workover rig job description in stock

POSITION OVERVIEW : Leads a one to five person rig crew while safely operating well servicing or drilling rig components. This is a safety sensitive position.

NOTE: * This is a safety sensitive position. Essential mental alertness requirements, which include the following, are required to be met as part of the essential job functions, and must be met by Basic Energy Services applicants and current employees. To be considered and eligible for hire, each and every applicant and employee must: Work in a constant state of alertness and safe manner Have, display & maintain the ability to perform tasks involving high levels of cognitive function and judgment Not be mentally or physically impaired from any cause, that can adversely affect an employee s ability to safely and completely perform the duties of the position Have, display & maintain the ability to work in an unfatigued state Have, display & maintain the ability to accurately gauge lengths of time and distance Have, display & maintain the ability to quickly store and recall instructions in one s short term memory Have, display & maintain the ability to concentrate Have, display & maintain the ability to cope with sudden changes in surrounding and/or emergency situations and/or alarms Have, display & maintain, demonstrated caring, committed and concerned attitude about safety

Workover rigs, also called pulling unit rigs, are specialized oil rigs set up for inserting or pulling pipe tubing in and out of wells. Workover crews are called when an oil well has been drilled, is undergoing repair or is being retired, as indicated by Schlumberger.

These crews are relatively small compared to other rig crews and consist of tool pushers, operators or relief operators, derrick men and floormen or roughnecks. The average workover rig salary overall was $65,039 as reported by Simply Hired in 2022. Available workover rig jobs and descriptions can be found on the Rigzone website.

The acting supervisor on a workover rig is called the tool pusher. The main task of a pusher is to hire, fire and supervise contracting work crews. When contractors have an issue on site, the first person they report concerns to is the tool pusher. Pushers need to have an intimate knowledge of how each and every part of a rig works, both individually and as an overall part of the drilling operation as a whole.

If equipment fails or needs to be reordered, the tool pusher talks with suppliers to get the right parts out on site with a minimum of downtime for the rig. The pusher is responsible for the overall safety of a rig. If the tool pusher has any safety concerns, he has the power to halt production until the concern is resolved.

The operator/relief operator is next in order of responsibility to the tool pusher on a workover rig. The main task of an operator is to control the crane and derrick that hauls pipe in and out of the bored well. In smaller crews, the operator is also the one who drives the rig truck. When laying pipe into a well, the operator directs the truck or derrick to the optimum spot next to the bore opening.

The operator then instructs the derrick hands and roughnecks where to place the bore pipe for easy access by the crane or by hand-loading methods. During a well breakdown or repair, the operator directs the crew hands in storage of extracted pipelines. Because the operators work most closely with derrick hands and roughnecks, they are typically responsible for selection and maintenance of their immediate workover rig crew.

In the pulling unit rig crew hierarchy, the derrick hands come after the operator/relief operators. The main responsibility of a derrick hand is everything that is above ground on the rig. During laying operations, derrick hands assist the operators/relief operators in inserting boring into the well. During repair or breakdown, they assist the operator in pulling pipe out of the well and storing it properly.

In between laying, derrick hands have other responsibilities as well, depending on the size of the crews. In smaller crews, Derrick hands also see to the maintenance of the rig-based electric and diesel generators necessary to power rig equipment.

At the bottom of the pulling unit rig crew in terms of seniority is the floorhand or roughneck. The main task of a roughneck is to perform any kind of tasks asked by either the derrick hand or the operator. These tasks can range from assisting with laying new pipe or removal of old tubing, general construction, to moving new equipment, such as generators. Most crew members on a work-about start their career as a floorhand or roughneck before working their way up to more senior positions.

The Workover Rig Derrick hand, performs and maintains service on oil wells as part of a 3-5 person crew of a workover rig. Works closely with various field personnel as a team. Maintains and implements all parts of a rig, demonstrating knowledge of all aspects and equipment on site.

Complete our employment application and upload your resume to the Careers page of our website at www.contango.com or go directly to our jobs page at http://contango.applicantpro.com/jobs/.

Contango Oil & Gas Company is an equal opportunity employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, national origin, sex, gender identity, sexual orientation, age, genetic information, or pregnancy, status as a protected veteran, status as a qualified individual with a disability, or any other status protected by federal, state or local law.

