workover rig inspection checklist factory

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

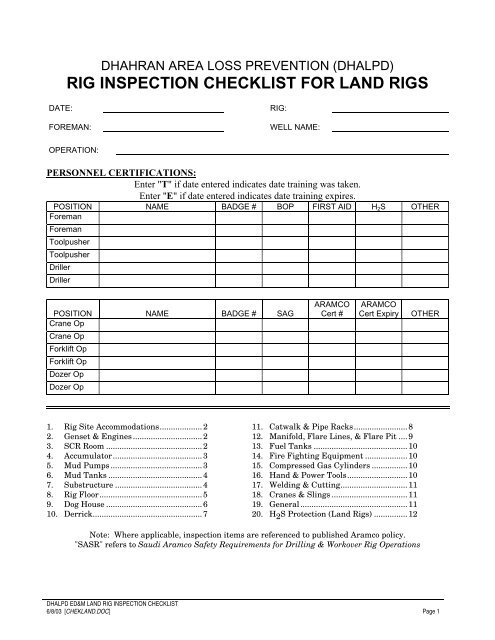

Download Workover & Drilling RigInspection Checklist For Onshore & OffshoreRigsContents hide 1 Download Workover & Drilling Rig Inspection Checklist For Onshore & Offshore Rigs1.1 Workover & Drilling Rig Inspection Checklist For Onshore Rigs Content1.1.1 Drilling Rig Inspection Checklist For Drilling Equipment1.1.1.1 Hoisting Equipment Group1.1.1.2 Drill Floor Equipment Group1.1.1.3 Pipe Handling Equipment Group1.1.2 Drilling Rig Inspection Checklist For Mud System1.1.3 Drilling Rig Inspection Checklist For Well Control Equipment1.1.3.1 1 Ram Type Preventers1.1.3.2 2 Annular Type Preventers1.1.3.3 3 Gate Valves (Bop Mounted)1.1.3.4 4 Choke Manifold1.1.3.5 5 Cameron Style Hub Clamps1.1.3.6 6 Bop Handling Equipment1.1.3.7 7 Surface Hydraulic Bop Control Unit.1.1.3.8 8 Diverter System1.1.4 Drilling Rig Inspection Checklist For Power Plant1.1.5 Drilling Rig Inspection Checklist For Electrical System1.1.6 Drilling Rig Inspection Checklist For Electrical System1.1.7 Maintenance System1.1.8 Spare Parts1.2 Download Workover & Drilling Rig Inspection Checklist For Onshore Rigs1.3 Workover & Drilling Rig Inspection Checklist For Offshore Rigs Content (Can Be Used For OnshoreRigs)1.3.1 Drilling Rig Inspection Checklist For Drilling Equipment And Operations1.3.2 Lifting Equipment1.3.3 Drilling Rotating Equipment1.3.4 Man Riding Winch1.3.5 Tubular Handling1.3.6 Wireline Logging Equipment1.3.7 Well Control Equipment1.3.8 Other Equipment1.3.9 Mud System1.3.10 Cementing System1.3.11 Brine System1.3.12 Bulk System1.3.13 Oilbased Mud Obm (If Applicable)1.3.14 Additional Equipment And Documents Requirements1.3.15 Mooring System1.3.16 Accommodation1.3.17 Safety Equipment1.3.18 Miscellaneous1.3.19 Storage And Other Areas1.3.20 Health, Safety & Environmental Concerns1.4 Download Workover & Drilling Rig Inspection Checklist For Offshore Rigs1.4.1 Like this:

Now you can download workover & drilling rig inspection checklist free from DrillingManual.First subscribe with us. Also please take in your consideration that various items on thesechecklists are shaded grey. This is an INDICATION ONLY of items that are LESS safety criticalto check. Therefore by default the remaining items are the more safety critical ones.Enter your email address:

Related Posts BOP Control System AcceptanceBOP Stack Acceptance GuidelinesChoke Manifold Acceptance GuidelinesMud Circulation System Inspection GuidelinesCementing Unit Acceptance GuidelinesPrime movers acceptance guidelinesWorkover & Drilling Rig Inspection Checklist For OnshoreRigs ContentDrilling Rig Inspection Checklist For Drilling Equipment

