workover rig inspection checklist supplier

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

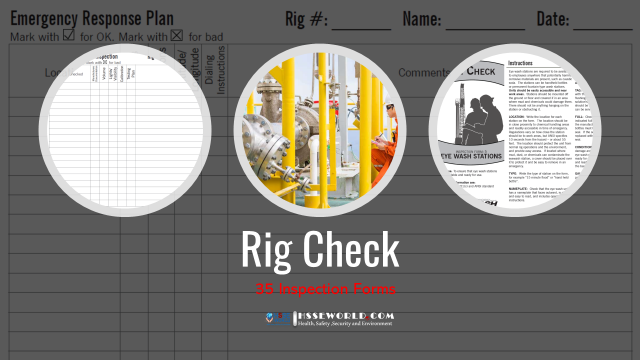

Rig Check was developed by the National Institute for Occupational Safety and Health (NIOSH) in partnership with safety experts from the oil and gas extraction industry. It is made up of 35 inspection forms. The forms are designed to be used by rig workers to document the inspection of tools and equipment commonly found on rotary and workover rigs. Each inspection form includes instructions for assessing and recording the condition of the equipment. When applicable, relevant federal regulations and industry recommended practices are included.

The Rig Check inspection forms are an excellent training tool for short service employees, who may not be familiar with the tools and equipment found on oil and gas rigs. Small companies whose safety and health resources are limited may find Rig Check useful for enhancing their HSE programs.

Ensure that each well has an emergency response plan, which includes simple instructions for notifications in the event of a rig-based emergency. Notification protocols for medical emergencies, fire on the rig or location, gas release or loss of well control, or a security breach should all be included. In most cases, there will be contingency plans in place for the well that address notifications for long-term events that include notification of government agencies and outside well control expertise. These contingencies can be noted in the working plan but should not complicate the posted action plan.

LOCATIONS: Write locations of posted, current emergency response plans. These should be in central locations such as the rig doghouse, change house, Rig Supervisor’s office, Company Man’s office, and rig camp.

In addition, check that the response plan is posted anywhere emergency communications may be made, including the Rig Supervisor’s truck, and the guard shack.

ALARMS:Rig emergency alarms may be automatic or operated by personnel from various locations manually. Whichever the case, the alarms should be heard throughout the rig and on the location. The alarms should be distinctive and easy to identify as to their purpose. Alarms that work in conjunction with lights should be visible from the entrance of the location. It is a good practice to include a wind direction indicator in close proximity to the lights. All employees should be trained to activate manual alarms and understand what triggers automatic alarms.

DEVICES:Emergency shut-down devices (ESD) that will close off the combustion air should be installed on all of the rig’s diesel engines. It is important to understand just how particular ESD functions BEFORE you attempt to test it. Engine shutdowns or rig savers may damage engine components if they are engaged when the engine is running at speed. Careful plans should be made with the mechanics to develop a test protocol that will ensure the functionality of the devices without damaging the engine. In most cases, these devices can be checked with the engine shut down. Manual engine shutdown devices that shut off the fuel to the engines can also be tested while the engine is shut down.

SMOKE ALARMS:Smoke alarms in trailers and outbuildings should be function tested monthly or following a rig move. Note on the inspection form when batteries are changed each year.

the rig should have a written plan for calibrating and testing alarms and shutdown devices. The inspection should include a review of these documents to ensure new equipment and or rig modifications have not altered the function of the devices.

These checklists are not all inclusive. You may wish to add to them or delete portions that do not apply to your workplace. Carefully consider each item as you come to it and then make your decision. Do not spend time with items that have no application to your workplace.

Drilling rigs are some of the most dangerous workplaces or "sites" on Earth. Working on and around a drilling rig introduces many of the most dangerous hazards associated with industrial work including heights, dangerous chemicals, high pressures, explosive materials and more.

To prevent disasters and ensure that everyone working on these rigs does remain safe (and that the reputation of drilling and energy companies remains in tact), companies and workers engage in a number of safety procedures including drilling rig inspections.

These inspections are designed to guide an inspector, auditor or applicable person through a series of checklist questions which have been created to surface any obvious, urgent or problematic issues.

The template comes pre-built with sections for permits, site, stairs and ladders, the rig floor, fuel tanks, electrical systems, material handling and more.

You can also export the resulting checklist report, so that you can make your inspection process nice and efficient while having the convenience of perfectly formatted PDF reports as well.

