operations, extended products and services and greater geographic diversity.

Weatherford is listed in the ‘Euronext Vigeo World 120 index’, an exclusive categorization comprising of 120 of the most advanced companies in the European, North American and APAC regions.

Weatherford was pursuing a groundbreaking OneStim JV with Schlumberger that would have elevated the company’s game considerably. However, as of Jan-2018, this JV has been scrapped.

Currently, Weatherford’s shares are trading at an eight year low. However, these shares have massive gain potential, thus, the company is a favorite at the stock markets.

With many successful refurbishments and new building projects, the Aberdeen, Scotland-based Stena Drilling has been a pioneer in many areas of technological innovation and developments in the offshore drilling companies list. The company operates globally with three midwater drilling rigs and four ultra deepwater drillships. Stena Drilling has been successful in obtaining commercial contracts for a majority of its fleet at attractive rates, thereby securing a prime source of cash flow.

In 2018, Stena Drilling secured a highly lucrative contract to work the giant Samo prospect, located off the coast of Gambia, Africa. This offshore project is expected to churn out 825 million barrels of oil annually.

With nearly five decades of experience in offshore drilling operations, China Oilfield Services Limited (COSL),one of the largest offshore drilling companies in China, is a versatile offshore oilfield service solution provider with sought-after integrated functions and bundled service chain in China and other countries worldwide. The company works in the four major business segments including drilling services, marine, transportation services, geophysical services and well services, covering the exploration, production and development phase of the oil and gas industry.

Nabors Industries, is the largest land drilling company in the US and one of the top international land drilling contractors, with a fleet of more than 200 land drilling rigs operating in significant oil, gas, and geothermal drilling markets worldwide. The company is also grabbing substantial market share in offshore drilling services through dozens of its offshore, barge and jack-up rigs as well as a wide range of complementary oilfield engineering, management, and logistics services, making it one of the leading offshore drilling companies in the world.

As a supplier of offshore platform workover and drilling rigs, Nabors is highly commended for its jack-up and platform rigs, both of which are nestled on the bleeding edge of innovation.

The offshore fleet of the Norwegian company Fred. Olsen Energy with subsidiaries consists of five mid-water semi-submersible drilling rigs and two ultra-deepwater units. Three of its semi-submersible drilling rigs are operating on the Norwegian Continental Shelf. The company’s shipyard, Harland & Wolff, in Northern Ireland, focuses on steel fabrication, ship repair, and engineering services, alongside services for activities associated with offshore wind farms.

KCA Deutagis among the largest offshore drilling companies in the UK. It is a world’s leading provider of drilling and engineering expertise and operates both onshore and offshore. A reliable brand name, KCA Deutag has won several new contracts in recent times. With 125 years of experience, the company is well poised to dominate the global offshore drilling industry. The group consists of four business segments: design and engineering, oilfield equipment manufacturing, land rig and offshore drilling. KCA Deutag operates roughly 90 drilling rigs in more than 20 countries.

Parker Drilling is one of the largest offshore drilling companies in the world, and it is an expert in advanced drilling solutions and is a key entity in the global energy industry. Operational across the world, Parker Drilling specializes in complex offshore-onshore drilling projects, rental tools and project management. The latter includes specialized options such as rig design and construction, alongside the management of its operations.

Other top offshore drilling companies in India, China, the USA, or other regions can be found in Technavio’s Global Offshore Drilling Market Report 2018-2022. Click HERE to get a market snapshot for FREE!

/cloudfront-us-east-2.images.arcpublishing.com/reuters/XMYRPMRVYVIVFDQ3B63SKJODDY.jpg)

An oil rush is on in North Dakota, where production has risen 12-fold since 2000. But along the way, the business has also become dangerous. At least 74 people have died in the Bakken oil fields since 2006. And major oil companies, which have most profited from the boom, often evade accountability when accidents happen.

And the guy told him, you put your time in here, in a year, year-and-a-half, you will be up over $100,000 a year. For a 21-year-old kid, that"s pretty exciting.

