workover rig elevators brands

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Company covers an area of more than 40,000 square meters, registered capital 50.8 million Yuan. And its main products include manual tongs series, slips series, elevators series, elevator links series, bushing series, casing spider series and pneumatic slips series etc. There are 12 products won the national utility model patent product, one invention patent products, five high-tech products, 2 in Nantong famous brand product.

Our products have been sold to various domestic oilfields and exported to Europe, America, Middle East, Central Asia, North Africa and South-East Asia and other overseas regions. Equipped with excellent equipment, strong technique force and completed test facilities, the company constantly innovate and expand market. Now the company has become a first-level supply member of Chinese Petroleum & Natural Gas Consortium, as well as the member of China Petrochemical Material Resources Market. We have obtained the Production License issued by the nation. Strict quality control has allowed us to gain the ISO9001-2008 certificate of quality management system, ISO1400:2004 environment management system certification and GB/T28001-2011 occupational health and safety management system certification and have the right to use API Spec 7K, 8C monogram. Since 2004 and has become a network members Petrochina, CNOOC, Sinopec level, won the "private technology enterprises in Jiangsu province" title, and won the "enterprise credit AAA level" and Nantong "contract" AAA level enterprise title Exploring the way forward in practice and surpassing self in innovation, our ‘Zero Defect and Zero Distance’ service purpose is bringing us more and more business partners.

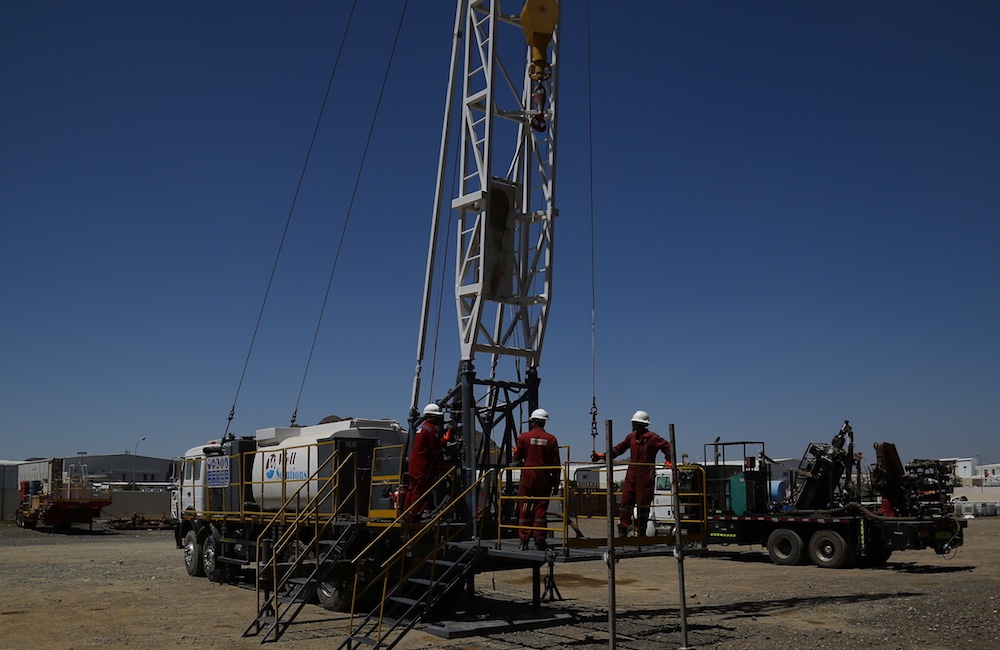

Watson/Hopper, Inc. was incorporated in the State of New Mexico in May 1993. Watson Hopper is 100% owned by Watson Truck & Supply, Inc. which has been in business since 1943. Watson Hopper is engaged in the manufacturing and sale of replacement parts for Hopper rigs, as well as the manufacturing of new well service units, which are called Watson/Hoppers. In November 2003, Watson/Hopper also acquired the blueprints, drawings and trade name “Corsair” from the Crane Carrier Company of Tulsa, Oklahoma. Watson/Hopper markets and manufactures replacement parts and new equipment for the Corsair line of rigs. The company has been in the same family since 1943.

Oilfield Supply, LLC provides all the parts and handling tools needed on well service rigs. This includes blocks, tongs, slips, elevators, weight indicators and anything else you can imagine. We strive to be able to provide a one stop shop for all your needs.