Rig Inspections will be conducted using the OCS Group Acceptance Guidelines Program, which includes testing of all equipment and systems to verify their condition and performance.

Intrusive inspections of the internal parts of specific equipment including critical measurements and clearance to ensure equipment is running within recommended tolerances.

Verification that the rig equipment complies with API standards, the equipment manufacturer’s specifications and recommendations and good engineering practices.

Rig Inspections are preferably completed between wells, so access to all equipment can be managed however they can be completed at Inspections can also be conducted when the rig is at the well location so full testing can be safely and efficiently conducted.

The assistance of the crew is required to operate the equipment for testing, and assist with testing of various items such as isolation or preparation for internal inspection, including measurement of clearances. During the inspection the rig has to be adequately manned, and the crew must be familiar with the rig specific systems.

All consumables and equipment should be available on the rig like water in the pits, a sufficient quantity of barite and sufficient drill pipe to make up stands.

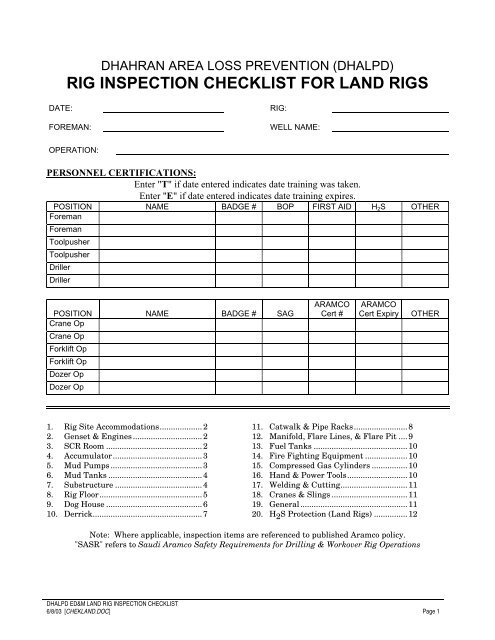

INTRODUCTION..........................................................................................................................................................2PROCEDURE..................................................................................................................................................................2INSPECTION SECTION..............................................................................................................................................5CONTRACTOR PERSONNEL..................................................................................................................................5Specifications..........................................................................................................................................................5Inspection...............................................................................................................................................................5MAST, DERRICK, SUBS AND CROWN..................................................................................................................6DRAWWORKS, BRAKES AND POWER SYSTEMS..............................................................................................7HOISTING SYSTEMS...............................................................................................................................................8ROTARY TABLE, BUSHINGS, AND SLIPS...............................................................................................................9KELLY, SWIVEL, SPINER AND KELLY COCKS.................................................................................................10ANCILLARY RIG FLOOR TOOLS.........................................................................................................................11ACCUMULATORS AND BOPS..............................................................................................................................12MUD PUMPS AND CHARGING SYSTEMS.........................................................................................................13PRIME MOVERS, GENERATORS AND COMPRESSORS..................................................................................14MUD PITS AND FLUID PROCESS EQUIPMENT................................................................................................16DRILL STRING AND FISHING TOOLS................................................................................................................17ACCEPTANCE TEST.................................................................................................................................................20CONTRACTOR PERSONNEL................................................................................................................................20MAST, DERRICK, SUBS AND CROWN................................................................................................................21DRAWWORKS, AUXILIARY BRAKE, POWER SYSTEM..................................................................................231.0 Detailed Inspection.....................................................................................................................................232.0 Load Tests...................................................................................................................................................24HOISTING TOOLS...................................................................................................................................................26ROTARY TABLE, BUSHINGS, SLIPS....................................................................................................................28KELLY, KELLY SPINNERS, KELLY COCKS........................................................................................................29ANCILLARY RIG FLOOR TOOLS.........................................................................................................................31CLOSING UNIT, BOP"S, ASSOCIATED EQUIPMENT.........................................................................................331.0 Detailed Inspection.....................................................................................................................................332.0 Operational Test..........................................................................................................................................34MUD PUMPS, CHARGING SYSTEM....................................................................................................................351.0 Detailed Inspection.....................................................................................................................................352.0 Load Test.....................................................................................................................................................36MUD PITS AND FLUID PROCESS EQUIPMENT................................................................................................38DRILL STRING AND FISHING TOOLS................................................................................................................40

INTRODUCTIONThe purpose of the Rig Inspection and Acceptance Booklet is two fold. The first function is todetermine by means of an on site inspection those rigs whose equipment maintenance, condition,and personnel make them capable of efficiently performing the work planned. This function isfulfilled by the Inspection section. The second section, the Acceptability Test, is intended tobe applied once the final rig choice has been made. This section provides performance tests,more detailed inspections, and other criteria which the rig should pass prior to final acceptance byPluspetrol. Realistically, depending on the location and status of the rig, there are times it will notbe practical to perform some of the tests given in the Acceptability Test section prior to puttingthe rig on contract. It is the intent, however, that whenever possible this be done.

