workover rig inspection checklist in stock

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

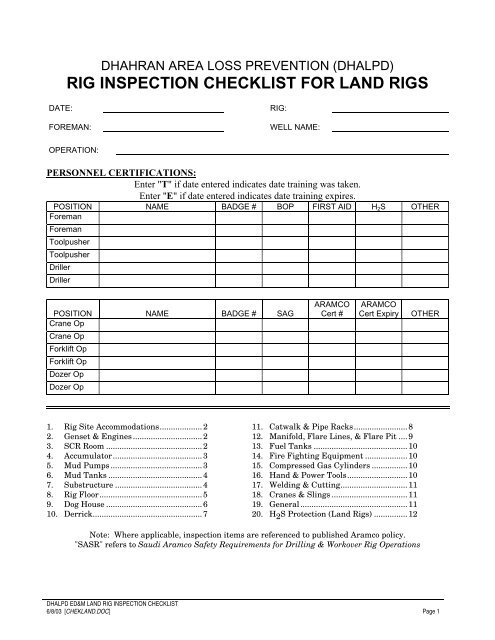

Download Workover & Drilling Rig Inspection Checklist As we mentioned in the Rig Audit Article, rig inspection is an important process that shall be done from time to time. Especially, after the rig moving to a new drilling location.

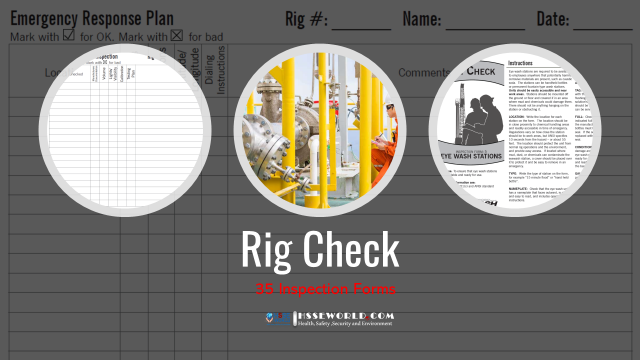

Rig Check was developed by the National Institute for Occupational Safety and Health (NIOSH) in partnership with safety experts from the oil and gas extraction industry. It is made up of 35 inspection forms. The forms are designed to be used by rig workers to document the inspection of tools and equipment commonly found on rotary and workover rigs. Each inspection form includes instructions for assessing and recording the condition of the equipment. When applicable, relevant federal regulations and industry recommended practices are included.

The Rig Check inspection forms are an excellent training tool for short service employees, who may not be familiar with the tools and equipment found on oil and gas rigs. Small companies whose safety and health resources are limited may find Rig Check useful for enhancing their HSE programs.

Ensure that each well has an emergency response plan, which includes simple instructions for notifications in the event of a rig-based emergency. Notification protocols for medical emergencies, fire on the rig or location, gas release or loss of well control, or a security breach should all be included. In most cases, there will be contingency plans in place for the well that address notifications for long-term events that include notification of government agencies and outside well control expertise. These contingencies can be noted in the working plan but should not complicate the posted action plan.

LOCATIONS: Write locations of posted, current emergency response plans. These should be in central locations such as the rig doghouse, change house, Rig Supervisor’s office, Company Man’s office, and rig camp.

In addition, check that the response plan is posted anywhere emergency communications may be made, including the Rig Supervisor’s truck, and the guard shack.

ALARMS:Rig emergency alarms may be automatic or operated by personnel from various locations manually. Whichever the case, the alarms should be heard throughout the rig and on the location. The alarms should be distinctive and easy to identify as to their purpose. Alarms that work in conjunction with lights should be visible from the entrance of the location. It is a good practice to include a wind direction indicator in close proximity to the lights. All employees should be trained to activate manual alarms and understand what triggers automatic alarms.

DEVICES:Emergency shut-down devices (ESD) that will close off the combustion air should be installed on all of the rig’s diesel engines. It is important to understand just how particular ESD functions BEFORE you attempt to test it. Engine shutdowns or rig savers may damage engine components if they are engaged when the engine is running at speed. Careful plans should be made with the mechanics to develop a test protocol that will ensure the functionality of the devices without damaging the engine. In most cases, these devices can be checked with the engine shut down. Manual engine shutdown devices that shut off the fuel to the engines can also be tested while the engine is shut down.

SMOKE ALARMS:Smoke alarms in trailers and outbuildings should be function tested monthly or following a rig move. Note on the inspection form when batteries are changed each year.

the rig should have a written plan for calibrating and testing alarms and shutdown devices. The inspection should include a review of these documents to ensure new equipment and or rig modifications have not altered the function of the devices.

These checklists are not all inclusive. You may wish to add to them or delete portions that do not apply to your workplace. Carefully consider each item as you come to it and then make your decision. Do not spend time with items that have no application to your workplace.