Our continuing operations include: Full Service, Franchised International Truck Dealer, Authorized Dealer for Allison and Cummins, Oilfield Supply Store with nationally recognized brands represented for blocks, tubing tongs, rod tongs, slips, elevators and just about anything else you need in the oilfield. We have a fantastic facility for refurbishment, repair and fabrication of virtually any type of heavy equipment which we call our Unit Shop.

Watson Hopper which is a wholly owned subsidiary of Watson Truck & Supply offers the Watson Hopper, Watson Corsair product line of workover rigs as well as the Raven pump. Our facility in Hobbs is API 4(f) certified. Our welding programs are overseen by two certified weld inspectors (CWI) and our engineering department is headed by a Professional Engineer (PE).

Attached to the hook or top drive with bails, our elevators help you to handle singles or strings of casing, tubing, risers, and high corrosion-resistant-alloy completion tubing. These elevators—including automated, flush joint, remote operated, and spider/elevator combinations—offer various operating methods, from manual to remote, and they enable running pipe with or without collars.

Unlike conventional elevators, our remote-operated single-joint elevator lifts single joints of tubing and casing without manual handling. The elevator accommodates pipe sizes between 3-1/2 and 20 in. and has a weight load limit of 6 tons (5,443 kg).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

WILSON WELL SERVICE RIG (Ref#3000Ta) 103’ x 248,000# derrick, Out of service since 2017, lot of rust, will start and run and/or drive down the road POR

Refurbished, 700 hp, Double drum 2042 drawwroks with Parmac 202 brake assist, (2) Caterpillar 3406 Engines, (2) rebuilt Allison 750 6 speed auto transmission with reverse. 112" x 300,000 # hook load capacity on 8 lines, clear height 97 feet, leg spread 7" 6-1/2", racking board, oil bath chain case, elevated rotary drive, all raising lines and guidelines. The Draw-works, hydro-mantic break, and crown assembly have been rebuilt. Heavy duty Draw works drive propeller shaft through right angle gear box, rotary drive propeller shaft, heavy duty reverse gear box and oil bath roller chain, and a self-locking handling winch. Mounted on triple front axle mechanical 6 axle carrier with 134,000# capacity designed to meet highway safety standards with necessary toughness for off road operations. Price: $265,000

Manufactured 2014, 72’ x 180,000# derrick on 4-line (250,000# on 6-line), mounted on 5 axle carrier, Detroit Series 60, Allison transmission, all hydraulic, 8000’ of 5/8” sandline, 100 ton McKissick casing blocks, 1” line 42” x 12” casing drum, 42” x 12” sand drum, disc assist on casing drum, 1500 hours, 3000 miles. Westco power tongs 1-1/2”, 2”, 2-7/8” and 5-1/2”, set of bails/links, tubing elevators 1-1/2” – 2”, rod hook, elevators, wrenches, swab tools, Martin Decker weight indicator, stored inside Price: $645,000

Derrick fell onto rig when being raised, derrick would need to be replaced or repaired. Built 1981, double drum, 42 x 12, 42 x 8, swab drum removed from jack shaft, 5-axle back in carrier, 250,000# derrick with double racking board and triple rod basket, Cat 3408, CLT 5860 transmission, Cooper right angle box, 4 hydraulic leveling jacks, air rod transfer in derrick, hydraulic winch, Kerr 6 cyd 10000 psi Mustang pump powered from jack shaft, Kerr 3-valve release 10,000 psi, tong carrier f/Foster, steel work platform, Parmac 22 SR hydromatic brake. Extra rebuilt 3408 Cat engine. Price as is: $112,500

Manufactured 1981, mounted on 5 axle carrier, double triple service rig, 96’ x 250,000# derrick, Detroit Series 60 12.7 diesel engine, Allison transmission, 9/16” sandline, 1” drill line, hydraulic jacks, hydraulic catwalk, travelling block, tubing bard, rod basket and all necessary lines. Tooling not included. Price: $115,000

Manufactured 1983, double drum, 96’ x 180,000# derrick, mounted on 5 axle carrier with 92T engine, Allison transmission Price rig only: $300,000 Price with tooling:$340,000

WILSON 42 WELL SERVICE RIG(Ref#7562Ta) Manufactured 1975, 180,000# Pemco double/triple derrick, mounted on Wilson carrier with Detroit 8V71 engine, 4 hydraulic leveling jacks, ready to work Price rig only: $74,500 Price with tooling: $94,500