Workover & Drilling Rig Inspection Checklist For OffshoreRigs Content (Can Be Used For Onshore Rigs)Drilling Rig Inspection Checklist For Drilling Equipment And Operations

1100 Mast Equipment1110 Mast Raising/Lowering And Rig-Up1120 Mast Inspection1130 Derrickman’s Platform (Monkey Board – Mb)1140 Escape One And Slide1150 Utility Lines1160 General Rig Floor And Mast1170 Skidding Equipment

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Are you looking for a more convenient way to conduct inspections of drill rigs and drilling equipment? This easy to use app for drilling rigs and drilling rig components makes it easy to complete inspections from anywhere. Simply open a new inspection checklist form using your smartphone or tablet, and you"ll be prompted to inspect the drilling equipment and drill rigs before they are used in the field.

The checklist covers the important safety considerations for land drilling rigs, including checking the drill bit, drill rod, drilling fluid and drill collars for wear and tear and inspecting the drill pipe for erosion. With the app, any drilling company or individual who offers drilling services can quickly and easily perform inspections and save them electronically for their records.

Drilling rigs are some of the most dangerous workplaces or "sites" on Earth. Working on and around a drilling rig introduces many of the most dangerous hazards associated with industrial work including heights, dangerous chemicals, high pressures, explosive materials and more.

To prevent disasters and ensure that everyone working on these rigs does remain safe (and that the reputation of drilling and energy companies remains in tact), companies and workers engage in a number of safety procedures including drilling rig inspections.

These inspections are designed to guide an inspector, auditor or applicable person through a series of checklist questions which have been created to surface any obvious, urgent or problematic issues.

The template comes pre-built with sections for permits, site, stairs and ladders, the rig floor, fuel tanks, electrical systems, material handling and more.

You can also export the resulting checklist report, so that you can make your inspection process nice and efficient while having the convenience of perfectly formatted PDF reports as well.

Kelly bushings on oil drilling rigs that are smooth and do not present a potential hazard to employees that might come in contact with the bushings, do not require guarding.

Applus+ K2’s highly experienced and multi-skilled personnel provide high-quality services in rig inspections and rig commissioning to the oil and gas industry. Our efficient approach enables us to reduce the number of personnel required to complete a rig inspection programme, resulting in real cost-savings. Prior to each project, tailored work-scopes are prepared to the client’s requirements and the type of asset being inspected (land rig, jack-up, semi-sub, drillship, etc.). This focus on work-scope helps to reduce the amount of time required onsite.

Applus+ K2’s clients can be confident that all our services for rig inspections and rig commissioning are undertaken professionally and in accordance with the relevant standards because all inspection personnel have prior supervisory-level experience on drilling assets, as well as mechanical and electrical backgrounds. The high level of experience and expertise of our teams enables them to rapidly and accurately identify non-conforming issues and propose the suitable corrective action.

Reports for rig inspection, rig audit and rig commissioning are available for viewing at any time during the project via our dedicated online reporting portal. The detailed reports include categorised observations and recommendations (critical, major and minor) to help clients prioritise the required corrective measures. The rig inspection reports also detail the rig’s operational status or readiness, depending on the nature of the inspection.

Rig Inspections will be conducted using the OCS Group Acceptance Guidelines Program, which includes testing of all equipment and systems to verify their condition and performance.

Intrusive inspections of the internal parts of specific equipment including critical measurements and clearance to ensure equipment is running within recommended tolerances.

Verification that the rig equipment complies with API standards, the equipment manufacturer’s specifications and recommendations and good engineering practices.

Rig Inspections are preferably completed between wells, so access to all equipment can be managed however they can be completed at Inspections can also be conducted when the rig is at the well location so full testing can be safely and efficiently conducted.

The assistance of the crew is required to operate the equipment for testing, and assist with testing of various items such as isolation or preparation for internal inspection, including measurement of clearances. During the inspection the rig has to be adequately manned, and the crew must be familiar with the rig specific systems.

All consumables and equipment should be available on the rig like water in the pits, a sufficient quantity of barite and sufficient drill pipe to make up stands.

8613371530291

8613371530291