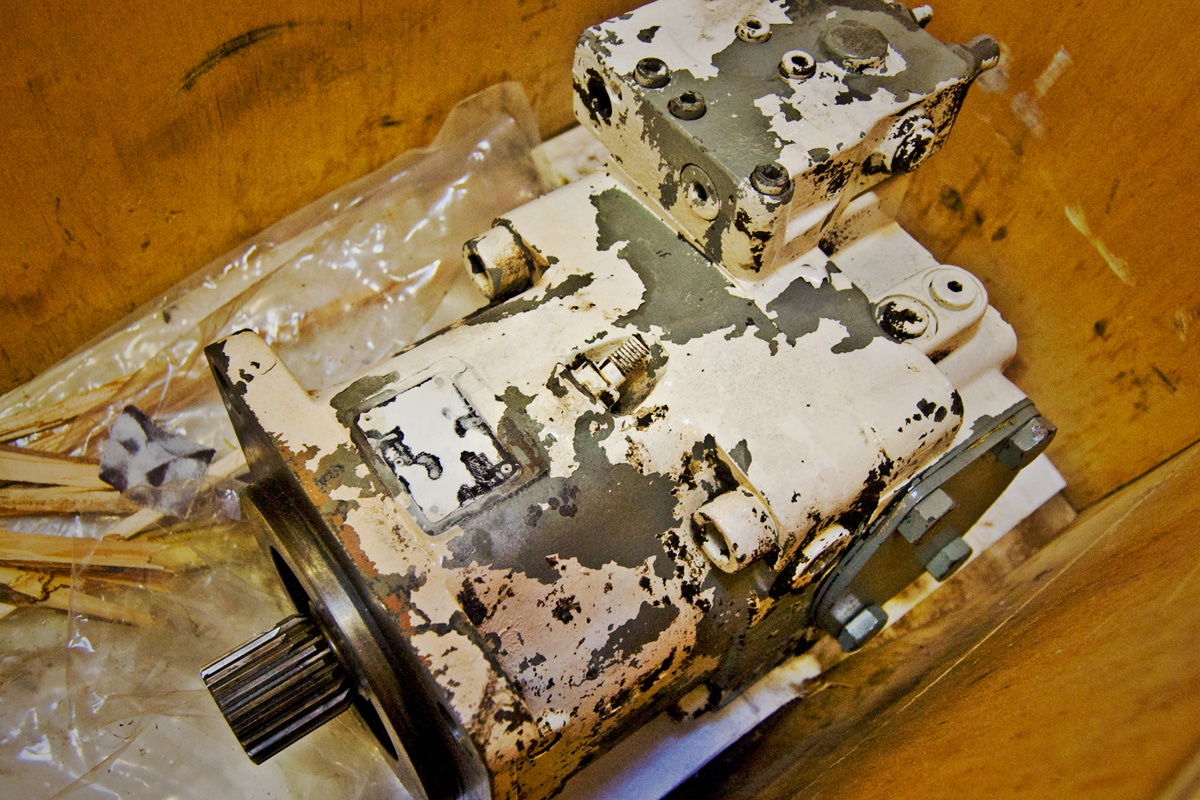

old hydraulic pump supplier

Hydraulic systems are in general members of the fluid power branch of power transmission. Hydraulic pumps are also members of the hydraulic power pack/hydraulic power unit family. Hydraulic units are encased mechanical systems that use liquids for hydraulics.

The hydraulic systems that hydraulic pumps support exist in a range of industries, among them agriculture, automotive manufacturing, defense contracting, excavation, and industrial manufacturing. Within these industries, machines and applications that rely on hydraulic pumps include airplane flaps, elevators, cranes, automotive lifts, shock absorbers, automotive brakes, garage jacks, off-highway equipment, log splitters, offshore equipment, hydraulic motors/hydraulic pump motors, and a wide range of other hydraulic equipment.

When designing hydraulic pumps, manufacturers have many options from which to choose in terms of material composition. Most commonly, they make the body of the pump–the gears, pistons, and hydraulic cylinders–from a durable metal material. This metal is one that that can hold up against the erosive and potentially corrosive properties of hydraulic fluids, as well as the wear that comes along with continual pumping. Metals like this include, among others, steel, stainless steel, and aluminum.

First, what are operating specifications of their customer? They must make sure that the pump they design matches customer requirements in terms of capabilities. These capabilities include maximum fluid flow, minimum and maximum operating pressure, horsepower, and operating speeds. Also, based on application specifications, some suppliers may choose to include discharge sensors or another means of monitoring the wellbeing of their hydraulic system.

Next, what is the nature of the space in which the pump will work? Based on the answer to this question, manufacturers will design the pump with a specific weight, rod extension capability, diameter, length, and power source.

Manufacturers must also find out what type of substance does the customer plan on running through the pumps. If the application calls for it, manufacturers can recommend operators add other substances to them in order to decrease the corrosive nature of certain hydraulic fluids. Examples of such fluids include esters, butanol, pump oils, glycols, water, or corrosive inhibitors. These substances differ in operating temperature, flash point, and viscosity, so they must be chosen with care.

All hydraulic pumps are composed in the same basic way. First, they have a reservoir, which is the section of the pump that houses stationary fluid. Next, they use hydraulic hoses or tubes to transfer this fluid into the hydraulic cylinder, which is the main body of the hydraulic system. Inside the cylinder, or cylinders, are two hydraulic valves and one or more pistons or gear systems. One valve is located at each end; they are called the intake check/inlet valve and the discharge check/outlet valve, respectively.

Hydraulic pumps operate under the principle of Pascal’s Law, which states the increase in pressure at one point of an enclosed liquid in equilibrium is equally transferred to all other points of said liquid.

To start, the check valve is closed, making it a normally closed (NC) valve. When the check is closed, fluid pressure builds. The piston forces the valves open and closes repeatedly at variable speeds, increasing pressure in the cylinder until it builds up enough to force the fluid through the discharge valve. In this way, the pump delivers sufficient force and energy to the attached equipment or machinery to move the target load.