Operate the rig safely during rig up/down and pulling operations. Perform all required equipment inspections-workover rig, fall arrest system, derrick, hoisting…

Operating a derrick equipped workover rig: 1 year (Required). Production maintenance (tubing/rod jobs) and plugging work. 10 days on 4 days off schedule.

Manages tools on the workover rig floor and assists in daily maintenance. Must have a minimum of 1 year of experience as a workover rig floorhand to be…

Spot in, rig up, and rig down well service unit (rig). Minimum of 1 year operating rig. Workover rig experience (minimum 6 months verified experience).

Ensures all crew members are at the rig and prepared to work at the scheduled time. Determines how a service job will be performed based on specific conditions…

The successful candidate will have an outstanding track record of success in workover rig experience in operating heavy equipment while ensuring communication…

Assists the operator in rigging up and down, lining up the well service rig with the well. May be required to work floors or operate the rig when needed.

Inspects the setting up, taking down and transportation of the assigned workover rig. The Rig Operator, reporting to the assigned Tool Pusher/Field Supervisor,…

Installs / disassembles (rig up/rig down) of wireline and pressure control equipment in accordance with original equipment manufacturer’s standards including…

Assists the operator in rigging up and down, lining up the well service rig with the well. May be required to work floors or operate the rig when needed.

Communicates with customer and/or the delegated well site representative, rig crew and field support staff. Plans, directs, supervises, and evaluates the work…

A Workover Rig Operator is responsible for all activities in regards to operating a workover rig, supervising a crew, and ensuring customer satisfaction with…

Perform services on oil and gas wells as part of a 3-5 person workover rig crew. Lifts, removes, installs and operates well head pump, jacks and performs other…

Class B CDL license to drive workover rig (not required-but encouraged). A SSEs duties also includes cleaning, fueling, repairing and maintaining workover rig…

Assists the Rig Operator in performing job activities associated with the rig-up and rig-down of the workover rig, picking up/laying down and standing back rods…

The Floor Hand position is part of a 4-5 person workover rig crew on a well service rig, who are responsible for performing services on oil and gas wells…

2+ years previous oilfield and/or workover rig experience preferred. Work on floors or derricks on the rig as needed. May offer relocation package DOE.

Operating a derrick equipped workover rig: 1 year (Required). Production maintenance (tubing/rod jobs) and plugging work. 10 days on 4 days off schedule.

The Crew Worker, under the direction of the Rig Operator, performs activities and operates hand and power tools to perform maintenance and repairs to oil or gas…

Looking for experienced Floorhands for Workover Rigs in North Dakota. Full benefits, competitive pay with desirable schedule of TWO WEEKS ON / TWO WEEKS OFF.

*Floor Hands - *minimum experience required 6 months. *Derrick Hands - *minimum experience required 1 year. Job Requirements: *Job requirements include but are…

Manages tools on the workover rig floor and assists in daily maintenance. Picks up/lays down pipe and latches tubing in elevators. This is a full-time position.

Manages tools on the workover rig floor and assists in daily maintenance. Must have a minimum of 1 year of experience as a workover rig floorhand to be…

The successful candidate will have an outstanding track record of success in workover rig experience in operating heavy equipment while ensuring communication…

Crew Member positions include Rig Trainee (no experience required), and Floor hand, Derrick hand, Relief Crew Chief, and Crew Chief, which are experience…

As a rig hand, you will need to safely complete tasks and operations as the onsite supervisor instructs. You will be responsible for all aspects of maintaining…

Minimum 5 years production rig workover experience. Rig workover: 5 years (Preferred). The Gorilla Jack is designed as a supplement to workover rigs and is…

Spot in, rig up, and rig down well service unit (rig). Minimum of 1 year operating rig. Workover rig experience (minimum 6 months verified experience).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We like to throw around “blog ideas” over here at Croft to help my fellow blog partner, Amy and I have a new fresh blog every week. We try to keep our readers up to date with both the new and the old. Someone threw out the idea of writing about a workover rig. Still being new to the industry, I snatched this topic up because I simply wanted to learn more about it myself! My main focus for this blog is simply discussing what is a workover rig and why it is important.