Manufactured 1983, 70" x 120,000# non telescoping stiff mast, double drum 26 x 8, Detroit 6V71 diesel engine, 740 Allison transmission with Spicer power divider, mounted on 4 axle carrier. Rig runs and truck drives, stacked for several years, good condition Price: $93,500 USD

Manufactured 2009, Detroit 60 Series engine, 96" x 225,000# mast, mounted on 5 axle carrier, blocks, elevators, air slips, one owner Price: $420,000

FRANKS 500 WORKOVER RIG(Ref#7615Tc) Built 1980, refurbished 2018, 102’ derrick, 150 ton blocks, 15,000’ sandline, new engine and transmission, ready to work Price: $430,000

FRANKS 400 WORKOVER RIG(Ref#7615Ta) Built 1979, refurbished 2017, 102’ x 215,000# derrick, 100 ton blocks, 15,000’ sandline, 4 lines Price: $390,000

FRANKS 300 SERVICE RIG(Ref#1169Ta) 4-legged derrick, Series 60 Detroit engine, 6850 Allison transmission, blocks, Foster tongs, mounted on 4 axle carrier, working condition Price: $37,500

Manufactured 2004, Cat diesel engine, 96" x 250,000# mast, mounted on 5 axle carrier, blocks, elevators, air slips, needs new air lines Price: $170,000

Manufactured 1979, double drum drawworks, Lebrus grooved for 1-1/8" drill line swedged to 1", 9/16" sandlne, Totco 190,000# weight indicator, air clutches, Parmac single hydromatic brake, hydraulic and pneumatic controls, Wilson 96" x 180,000# mast hydraulically raised and scoped, 3-stage raising ram, crown safety platform, double tubing board, triple rod board, ladder, guylines, adjustable working platform. Wilson tandem axle front, tri axle rear carrier with Detroit Series 60 diesel engine, electric start, radiator, gauges, Allison automatic transmission, air compressor, hydraulic pump, single man cab, Braden hydraulic winch, hyd reservoir, water tank, 4 hyd levleing ajcks, folding walkways, safety rails, toolboxes, McKissick 100 ton block, 84"L elevators, Foster hyd tubing tongs, Gill rod tongs, Cavins Type C tubing slips, 2-7/8" tubing elevators, 2-3/8 tubing elevators, rod elevators Price: $245,000

WILSON MOGUEL 42 WELL SERVICE RIG(Ref#3177Tb) Two available, 96" x 280,000# mast, Detroit Series 60 engine, 5860 Allison transmission, mounted on 5 axle Wilson carrier, handling tools Price: $315,000

Workover rig with 83’ telescoping derrick, 10’ crown extension, 200,000# lift capacity, 100,000# snubbing capacity. Catwalk with 42’ reach, forward and revere motion, hydraulic pipe slide, six portable pipe racks, powered by workover rig. 5000 ft/lb hydraulic rotary, 15k psi working pressure capability kelly hose, 300 ton mast with 5 x 5 heavy wall box tubing and 2 x 2 heavy wall cross sections, (2) mast raising cylinders, 9-1/8 x 25’ telescoping cylinders/crown sheaves with cable guides, (2) winch sheaves/snubbing sheaves, SRS fall protection, retractable flow tube design, non-swivel boom pole on curb side winch, (2) mast supports, 1” lifting cables, mounted on 5 axle Crane Carrier (3rd axle drop), with 375k Volvo Penta engine, 150 gal fuel capacity, hydraulic self-leveling components, 6 speed Allison transmission, 1:1 gear box, (2) 65 gpm pumps, (2) 30 gpm pumps, (1) 28 gpm Commercial shearing pump, 40 gal accumulator storage, single man cab, hydraulic leveling jacks Price on Request

Year 2006, double drum, 8V71 Detroit diesel engine, 5860 Allison automatic transmission, mounted on 5 axle Crane Carrier, 108’ x 225,000# derrick, 100 ton McKissick 3-sheave block, fully tooled with 6’ bailers, 58-93 tongs, 2-3/8 and 2-7/8 elevators, 3/4 and 7/8 rod elevators and wrenches, eight indicator, laydown floor Price: $162,500