When the fluid becomes pressurized enough, the piston withdraws long enough to allow the open check valve to create a vacuum that pulls in hydraulic fluid from the reservoir. From the reservoir, the pressurized fluid moves into the cylinder through the inlet. Inside the cylinder, the fluid picks up more force, which it carries over into the hydraulic system, where it is released through the outlet.

Piston pumps create positive displacement and build pressure using pistons. Piston pumps may be further divided into radial piston pumps and axial piston pumps.

Radial pumps are mostly used to power relatively small flows and very high-pressure applications. They use pistons arranged around a floating center shaft or ring, which can be moved by a control lever, causing eccentricity and the potential for both inward and outward movement.

Axial pumps, on the other hand, only allow linear motion. Despite this, they are very popular, being easier and less expensive to produce, as well as more compact in design.

Gear pumps, or hydraulic gear pumps, create pressure not with pistons but with the interlocking of gear teeth. When teeth are meshed together, fluid has to travel around the outside of the gears, where pressure builds.

External gear pumps facilitate flow by enlisting two identical gears that rotate against each other. As liquid flows in, it is trapped by the teeth and forced around them. It sits, stuck in the cavities between the teeth and the casing, until it is so pressurized by the meshing of the gears that it is forced to the outlet port.

Internal gear pumps, on the other hand, use bi-rotational gears. To begin the pressurizing process, gear pumps first pull in liquid via a suction port between the teeth of the exterior gear, called the rotor, and the teeth of the interior gear, called the idler. From here, liquid travels between the teeth, where they are divided within them. The teeth continue to rotate and mesh, both creating locked pockets of liquid and forming a seal between the suction port and the discharge port. Liquid is discharged and power is transported once the pump head is flooded. Internal gears are quite versatile, usable with a wide variety of fluids, not only including fuel oils and solvents, but also thick liquids like chocolate, asphalt, and adhesives.

Various other types of hydraulic pumps include rotary vane pumps, centrifugal pumps, electric hydraulic pumps, hydraulic clutch pumps, hydraulic plunger pumps, hydraulic water pumps, hydraulic ram pumps, portable 12V hydraulic pumps, hydraulic hand pumps, and air hydraulic pumps.

Rotary vane pumps are fairly high efficiency pumps, though they are not considered high pressure pumps. Vane pumps, which are a type of positive-displacement pump, apply constant but adjustable pressure.

Centrifugal pumps use hydrodynamic energy to move fluids. They feature a rotating axis, an impeller, and a casing or diffuser. Most often, operators use them for applications such as petroleum pumping, sewage, petrochemical pumping, and water turbine functioning.

Electric hydraulic pumps are hydraulic pumps powered by an electric motor. Usually, the hydraulic pump and motor work by turning mechanisms like impellers in order to create pressure differentials, which in turn generate fluid movement. Nearly any type of hydraulic pump can be run with electricity. Most often, operators use them with industrial machinery.

Hydraulic clutch pumps help users engage and disengage vehicle clutch systems. They do so by applying the right pressure for coupling or decoupling shafts in the clutch system. Coupled shafts allow drivers to accelerate, while decoupled shafts allow drivers to decelerate or shift gears.

Hydraulic ram pumps are a type of hydraulic pump designed to harness hydropower, or the power of water, to elevate it. Featuring only two moving hydraulic parts, hydraulic ram pumps require only the momentum of water to work. Operators use hydraulic ram pumps to move water in industries like manufacturing, waste management and sewage, engineering, plumbing, and agriculture. While hydraulic ram pumps return only about 10% of the water they receive, they are widely used in developing countries because they do not require fuel or electricity.

Hydraulic water pumps are any hydraulic pumps used to transfer water. Usually, hydraulic water pumps only require a little bit of energy in the beginning, as the movement and weight of water generate a large amount of usable pressure.

Air hydraulic pumps are hydraulic pumps powered by air compressors. In essence, these energy efficient pumps work by converting air pressure into hydraulic pressure.

Hydraulic pumps are useful for many reasons. First, they are simple. Simple machines are always an advantage because they are less likely to break and easier to repair if they do. Second, because fluid is easy to compress and so quick to create pressure force, hydraulic pumps are very efficient. Next, hydraulic pumps are compact, which means they are easy to fit into small and oddly shaped spaces. This is especially true in comparison to mechanical pumps and electrical pumps, which manufacturers cannot design so compactly. Speaking of design, another asset of hydraulic pumps is their customizability. Manufacturers can modify them easily. Likewise, hydraulic pumps are very versatile, not only because they are customizable, but also because they can work in places where other types of pump systems can’t, such as in the ocean. Furthermore, hydraulic pumps can produce far more power than similarly sized electrical pumps. Finally, these very durable hydraulic components are much less likely to explode than some other types of components.

To make sure that your hydraulic pumps stay useful for a long time, you need to treat them with care. Care includes checking them on a regular basis for problems like insufficient fluid pressure, leaks, and wear and tear. You can use diagnostic technology like discharge sensors to help you with detect failures and measure discharge pressure. Checking vibration signals alone is often not enough.

To keep yourself and your workers safe, you need to always take the proper precautions when operating or performing maintenance and repairs on your hydraulic pumps. For example, you should never make direct contact with hydraulic fluid. For one, the fluid made be corrosive and dangerous to your skin. For two, even if the pump isn’t active at that moment, the fluid can still be pressurized and may potentially harm you if something goes wrong. For more tips on hydraulic pump care and operation, talk to both your supplier and OSHA (Occupational Safety and Health Administration).

Pumps that meet operating standards are the foundation of safe and effective operations, no matter the application. Find out what operating standards your hydraulic pumps should meet by talking to your industry leaders.