2) The specification of each major equipment groups (main body and/or applicable appendix)should be filled out when the tenders are received. A comparative study of the contractorsupplied equipment should be developed to aid in effective short listing of contractors. Thespecification sheets should be filled out as completely as possible prior to the actual fieldinspection.3) Prior to actual field inspection, questions pertaining to maintenance records, failure forcedrepairs, and preventative maintenance should be answered (main body and/or applicableappendix).4) Arrange a meeting with the individual drilling contractors management for the purpose oforganizing an inspection tour. Insure both the contractor Operations Manager and DrillingSuperintendent will be present. Use this opportunity to informally interview them. Also,determine the present and near future operation on the rig - this will effect the type, amount,and difficulty of inspecting to be performed.Note: Make sure you are in legal compliance prior to the actual rig visit!5) Upon arrival at the rig, arrange an informal meeting with all supervisory personnel. It is veryimportant to establish a good rapport with the contractor"s supervisory personnel. Explainwhat our purpose is. Informally interview them separately while inspecting their area ofresponsibility.6) Make a general walk around inspection of the rig. Take note of the housekeeping, obvioussafety hazards, and organization. Also, continuously monitor the personnel morale.7) Follow the inspection guidelines established in this document. The order of inspection is notnecessarily important and if more than one OPERATOR person is on the inspection tour, splitthe workload. The operating status of the rig will affect the extent to which you can inspectequipment. Make note of equipment variations from specifications. Why do they vary?Remember, the major purpose of this exercise is not to answer questions, but to determinethe units overall operability and apparent dependability!

8) Following the inspection of all rigs, the person in charge of the inspections should notify, inwriting, the Drilling Superintendent of the results. The notification should state whether ornot each rig inspected is deemed capable of efficiently drilling the well or wells planned. Anymajor advantages or disadvantages to the use of any of the rigs should be stated. Also, anymodifications which would be required should be pointed out. The rigs inspected should beforce ranked in terms of their overall apparent dependability and suitability. The completed"Specification" and "Inspection" sections for the rigs inspected should also be forwarded tothe Drilling Superintendent and Drilling Manager at this time.9) After the region has selected the rig to be used, then the acceptability test in each section(main body and/or applicable appendix) should be performed. Rig location and statuspermitting, the acceptability test will be completed prior to the rig being placed on contract.This testing phase should be carried out by the person in charge of the initial inspection and/orthe drilling foreman and drilling superintendent assigned to the project. The drilling managershould be notified as soon as possible when the acceptability test is completed. Any items notacceptable should be documented in this booklet, and in letter correspondence to the DrillingManager. The person in charge should make recommendations in this letter to accept the rigas it is, reject the rig until deficiencies are corrected, or to accept the rig as it is with theunderstanding from the contractor and management that the deficiencies will be correctedwithin a specified time frame. In the latter case, there should be no future shut downsassociated with the repair or loss of efficiency.10) A complete copy of this booklet and all pertinent correspondence should be forwarded to theOPERATOR Drilling Manager office.

INSPECTION SECTIONCONTRACTOR PERSONNELSpecificationsA resume for all key personnel should be requested with the tender for drilling rigs. Theresumes should include items normally shown, i.e., age, education, Years of experience,etc. They should additionally indicate operating experience on the rig being proposed, acopy of their last two personnel evaluations and a listing of all valid certificates heldwith the date of expiration. Key personnel to obtain resumes from are: ContractorOperations Manager, Drilling Superintendents, Toolpushers, Drillers, Medics (SafetySupervisors), Chief Electricians and Electricians, and Mechanics.InspectionThis may be the most important part of the rig inspection. Our objective should be togain as much truthful information about the rig and the contractors organization aspossible. How questions are answered is equally as important as the answer itself -- dothey mean what they say! Although you will have to steer the conversation, keep thecontractor in the lead, explaining details.Review resumes of all key personnel and personally interview as many of these aspossible. In general, points to determine include length of time the individual hasworked in his current position, length of time with this drilling contractor, length of timeon this rig, the individual"s opinion of the contractor and the rig, and his languagecapabilities. Have the individual describe his job function and the rig equipment forwhich he is responsible. Try to determine how well the individual knows his job.Discuss with the previous operator the performance of the rig crew and any problems heexperienced. Based on your findings, comment on any individuals you recommend to bereplaced if OPERATOR contracts the rig.Comments:___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________MAST, DERRICK, SUBS AND CROWN