If you have ever seen a workover rig, there"s — there"s stacks of pipes in there. His job would be to stand up there and uncouple them or couple them together. And the day of the accident was actually his first day working on the rig.

A blowout. Oil shot 50 feet in the air. Brendan was trapped. The well"s operator had injected saltwater to make the well safe to work on. Even so, the well exploded.

And I go out there and asked him where everybody"s at and how many are there? And he just says, derrick man"s dead, the derrick man"s dead. That"s when I looked up and I saw what I later find out is Brendan burning in the derrick.

Within hours, the rig was a twisted hulk of smoking steel, pinning Brendan"s body under the collapsed wreck. One other worker died. Another lost his legs and later committed suicide. It was the deadliest accident in the Bakken in the last decade.

ERIC BROOKS, Occupational Safety and Health Administration: And in this particular instance, you had an employee that was up on the mast. And so now you have a fire and an explosion. And he doesn"t have anywhere to go, because your emergency egress line wasn"t installed. So, his only avenue would have either been to jump or try to climb down into the flames.

First and foremost, we talk about what we call the exposing employer. You know, I work for you, that relationship. And that"s where the major accountability holds, is with that exposing employer.

There are many layers of contractors in the oil fields. In this case, Brendan was hired by Carlson Well Service, who in turn was working for Oasis Petroleum North America. They"re part of Oasis Petroleum, based in Houston.

A key way energy companies like Oasis further insulate themselves is to hire what are known as company men. They"re site supervisors, but they"re mostly independent contractors outside of OSHA"s purview.

By using independent contractors to oversee their wells, energy companies like Oasis can avoid penalties when things go awry. Oasis misjudged the pressure in the well, the root cause of the accident, says the lawyer for Brendan"s parents, Justin Williams.

JUSTIN WILLIAMS, Attorney for Wegners: All the decisions and all the information with regard to that well were made by Oasis. There was no decisions made that reflected a mentality towards safety.

Williams says Oasis had ultimate control over the site that day. Like most companies, Oasis Petroleum typically receives real-time data on well conditions, pressure, and progress. In fact, this e-mail shows that the very well Brendan was working on had been recognized for setting a drilling speed record just months before.

But OSHA gave Oasis cursory attention in its accident investigation. The attorney for Brendan"s parents says the agency lacks a sophisticated understanding of the oil and gas industry. One of its safety reports on the explosion included a quote straight from Wikipedia.

In fact, that means regulators could not cite the company. A handwritten note from an OSHA investigator shows that, while Baltrusch shut down the well the day before the explosion, the investigator still concluded no Oasis employee was on site.

As a result, while Carlson was fined $63,000, Oasis paid no penalty. Carlson, Baltrusch, and Oasis all declined to be interviewed, but Oasis said the well was safe to work on and sent us this statement: "Oasis puts worker and environmental safety first. Any suggestion that Mr. Baltrusch or Oasis Petroleum might have knowingly put workers in danger is patently false. The release of gas and the subsequent fire was caused by a kick, or sudden and unexpected flow of gas into the wellbore."

There"s another reason top energy companies are not held accountable. Attorney Paul Sanderson says oil field contracts can shield the companies even when they are responsible for accidents.

Sanderson crafted an anti-indemnification bill similar to ones that passed in other oil states like Texas. But Sanderson says he was outgunned by the oil lobby.

And by killing this bill, they certainly created a system where they are continued to allow them to shift the responsibility for their own negligence onto other parties.

Literally, you got the fox in the henhouse. It"s easy to see why they — everybody wants to come to North Dakota and do business, because there"s no restrictions.

And that is one reason the Bakken is so dangerous. Schmitz says it"s often hard for contractors to insist on safety if that gets in the way of production.

If they are incentivized in the wrong way, it is very difficult to tell the person who literally carries the balance of work for your entire company, no, we can"t do this, or, no, we can"t do it that way because it"s unsafe.

Heading to the site of Brendan"s accident, I could see another rig drilling on the very same spot. The new oil well is less than 100 feet from the one that blew up. A simple wood cross commemorates the spot where Brendan was killed four years ago.