The highest quality hydraulic pumps come from the highest quality hydraulic pump manufacturers. Finding the highest quality hydraulic pump manufacturers can be hard, which is why we have we listed out some of our favorites on this page. All of those whom we have listed come highly recommended with years of experience. Find their information nestled in between these information paragraphs.

Once you have put together you list, get to browsing. Pick out three or four hydraulic pump supply companies to which you’d like to speak, then reach out to each of them. After you’ve spoken with representatives from each company, decide which one will best serve you, and get started on your project.

EquipNet is the leading global provider of preowned processing equipment including used hydraulic pumps and much more. Our exclusive contracts with our clients yield a wide range of used hydraulic pumps from a number of respected OEMs, including Vickers, Voith, Columbia Machine and many others. We are constantly receiving used hydraulic pumps in a range of models and styles. If you don"t see the used hydraulic pumps you are looking for, call one of our representatives and we"ll find it for you. We can also source the right tooling and change parts that you need through our huge network of corporate clients from around the globe.

Hydraulic pumps (sometimes erroneously referred to as "hydrolic" pumps) are devices within hydraulic systems that transport hydraulic liquids from one point to another to initiate the creation of hydraulic power. They are an important component overall in the field of hydraulics, a specialized form of power transmission that harnesses the energy transmitted by moving liquids under pressure and converts it into mechanical energy. Other types of pumps that are used to transmit hydraulic fluids may also be called hydraulic pumps. Because of the wide variety of contexts in which hydraulic systems are employed, hydraulic pumps are very important in various industrial, commercial and consumer utilities.

The term power transmission refers to the overall process of technologically converting energy into a useful form for practical applications. Three main branches compose the field of power transmission: electrical power, mechanical power, and fluid power. Fluid power encompasses the use of moving gases and well as moving liquids for power transmission. Hydraulics, then, can be considered as a sub-branch of fluid power which focuses on liquid usage as opposed to gas usage. The other field of fluid power is known as pneumatics and revolves around storing and releasing energy with compressed gas.

As described above, the incompressible nature of fluid within hydraulic systems enables an operator to create and apply mechanical power in a very efficient manner. Practically all of the force generated within a hydraulic system is applied to its intended target.

Because of the relationship between force, area, and pressure (F = P x A), it is relatively easy to modify the force of a hydraulic system simply by modifying the size of its components.

Hydraulic systems can transmit power on par with many electrical and mechanical systems while being generally simpler at the same time. For example, it is easy to directly create linear motion with a hydraulic system. On the contrary, electrical and mechanical power systems generally require an intermediate mechanical step to produce linear motion from rotational motion.

Hydraulic power systems are generally smaller than their electrical and mechanical counterparts while generating similar amounts of power, thus providing the advantage of conserving physical space.

The basic design of hydraulic systems (a reservoir/pump connected to actuators by some sort of piping system) allows them to be used in a wide variety of physical settings. Hydraulic systems can also be used in environments that are impractical for electrical systems (e.g. underwater).

Using hydraulic systems in place of electrical power transmission increases relative safety by eliminating electrical safety hazards (e.g. explosions, electric shock).

A major, specific advantage of hydraulic pumps is the amount of power they are able to generate. In some cases, a hydraulic pump can produce ten times the amount of power produced by an electrical counterpart. Some types of hydraulic pumps (e.g. piston pumps) are more expensive than the average hydraulic component. These types of disadvantages, however, may be offset by the pump’s power and efficiency. For example, piston pumps are prized for their durability and ability to transmit very viscous fluids, despite their relatively high cost.

The essence of hydraulics lies in a fundamental physical reality: liquids are incompressible. Because of this, liquids resemble solids more than compressible gases. The incompressible nature of liquid enables it to transmit force very efficiently in terms of force and speed. This fact is summarized by a version of "Pascal’s Law" or "Pascal’s Principle", which states that virtually all of the pressure applied to any part of a (confined) fluid will be transmitted to every other part of the fluid. Using alternative terms, this scientific principle states that pressure exerted on a (confined) fluid transmits equally in every direction.

Furthermore, force transmitted within a fluid has the potential to multiply during its transmission. From a slightly more abstract point of view, the incompressible nature of liquids means that pressurized liquids must maintain a constant pressure even as they move. Pressure, from a mathematical point of view, is force acting per a specific area unit (P = F/A). A rearranged version of this equation makes it clear that force equals the product of pressure times area (F = P x A). Thus, by modifying the size or area of certain components within a hydraulic system, the force acting within a hydraulic system can also be modified accordingly (to either greater or lesser). The need for pressure to stay constant is responsible for making force and area reflect each other (in terms of either growing or shrinking). This force-area relationship can be illustrated by a hydraulic system containing a piston that is five times bigger than a second piston. if a certain force (e.g. 50 pounds) is applied to the smaller piston, that force will be multiplied by five (e.g. to 250 pounds) as it is transmitted to the larger piston within the hydraulic system.

The chemical nature of liquids as well as the physical relationship between force, area, and pressure form the foundation of hydraulics. Overall, hydraulic applications enable human operators to create and apply massive mechanical forces without exerting much physical effort at all. Water and oil are both used for power transmission within hydraulic systems. The use of oil, however, is far more common, due in part to its very incompressible nature.

It has previously been noted that "Pascal’s Law" applies to confined liquids. Thus, for liquids to act in a hydraulic fashion, it must function with some type of enclosed system. An enclosed mechanical system that uses liquid hydraulically is known as a hydraulic power pack or a hydraulic power unit. Though specific operating systems are variable, all hydraulic power packs (or units) have the same basic components. These components generally include a reservoir, a pump, a piping/tubing system, valves, and actuators (including both cylinders and motors). Similarly, despite the versatility and adaptability of these mechanisms, these components all work together within similar operating processes, which lie behind all hydraulic power packs.

Hoses or tubes are needed to transport the viscous liquids transmitted from the pump. This piping apparatus then transports the solution to the hydraulic cylinder.

