Drill Pipe Protectors: Ensuring Safety and Longevity in Oil and Gas Operations

Introduction (150 words)

In the oil and gas industry, drill pipe protectors play a crucial role in safeguarding drill pipes from damage and ensuring the overall success of drilling operations. These protectors act as a shield against wear and tear, corrosion, and other hazards that can compromise the integrity and performance of the drilling equipment. This article will delve into the importance of drill pipe protectors, their types, benefits, and best practices for their utilization.

1. Understanding Drill Pipe Protectors (200 words)

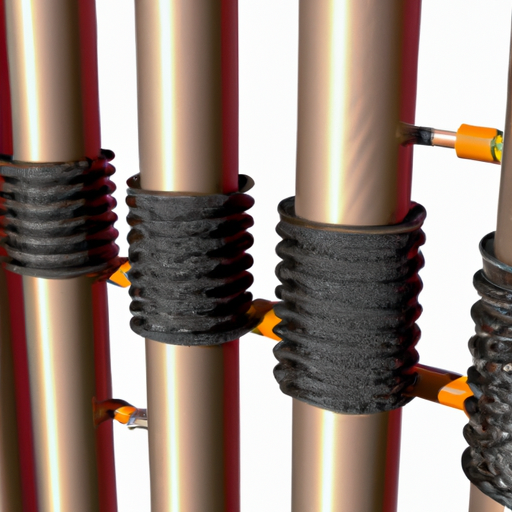

Drill pipe protectors are devices designed to safeguard the threaded ends of drill pipes used in oil and gas exploration and extraction. These protectors are typically made from durable materials like steel, plastic, or composite materials to withstand the demanding conditions experienced during drilling operations.

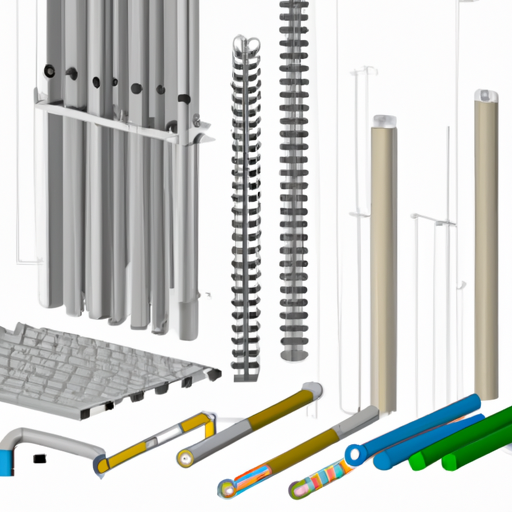

2. Types of Drill Pipe Protectors (200 words)

a) Threaded Protectors: These protectors are screwed onto the threaded ends of the drill pipe, providing a physical barrier against damage during transportation, storage, and makeup or breakout operations.

b) Composite Protectors: These protectors combine the strength of steel with the lightweight nature of plastic or composite materials. They are highly durable and offer excellent protection against impact, corrosion, and environmental elements.

c) Plastic Protectors: Plastic drill pipe protectors are cost-effective, lightweight, and easy to install. They provide a protective layer against scratches, impact, and corrosion during various stages of drilling operations.

3. Benefits of Drill Pipe Protectors (250 words)

a) Enhanced Safety: Drill pipe protectors minimize the risk of accidents and injuries by preventing damage to the threads, which can result in pipe failure and subsequent mishaps.

b) Increased Longevity: By shielding drill pipes from corrosion, abrasion, and other forms of damage, protectors extend the lifespan of the equipment, reducing the need for frequent replacements and associated costs.

c) Improved Efficiency: Drill pipe protectors ensure smooth and efficient drilling operations by maintaining the integrity of the pipe threads, allowing for easier makeup and breakout processes.

d) Cost Savings: Investing in quality drill pipe protectors can significantly reduce maintenance and replacement expenses, as well as minimize downtime caused by damaged pipes.

4. Best Practices for Drill Pipe Protector Utilization (250 words)

a) Proper Installation: Ensure correct installation of protectors to guarantee complete coverage and protection of the threaded ends. Follow manufacturer guidelines and torque specifications for optimal performance.

b) Regular Inspection and Maintenance: Regularly inspect and maintain the protectors to identify any signs of wear, damage, or corrosion. Replace damaged or worn-out protectors promptly to avoid compromising the drill pipe's integrity.

c) Environmental Considerations: Select the appropriate drill pipe protectors based on the specific environmental conditions encountered during drilling operations. Consider factors such as temperature, humidity, and chemical exposure to ensure optimal protection.

d) Training and Awareness: Educate drilling personnel about the importance of using and maintaining drill pipe protectors correctly. Implement training programs to promote proper handling, storage, and installation procedures.

Conclusion (150 words)

Drill pipe protectors are indispensable components in the oil and gas industry, ensuring the safety, longevity, and efficiency of drilling operations. By minimizing risks associated with pipe failure, protectors contribute to a safer working environment and reduce operational costs. Selecting the appropriate drill pipe protectors, adhering to best practices, and prioritizing regular maintenance will enhance the overall performance and lifespan of drilling equipment. It is crucial for industry professionals to recognize the importance of these protectors and incorporate their use into drilling operations to achieve optimal results.

8613371530291

8613371530291