Manufactured 1960’s, double drum, single rig mast, 64’ x 250,000# (tubing and rod racks), 70 ton blocks, 2 lines, Detroit diesel 60 gpm @ 2000 psi, hydraulic system, air clutch. Rig was refurbished 2013/2014 at a cost of $130,000: repairs included used 65’ derrick installed, new 1” main line, repairs to air system, hydraulic system upgrade, leveling jacks, derrick ljghting, tires, 70 ton blocks installed. But the rig has been sitting since 2015 and now needs rebuilding. It doesn’t run. Price as is: $19,500

Manufactured 1980, completely refurbished 2004, 5 axle double drum well service unit, double 15 Parmac brake on main drum, 96" x 180,000# hydraulic raised mast, mast lighting, Detroit 60 Sereis engine, 5860 Allison 6 speed transmission, 4 hydraulic leveling jacks, dual manual outriggers, PD12 Braden utility winch, McKissick 100 ton tubing block 21-31 diving, 1000" of 1" tubing line, 13000" of 9/16" sandline Price: $225,000

CARDWELL KB200B SERVICE RIG(Ref#11674Ta) 72’ x 140,000# stiff mast, 40 x 10 double drum drawworks, 2 aux deck winches, tubing board, rod board, cat walks, railing, stairs, floor BOP controls and accumulator bottles, McKissick 75 ton tubing block and hook, mounted on 5 axle carrier, Detroit 8V71 diesel engine, Alliston CLBT4460 auto transmission PRICE: $127,500

Rig manufacture 1980, mounted on 1980 GMC Brigadier with Cat 3208 engine, includes elevators & misc tools, also includes 1996 1-ton Super Duty tool truck, tandem axle, Cat 3208 diesel, sitting 1-1/2 years Price: $92,500

1980, 475 hp, single drum (new), reworked, 96" x 205,000# hydraulically raised mast, 6 lines, crown block: 3 new sheaves blocks and bearings, racking board, guide wires, (2) hydraulic hoist, weight indicator, block, elevator links, fall safety device, work platform, mounted on 4 axle carrier with Detroit Series 60 diesel engine, Allison transmission, rig in excellent condition and has been well maintained, ready for use PRICE: $115,000

SKYTOP BREWSTER RR400(Ref#13190T) Mounted on 4 axle carrier, single drum drawworks, 8x7 disc assisted brakes, tubing board, Cat3406B engine, Allison 860DB transmission, 100 ton McKissick block, Foster 58-92R tongs, misc hand tools, approx 36" base beam for rig, ready to work Price: $110,000

Manufactured 1976, 50 Series Detroit engine, 4460 Allison auto transmission, 96" x 180,000# Skytop derrick, 100 ton McKissick blocks, 7000" of 9/16" sandline, BJ tubing tongs, Guiberson air slips, 2-3/8 and 2-7/8 elevators, rod wrench, rod elevators, weight indicator, lubricator pump, misc tools Price: $320,000

Refurbished 2017, 4 lines, 96’ x 205,000# mast, 8V71 Detroit engine, mounted on CCC, 75 ton McKissick blocks, tubing board, rod basket, work platform, rigged up and working in field Price: $295,000

Manufactured 1977, 72’ x 125,000# derrick, 8V71 Detroit engine (rebuilt), Allison 750 transmission, 6500’ of new 5/8” sand line, tubing line new, drum brakes new, new style McKissick blocks, working daily Price rig only: $157,500

Double drum drawworks with hydromatic brake, 10" brakes, 96" x 180,000# derrick, mounted on 4-axle PEMCO carrier with hydraulic support legs, 8V71 Detroit, 4460 Allison transmission, Spicer 784 split shaft gearbox, 250 hp right angle drive, 650" of 7/8" tubing line, 8000" of 9/16" swab line, 100 ton Sowa block, hydraulic winch, hydraulic weight indicator, 84" links, 2-3/8" and 2-7/8" tubing elevators, BJ tubing slips, Foster 5893R power tongs with lift in derrick, rod hook, rod stripper, rod elevators, wrenches, transfers, rod fishing tools, misc hand tools and connections Price: $140,000