Actuators are hydraulic components which perform the main conversion of hydraulic energy into mechanical energy. Actuators are mainly represented by hydraulic cylinders and hydraulic motors. The main difference between hydraulic cylinders and hydraulic motors lies in the fact that hydraulic cylinders primarily produce linear mechanical motion while hydraulic motors primarily produce rotary mechanical motion.

Hydraulic systems possess various valves to regulate the flow of liquid within a hydraulic system. Directional control valves are used to modify the size and direction of hydraulic fluid flow, while pressure relief valves preempt excessive pressure by limiting the output of the actuators and redirecting fluid back to the reservoir if necessary.

Two main categories of hydraulic pumps to be considered are piston pumps and gear pumps. Within the piston grouping are axial and radial piston pumps. Axial pumps provide linear motion, while radial pumps can operate in a rotary manner. The gear pump category is also divided into two groupings, internal gear pumps and external gear pumps.

No matter piston or gear, each type of hydraulic pump can be either a single-action or double-action pump. Single-action pumps can push, pull or lift in only one direction, while double-action pumps are multidirectional.

The transfer of energy from hydraulic to mechanical is the end goal, with the pump mechanism serving as a generator. In other cases, however, the energy is expelled by means of high pressure streams that help to push, pull and lift heavy loads.

Hydraulic piston pumps and hydraulic clutch pumps, which operate in slightly different ways, are all utilized in heavy machinery for their versatility of motion and directionality.

And hydraulic water pumps are widely used to transfer water. The design of these pumps dictates that, although a small amount of external energy is needed to initiate the action, the weight of the water and its movement can create enough pressure to operate the pump continuously thereafter. Hydraulic ram pumps require virtually no maintenance, as they have only two moving parts. Water from an elevated water source enters one of two chambers through a relatively long, thick pipe, developing inertia as it moves down to the second chamber, which starts the pump.

The initial energy within a hydraulic system is produced in many ways. The simplest form is the hydraulic hand pump which requires a person to manually pressurize the hydraulic fluid. Hydraulic hand pumps are manually operated to pressurize a hydraulic system. Hydraulic hand pumps are often used to calibrate instruments.

Energy-saving pumps that are operated by a compressed air source and require no energy to maintain system pressure. In both the single and two-stage air hydraulic pumps, air pressure is simply converted to hydraulic pressure, and they stall when enough pressure is developed.

Non-positive displacement pumps that are used in hydraulics requiring a large volume of flow. Centrifugal pumps operate at fairly low pressures and are either diffuser or volute types.

Convert hydraulic energy to mechanical power. Hydraulic pumps are specially designed mechanisms used in industrial, commercial and residential settings to create useful energy from the pressurization of various viscous fluids. Hydraulic pumps are extremely simple yet effective mechanisms for moving liquids. "Hydralic" is actually a misspelling of "hydraulic;" hydraulic pumps rely on the power provided by hydraulic cylinders to power various machines and mechanisms.

Pumps in which the clamps and cylinders are quickly extended by high flow at low pressure in the first stage of operation. In the second stage, piston pumps build pressure to a preset level and then maintain that level.

The construction, automotive manufacturing, excavation, agriculture, defense contracting and manufacturing industries are just a few examples of operations that utilize the power of hydraulics in normal, daily processes. Since the use of hydraulics is so widespread, hydraulic pumps are naturally used in a broad array of industries and machines. In all of the contexts which use hydraulic machinery, pumps perform the same basic role of transmitting hydraulic fluid from one place to another to create hydraulic pressure and energy (in conjunction with the actuators).

Various products that use hydraulics include elevators, automotive lifts, automotive brakes, airplane flaps, cranes, shock absorbers, motorboat steering systems, garage jacks, log splitters, etc. Construction sites represent the most common application of hydraulics in large hydraulic machines and various forms of "off-highway" equipment such as diggers, dumpers, excavators, etc. In other environments such as factories and offshore work areas, hydraulic systems are used to power heavy machinery, move heavy equipment, cut and bend material, etc.

While hydraulic power transmission is extremely useful in a wide variety of professional applications, it is generally unwise to depend exclusively on one form of power transmission. On the contrary, combining different forms of power transmission (hydraulic, pneumatic, electrical and mechanical) is the most efficient strategy. Thus, hydraulic systems should be carefully integrated into an overall strategy of power transmission for your specific commercial application. You should invest in finding honest and skilled hydraulic manufacturers / suppliers who can assist you in developing and implementing an overall hydraulic strategy.

When selecting a hydraulic pump, its intended use should be considered when selecting a particular type. This is important since some pumps may carry out only one task, while others allow more flexibility.

The material composition of the pump should also be considered in an application-specific context. The pistons, gears and cylinders are often made of durable materials such as aluminum, steel or stainless steel which can endure the constant wear of repetitive pumping. The materials must hold up not only to the process itself, but to the hydraulic fluids as well. Oils, esters, butanol, polyalkylene glycols and corrosion inhibitors are often included in composite fluids (though simply water is also used in some instances). These fluids vary in terms of viscosity, operating temperature and flash point.

Along with material considerations, manufacturers should compare operating specifications of hydraulic pumps to ensure that intended use does not exceed pump capabilities. Continuous operating pressure, maximum operating pressure, operating speed, horsepower, power source, maximum fluid flow and pump weight are just a few of the many variables in hydraulic pump functionality. Standard measurements such as diameter, length and rod extension should also be compared. As hydraulic pumps are used in motors, cranes, lifts and other heavy machinery, it is integral that they meet operating standards.

It is important to remember that the overall power produced by any hydraulic drive system is affected by various inefficiencies that must be taken into account to get the maximum use out of the system. For example, the presence of air bubbles within a hydraulic drive is notorious for diverting the energy flow within the system (since energy gets wasted en route to the actuators on compressing the bubbles). Using a hydraulic drive system must involve identifying these types of inefficiencies and selecting the best components to mitigate their effects. A hydraulic pump can be considered as the "generator" side of a hydraulic system which begins the hydraulic process (as opposed to the "actuator" side which completes the hydraulic process). Despite their differences, all hydraulic pumps are somehow responsible for displacing fluid volume and bringing it from the reservoir to the actuator(s) via the tubing system. Pumps are generally enabled to do this by some type of internal combustion system.