His parents reached a settlement with Oasis for an undisclosed amount. But the indemnification helped the oil giant pass on part of these costs to their contractor"s insurance company. Brendan"s father says there"s no real incentive for oil companies to keep workers safe.

To them, there"s just dollar signs coming out of the ground. I don"t think they have any regards to how they"re getting it, and I think they should be responsible for the well-being of the people working on their site.

Our story was produced by Reveal from the Center for Investigative Reporting. You can subscribe to their podcast on iTunes and hear their monthly show on public radio stations across the country. Find a link to their full investigation on our Web site.

The North Dakota oil boom refers to the period of rapidly expanding oil extraction from the Bakken Formation in the state of North Dakota that lasted from the discovery of Parshall Oil Field in 2006, and peaked in 2012,Great Recession, the oil boom resulted in enough jobs to provide North Dakota with the lowest unemployment rate in the United States from 2008 to at least 2014.gross domestic product (GDP) in 2001, rose steadily with the Bakken boom, and had a per capita GDP 29% above the national average by 2013.

By October 2020, total oil rig count in the state had fallen dramatically. According to the North Dakota Department of Mineral Resources, the total oil rig count in the state had fallen from 58 active rigs on October 3, 2019, to only 11 active rigs on October 3, 2020, a reduction of over 80 percent.

By 2012, income from oil royalties was reportedly paying many local mineral owners $50,000 to $60,000 per month, and some more than $100,000 per month. Bruce Gjovig, head of the UND Center for Innovation Foundation in Grand Forks, estimated that the boom was creating 2,000 millionaires per year in North Dakota. By 2010, the average income in Mountrail County more than doubled to $52,027, putting the county into the top 100 richest counties in the United States.

The Bakken boom propelled North Dakota into the top ranks of oil-producing states. By 2007, North Dakota ranked 8th among the states in oil production. In 2008, the state overtook Wyoming and New Mexico; in 2009 it outproduced Louisiana and Oklahoma; and in 2011 and 2012 it surpassed California and Alaska respectively. By 2012, North Dakota was exceeded only by Texas in oil production.

In addition to severance taxes, the state of North Dakota owns extensive mineral rights, which are leased by competitive bidding. In fiscal year 2010, the State Land Department reported that mineral income on its land earned $265 million for the North Dakota school trust fund, and that the trust fund had grown to $1.3 billion.

The federal government is also a major owner of mineral rights in the region, and leases the rights to companies in competitive bidding. In a January 2013 federal lease sale, the top bid was $19,500 per acre for a lease on one tract in North Dakota. Of the lease sale and royalties from the federal tracts, the federal government keeps 52 percent, and passes 48 percent on to the state of North Dakota.

The industrialization and population boom put a strain on roads, water supplies, sewage systems, and government services in the area. Some counties increased in population by almost double from 20,000 to 40,000.

The boom also brought with it increases in crime and social problems.man camps for housing them. Law enforcement agencies reported sharp increases in offenses, particularly violent crime,missing and murdered Indigenous women crisis.

The boom brought dramatic increases in the infrastructure of Western North Dakota. The oil boom"s effect on families is the subject of the Academy Award-nominated documentary short film,

The oil boom in North Dakota experienced a brief decline in 2014 after the Saudi Arabian oil industry increased its output and the price of crude oil fell from $108 to $40.

By October 2020, total oil rig count in North Dakota had fallen. According to the North Dakota Department of Mineral Resources, the total oil rig count in the state had fallen from 58 active rigs on October 3, 2019, to only 11 active rigs on October 3, 2020, a reduction of over 80 percent.

Sankararaman, Darshana; Medhora, Narottam (29 January 2015). "UPDATE 2-Helmerich & Payne may cut 2,000 jobs as it idles rigs". Reuters. Archived from the original on 14 February 2015. Retrieved 3 October 2020.

Gebrekidan, Selam (8 March 2012). "Shale boom turns North Dakota into No. 2 oil producer". Reuters. Archived from the original on 21 September 2013. Retrieved 17 April 2012.

8613371530291

8613371530291