Drill Pipe Protectors: Ensuring Safety and Efficiency in Oil and Gas Exploration

Introduction (100 words)

Drill pipe protectors play a crucial role in the oil and gas industry, safeguarding the integrity of drill pipes during transportation, storage, and drilling operations. These protective devices shield the drill pipes from damage, corrosion, and other potential hazards, ensuring the overall safety and efficiency of drilling operations. This article delves into the significance of drill pipe protectors, their types, and the benefits they offer to the oil and gas industry.

1. Understanding Drill Pipe Protectors (200 words)

Drill pipe protectors are robust coverings designed to shield the vulnerable threads and connections of drill pipes from external damage, such as impact, corrosion, and contamination. These protective devices are typically made from high-quality materials, including plastic, steel, or composite materials, to withstand the harsh conditions encountered during drilling operations. By preventing damage to the drill pipes, these protectors not only extend the lifespan of the equipment but also reduce the risk of costly repairs and downtime.

2. Types of Drill Pipe Protectors (200 words)

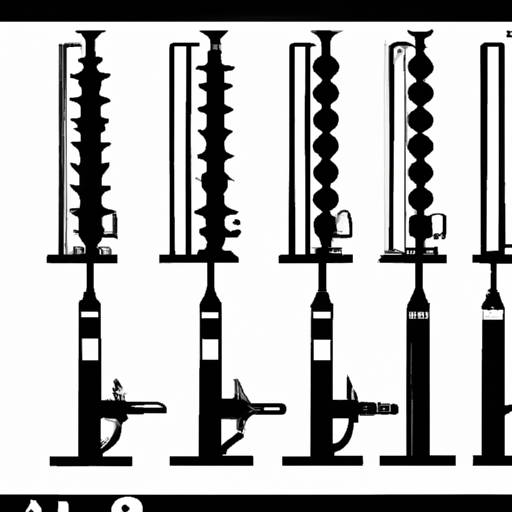

There are several types of drill pipe protectors available in the market, each with its unique features and advantages. The most common types include:

a. Plastic Thread Protectors: These protectors are lightweight, easy to install and remove, and provide excellent protection against impact and corrosion. They are cost-effective, making them a popular choice for short-term storage and transportation.

b. Steel Thread Protectors: These protectors are highly durable and preferred for long-term storage and heavy-duty operations. They offer superior protection against impacts, contaminants, and extreme weather conditions, ensuring the integrity of the drill pipes during harsh environments.

c. Composite Thread Protectors: Combining the benefits of plastic and steel protectors, composite protectors are lightweight, yet robust and resistant to impact, corrosion, and extreme temperatures. They are suitable for both short-term and long-term storage needs.

3. Importance of Drill Pipe Protectors (200 words)

The significance of drill pipe protectors cannot be overstated. Here are some key reasons why these protective devices are crucial in the oil and gas industry:

a. Preventing Thread Damage: The threads and connections of drill pipes are vulnerable to damage during transportation and storage. Thread damage can lead to leaks, reduced drilling efficiency, and even catastrophic failure. Drill pipe protectors provide a reliable barrier that shields these critical areas, preventing costly thread damage.

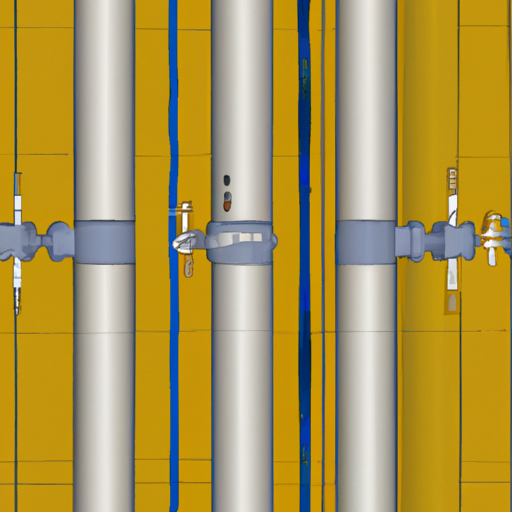

b. Reducing Corrosion Risks: Drill pipes are exposed to corrosive elements, such as moisture, chemicals, and salts, during drilling operations. Corrosion weakens the structural integrity of the pipes and can lead to premature failure. By effectively sealing the pipes from external elements, protectors minimize the risk of corrosion, prolonging the lifespan of the equipment.

c. Ensuring Safety: Well-maintained drill pipes are crucial for the safety of personnel and the environment during drilling operations. Drill pipe protectors enhance safety by preventing accidents caused by damaged or compromised pipes, such as pipe disconnections, blowouts, or spills.

d. Cost Savings: Investing in drill pipe protectors may seem like an additional expense; however, it offers significant cost savings in the long run. By mitigating damage and corrosion risks, protectors reduce the need for frequent repairs, replacements, and downtime, resulting in substantial cost savings for drilling companies.

4. Benefits of Drill Pipe Protectors (200 words)

Drill pipe protectors offer numerous benefits that contribute to the efficiency and productivity of oil and gas exploration. Some key advantages include:

a. Enhanced Equipment Longevity: By shielding drill pipes from external damage and corrosion, protectors extend their lifespan, reducing the frequency of replacements and associated costs.

b. Increased Operational Efficiency: The use of protectors ensures that drill pipes remain in optimum condition, minimizing the risk of equipment failures and downtime. This leads to improved operational efficiency and increased productivity.

c. Easy Installation and Removal: Drill pipe protectors are designed for easy installation and removal, saving valuable time during transportation, storage, and drilling operations. Their user-friendly design allows for quick application, enabling seamless operations.

d. Compatibility and Versatility: Drill pipe protectors are available in various sizes and designs, ensuring compatibility with different pipe dimensions and thread types. This versatility makes them suitable for a wide range of drilling applications.

Conclusion (100 words)

Drill pipe protectors are indispensable in the oil and gas industry, safeguarding drill pipes from damage, corrosion, and other risks. By preventing thread damage, reducing corrosion risks, ensuring safety, and offering cost savings, these protective devices play a vital role in maintaining the integrity and efficiency of drilling operations. Investing in high-quality drill pipe protectors not only extends the lifespan of equipment but also enhances operational efficiency, leading to improved productivity in the oil and gas exploration sector.

8613371530291

8613371530291