Even though hydraulic systems are simpler when compared to electrical or mechanical systems, they are still sophisticated systems that should only be handled with care. A fundamental safety precaution when interacting with hydraulic systems is to avoid physical contact if possible. Active fluid pressure within a hydraulic system can pose a hazard even if a hydraulic machine is not actively operating.

Insufficient pumps can lead to mechanical failure in the workplace, which can have serious and costly repercussions. Although pump failure has been unpredictable in the past, new diagnostic technologies continue to improve on detection methods that previously relied upon vibration signals alone. Measuring discharge pressures allows manufacturers to more accurately predict pump wear. Discharge sensors can be easily integrated into existing systems, adding to the safety and versatility of the hydraulic pump.

A container that stores fluid under pressure and is utilized as a source of energy or to absorb hydraulic shock. Accumulator types include piston, bladder and diaphragm.

A circumstance that occurs in pumps when existing space is not filled by available fluid. Cavitation will deteriorate the hydraulic oil and cause erosion of the inlet metal.

Any device used to convert potential energy into kinetic energy within a hydraulic system. Motors and manual energy are both sources of power in hydraulic power units.

A slippery and viscous liquid that is not miscible with water. Oil is often used in conjunction with hydraulic systems because it cannot be compressed.

A device used for converting hydraulic power to mechanical energy. In hydraulic pumps, the piston is responsible for pushing down and pulling up the ram.

A hydraulic mechanism that uses the kinetic energy of a flowing liquid to force a small amount of the liquid to a reservoir contained at a higher level.

A device used to regulate the amount of hydraulic or air flow. In the closed position, there is zero flow, but when the valve is fully open, flow is unrestricted.

Manufacturer and distributor of standard and custom liquid pumps including hydraulic pumps. Types include high-flow pumps and dual component injection pumps. Hydraulic pumps are available in single acting and double acting pump styles with single or double air drive head types. Features include different pressure ratios, air driven pressures ranging from 60 psi to 60000 psi, pilot air valves, explosion proof construction, external spool valves and air regulators. Liquid pumps are used for oil, water and chemical service applications including lifting, jacking, presses, tooling, roller tensioning, hydrostatic pressure testing, lubrication systems, trash compactors and truck or trailer wheel cylinders. Same day shipping available.

With Linde Hydraulics discontinuing their in-house remanufacturing program in February of 2023 - Hydraulex (our Washington State facility) is now 1 of 5 Authorized Linde Service Centers within the USA and Canada. We"ve worked closely with Linde for many years and have factory training & are factory supported by Linde.

Impeller blades revolve inside the casing, rotating the surround fluids. the blades also lubricate and cool the system. Pump bearings are often made to anti-friction, to help the impeller rotate inside the casing. The pump shaft is made of steel, and its size corresponds to the size of the impeller.

A hydraulic hand pump transforms human power into hydraulic energy by combining pressure and flow. The foundation for hydraulic fluid delivery is the simple notion that a handle gives an internal piston leverage under manual pressure. The piston then pushes the hydraulic fluid into the cylinder port. Water and hydraulic fluid are the two most common fluids, and however other pressure media can also be used.

The hydraulic pressure generated can be used to test, calibrate, and adjust various measuring instruments and tools. Hydraulic hand pumps are widely used to load and test mechanical parts when a user requires precise adjustments. They are also used in lifting and lowering heavy things in material handling equipment, which similarly necessitates precise control over the movement of the objects.

The working medium, requisite pressure range, drive type, etc., are only a few of the functional and hydraulic system requirements that are considered when manufacturing hydraulic pumps. In addition, there are numerous design philosophies and hydraulic pump combinations to choose from. Due to this, only a few pumps can completely fulfill all needs. The most common types of hydraulic pumps have already been described.

The use of hydraulic pumps is still common in industrial settings. Elevators, conveyors, mixers, forklifts, pallet jacks, injection molding machines, presses (shear, stamping, bending, etc.), foundries, steel mills, and slitters are examples of equipment used in material handling. With an application"s need, a hydraulic pump is more likely to be used.

Additionally, hydraulic pumps are used in every conceivable mobile or industrial hydraulic machine. They are used on many different pieces of gear, such as excavators, cranes, loaders, tractors, vacuum trucks, forestry equipment, graders, dump trucks, and mining equipment. Mobile applications use hydraulic pumps more commonly than industrial applications since industrial devices typically don"t use electric actuators.

Norman Equipment has been a leading supplier of hydraulic equipment including hydraulic piston pumps and motors for over 70 years. Full-line authorized stocking distributor of quality hydraulic components and systems from top manufacturers renowned for performance and reliability.

We recommend using the piston pumps in high-pressure applications. In some cases, it is more economical to run a piston pump compensated that puts out a very low output flow until needed. This lowers electric cost and pump wear that may reduce system down time.

Norman currently stocks the Parker Denison PV (PVP) units and is part of the Parker Denison Distribution Network if another unit is needed that is not in stock at Norman Equipment. Denison is one of the most recognized names in hydraulic units in the world. For many years, their products were recognized by their distinctive blue color. Today, the Denison brand is part of the Parker-Hannifin family and all pumps are painted black.

In a hydraulic system, fluid is conveyed through the various components by the activity of a pump. Pumps work by converting mechanical energy—e.g., the turning of a gear—into hydraulic (i.e., fluid) energy. Hydraulic pumps may be either fixed displacement (conveys a precise, unchangeable amount of fluid during each rotation) or variable displacement (can be altered to change the amount of fluid conveyed). Of these two types, variable displacement pumps are more complicated in design and, therefore, tend to be more expensive.