First off, maybe you know a workover rig by a different name. They can be called completion wells or pulling units. I just want to try to avoid any confusion! I am going to give Wikipedia’s definition first and then break it down to layman’s terms for those of you who don’t quite understand what the Wiki is trying to say (Like me). According to Wikipedia, “The term workover is used to refer to any kind of oil well intervention involving invasive techniques, such as wireline, coiled tubing or snubbing. More specifically though, it will refer to the expensive process of pulling and replacing a completion.” Let’s break down some of that Terminology…

Snubbing: This method is used in more demanding situations when wireline and coiled tubing does not offer the strength and durability needed. Snubbing runs the bottom hole assembly on a pipe string using a hydraulic workover rig.

So basically, the purpose of a workover rig is to replace a well with a fresh completion. This may have to happen due to the well deteriorating or the changing of reservoir conditions. This is performed if a well completion is unsuitable for the job at hand. An example of the well deteriorating is the equipment may have become damaged or corroded such as production tubing, safety valves, electrical pumps, etc. An example of the changing of reservoir conditions maybe if the flow of a well has decreased over time. If this happens, when the well was originally drilled, it was fit for tubing that was big enough for a higher flow of oil and gas. As the flow decreased, smaller tubing is now needed.

For a workover to take place, a well must be killed or in other words, stop the flow of oil or gas. This is an intense procedure for a workover to take place, so they are planned long in advance.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

When it comes to searching for a job, many search for a key term or phrase. Instead, it might be more helpful to search by industry, as you might be missing jobs that you never thought about in industries that you didn"t even think offered positions related to the work over rig operator job title. But what industry to start with? Most work over rig operators actually find jobs in the finance and automotive industries.

If you"re interested in becoming a work over rig operator, one of the first things to consider is how much education you need. We"ve determined that 15.8% of work over rig operators have a bachelor"s degree. In terms of higher education levels, we found that 0.0% of work over rig operators have master"s degrees. Even though some work over rig operators have a college degree, it"s possible to become one with only a high school degree or GED.

The following is a list of seasonal work gear worn by service rig workers. Savanna supplies rig employees with coveralls, hard hat, safety glasses, and hearing protection (ear plugs). Always have at least one set of extra clothes to change into if your current work wear gets contaminated.

Service rigs typically work from a base location, and crews work between 4 and 12 hour shifts each day. Service rig crews are generally made up of five (5) people: Rig Manager, Driller/Operator, Derrickhand, and two Floorhands.

Most days begin by meeting the Driller/Operator who drives the crew to the rig in a company vehicle or personal vehicle. Each member of the crew is responsible for getting themselves to the meeting point, so having a reliable vehicle is an asset. At the end of each shift, the crew returns to the meeting point and is dropped off.

Work in the oil and gas services industry is seasonal. Because of the weight of rigs and their equipment, and the remote location of wells, these locations are often only accessible when the ground conditions can tolerate heavy loads. Therefore, wells are typically drilled and serviced in the winter when the ground is frozen solid, or in the summer, when the ground has thawed and dried sufficiently. During the spring and fall, when the ground is in a transitional state, it is too soft to move equipment on and easily damaged. For this reason, provincial governments implement “road bans” prohibiting heavy loads from operating in certain areas. During this time, rig work is slower, and many rigs are shut down and their crews sent home. Be prepared to be off for anywhere from 6 to 12 weeks without pay during this time. However, rigs that are shut down are usually in need of maintenance, and there may be opportunities for employees who would like to help in this regard. Employees may be eligible for Employment Insurance benefits during seasonal shutdowns.

If you would like to work on a service rig, you should live in or near these areas. In some instances, rigs are required to operate in remote locations for extended periods of time. When this happens, rig crews either live in camps or in local hotels, and their room and board are paid for by Savanna.

Once you have completed your orientation, you will immediately receive any other necessary training. This involves Workplace Hazardous Materials Information System (WHMIS) and Transportation of Dangerous Goods (TDG), along with an in-depth General Safety Orientation. This training is mandatory and provided by Savanna at no cost to the employee. Job-related, hands on training is conducted in the field through the Enform Service Rig Competency Program.