Manufactured 1974, double drum drawworks, double triple 96" x 180,000# derrick with a hydromatic. The rig has working line with heavy traveling block and approx. 12,000" 9/16 sand line. Mounted on Skytop carrier with tandem steering and rear ends 4 axles W/ tag axle, 4 leveling jacks, powered by an 8V-71 with a Allison 4460 transmission, (note transmission was overhauled in early 2000"s) and the engine has a new head on right bank. The rig has two leveling jacks on the rear and two leveling jacks on the front which are located right behind the steering axels. Tooled out with hydraulic rod and hydraulic tubing tongs, air slips, rod and tubing elevators, hand tools and misc over items. PRICE REDUCED: $115,000

10 x 13 pole, double Drum, Franks 33” air over grease, brakes in good shape, 7/8” tubing line, tubing blocks, tong pressure adjustment, hi/low on tubing, air slips control, master kill on drawworks, Foster 36 with 8’ lift ram, air backup, swing around tong rack, mounted on 2001 Freightliner F80 truck, Cat C12 Series 3125, Fuller 9-speed transmission, PTO, winch for pole scope Tulsa 48, blocks raise pole, dual fuel tank, dual battery, 50 gal hyd tank, toolboxes, hydraulic outriggers, BJ rod tongs, ¾” and 7/8” heads, tools, swabs, extra tongs, orbits, drilling head Price: $242,500

Built 1979, 65’ 10” x 13” poles hydraulically raised, block line, sandline, winch line, hydromatic brake, new Detroit 8V71 engine (installed by Stewart Stevenson) and new Allison 750 transmission, mounted on 4-axle carrier with single man cab, hydraulic leveling jacks, hydraulic utility hoist, air and hydraulic control and floatation tires, sand pump, two bailers, Foster tongs, 2 bailers, sand pump, rod and tubing elevators and all tools Price:$94,500

Double drum (second drum is removed, rig is running as single drum), hyd pole and down riggers, mounted on 1990 Crane Carrier, 9 sp Eaton Fuller transmission, 100,000 miles, 8 x 10 telescoping poles, 3/4” cable, no tooling Price: $52,500

10 x 13” pole, single drum, mounted on 1980 Brigadier 9500 Series truck with 671 inline Detroit, drop box, travelling blocks, tubing lines, hyd jacks, no tooling, sitting since 2000 PRICE: $49,500

Cable Tool Drilling and Completion Rig, 60" double poles rated to 150,000#, 5000" drill capacity, 10,000" pull capacity, propane Waukesha 145 engine, 500 gal propane tank, trailer moutned with International 4300 truck, last drilled 2012, 2300" drill line on drum, 3500" on spool casing drum, heavy block sandline drum, cat heads each side, tooling, spare engine Price: $72,500

400’ of 7/8” block line, 9/16” sandline drum (no cable), 2000’ of ¾” drilling drum, 3 McKissick sheaves, air clutches and controls, mounted on 1961 Mack truck with 250 hp Cummins engine, older rig but runs good. Includes elevators, oil saver pump, no BJ tongs, currently working. Price: $87,500 - Pennsylvania

Triple drum, friction clutch, cathead (sandline holds 2400’ of 5/8” line), mounted on tandem axle Chevy truck with 427 gasoline engine, 8-5/8” x 45’ single pole, new tires, power steering, wireline unit, good usable rig for shallow oil/gas lease, drills, workover, swab capabilities, no tools Price: $112,500 - Oklahoma

If within 7 days you would like to return a photograph for any reason just place the photograph in the original shipping carton and return undamaged to us.

Since 1999, Rig Tool Products has been serving the Drilling and Well Servicing community to meet the demand for products that exceed industry standards. Our many years of experience in manufacturing have given us the knowledge to meet these demands, allowing us to produce quality parts at affordable prices.

Rig Tool Products offers many consumable parts for name brand handling tools in today’s marketplace. Our specializations include tong dies, slip inserts, tubing spiders, manual slips, power tong parts, elevators, manual tong parts, rubber products, brake blocks, brake rims and brake bands. Through precise engineering, our goods have the ability to interchange with OEM tools such as Varco, Baash Ross, Woolley, Guiberson, Cavins, Foster, BJ, Oil Country and many more.

With multiple manufacturing facilities, we have allowed ourselves the opportunity to expand our product lines as well as increase our inventory, giving us the ability to meet your needs when you need it most. As Rig Tool Products continues to expand our global presence, our company and employees remain dedicated to the standard of service and parts we’ve come to be known for!