Visual Inspection of:a)Drawworks drive chain and sprockets.b)Drawworks oiler system.c)Line guides and rollers.d)Drum, drum flanges, wear flanges, and Lebus grooving.e)Brake beam is it level, or is only one side doing all the work.Comments:___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Review maintenance records, IADC reports and latest magnetic particle inspections.Make note of failed connections, swivel packing failures, trouble with Kelly spinners etc.Did Kelly cocks and Kelly hose pass last BOP test.Comments:___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Make a visual inspection of the drilling instrumentation, tongs, spinning wrench,wireline unit, air hoist, survey instruments and rig floor tools. Make note of these toolsappearance, organization, operability and apparent dependability. Are SWL posted on allhoisting equipment?Comments:___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Diverter1.Blooie line - is it relatively straight without sharp bends?2.Ease of rigging up - can it be handled with BOP handling system?3.Comment on operation (ball valve operates before bag closes).

Visual inspection of:a)Oil leaks on the mechanical end of mud pumpb)Contaminants in the oil.c)Housekeeping in the pump area or room.d)Rod Oilers and their reservoirs.e)Organization and adequacies of mud pump spare parts.Comments:___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Visual Inspection of Motorsa)Housekeeping.b)Level and conditions of oil in engine.c)Guards and safety shields.d)Oil, air, or coolant leaks.e)Are the safety shut downs blocked open?f)What types of shutdowns do they have?Comments:___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Review the contractors Drill String Inspection records and IADC reports. What type ofDrill String related problems (failures) have been occurring? When was the last thirdparty inspections. How much footage has been drilled since that inspections Has thedrill string been exposed to corrosive fluids or gases? - How does the contractor monitorcorrosion rates? Does he keep good records of the tests?Comments:___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Is the Mast (Derrick), Substructure and associated equipment acceptable as is?Yes or NoIf it is not, what specific modifications or further inspections must be made to bring thisequipment to an acceptable level. Be specific and include an estimate of time required tocomplete same.Comments:_________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Load TestsIf possible, perform a short duration drawworks load test using the friction brake tosimulate loads, or by observing a hook horsepower test if the rig is operating on a well.Drawworks Ratio

If it is not, what specific modifications, or further inspections must be made to bring theunit to an acceptable level. Be specific and include an estimated time required tocomplete same.Comments:_________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Do the bottle neck elevators fit on drill pipe correctly?What is the condition of load surface on square shoulder elevators?Will slip segments slide in easily, or are slip segment slots worn excessively?Is the inventory of slip segment adequate?Is there excessive wear on the ears?Are the hinge pins or hinge pin holes excessively worn?Will the rig inventory of elevators meet all our anticipated needs?When were the elevators last magnetically inspected?

If it is not, what specific modifications, repairs, increase in inventory, or furtherinspections must be made to bring this equipment to an acceptable level. Be specific andinclude an estimated time required to complete same.Comments:_________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

If they are not acceptable what specific changes, modifications, or further inspectionsmust be made to bring this unit to an acceptable level. Be specific and include andestimate of time required to complete same.Comments:____________________________________________________________________________________________________________________________________________________________________________________________________________

Will the rollers take grease freely?Will the Kelly cocks operate freely?Are there saver subs on rig? How many? Who is the mfg?What size? Will free point tools pass through the Kelly?

If it is not acceptable what specific changes, modifications or further inspections must bemade to bring this unit to an acceptable level? Be specific and include and estimate oftime required to complete.Comments:__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

If they are not what specific changes, additions to the inventory or further inspectionsmust be made to bring them to an acceptable level? Be specific and include an estimatedof time required to complete same.Comments:_______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

If it is not acceptable what specific changes, modifications, or further inspection must bemade to bring this equipment to an acceptable level? Be specific and include anestimated of time to complete same.Comments:_____________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Does it exist as originally designed?Contractors volume and horsepower calculations.Is there a pressure gauge?Precharge pressure on suction flow stabilizer and pulsation dampener.

Make note of any problems with the pumps or with the rigs ability to supply power to thepumps. Also note the effectiveness of the rod oilers, oil leaks on mechanical ends,pulsation problems, etc.