Download Workover & Drilling RigInspection Checklist For Onshore & OffshoreRigsContents hide 1 Download Workover & Drilling Rig Inspection Checklist For Onshore & Offshore Rigs1.1 Workover & Drilling Rig Inspection Checklist For Onshore Rigs Content1.1.1 Drilling Rig Inspection Checklist For Drilling Equipment1.1.1.1 Hoisting Equipment Group1.1.1.2 Drill Floor Equipment Group1.1.1.3 Pipe Handling Equipment Group1.1.2 Drilling Rig Inspection Checklist For Mud System1.1.3 Drilling Rig Inspection Checklist For Well Control Equipment1.1.3.1 1 Ram Type Preventers1.1.3.2 2 Annular Type Preventers1.1.3.3 3 Gate Valves (Bop Mounted)1.1.3.4 4 Choke Manifold1.1.3.5 5 Cameron Style Hub Clamps1.1.3.6 6 Bop Handling Equipment1.1.3.7 7 Surface Hydraulic Bop Control Unit.1.1.3.8 8 Diverter System1.1.4 Drilling Rig Inspection Checklist For Power Plant1.1.5 Drilling Rig Inspection Checklist For Electrical System1.1.6 Drilling Rig Inspection Checklist For Electrical System1.1.7 Maintenance System1.1.8 Spare Parts1.2 Download Workover & Drilling Rig Inspection Checklist For Onshore Rigs1.3 Workover & Drilling Rig Inspection Checklist For Offshore Rigs Content (Can Be Used For OnshoreRigs)1.3.1 Drilling Rig Inspection Checklist For Drilling Equipment And Operations1.3.2 Lifting Equipment1.3.3 Drilling Rotating Equipment1.3.4 Man Riding Winch1.3.5 Tubular Handling1.3.6 Wireline Logging Equipment1.3.7 Well Control Equipment1.3.8 Other Equipment1.3.9 Mud System1.3.10 Cementing System1.3.11 Brine System1.3.12 Bulk System1.3.13 Oilbased Mud Obm (If Applicable)1.3.14 Additional Equipment And Documents Requirements1.3.15 Mooring System1.3.16 Accommodation1.3.17 Safety Equipment1.3.18 Miscellaneous1.3.19 Storage And Other Areas1.3.20 Health, Safety & Environmental Concerns1.4 Download Workover & Drilling Rig Inspection Checklist For Offshore Rigs1.4.1 Like this:

Now you can download workover & drilling rig inspection checklist free from DrillingManual.First subscribe with us. Also please take in your consideration that various items on thesechecklists are shaded grey. This is an INDICATION ONLY of items that are LESS safety criticalto check. Therefore by default the remaining items are the more safety critical ones.Enter your email address:

Related Posts BOP Control System AcceptanceBOP Stack Acceptance GuidelinesChoke Manifold Acceptance GuidelinesMud Circulation System Inspection GuidelinesCementing Unit Acceptance GuidelinesPrime movers acceptance guidelinesWorkover & Drilling Rig Inspection Checklist For OnshoreRigs ContentDrilling Rig Inspection Checklist For Drilling Equipment

Workover & Drilling Rig Inspection Checklist For OffshoreRigs Content (Can Be Used For Onshore Rigs)Drilling Rig Inspection Checklist For Drilling Equipment And Operations

1100 Mast Equipment1110 Mast Raising/Lowering And Rig-Up1120 Mast Inspection1130 Derrickman’s Platform (Monkey Board – Mb)1140 Escape One And Slide1150 Utility Lines1160 General Rig Floor And Mast1170 Skidding Equipment

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Drilling rigs are some of the most dangerous workplaces or "sites" on Earth. Working on and around a drilling rig introduces many of the most dangerous hazards associated with industrial work including heights, dangerous chemicals, high pressures, explosive materials and more.

To prevent disasters and ensure that everyone working on these rigs does remain safe (and that the reputation of drilling and energy companies remains in tact), companies and workers engage in a number of safety procedures including drilling rig inspections.

These inspections are designed to guide an inspector, auditor or applicable person through a series of checklist questions which have been created to surface any obvious, urgent or problematic issues.

The template comes pre-built with sections for permits, site, stairs and ladders, the rig floor, fuel tanks, electrical systems, material handling and more.

You can also export the resulting checklist report, so that you can make your inspection process nice and efficient while having the convenience of perfectly formatted PDF reports as well.

Performing drilling rig inspections is tedious work, whether your crew is inspecting drilling equipment, the oil-water separator, drill pipe, rig equipment, or performing any other equipment inspections, you need a way to quickly document deficient items and communicate them immediately to the maintenance crew. Failure to do so can be newsworthy, think deepwater horizon or lesser known Puget Sound, and you get the idea. With GoCanvas, you can migrate paper inspection forms to mobile apps, allowing rig managers, drilling managers, drilling engineers and so on the ability to perform inspections right from their mobile device. A PDF is automatically generated that can be emailed and is stored in the cloud for easy access. Browse our Application Store with over 30 checklist apps designed specifically for drilling rig inspections.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Proprietary Rights - Nimonik owns, solely and exclusively, or licenses all rights, title and interest in and to the Site, all the content (including, for example, audio, photographs, illustrations, graphics, other visuals, video, copy, text, software, titles, etc.), code, data and materials thereon, the look and feel, design and organization of the Web Site, and the compilation of the content, code, data and materials on the Site, including but not limited to any copyrights, trademark rights, patent rights, database rights, moral rights, sui generis rights and other intellectual property and proprietary rights therein. Any content, code, data or materials the Users may access on or through the Site belonging to Nimonik is not granted to the Users.