KET is a leading manufacturer of Drill Pipe Elevators. We design and precision-machine all of our elevators to meet and exceed API Standards (API 8C or API 7K Standards), with KET and the API monogram stamped on our equipment, you can be sure you are getting high-grade equipment at a competitive price, made in the USA.

We understand the critical requirements of the oil and gas industry and the need for high-quality tools and parts. Our elevators include Safety Latch Lock Pins – designed to keep the elevator’s safety latch locked in place, preventing the elevator from being accidentally released

Oilfield elevators are used to wrap around the tool joint of drip pipe or casing, and to facilitate the lifting and lowering of the pipe or the drill string. Of all the components on a rig, elevators are one of the most stressed, and require regular inspection. Ideally, sets of spare elevators are often required for general operations.But, realistically, elevators aren’t always recertified as often as they should be. Due to the prevailing conditions of the offshore drilling business (as well as the difficulty of reaching offshore rigs in general), routine inspections may often be skipped. But this is a lose-lose proposition for the rig — faulty and potentially risky elevators can stop operations and cost companies millions.That’s why you need to ensure that all your offshore equipment is recertified. Recertification is not only a good idea for daily operations, but it also gives your company an easy way out via insurance in the event of an accident.

Of course, it’s not quite that simple. The reason many rigs tend to lapse in their recertification is because it’s a complex and often tedious process that stops operations, and which can incur hefty costs in the form of penalties and new equipment.Still, it doesn’t have to be that way. The proper habits and precautionary steps can ensure that recertification is always a simple, relatively straightforward experience with minimal costs to the company.

One surefire way to guarantee recertification is by only buying certified equipment in the first place.The American Petroleum Institute (API) licenses “Drilling and Production Hoisting Equipment” manufacturers under API Spec 8C, which covers elevator links, tubing and rill pipe elevators, sucker rod elevators, spiders (if capable of being used as elevators) and various other types of hoisting equipment. Any elevator manufacturer who wishes to have the API’s seal of approval needs to fill out this form to apply for the official monogram.The API is a globally recognized certification and licensing leader in various industries, and also has extensive experience licensing and certifying regular elevators as well. Any manufacturer with the API seal of approval is likely to have already undergone a few of the necessary certification requirements.

But it goes without saying that an elevator that goes over the 10-year mark is probably nowhere near the same condition it was when you bought it.That’s why routine inspection is so important. All drill rig elevators should be examined on a weekly basis for cracks, dents, loose couplings or other signs of wear and tear. Any potentially damaged elevators should be swapped out with their fresh replacements before an accident occurs and brings ground operations to a halt.This simple visual inspection can end up saving your rig hundreds of thousands of dollars throughout its lifetime, and allow you to make the most of your equipment without unnecessary headaches.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Providing the right equipment and delivering the highest quality, customized services is our priority. Meeting customer needs with efficiency & safety is our aim. We are available 24/7 to provide installation, service and repair to your equipment. At Liberty Lift, we know that when the oil stops flowing, your company stops profiting. Let us help you continue to work quickly, safely and with maximum uptime.Contact Liberty Liftin Midland, Texas, today.

Artificial lift systems are our passion. Oil does not flow naturally from drilled wells, and artificial lift equipment is a key solution to that problem. Efficient and reliable artificial lift operations require the right equipment and servicing. At Liberty Lift, we offer field-proven equipment that has been designed by thoughtful, experienced engineers in the oil and gas industry. We manufacture and offer beam pumping units, hydraulic jet pumps, long stroke pumping units, and gas lift systems that can either be leased or purchased.

If you are in the business of gas or oil production and conduct drillings, have an oil rig, need parts or repairs, among other many tasks and operations, we havethe equipment you needto get the job done right.

Our XL Long Stroke pumping unit solves problems. Due to fewer cycles, problems with rods, tubing and workover frequency are reduced. Among other benefits, this unit features top sprockets, a counterweight box, gear reducers, top drum supported by two self-aligning double-row spherical roller bearings, and unit sentry operational safety monitoring, in addition to all the standard features of a long stroke pumping unit. Learn more about ourXL Long Stroke pumping units.

Single Joint Elevator also called Auxiliary Elevator. Lake Petro provides Single Joint Elevator with SJ type, SP type and SJX type. All of these elevators are designed and manufactured according to 8A/8C spec.

SLX auxiliary elevators are hoisting tools for handling single pipes or working together with the professional tools CRT to move the tubulars from gate to well centre.

8613371530291

8613371530291