If not what specific modifications, repairs, or further inspections must be made to bringthe unit to an acceptable level. Be specific and include an estimated time required tocomplete same.Comments:_________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

Are the pits and associated equipment acceptable as is?Yes or NoIf not what specific charges, modifications, or further inspections must be made to bringthis unit to acceptable condition? Be specific and include an estimated time required tocomplete same.Comments:__________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

All rotary shouldered connections should be inspected. If there is a low confidence in theavailable inspection services then a third party would be necessary. Attach a copy ofinspection reports.Comments:___________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

NOTE: The following Rig Inspection Checklists are not a complete listing of requirements. Theywere developed to assist employers and workers with training, equipment and documentationrequirements in rigging.

Training Requirements – Rig Inspection Checklist OHS Regulation/ WC Act1. Derrick man must be trained and demonstrate proficiency to use 23.39.2 (4)(c) the emergency escape system installed on the rig; the escape 23.39.3(3)(a)(b) system must be inspected on a frequency as required by 23.39.3(4)(a)(b) regulation, by a qualified person and the inspection recorded and records available.2. Simulated Derrick rescue once a year and documented 4.14(3) 32.2(2)3. 2 crew members with “ENFORM RIG RESCUE” training on tower 32.2(1) at all times

13. Training of workers conducting rigging and slinging operations - 15.2 Definition of qualified - OHS Regulation Part 1 1.1

1Revised April 2009 Equipment Requirements – Rig Inspection Checklist OHS Regulation/ WC Act1. Suitable Self Retracting Lifeline (a) Floor to Crown 11.5, 11.6 (b) Crown to racking board (c) Soft line to Retract SALA Block Line when not in use (Reel) – optional (d) Additional anchor point and assemblies for working lifelines2. Equipped with an Emergency escape system from the racking 23.39.1 board that meets the requirements of 23.39.2 or 23.39.33. Location of escape equipment to allow unimpeded exit from 4.14(2) racking board (refer to CAODC RP #9 – Derrick Egress) 23.39.2(1)(a)4. Fall Restraint system for the roof of the doghouse or any other 11.2 area over 3 meters5. Rig Rescue Equipment – inspected and maintained in good 11.9 working order6. Lock-out Station / Board ( locks / tags / scissor hasps) 10.1 10.47. 4 – Positive pressure (no donning switch) SCBA on site - 2 units at 23.36 two different locations / 4 spare bottles CSA 94-48. Safety chain across “V” door 4.55(a)9. Cat head spools removed or covered 23.2010. Crown saver in place / functioned each day 23.49(2)(3)11. Risk assessment done for eye washing facilities/emergency shower 5.8812. Oil based mud system – coveralls being cleaned at employers 8.8, 5.85 expense / hand wash/ shower available13. 15 meter clear area under the end of the escape buggy line 23.39.2(2)14. Rigging, fittings & slings have Manufacture’s ID / Working Load 15.5(1) Limit (WLL) attached15. Stairs with 4 or more risers must have handrails 4.6216. DST’s, underbalanced drilling & oil based mud systems require 23.43 2 2 L.E.L / H S / O detectors in an enclosed substructure or adequate ventilation. Size of ventilation openings, mechanical ventilation, and cold weather provisions17. Signs under overhead power lines identifying location 19.518. Degasser vents lines use appropriate fittings 23.13(1)19. Exhaust fan in mud mixing room 5.64, 5.6520. BOP requirements different than Alberta – 1850 Meters and deeper 4.1 require gut line – **REFER TO Drilling & Production Regulation (Oil & Gas Commission)21. Coordination of Multiple Employer workplaces 23.4 & WCA 11822. Control of Static Electricity-grounding and Bonding 23.6, 5.2823. Fire hazards – No Smoking or open flames within 25 meters 23.724. Control of Ignition Sources – BC Electrical Code 23.8(1)(a)25. Control of Ignition Sources – Positive Air Shutoffs for Diesel Engines 23.8(1)(b) 23.8(2)26. Flare Pits & Flare Lines – lighting, safe access 23.927. Fire Extinguishers 4 X 40-BC 23.1028. Air Operating Systems – Alcohol restrictions 23.1129. Pipelines, fittings & valves – standards, safe work procedures 23.12