Hydraulic pumps are used in a wide range of industrial equipment and, for this reason, they exist in a broad assortment of designs, including the following:

Vane pumps – Vane pumps feature a rotating shaft with a number of thin vanes protruding from it. The vanes effectively separate the housing into distinct compartments, each of which conveys fluid from the input to the output as the central rotor turns. Because the rotor is positioned eccentrically, its motion first steadily increase the volume of space in each compartment as the compartments fill and then decreases them as they empty when the fluid is forcefully expelled through the output.

Gear pumps – The typical gear pump has two interlocking gears, one of which is connected to a drive shaft. As the shaft turns, the two gears are put into motion, conveying the hydraulic fluid around the outer perimeter of the housing and finally through the outlet.

Piston pumps – A piston pump is characterised by the presence of one or more pistons, consisting of a cylinder inside a cylinder. The up-and-down motion of the piston conveys hydraulic fluid to the output. These pumps are available in axial and radial designs.

In addition to supplying all types of hydraulic pumps, from stock White House Products can also manufacture piston gear and vane pumps to order. For gear pumps consult the Tailor Made gear pump section of our catalogue. For Vane pumps see the available options in the Vane pump and mtors section of the catalogue. For Piston pumps see the available options in the Standard Piston Pumps section.

If your hydraulic pump requires new parts or to be repaired White House Products can assist with a wide range of spare parts and full repair and test facilities for all types and styles of hydraulic pump. So if you need to replace the entire system, a component or need a component repair, you can count on White House Products for the exact part numbers. Parts for Cessna, Kayaba, Saeur Danfoss, Vickers, and other pump brands are available from stock.

Sometimes, it is a challenge to find an exact match to your application. If a particular hydraulics system manufacturer does not produce a pump for your requirements, we can help. You can have one built to your own specifications, which sets our operation apart from other hydraulic pump suppliers. Register to access this feature, but not before conducting a complete search of our catalogues, as this is the world’s largest selection of hydraulic pumps.

Search filters and the “Quick Find” feature simplify the process of browsing thousands of products from a leading pump system supplier. Your search can be as simple as entering a keyword or part number. By registering, instantly see stock availability and hydraulic pump pricing, and use instant online ordering; for help, our technical support team is always standing by.

The goal of a hydraulic pump is to move hydraulic fluid through a hydraulic system, acting much like the beating heart of the system. There are two things that all hydraulic pumps have in common: (1) they provide hydraulic flow to other components (e.g., rams, hydraulic motors, cylinder) within a hydraulic system, and (2) they produce flow which in turn generates pressure when there is a resistance to flow. In addition, most hydraulic pumps are motor-driven and include a pressure relief valve as a type of overpressure protection. The three most common types of hydraulic pumps currently in use are gear, piston, and vane pumps.

In a gear pump, hydraulic fluid is trapped between the body of the pump and the areas between the teeth of the pump’s two meshing gears. The driveshaft is used to power one gear while the other remains idle until it meshes with the driving gear. These pumps are what is known as fixed displacement or positive displacement because each rotation of the shaft displaces the same amount of hydraulic fluid at the same pressure. There are two basic types of gear pumps, external and internal, which will be discussed in a moment.

Gear pumps are compact, making them ideal for applications that involve limited space. They are also simple in design, making them easier to repair and maintain. Note that gear pumps usually exhibit the highest efficiency when running at their maximum speed. In general, external gear pumps can produce higher levels of pressure (up to 3,000 psi) and greater throughput than vane pumps.

External gear pumps are often found in close-coupled designs where the gear pump and the hydraulic motor share the same mounting and the same shaft. In an external gear pump, fluid flow occurs around the outside of a pair of meshed external spur gears. The hydraulic fluid moves between the housing of the pump and the gears to create the alternating suction and discharge needed for fluid flow.

External gear pumps can provide very high pressures (up to 3,000 psi), operate at high speeds (3,000 rpm), and run more quietly than internal gear pumps. When gear pumps are designed to handle even higher pressures and speeds, however, they will be very noisy and there may be special precautions that must be made.

External gear pumps are often used in powerlifting applications, as well as areas where electrical equipment would be either too bulky, inconvenient, or costly. External gear pumps can also be found on some agricultural and construction equipment to power their hydraulic systems.

In an internal gear pump, the meshing action of external and internal gears works with a crescent-shaped sector element to generate fluid flow. The outer gear has teeth pointing inwards and the inner gear has teeth pointing outward. As these gears rotate and come in and out of mesh, they create suction and discharge zones with the sector acting as a barrier between these zones. A gerotor is a special type of internal gear pump that eliminates the need for a sector element by using trochoidal gears to create suction and discharge zones.

Unlike external gear pumps, internal gear pumps are not meant for high-pressure applications; however, they do generate flow with very little pulsation present. They are not as widely used in hydraulics as external gear pumps; however, they are used with lube oils and fuel oils and work well for metering applications.

In a piston pump, reciprocating pistons are used to alternately generate suction and discharge. There are two different ways to categorize piston pumps: whether their piston is axially or radially mounted and whether their displacement is fixed or variable.

Piston pumps can handle higher pressures than gear or vane pumps even with comparable displacements, but they tend to be more expensive in terms of the initial cost. They are also more sensitive to contamination, but following strict hydraulic cleanliness guidelines and filtering any hydraulic fluid added to the system can address most contamination issues.

In an axial piston pump, sometimes called an inline axial pump, the pistons are aligned with the axis of the pump and arranged within a circular cylinder block. On one side of the cylinder block are the inlet and outlet ports, while an angled swashplate lies on the other side. As the cylinder block rotates, the pistons move in and out of the cylinder block, thus creating alternating suction and discharge of hydraulic fluid.

Axial piston pumps are ideal for high-pressure, high-volume applications and can often be found powering mission-critical hydraulic systems such as those of jet aircraft.