Scope of Use. The Users are granted a non-exclusive, non-transferable, limited right to access and use the Site for information purposes. The User may only use the software and information on the site for the business activities of the User or Affiliates controlled by the User. "Controlled" means the legal or beneficial ownership of (a) fifty percent (50%) or more of the outstanding voting stock of a corporation, or (b) fifty percent (50%) or more of the equity of a limited liability company, partnership, or joint venture. The User and its affiliates must consider the Nimonik’s Licensed Content as confidential information and agree to protect the confidentiality of this information with at least the same degree of care that it utilizes with respect to its own similar proprietary information. The User and its affiliates cannot, (a) sell, rent, give or transfer all or any portion of Nimonik’s Licensed Content to another party for that party’s business use, or (b) post on the internet or via any means where all or any portion of Nimonik’s Licensed Content can be viewed by the public, or (c) use all or any portion of Nimonik’s Licensed Content in such a manner that the content’s use is or may potentially be in competition with Nimonik’s Licensed Content.

Changes to Terms of Use - We reserve the right, at our sole discretion, to change, modify, add or remove any portion of the Terms and Conditions, in whole or in part, at any time. Changes in the Terms and Conditions will be effective when posted. Your continued use of the Site and/or the services made available on or through the Site after any changes to the Terms and Conditions are posted will be considered acceptance of those changes.

Drilling Rig Inspection app is designed to make quick inspections of drilling rigs and ensure safety of works performed on sites. The app works offline that makes it possible to collect and save information at areas with limited connection coverage.

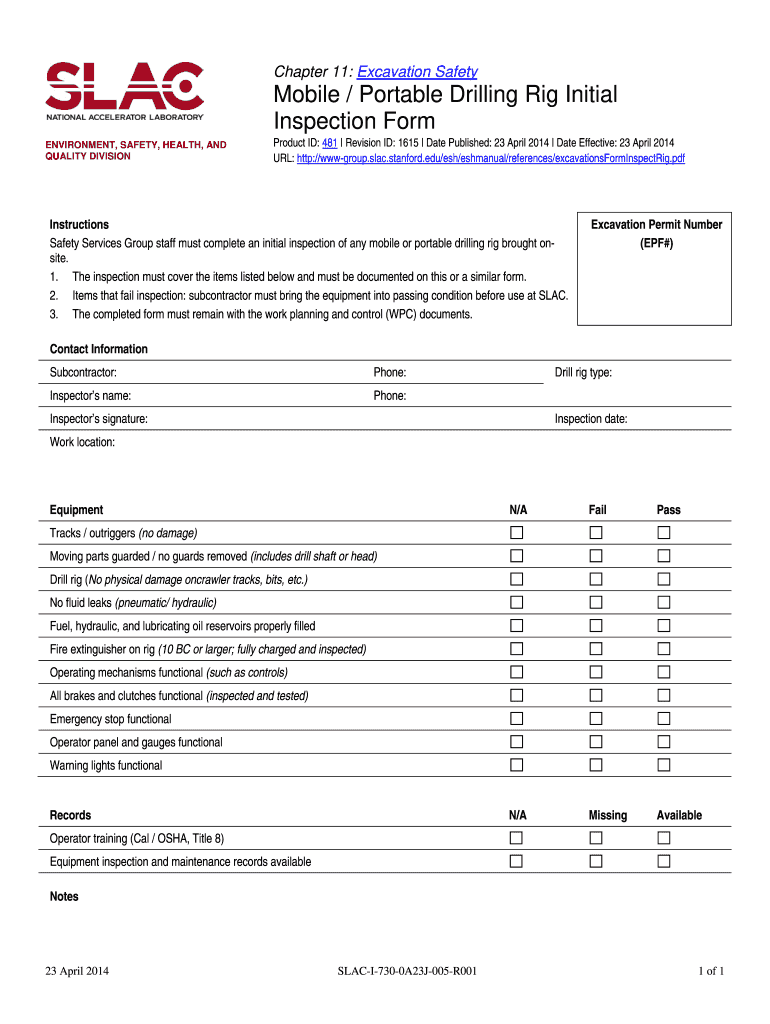

Initial Drilling Rig Inspection form includes equipment inspection of tracks and outriggers, moving parts, drill rig, fluids, fuel and hydraulics, fire safety, brakes, emergency stop function, operational gauges and warning light functionality.

In addition to using free Drilling Rig Inspection App version you can get unlimited number of form submissions by subscribing via an optional In-App Purchase and remove all ads by purchasing onetime fee. Subscribe from your device and access these services via mobile app.

8613371530291

8613371530291