2Revised April 2009 Equipment Requirements (cont’d) – Rig Inspection Checklist OHS Regulation/ WC Act30. Hose Connections – design, service 23.1331. Pumps – positive displacement, PSV 23.1432. PSV – when required (Boiler & Pressure Vessel Act) 23.1533. PSV – installation – discharge pressure, valves, restrictions, 23.16 shear pins34. Pipe Racks – loads, level surface, pins and spacers 23.1735. Handling Pipe – nubbins, movement, deck pins, loading 23.1836. Kelly hose – safety lines, clamps, shock hoses 23.1937. Rigging up – signals, rigging, tag lines, location of worker, winching 23.2138. Horizontal static line & walkway when derrick is laid down 11.239. Steep slopes – engineering, written plan, snubbing & yo-yoing 4.3, 23.23(2)40. Roads – comply with OHSR – Part 26 23.2441. Size of work area – emergency response, loads, safely moved 23.3142. Inspection & Repair – RP’s 1.0/1.0A/2.0/3.0/4.0 – CAODC log book 23.3243. Rig Moves – lifting points, raising & lowering the derrick 23.33 (2)44. Manufactures or PEng Identification and Instructions for the 3.3(c), assembly and disassembly of the drilling or Service rig 14.3(1)(2)(3) 14.12(2)45. BOPS – installing, slinging 23.3746. Spudding in – guards in place, platforms/stairways installed, escape 23.38 line47. Draw works controls – identified, guarded, locking devices 23.4048. Stabbing boards – dimensions, securing, fall protection 23.4149. Derrick enclosures – weather, climbing on, exits 23.4250. Pits & Tanks – sources of ignition, adequate ventilation 23.4451. Hoisting lines – 5 wraps on the draw works drum 23.4852. Securing fingers – unsupported ends on the monkey board 23.5453. Weight indicators – required, safety line 23.5654. Brakes – tested, automatic feed, hold down chain 23.5755. Guarding of the rotary table and Kelly 12.256. Rotary tongs – preventing uncontrolled movement 23.6057. Guy lines – installation, testing spec plate, documentation 23.6358. Drill Stem Testing - requirements 23.6459. Swabbing at night – lighting, sand line depth meter, flags, wind 23.65 direction60. Air intakes – 6 meters from rig tank, tank truck loading 23.6861. Flow piping – anchored, restricted areas, pressure testing 23.6962. Pressure testing – 10% rule, documentation of tests, bleeding air 23.7263. Hot oiling – vent line 10 meters from source of ignition 23.73

3Revised April 2009 Documentation Requirements – Rig Inspection Checklist OHS Regulation/ WC Act1. BC WCB – OHS Regulations on site WCA 115(2)(f)2. CAODC “Fall Protection Manual” on site (fall protection plans) 11.33. Accident Reporting Kit WCA 1724. Derrick climbing procedure posted 11.35. Racking board rescue procedures posted 4.13(3)6. Noise level survey done and posted 7.37. Boiler certification on site (BOILER & PRESSURE VESSEL ACT) 4.18. Respirable air quality documentation on site – tested every 12 8.37 months CSA Z180.1 M859. Fit testing documentation on site 8.4410. SCBA inspection and maintenance records 8.4411. List of weights of all items which can be lifted or winched 23.34, 14.36(1) Critical or Tandem life procedures available followed 14.42(1)(2)(3) 14.42.1(1-5)12. Emergency Escape system inspection and documentation as per 23.39.2(4)(c) Requirements of system used i.e.; weekly, monthly or each time 23.39.3(3)(a)(b) Erected (Manufacturers’ instructions)13. Simulated derrick rescue performed and documented once a year 4.14(3), 32.2(2)14. Safe work procedures for all jobs available for all workers 23.515. All certification for rig equipment (mast, substructure, BOP’s, etc) 23.32 available on site16. CAODC log book available on site 23.32(2) (3)17. Monitoring and Sampling results when drilling with Non-Water Based 5.27(LEL) Drilling and Completions/Well Servicing Fluids (IRP#14), Exposure 5.48, 5.54, 5.55 Control monitoring conducted and Exposure Control Plan developed (OEL’s) and implemented according to Industrial Hygiene principals18. Casing Bowl Welding-Done in accordance with ASME,CSA and API 4.1 Standards, welds NDT tested (dye testing) and pressure tested, 4.3(1)(a)(b) casing bowl Installation procedures followed and available for review 23.72(1)Comments:

From crowded street corners to far removed places, tackle various environmental, geotechnical and exploration applications with a single machine combining rotary drilling and direct push, saving time and money required to mobilize multiple drill rigs.

8613371530291

8613371530291