In a bent-axis piston pump (which many consider a subtype of the axial piston pump), the pump is made up of two sides that meet at an angle. On one side, the drive shaft turns the cylinder block that contains the pistons which match up to bores on the other side of the pump. As the cylinder block rotates, the distances between the pistons and the valving surface vary, thus achieving the necessary suction and discharge.

In a radial piston pump, the pistons lie perpendicular to the axis of the pump and are arranged radially like spokes on a wheel around an eccentrically placed cam. When the drive shaft rotates, the cam moves and pushes the spring-loaded pistons inward as it passes them. Each of these pistons has its own inlet and outlet ports that lead to a chamber. Within this chamber are valves that control the release and intake of hydraulic fluid.

In a fixed displacement pump, the amount of fluid discharged in each reciprocation is the same volume. However, in a variable displacement pump, a change to the angle of the adjustable swashplate can increase or reduce the volume of fluid discharged. This design allows you to vary system speed without having to change engine speed.

When the input shaft of a vane pump rotates, rigid vanes mounted on an eccentric rotor pick up hydraulic fluid and transport it to the outlet of the pump. The area between the vanes increases on the inlet side as hydraulic fluid is drawn inside the pump and decreases on the outlet side to expel the hydraulic fluid through the output port. Vane pumps can be either fixed or variable displacement, as discussed for piston pumps.

Vane pumps are used in utility vehicles (such as those with aerial ladders or buckets) but are not as common today, having been replaced by gear pumps. This does not mean, however, that they are not still in use. They are not designed to handle high pressures but they can generate a good vacuum and even run dry for short periods of time.

There are other key aspects to choosing the right hydraulic pump that goes beyond deciding what type is best adapted to your application. These pump characteristics include the following:

Selecting a pump can be very challenging, but a good place to start is looking at the type of pump that you need. Vane pumps have been largely replaced by compact, durable gear pumps, with external gear pumps working best for high pressure and operating speeds while internal gear pumps are able to generate flow with very little pulsation. However, vane pumps are still good for creating an effective vacuum and can run even when dry for short periods of time. Piston pumps in general are more powerful but, at the same time, more susceptible to contamination.

Whether the pump is needed for the rugged world of mining, the sterile world of food and beverage processing, or the mission-critical aerospace industry, MAC Hydraulics can assist you with selecting, installing, maintaining, and repairing the right pump to meet the needs of your hydraulic system. In the event of a breakdown, our highly skilled technicians can troubleshoot and repair your pump — no matter who the manufacturer happens to be. We also offer on-site services that include common repairs, preventative maintenance, lubrication, cleaning, pressure testing, and setting.

We provide high quality used pumps and motors at your doorstep. Prices vary according to the condition of hydraulic pump and motors. We sell all type of hydraulic pumps and motors.Share your requirements on our whatsapp number - 8851066379

Hydraulic Power Sales Inc. partners with leading manufacturers to provide hydraulic pumps and motors. Regardless of what you’re looking for, we’re your complete solution—if we don’t have it in stock at our facilities in California, we will find it fast. Our mission is simple: getting you the right part and saving you time and money.

We provide Hydraulic pumps and can be styles such as gear, vane, and piston pumps. Applications can be fixed or variable displacement pumps. With so many styles and brands, it’s important to speak with an expert who can get you the hydraulic pump you need at an affordable price. We offer a wide variety of hydraulic pumps to support your applications and carry trusted brands including:

We provide Hydraulic motors and can be gear and vane, and motors used in simple rotating systems. Other hydraulic motors are gerotor motors, axial piston motors and radial piston motors. We help you select the best motor for your hydraulic applications, enhancing performance for optimal results. We’re proud to carry the following motors from brands you know and trust:

Hydraulic Power Sales Inc. is proud to offer high-quality hydraulic pumps and motors that support a wide range of mobile and industrial applications. Call us today at 916-631-9275 to learn more about our products.

An essential requirement for the optimum performance and service life of a hydraulic pump is that its pumping chambers fill freely and completely during intake. So if getting maximum pump life is your primary concern (and it should be), then anything that makes the free and complete filling of the pump"s chambers more difficult to achieve should be avoided.

Suction strainers and most other forms of inlet filtration are a common culprit. With rare exceptions, a suction strainer has no place in a properly designed and properly maintained hydraulic system.

But when you take a position against the majority, there will be many who disagree with you. And so I regularly hear from folks who feel they need to explain to me why their hydraulic system is different and why they have no alternative but to use this pump-killing device.

I prefer not to debate the point with people who have convinced themselves of the merits of suction strainers or, in some cases, use them as a substitute for proper design. I refer them to the pump manufacturer"s recommendation instead. Here is an excerpt from a Rexroth Hydraulics manual1 that dates back to 1979:

"The advantages of suction filtration are strongly outweighed by the disadvantage of the pressure drop created by the element. … Any benefit the suction filter offers by keeping contamination out of the pump is offset by the possibility of damaging the pump because of cavitation. …

"Another major disadvantage of the suction strainer is that it is located inside the oil reservoir, which makes it inconvenient to service. It is for this reason that many suction strainers in hydraulic systems go unserviced until they starve the pump and cause cavitation damage. ... Due to these disadvantages … filtration at the inlet of the pump is specifically not recommended."

It speaks volumes about the hydraulics industry that this 30-year-old advice from a leading hydraulic pump manufacturer is still widely ignored today. But a suction strainer isn"t the only "engineered in" barrier to the free and complete filling of the pump. Another is mounting the pump above the tank or, more precisely, above minimum oil level. In other words, making the pump "lift" the oil into its intake.

According to most manufacturers, mounting the pump above minimum oil level is an approved mounting position for many pump designs. "Approved" means that the manufacturer says it"s OK to do it. But approved does not mean it maximizes pump service life. That is because making the pump lift its oil does the opposite. This is particularly true for piston and vane pumps, which due to their design do not cope well with vacuum-induced forces.