While it is not mandatory to have this certification, each service rig crew is required to have two members who are certified in Standard First Aid with CPR level C. Therefore, obtaining a certification beforehand is a great way to improve your chances of being hired.

At Savanna, there is an excellent opportunity for good quality employees to quickly advance to more senior positions. If you would like to pursue a career as a Derrickhand or Driller, please speak to your Rig Manager or Human Resources. The service rig industry in Canada, through Enform, has adopted a competency assessment program to allow Drillers and Derrickhands to evaluate and promote Floorhands when they are ready. Savanna’s recruiters can provide you with more information if you would like to pursue a career in either one of these positions.

Workover Rig is available for both onshore as well as offshore Workover purposes at affordable prices. There are a number of companies that manufacture the Workover Rig as well as Rig packages that are required for different kinds of drilling jobs and meet the standards that have been set by the American Petroleum Institute or the API. The Rig packages are shipped worldwide. The rigs are included other than the simple Workover and they include the following:

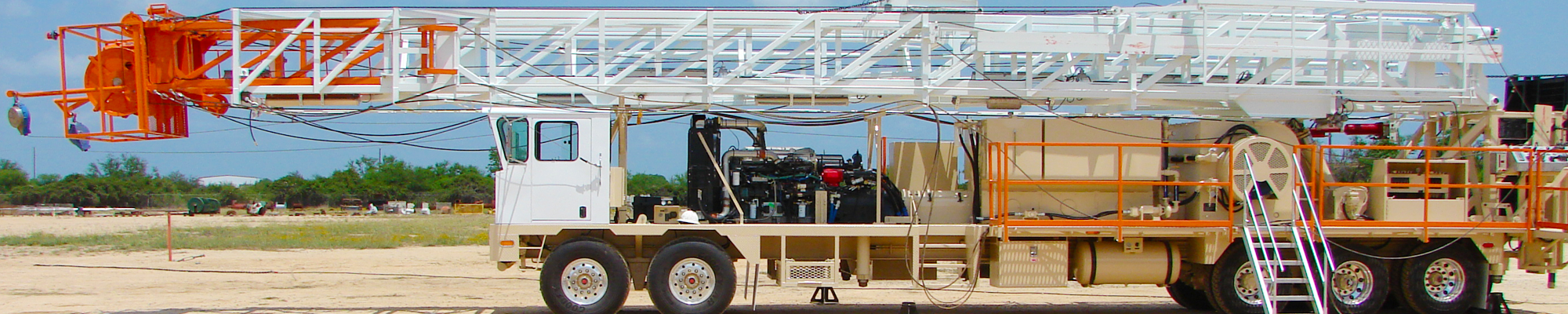

Workover Rig is known as the Workover the different types of rigs include the offshore and onshore Rig that range from 150 horsepower to 1000 horsepower. Workover rigs have a surface depth that is equipped with diesel engines and transmissions and is available from 8000 ft to 30000 ft. Workover rigs contain a full line of drilling packages. Rig takes into account the skid mounted drilling rigs and the ones that are trailer mounted. Workover skid mounted drilling rigs incorporate the diesel-electric AC/VFD or the DC/SCR drive rigs, mechanical drive rigs and the combination drive Rig that ranges from 1000 horsepower to 6000 horsepower; while the trailer mounted Rig ranges from 450 horsepower to 1000 horsepower.

A lot of Workover Rig uses the double telescopic mast with the help of a single mast and is operated by wide wheel base axels, high strength steel beam, low cross section tires, dual pipeline brakes as well as hydraulic assist steering for the Workover. Rig mast is a double section type and uses a telescopic mast for dual safety protection. The gear shift and throttle of the engine can be remote controlled.

Workover types of Rig are available in the form of the single drum as well as the double drum. The groove ensures the alignment of in place as well as for long life. The optional Workover accessories for the auxiliary brakes include air thrust disc type clutch, brakes for the braking of the main drum, forced water circulating cooling with the brake rims as well as the optional brakes. Workover rigs are centrally controlled with electricity. The other kinds of drilling equipment include drilling equipment, triplex mud pumps, well control equipment; solids control equipment, oil control tubular goods and quality equipment. Work over rigs run casing tools and clean outs inside and outside a hole already drilled.

8613371530291

8613371530291