Pump inlet conditions also affect noise and heat load. When exposed to atmospheric pressure at room temperature, mineral hydraulic oil contains between 6 and 12 percent of dissolved air by volume. If the pressure on the oil is reduced to less than atmospheric pressure - due to restriction in the pump intake or required lift - this air expands and becomes a greater percentage of the volume.

These expanding gas bubbles at the pump inlet collapse as the pumping chamber is exposed to system pressure (gaseous cavitation). The result is heat generation and noise. The larger the air bubble, the greater the noise level and heat generated. If the absolute pressure at the pump intake continues to fall (higher vacuum), the oil can start to change state from a liquid to a gas - known as vaporous cavitation.

For these reasons, the perfect pump inlet condition is 100 percent boost. This means that, ideally, you want the pump inlet to be supercharged under all operating conditions.

While supercharging the pump inlet is not practical in most applications, there is virtually no excuse for not having a flooded inlet. A flooded inlet means there"s a head of oil above the pump. In other words, the pump is mounted in such a way that its intake is below minimum oil level (Figure 1).

In the case of industrial power units, this rules out mounting the pump on top of the tank (Figure 2). And in most cases, it will rule out mounting the pump inside the tank - with the electric motor mounted vertically (Figure 3) — unless the pump is submerged to a depth where its inlet port is below minimum oil level (without the need to install a drop tube on the intake).

Besides making the pump lift its oil, both of these mounting positions (figures 2 and 3) make maintenance extremely difficult - with having the pump inside the tank being the worst. But unfortunately for the owners of this equipment, mounting the pump inside the tank has almost become standard practice for electric power units because it is a cheap and easy method of construction.

If you"ve been reading my column in Machinery Lubrication for a while, you"re probably already familiar with the problems associated with suction strainers. But unlike a suction strainer, which is easily removed, pump mounting position is not easy to change. So, what can be done about it?

Well, if you"re a hydraulic equipment user, specify that the pump must have a flooded inlet for all of your future equipment purchases. And if you design or manufacture hydraulic power units, do your customers (and your machine"s reliability) a favor: ensure all your hydraulic power units feature a flooded inlet.

Replacing a failing hydraulic pump can be challenging. If the wrong alteration is made, you risk damaging your entire hydraulics system. Furthermore, there are many reasons why your pump may be failing, but not all of them may require a full replacement.

If your hydraulic pump isn’t working like it used to, you need to start troubleshooting as quickly as possible. Waiting until total failure will only result in costly downtime for your plant.

Some of the most common causes of hydraulic pump failure include fluid contamination, excess pressure, poor fluid quality, cavitation, excessive temperatures, and uncorrected leaks.

Contaminated fluid is the most common cause of hydraulic pump failure. It can take place when particulates get into the system through a cylinder rod or breather valve. Sometimes deficient repairs are the culprit. Contaminants can change the fluid properties, create buildup, and corrode parts, all circumstances that reduce the system’s efficiency.

Every pump is built to work within a specific safe pressure range. Pressures greater than this overwork the pump. The pump is likely to become damaged and eventually stop working entirely. In extreme cases, excess pressure can cause an explosion.

It’s critical to use high-quality cooling and lubrication oil with the correct mineral content and viscosity. Purity of fluid content is especially important for higher-pressure systems. Fluid that’s too viscous can lead to cavitation, which is a serious risk for pump damage. If the viscosity is too low, heat and friction levels can become dangerously high.

If vapor cavities arise, they can implode under pressure, which can erode the metal and contaminate the fluid. To prevent this, it’s important to properly maintain intake lines, keep fittings and clamps tight, maintain the correct fluid level, and check for leaky pump shaft seals.

Leaks can arise from inadequate seals or internal component damage. If these aren’t taken care of, contaminants may enter the system and compromise the pump’s performance.

When inspecting your pump, looking out for these common signs:Increased Noise:All mechanical actuators make noise during operation, but hydraulic systems should not produce loud banging or knocking sounds. If you notice a new, unusual sound coming from your device, it may be experiencing cavitation or aeration.

High Temperatures: Hydraulic systems should never exceed 82 degrees Celsius/180 degrees Fahrenheit. If you detect a higher-than-average temperature, there may be a buildup of residue in the system. You need to address the problem quickly, as temperature changes can damage a pump quickly.

Put new oil in the tank. Be sure to fill the tank with the required oil grade, as pumps can fail if the wrong oil is administered throughout the system. Pumps require a consistent supply of oil and can fail if the levels drop too low.

Exact life expectancy depends on the specific pump and how frequently it’s used, but pumps often last for quite a few years. The manufacturer of your pump should specify how many hours or cycles a pump can be expected to provide before replacement is recommended.

Another critical factor in pump longevity is preventative maintenance. This includes daily maintenance tasks as well as those that need to be done annually.

In addition, perform any maintenance tasks the manufacturer recommends for your specific pump. And, always keep a record of completed maintenance tasks.

The exact cost depends on the type of pump, the pump manufacturer, and whether the replacement is done by a professional.Often a professional hydraulic pump replacement, including labor and parts, is in the vicinity of $1,500.The price depends on whether you buy directly from the manufacturer or from a third party.

Sometimes direct OEM replacement parts are expensive, and it can take weeks or months at times to receive the part. If you’re experiencing an emergency, or your pump has been discontinued by the manufacturer, purchasing a remanufactured pump may be the best solution for you, as they’re often less expensive than direct OEM replacements and the waiting times are typically shorter.

If you are purchasing a remanufactured pump, be sure to double check that your remanufacturer has an OEM guarantee, as you want to make sure the specifications of the remanufactured pump are the same as the OEM pump you are replacing.

Founded over 25 years ago, we’ve become the leading U.S. manufacturer of aftermarket hydraulic parts. We specialize in remanufacturing and repairing all types of pumps and components from manufacturers like Vickers/Eaton and Rexroth®. All of our pumps are made in-house in the U.S., guaranteed to meet OEM specifications, and are backed by a 12-month warranty.

8613371530291

8613371530291